In the world of power tools, a comprehensive understanding of the assembly and components is essential for effective usage and maintenance. Familiarity with each element enables users to troubleshoot issues, perform repairs, and optimize performance. This knowledge is particularly valuable for enhancing the longevity and reliability of these tools.

Detailed illustrations provide a visual reference that aids in grasping the intricate workings of the device. By examining these graphics, users can identify the various elements that contribute to the overall functionality. Such insights not only facilitate repairs but also enhance the user’s confidence when handling the equipment.

Moreover, knowing the layout and function of each component allows for informed decisions regarding upgrades or replacements. An efficient understanding of the tool’s structure ultimately leads to improved outcomes, whether for DIY enthusiasts or professionals in the field.

This section outlines the various elements involved in the operation of a power tool designed for drilling and fastening tasks. Understanding these components is essential for effective maintenance and repair, ensuring optimal performance.

- Overview of Tool Structure

- Motor Functionality

- Power Supply Types

- Transmission Mechanism

- Chuck Variants

- Gear Housing Insights

- Handle Ergonomics

- Trigger Assembly

- Safety Features

- Impact Mechanism

- Cooling System Importance

- Maintenance Tips

By exploring these headings, readers will gain a comprehensive understanding of how each component contributes to the functionality of the tool.

Key Parts of Hammer Drills

Understanding the essential components of these power tools is crucial for effective usage and maintenance. Each element contributes to the overall functionality, ensuring efficient operation in various tasks, from construction to home improvement.

Essential Components

Various vital components play significant roles in the performance of these tools. Here are a few of the most important:

| Component | Function |

|---|---|

| Motor | Powers the tool and drives the mechanism. |

| Chuck | Holds the bit securely in place during operation. |

| Impact Mechanism | Delivers rapid blows to the bit, enhancing drilling efficiency. |

| Gearbox | Regulates speed and torque according to the task. |

Importance of Maintenance

Regular upkeep of these critical elements is vital for longevity and optimal performance. Ensuring each component functions correctly can prevent breakdowns and enhance the overall effectiveness of the tool.

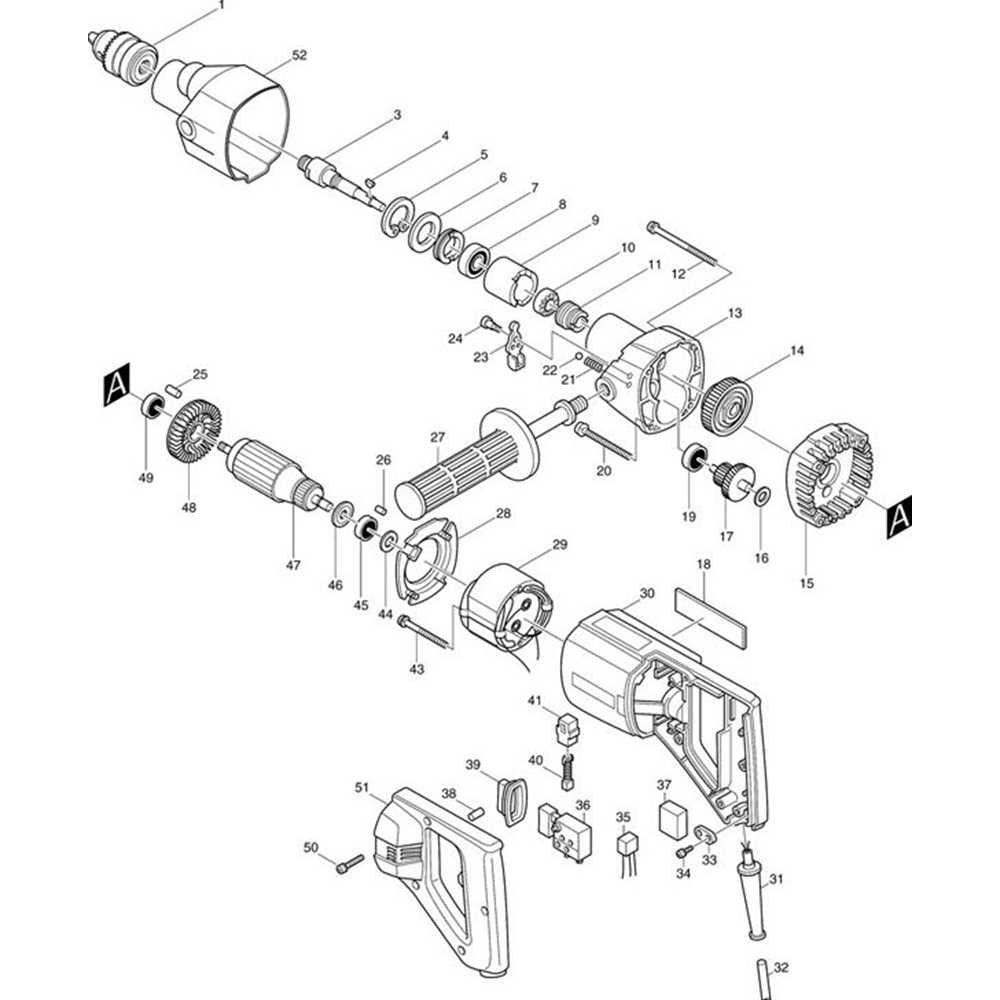

Exploring Drill Gear Assembly

The gear assembly is a crucial component in power tools, responsible for transferring rotational energy to the bit. Understanding its structure and function can enhance performance and efficiency in various applications.

| Component | Description |

|---|---|

| Gear Housing | Encases and protects the internal components, providing stability. |

| Spindle | Connects to the bit and facilitates rotation during operation. |

| Gears | Alter the speed and torque, allowing for versatile functionality. |

| Bearings | Reduce friction between moving parts, ensuring smooth operation. |

Function of Chuck and Key

The chuck and key play a crucial role in the operation of various power tools, facilitating the secure attachment and removal of bits. Understanding their functions helps users maximize the efficiency and safety of their equipment.

Role of the Chuck

The chuck is the component that holds the drill bit in place, allowing for precise drilling and driving. Its design enables quick changes between different bits, enhancing versatility. Here are some key aspects:

- Grip: Ensures a firm hold on the bit, preventing slippage during operation.

- Adjustment: Can be adjusted to accommodate various sizes of bits, making it adaptable for different tasks.

- Types: Available in several styles, including keyless and keyed types, each suited for specific applications.

Importance of the Key

The key is an essential tool for securing the chuck when using a keyed design. Its function includes:

- Stability: Tightens the chuck, ensuring that the bit remains securely in place during operation.

- Ease of Use: Allows for effortless adjustment of the chuck, making bit changes quick and straightforward.

- Safety: Reduces the risk of bit ejection, which can lead to accidents or damage to the workpiece.

Motor Specifications and Features

This section delves into the essential characteristics and capabilities of the motor utilized in power tools. Understanding these specifications is crucial for both performance evaluation and maintenance considerations, ensuring optimal functionality and longevity of the equipment.

| Specification | Details |

|---|---|

| Power Rating | Typically ranges from 600W to 1200W, depending on the model. |

| Voltage | Commonly operates on 110V or 220V systems. |

| Speed Settings | Features variable speed settings, often between 0-3000 RPM. |

| Torque | Adjustable torque settings, with peak values reaching up to 30 Nm. |

| Cooling System | Equipped with a ventilation system to prevent overheating during prolonged use. |

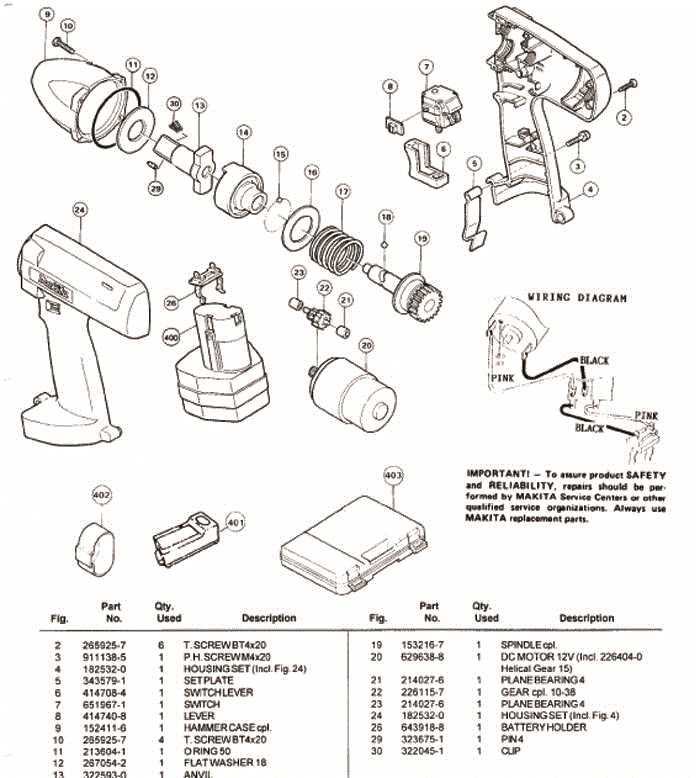

Electrical Wiring and Connections

Understanding the wiring and connections of power tools is essential for efficient operation and safety. Proper electrical setup ensures that the device functions optimally while minimizing the risk of malfunctions or hazards. This section outlines the key aspects of electrical connectivity, focusing on essential components and their roles in the overall system.

| Component | Description |

|---|---|

| Power Supply | Delivers electrical energy to the tool, typically from a wall outlet or battery. |

| Switch | Controls the flow of electricity, allowing the user to start and stop the tool. |

| Motor | Converts electrical energy into mechanical energy, driving the tool’s functions. |

| Wiring Harness | A set of wires that connects various components, facilitating electrical flow. |

| Connectors | Join different wiring sections, ensuring reliable electrical connections. |

Importance of the Hammer Mechanism

The mechanism that provides impactful force plays a crucial role in enhancing the efficiency of various power tools. This system enables the tool to penetrate hard materials effectively, ensuring optimal performance in construction and renovation tasks.

Enhanced Performance

Effective penetration into tough surfaces is achieved through this mechanism, allowing users to accomplish their projects with ease. By generating rapid impacts, it significantly reduces the effort required from the operator.

Versatility in Applications

Tools equipped with this technology are suitable for a range of tasks, from masonry work to heavy-duty drilling. The ability to adapt to different materials enhances the overall usability, making it an essential feature in modern equipment.

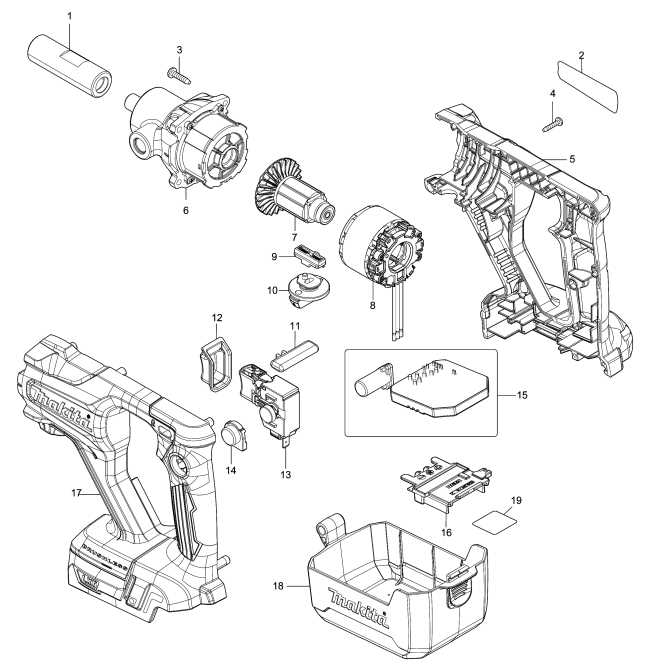

Interpreting the Parts Diagram

Understanding the schematic representation of a tool’s components is essential for effective maintenance and repair. By familiarizing oneself with the visual layout, users can easily identify individual elements and their respective functions, leading to better troubleshooting and assembly processes.

Key Components Overview

The illustration typically highlights various segments, showcasing how each part interacts within the overall mechanism. Recognizing these connections aids in diagnosing issues and planning replacements, ensuring optimal performance during use.

Utilizing the Reference Guide

A reference guide often accompanies the visual representation, providing detailed descriptions and specifications for each component. This information empowers users to make informed decisions regarding repairs and upgrades, enhancing the longevity and functionality of the tool.

Common Replacement Parts Overview

This section provides an overview of frequently needed components for power tools, focusing on items that often require replacement due to wear and tear or malfunction. Understanding these elements is essential for maintaining optimal performance and ensuring longevity.

Essential Components

Key components that typically need replacing include the motor brushes, which help maintain efficient operation, and the chuck, responsible for securing drill bits. Regular inspection of these items can prevent unexpected downtime.

Additional Accessories

Other noteworthy accessories are the battery packs and housing casings, which can suffer from damage over time. Ensuring these parts are in good condition is vital for overall functionality and safety.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the life of your power tools. By adopting a few simple practices, you can ensure optimal performance and reliability over time. Maintaining your equipment not only enhances functionality but also minimizes the risk of unexpected failures.

Routine Cleaning

Keeping your tools clean is crucial. After each use, remove any dust or debris that may have accumulated. Utilize a soft brush or a cloth to wipe down surfaces and ensure that moving parts are free from obstruction.

Lubrication and Inspection

Periodic lubrication of the mechanical components is vital for smooth operation. Apply appropriate lubricants to gears and bearings as needed. Additionally, conduct regular inspections to identify any signs of wear or damage early on, allowing for timely repairs.

Assembly Instructions for DIY Repairs

When tackling repairs on your power tool, understanding how to reassemble its components is crucial for effective maintenance. This guide provides essential steps to ensure that all elements are properly fitted, allowing for optimal functionality.

1. Gather Tools and Components: Before starting, collect all necessary tools such as screwdrivers, wrenches, and any replacement components needed for the repair.

2. Reference the Layout: Use an illustrative layout to visualize the arrangement of each component. This will serve as a roadmap during the assembly process, ensuring you don’t miss any crucial pieces.

3. Begin Assembly: Start by placing the main body in a stable position. Carefully insert each component in the correct order, paying attention to any alignment indicators.

4. Secure All Parts: Once components are positioned, tighten screws and fasteners securely but avoid over-tightening, as this can damage the unit.

5. Test Functionality: After assembly, perform a functionality check to confirm that everything operates smoothly. This step is vital to ensure that the tool is safe to use.

By following these instructions, you can confidently undertake repairs, prolonging the life of your tool while enhancing your DIY skills.

Identifying Issues with Components

Recognizing problems within various elements of power tools is essential for maintaining their efficiency and longevity. By systematically analyzing each component, users can detect irregularities that may lead to suboptimal performance or complete malfunction.

Wear and tear is a common issue that affects many parts. Regular inspection can reveal signs of damage, such as cracks or unusual noises during operation. Additionally, loose connections can result in poor functionality; ensuring that all parts are securely fastened is vital for optimal performance.

Another important factor to consider is the lubrication of moving parts. Insufficient lubrication can lead to increased friction, causing overheating and potential breakdowns. Always check for adequate lubrication to enhance the tool’s operational lifespan.

Where to Find Genuine Parts

Locating authentic components for your tools can be crucial for maintaining performance and longevity. Quality replacements ensure that your equipment operates efficiently and safely. Here are some reliable sources to consider when searching for original elements.

Authorized Retailers

Visiting authorized dealers is one of the best ways to obtain genuine components. These retailers have direct connections with manufacturers and offer verified products. Look for the following:

- Official store locator on the manufacturer’s website

- Verified online retailers that specialize in tool supplies

- Local hardware stores that are recognized dealers

Manufacturer’s Website

Another effective approach is to check the official website of the equipment brand. They often provide a dedicated section for genuine replacements, including:

- A detailed catalog of available items

- Online ordering options for convenience

- Support for identifying the correct components