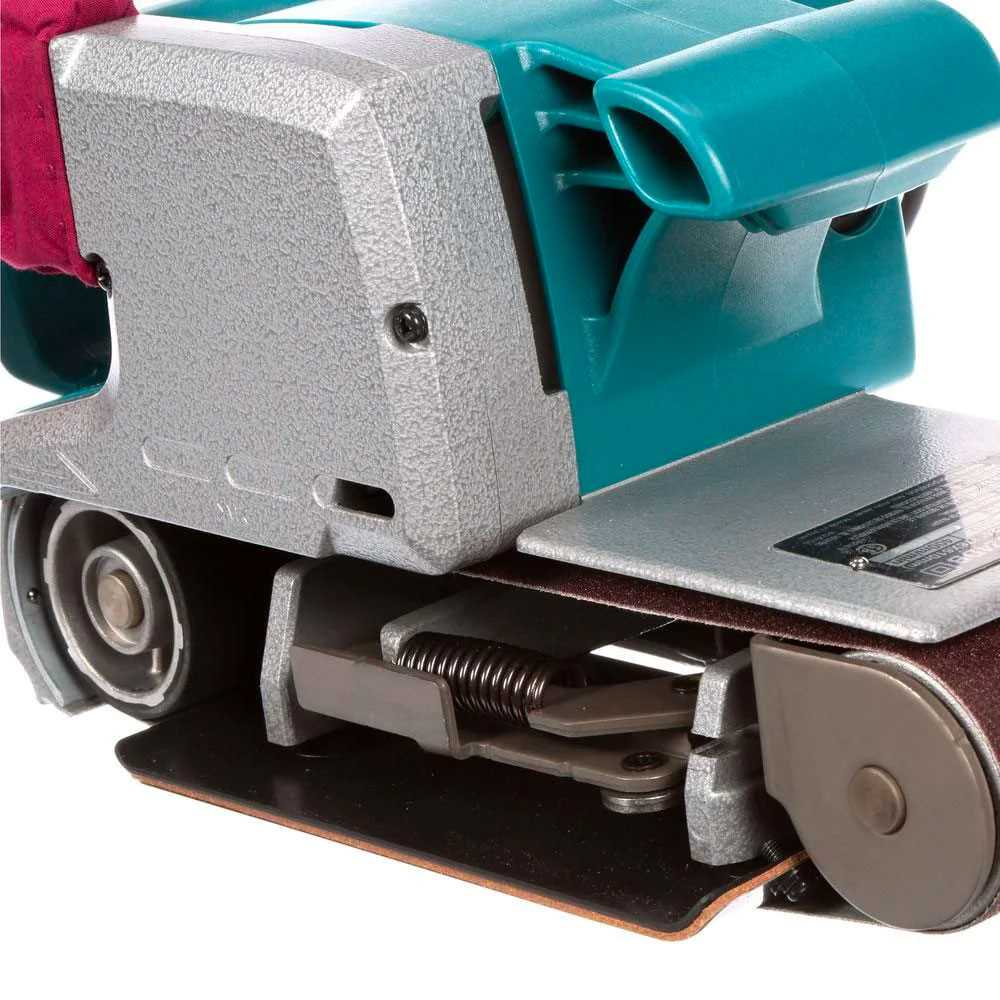

In the realm of power tools, having a clear understanding of the various components is essential for effective maintenance and repair. This section delves into the essential elements that make up a specific model, highlighting their functions and interconnections. A thorough grasp of these elements can greatly enhance the user experience and prolong the lifespan of the equipment.

Recognizing the significance of each component is vital for troubleshooting and ensuring optimal performance. By examining the individual parts, users can identify potential issues and make informed decisions regarding repairs or replacements. This knowledge empowers operators to maintain their tools efficiently, leading to improved reliability and productivity in various tasks.

Additionally, familiarizing oneself with the layout and relationships between different elements can simplify the repair process. Users who understand how the components work together are better equipped to tackle challenges that may arise during operation. Thus, this overview serves as a valuable resource for anyone looking to enhance their expertise and skill in handling their tools effectively.

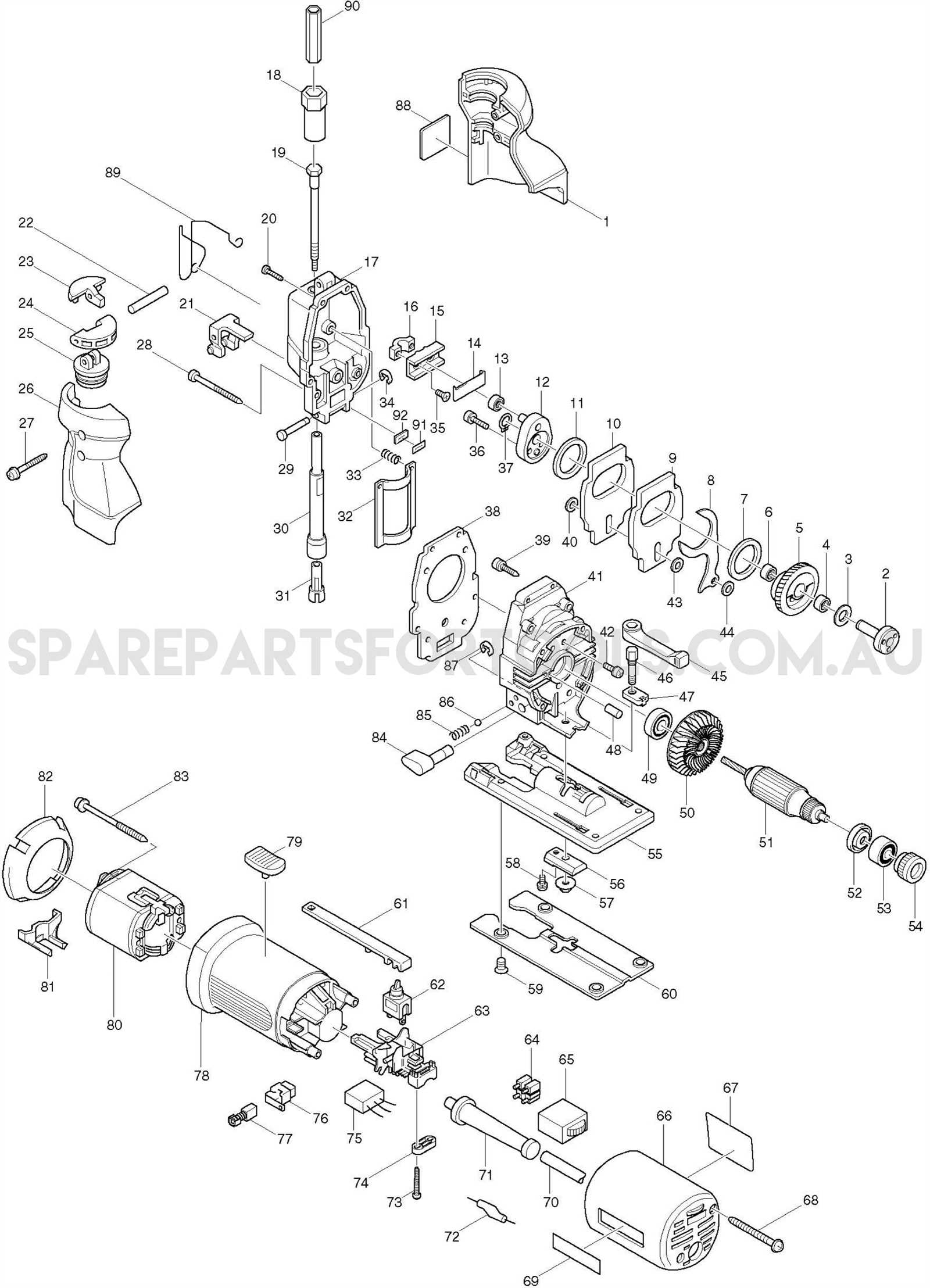

Overview of Parts and Functions

This section provides a comprehensive look at the various components and their respective roles within the device. Understanding these elements is essential for proper maintenance and effective operation.

| Component | Function |

|---|---|

| Motor | Generates power to drive the tool’s functions. |

| Housing | Protects internal components and ensures structural integrity. |

| Switch | Controls the on/off functionality of the device. |

| Belt | Transmits motion from the motor to other moving parts. |

| Guide | Directs the movement of the tool for precision work. |

| Handle | Provides a grip for user control and maneuverability. |

Identifying Key Assembly Areas

Understanding the main components of a tool is essential for effective maintenance and repair. By recognizing the crucial sections of an assembly, users can ensure smoother operation and longevity of the equipment. This knowledge aids in troubleshooting issues and simplifies the process of sourcing replacement elements.

Core Components Overview

The assembly is typically composed of several fundamental parts that work in unison. These include the power source, drive mechanism, and housing. Each area plays a pivotal role in the tool’s functionality, and familiarity with these components can significantly enhance user experience.

Maintenance and Replacement Insights

Regular checks on the key sections are vital for optimal performance. Identifying wear and tear in critical areas allows for timely interventions. Furthermore, understanding the layout facilitates easy access to parts that may require replacement, thus promoting efficient upkeep.

Common Issues with Parts

When dealing with equipment components, various challenges can arise, impacting functionality and efficiency. Understanding these common concerns can help in troubleshooting and maintaining optimal performance.

Wear and Tear

Durability is often compromised over time due to regular use. Frequent friction and pressure can lead to deterioration, resulting in diminished performance. Regular inspection is essential to identify signs of wear and initiate timely replacements.

Misalignment and Fit Issues

Improper alignment can lead to operational inefficiencies. If components do not fit correctly, it may result in vibrations or uneven performance. Ensuring precise installation and alignment can help mitigate these problems, enhancing overall functionality.

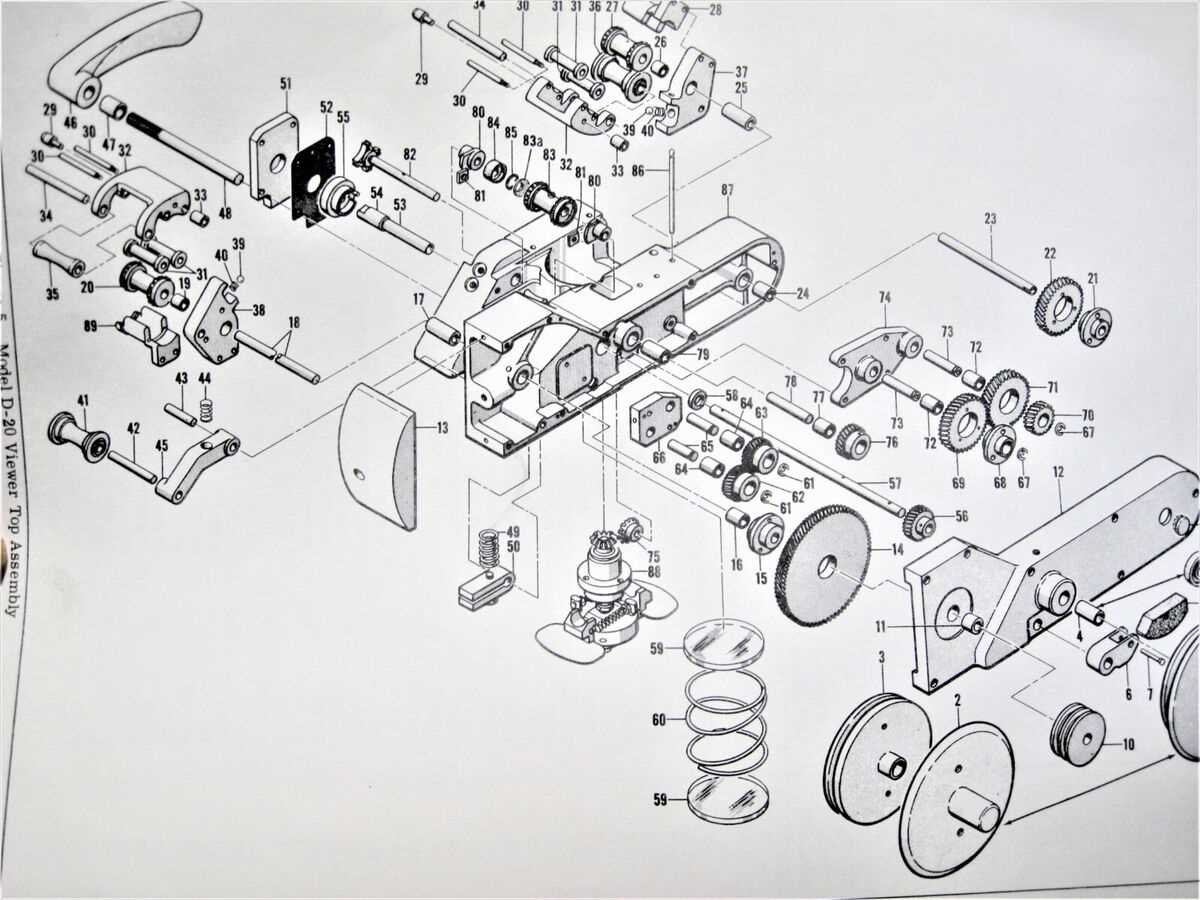

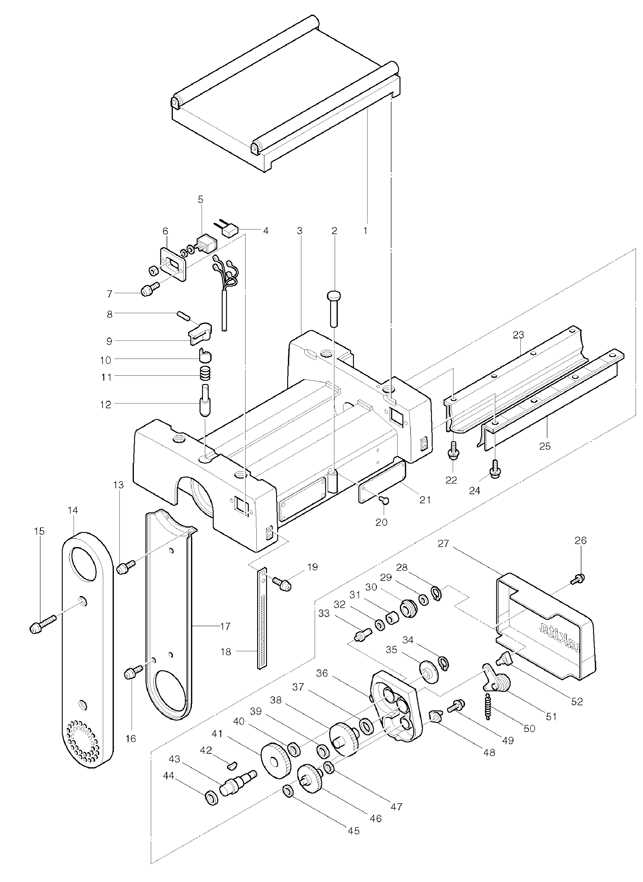

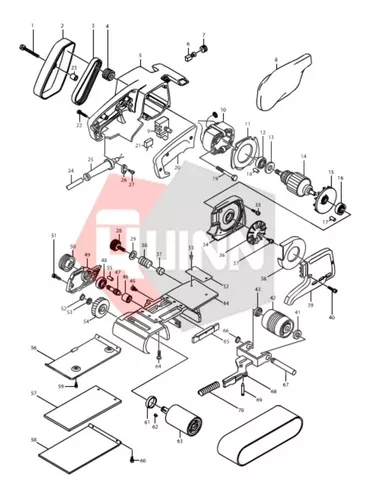

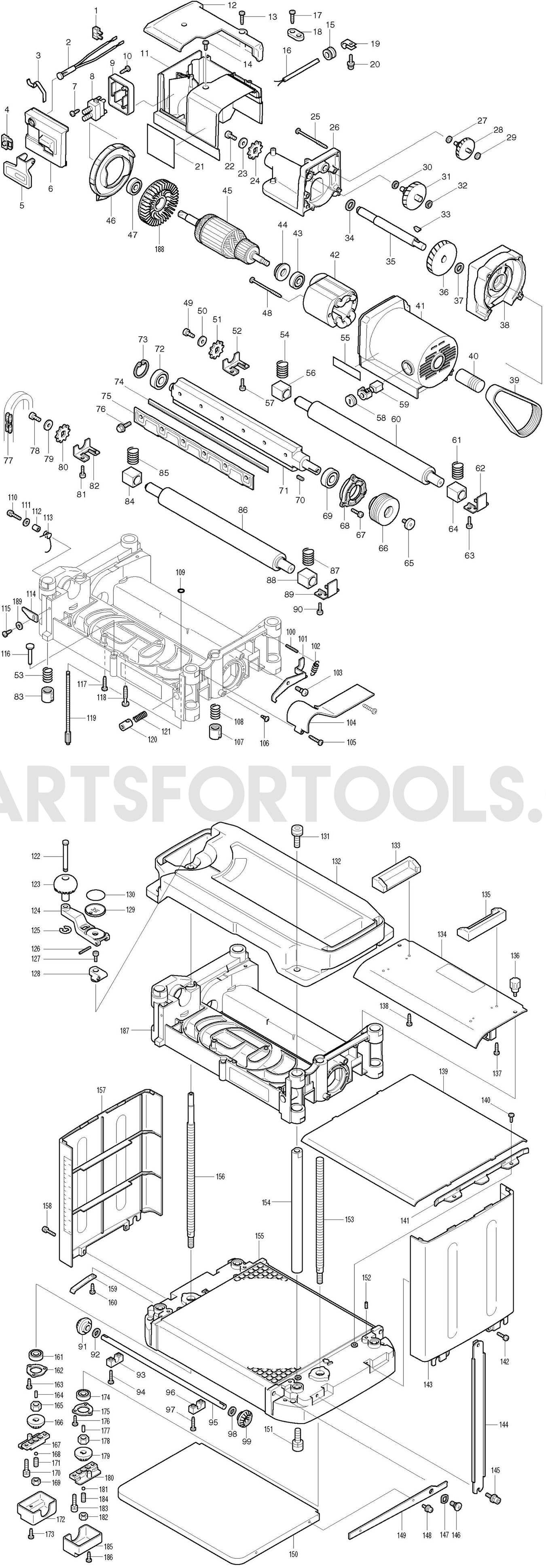

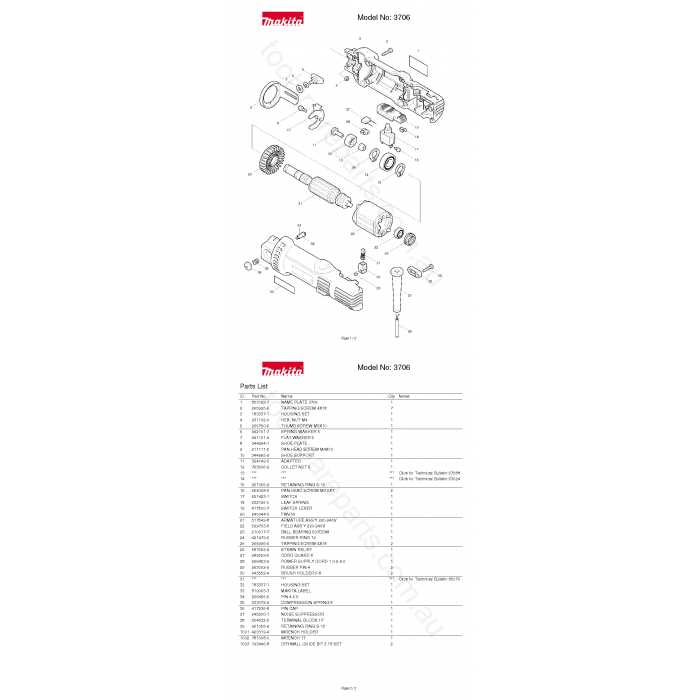

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations offer a detailed overview of each element within a system, making it easier to identify, locate, and comprehend their functions. By mastering the art of interpreting these visuals, one can streamline the troubleshooting process and enhance overall efficiency.

Identifying Components

Each visual representation typically labels the various elements, often using numbers or letters. Familiarizing oneself with these markings is crucial. Take time to study the key or legend associated with the illustration, as it provides valuable information about the function and placement of each component.

Understanding Relationships

Beyond identifying individual elements, it’s important to grasp how these components interact. Pay attention to connecting lines or arrows that indicate relationships or flow between parts. This understanding can help in diagnosing issues and planning repairs effectively.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often be a straightforward task if you know where to look. Understanding the available resources and methods can significantly simplify this process, ensuring that you find the exact items you need to keep your device functioning optimally.

Utilizing Online Resources

One of the most effective ways to find the necessary components is through online platforms. Here are some useful strategies:

- Search for specialized websites that offer a wide range of products related to your device.

- Utilize online forums and communities where enthusiasts share advice and resources.

- Check manufacturer websites for a list of available components.

- Look for videos or tutorials that may highlight specific components and where to acquire them.

Local Shops and Distributors

In addition to online options, local retailers can also be valuable resources. Consider the following:

- Visit nearby hardware or specialized stores that might stock components.

- Inquire with service centers that handle repairs and maintenance, as they often have access to various supplies.

- Establish relationships with distributors who can assist in locating specific items.

By combining these approaches, you can efficiently track down the necessary replacements to maintain the performance and longevity of your equipment.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your tools requires consistent attention and proper care. By following essential maintenance practices, you can enhance performance and reduce the likelihood of unexpected issues. This section provides valuable insights into maintaining your equipment effectively.

Regular Cleaning

Cleaning is a fundamental aspect of upkeep. After each use, remove dust and debris to prevent accumulation that can hinder functionality. Utilize a soft brush or cloth to reach tight spaces, ensuring all components remain free from grime.

Periodic Inspections

Conducting periodic inspections is vital for identifying potential wear and tear. Check all moving parts for signs of damage or irregularity. Address any concerns promptly to avoid further complications and maintain optimal performance.

Tools Needed for Disassembly

When undertaking the process of disassembly for any device, it is essential to gather the appropriate tools. Having the right instruments on hand ensures a smooth and efficient procedure, minimizing the risk of damage to components and enhancing overall safety. Below are some of the necessary tools that can facilitate this task.

Essential Instruments

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are crucial for removing screws of different types and sizes.

- Wrenches: Adjustable wrenches or socket sets are beneficial for loosening and tightening bolts.

- Pliers: Needle-nose pliers can be particularly useful for gripping and manipulating small parts.

Additional Accessories

- Hex Keys: These are essential for devices that use hexagonal screws.

- Parts Tray: A small tray can help keep small components organized and prevent loss during the disassembly process.

- Flashlight: Adequate lighting is necessary for inspecting hard-to-reach areas within the device.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to dismantling a specific tool effectively and safely. Following a systematic procedure ensures that all components can be accessed and serviced without causing damage or confusion. Each step is designed to be straightforward, allowing users to navigate the process with ease.

Required Tools and Safety Precautions

Before starting the disassembly, gather the necessary tools such as screwdrivers, pliers, and a clean workspace. Ensure you wear appropriate safety gear, including gloves and eye protection, to prevent injuries during the process.

Disassembly Steps

- Begin by unplugging the device and removing any attachments or accessories.

- Locate and unscrew the outer casing using the appropriate screwdriver.

- Carefully lift off the casing to expose the internal components.

- Identify and detach various parts, ensuring to note their positions for reassembly.

- Continue dismantling until the desired internal section is fully accessible.

Reassembling the Tool Correctly

Reassembling a device requires careful attention to detail to ensure that all components are fitted properly and function as intended. This process not only enhances the longevity of the equipment but also ensures optimal performance. Following a systematic approach can greatly simplify the task, making it more efficient and effective.

Steps for Successful Reassembly

- Gather All Components: Ensure that all parts are collected and organized. Check for any missing elements before starting the assembly process.

- Refer to a Guide: Utilize a schematic or guide to understand the correct order of assembly. This can help avoid confusion and mistakes.

- Start with the Base: Begin reassembly from the base or main housing, as this provides a solid foundation for the remaining components.

- Connect Internal Parts: Carefully attach internal elements, ensuring that they are aligned correctly and securely fastened.

- Reattach Outer Shell: Once internal components are in place, secure the outer casing, making sure all clips and screws are tightly fitted.

Final Checks

- Test Functionality: After reassembly, test the tool to ensure it operates smoothly. Check all functions to confirm everything is in working order.

- Inspect for Loose Parts: Before concluding the process, inspect the tool for any loose components that may affect its performance.

By following these guidelines, the reassembly of the equipment can be completed effectively, ensuring that it remains reliable and efficient for future use.

Aftermarket vs. Original Parts

When it comes to equipment maintenance and repair, the choice between non-genuine and genuine components can significantly impact performance and longevity. Understanding the distinctions between these options is essential for making informed decisions that suit individual needs.

Genuine components are crafted by the original manufacturer and are designed to meet specific standards. They often come with the following advantages:

- Quality Assurance: Made to exact specifications, ensuring compatibility and performance.

- Warranty Protection: Typically covered under manufacturer warranties, providing peace of mind.

- Reliability: Proven track record for durability and effectiveness in operation.

On the other hand, non-genuine options offer alternative solutions that can appeal to cost-conscious users. Their benefits may include:

- Cost Savings: Generally more affordable than original components.

- Variety: A wider range of options available, catering to different preferences.

- Accessibility: Often easier to find in local stores or online platforms.

Ultimately, the decision hinges on factors such as budget, performance expectations, and the specific requirements of the equipment in question. Assessing these elements will guide users towards the most suitable choice for their needs.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount to prevent accidents and injuries. This section outlines essential measures to consider before, during, and after undertaking repair activities. By adhering to these guidelines, individuals can create a secure working environment, ultimately enhancing efficiency and reducing risks.

Before starting any repair work, it is crucial to gather the necessary tools and materials. Additionally, inspecting the workspace for hazards can significantly contribute to a safer experience.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always don appropriate safety equipment such as gloves, goggles, and ear protection. |

| Disconnect Power Sources | Ensure that all power supplies are disconnected to prevent accidental activation of tools or devices. |

| Keep Workspace Organized | Maintain a clutter-free environment to minimize the risk of tripping or losing tools. |

| Follow Instructions | Adhere to manufacturer guidelines and instructions to avoid mishaps during repairs. |

| Use Tools Properly | Utilize tools as intended to prevent misuse and potential accidents. |

After completing the repair, it is essential to clean the work area and properly store all tools. This practice not only fosters a tidy environment but also ensures that tools remain in good condition for future tasks.

Resources for Further Information

For those seeking additional insights and support regarding specific tools and equipment, numerous resources are available to enhance your understanding and facilitate effective use. These sources can provide invaluable assistance in troubleshooting, maintenance, and optimal usage techniques.

Online Forums and Communities

Participating in online discussions can be beneficial. Many enthusiasts and professionals share their experiences and tips, creating a wealth of knowledge. Engaging with these communities allows for the exchange of ideas and solutions, helping users overcome challenges they may encounter.

Manufacturer Websites

Official websites of tool manufacturers often contain a variety of resources, including user manuals, instructional videos, and maintenance guides. Exploring these sites can lead to a deeper understanding of your equipment, ensuring you utilize it safely and efficiently.