When working with a specialized cutting device, grasping the various elements that contribute to its functionality is crucial. Each component plays a significant role in ensuring the tool operates smoothly and efficiently. Familiarizing oneself with these parts can enhance maintenance efforts and improve overall performance.

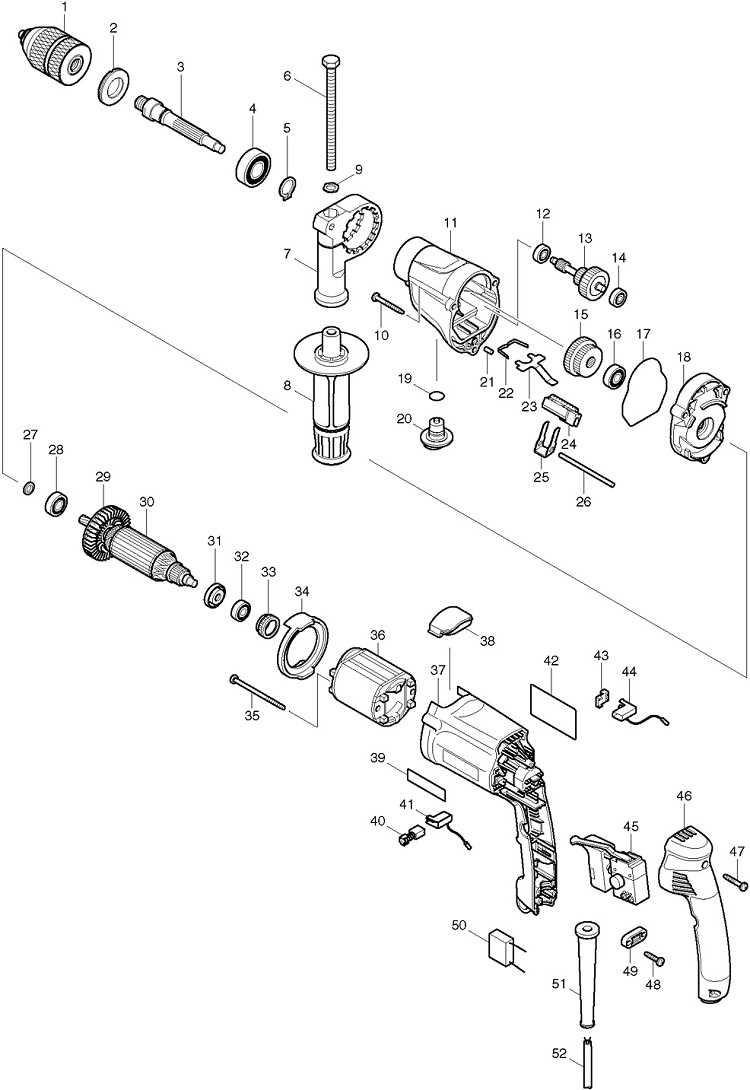

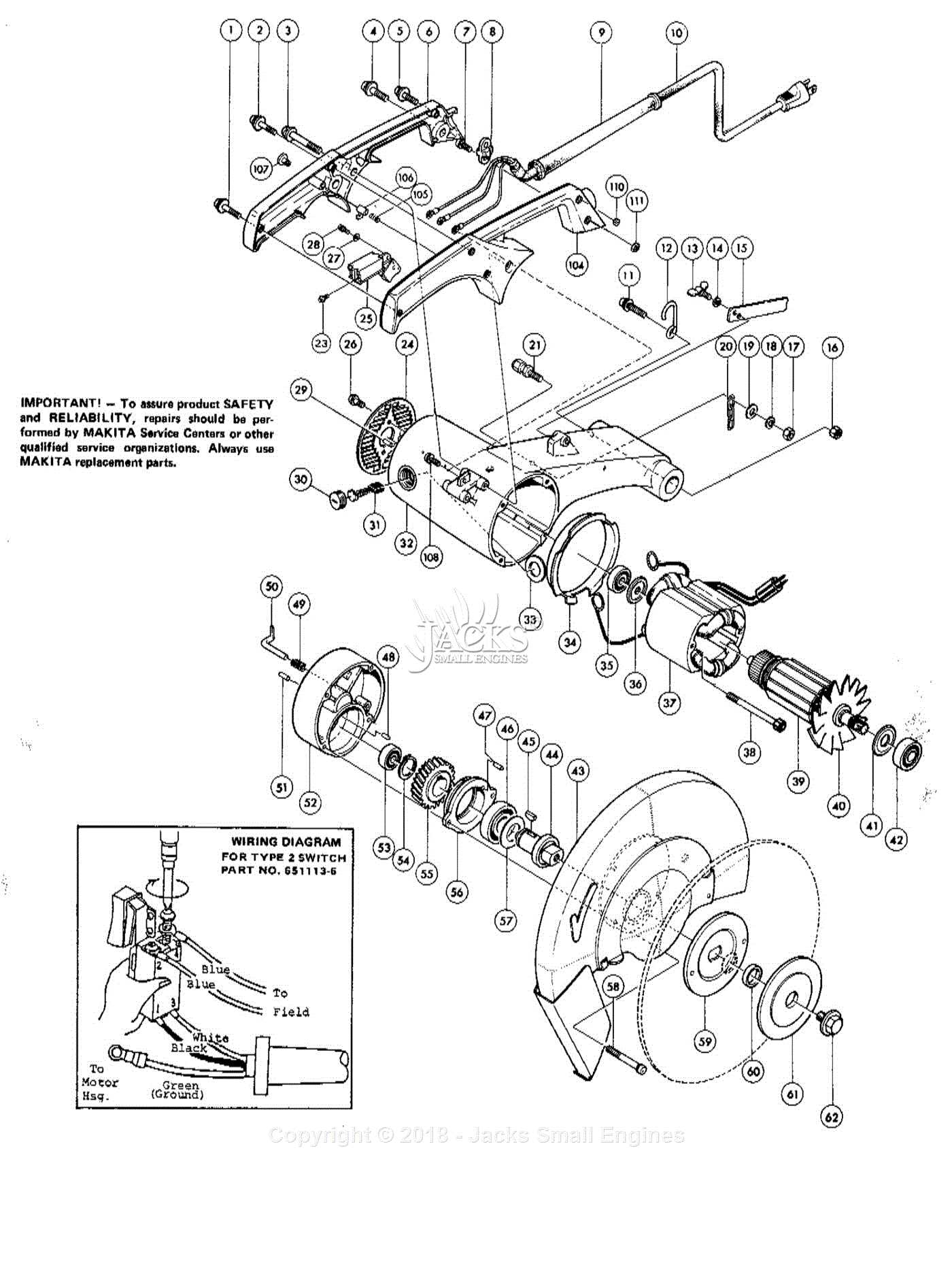

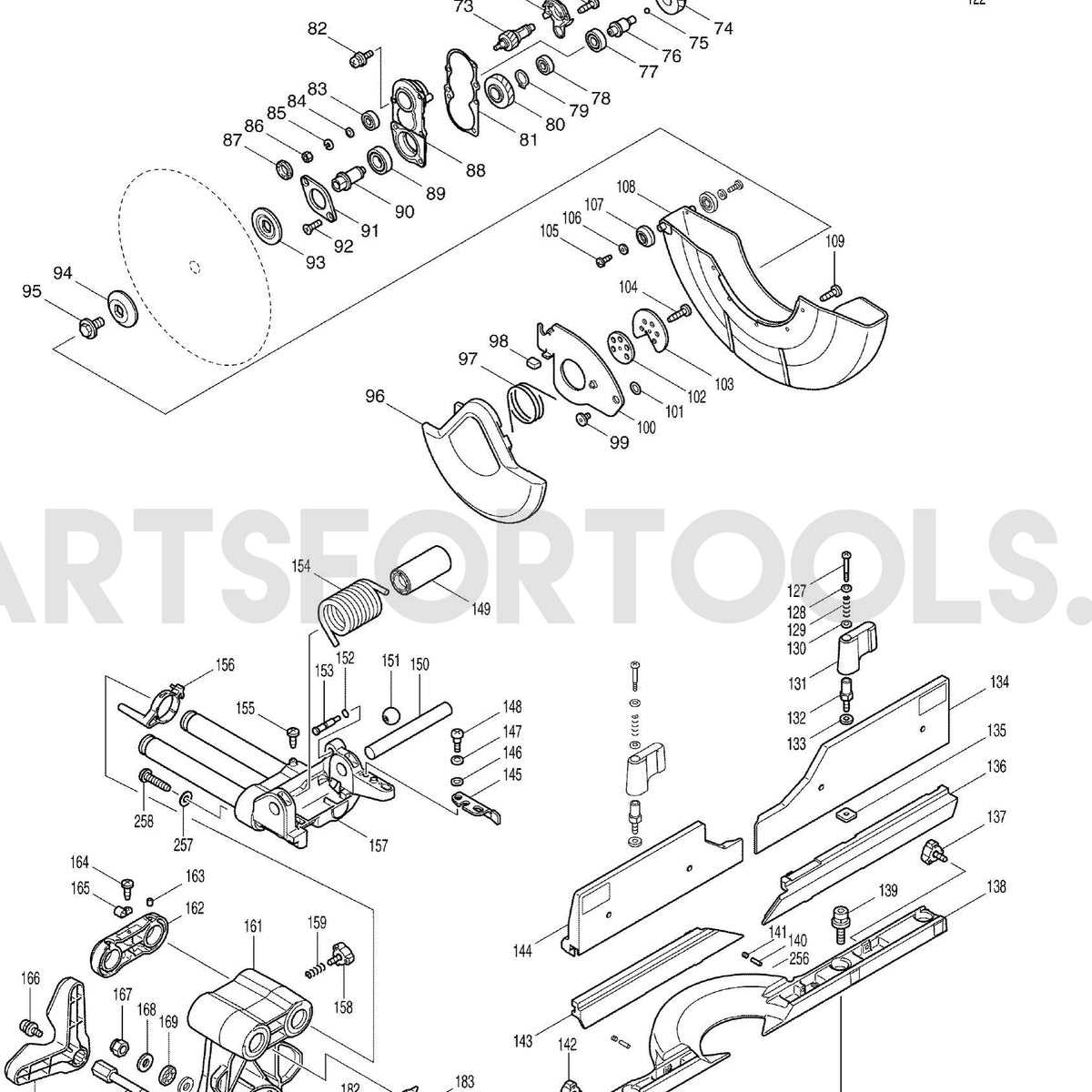

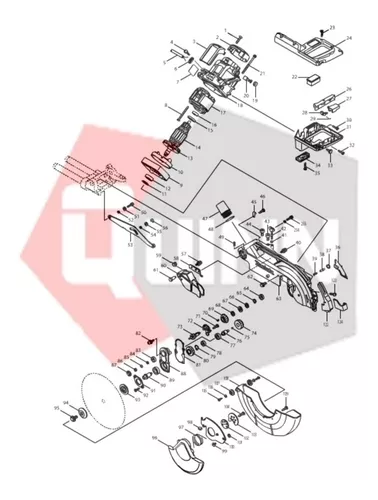

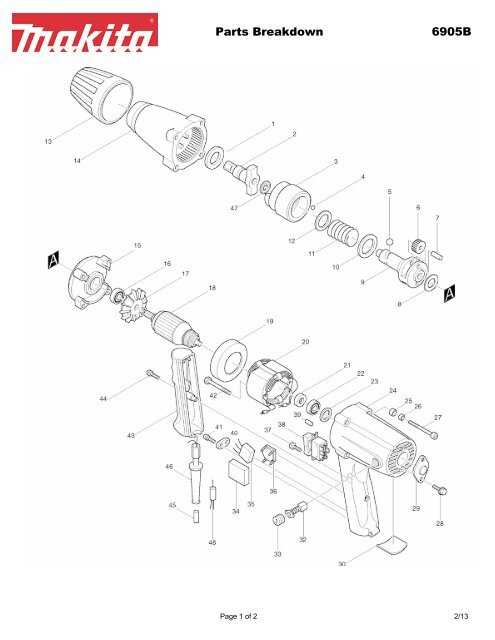

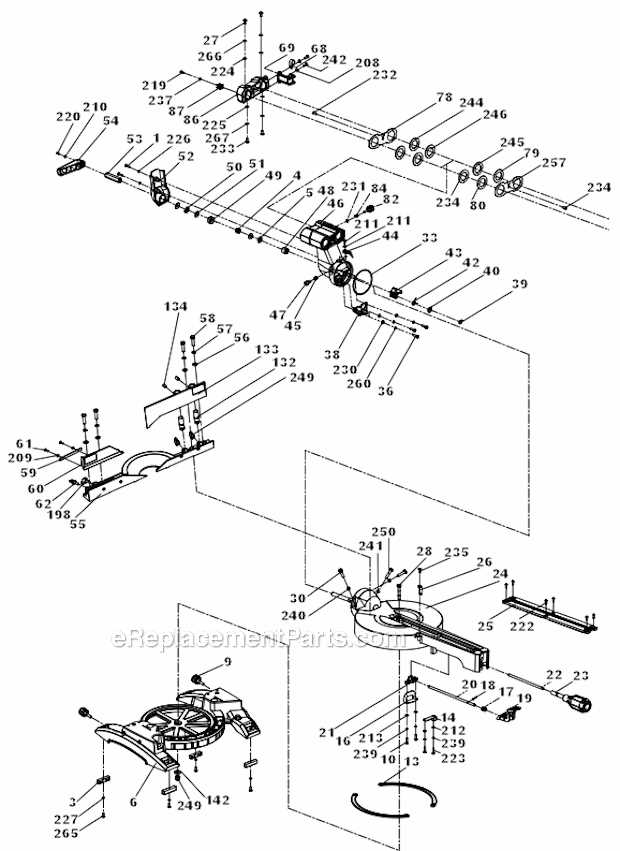

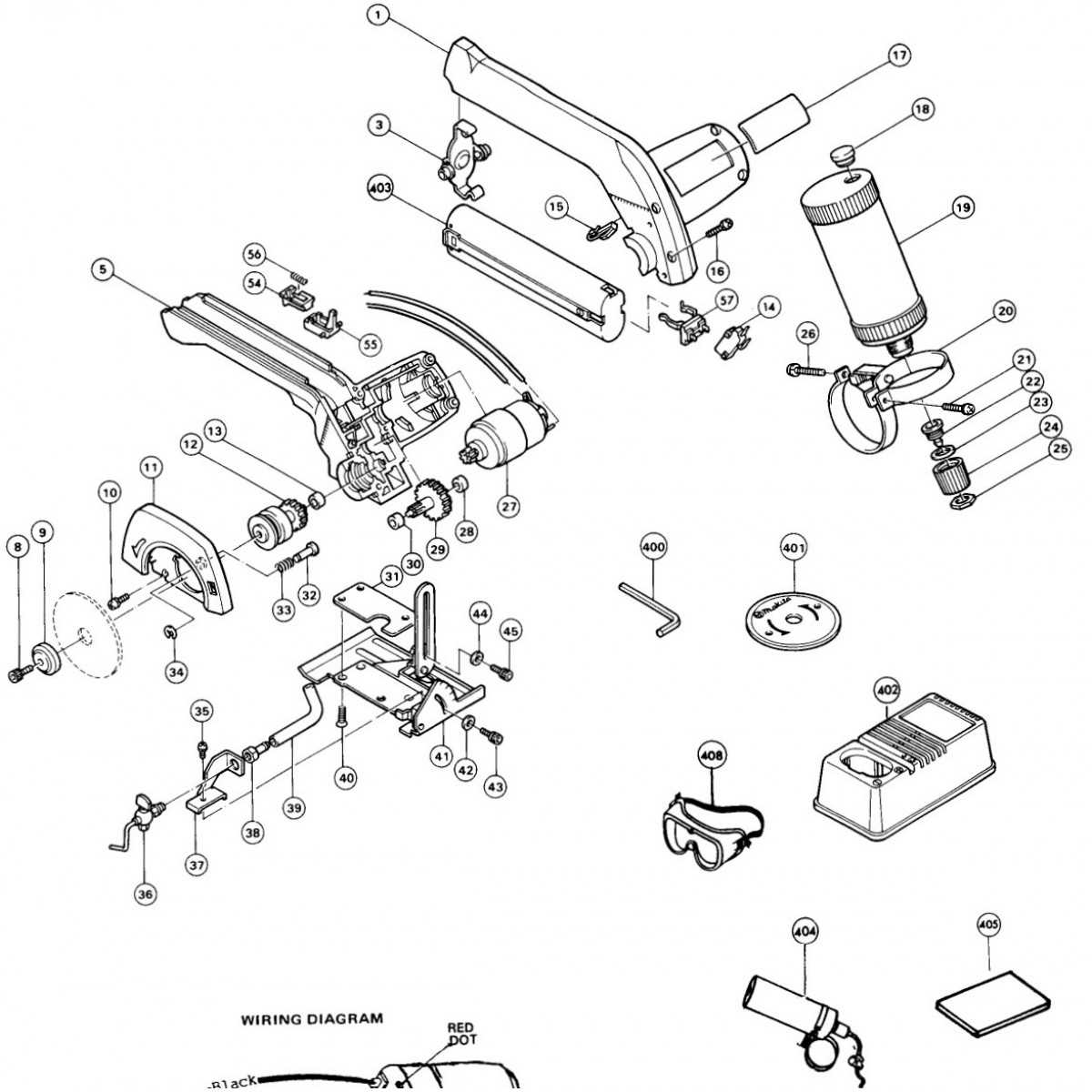

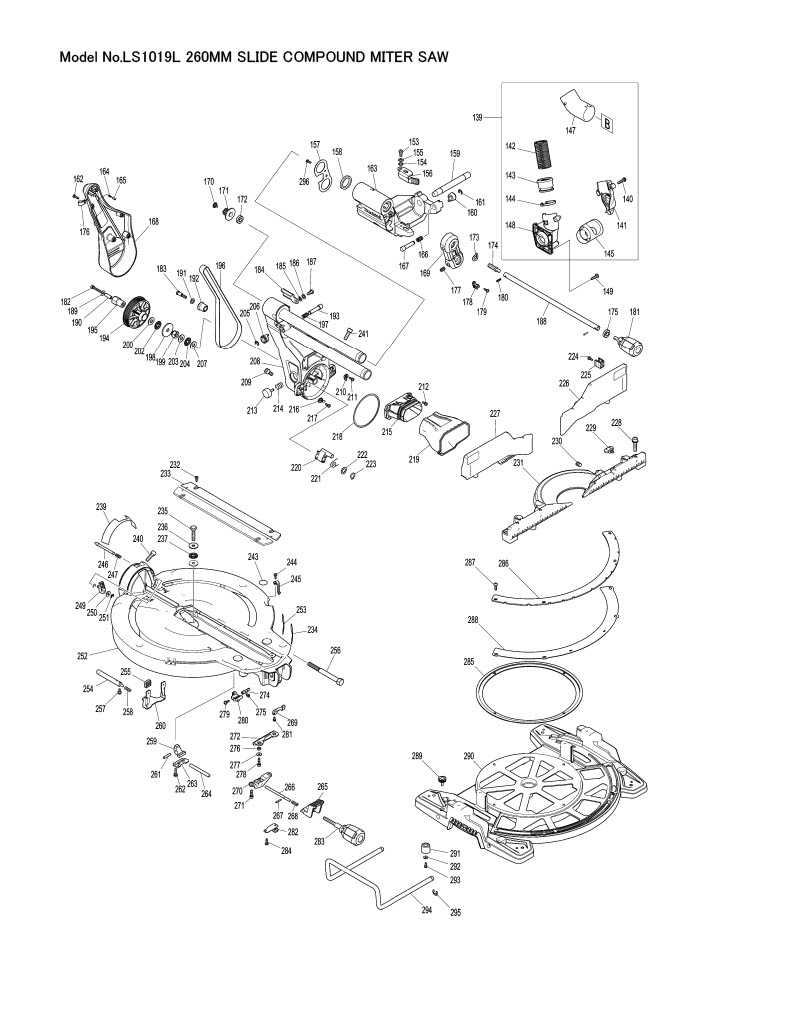

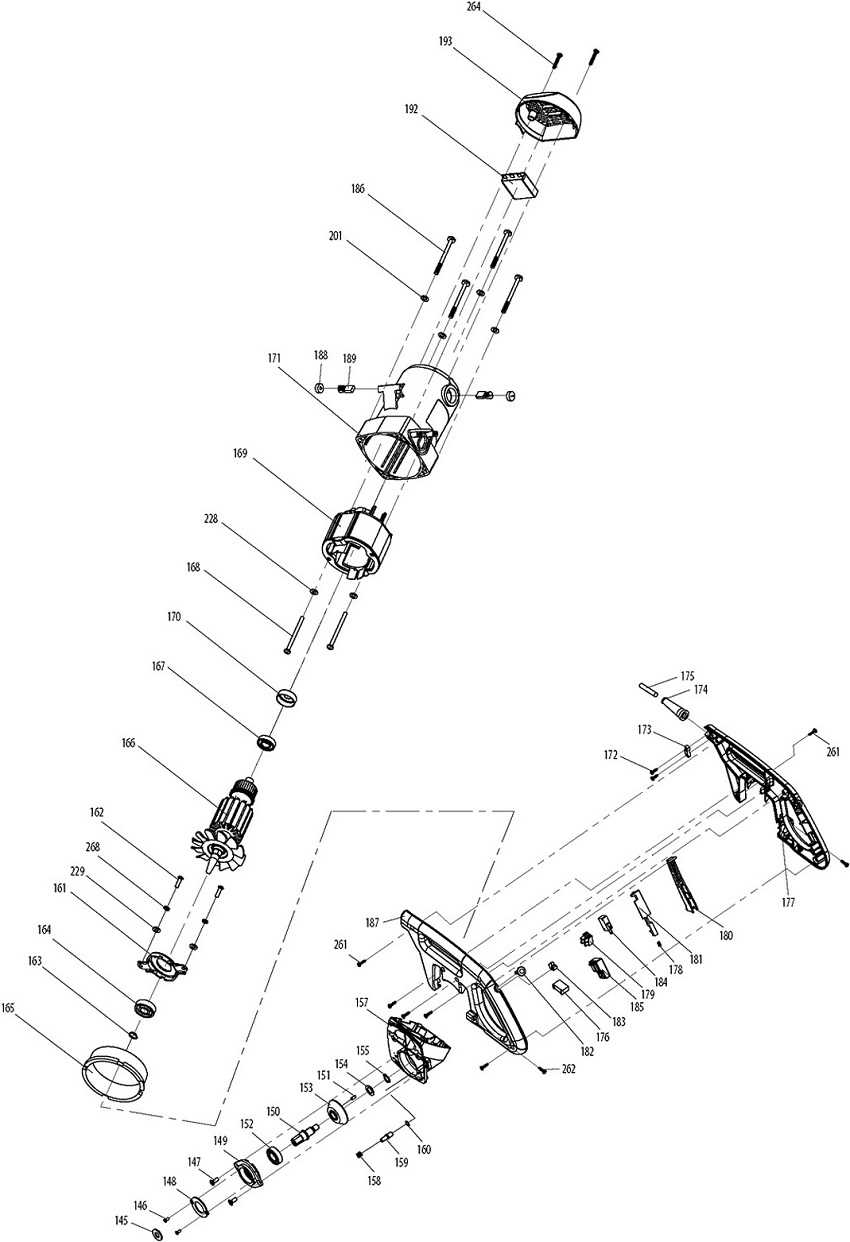

Visual representations of these components can aid in identifying and understanding their specific functions. Such illustrations serve as a valuable resource for both novices and experienced users alike, providing clarity on assembly and disassembly processes. By exploring these depictions, one can gain insight into the intricate design and engineering behind the equipment.

In-depth knowledge of the various elements not only assists in troubleshooting potential issues but also empowers users to perform routine upkeep. This understanding can lead to extended longevity and optimal performance of the device, ultimately benefiting users in their projects.

This section provides an overview of the crucial elements that contribute to the functionality and efficiency of the tool. Understanding these components is vital for proper maintenance and operation.

- Motor: The power source that drives the cutting mechanism.

- Blade: The sharp element responsible for making precise cuts through various materials.

- Base Plate: A sturdy foundation that ensures stability during operation.

- Fence: A guide that assists in making accurate cuts, providing support to the material being worked on.

- Handle: The part that allows for easy maneuverability and control of the tool.

- Adjustable Angle Settings: Features that enable the user to set different cutting angles for versatility.

- Dust Collection Port: A feature that aids in maintaining a clean workspace by directing debris away from the cutting area.

Each of these components plays a significant role in ensuring optimal performance, safety, and user satisfaction. Familiarity with them can enhance both the effectiveness and longevity of the equipment.

Importance of Parts Diagrams

Understanding the layout and components of a device is crucial for effective maintenance and repair. Visual representations serve as essential tools, allowing users to identify each element’s role and placement within a machine. This clarity enhances troubleshooting and ensures that repairs can be conducted efficiently, reducing downtime.

Benefits of Visual Representations

- Enhanced Clarity: Visual aids provide a clear overview, making it easier to comprehend complex assemblies.

- Streamlined Repairs: By knowing the specific locations of each component, repairs can be executed swiftly.

- Improved Communication: Technicians can share insights and strategies more effectively using visual references.

Facilitating Maintenance Tasks

- Identifying necessary tools and components for a specific job.

- Understanding how to disassemble and reassemble equipment without errors.

- Planning maintenance schedules by recognizing wear patterns on specific parts.

Common Issues and Solutions

When using power tools, various challenges may arise that can hinder performance and efficiency. Identifying these common problems and their respective solutions can significantly enhance the user experience and prolong the tool’s lifespan. Below are some typical concerns and remedies that can be applied.

Frequent Problems

- Tool not starting or lacking power

- Excessive noise during operation

- Inaccurate cuts or misalignment

- Overheating during prolonged use

Possible Solutions

- Check the power source: Ensure the tool is properly connected to a functioning outlet or that the battery is adequately charged.

- Inspect for wear: Examine the cutting components for any signs of damage or excessive wear and replace them if necessary.

- Adjust settings: Verify that the tool’s settings are correctly configured for the specific task to ensure precision.

- Allow cooling time: If overheating occurs, give the tool time to cool down before continuing use to prevent damage.

By addressing these issues promptly and implementing the suggested solutions, users can maintain optimal performance and extend the life of their equipment.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair tasks. Such illustrations provide a clear overview of the different elements and their respective positions within a machine. By familiarizing oneself with the layout and symbols used, one can easily identify each section and locate the necessary parts for replacement or repair.

Familiarize with the Layout

The first step in interpreting a visual representation is to recognize its structure. Typically, these illustrations are organized in a way that mirrors the actual assembly. Start by identifying the main sections and subcomponents. Each segment usually contains labels or numbers that correspond to a detailed list of components.

Utilize Reference Guides

Accompanying documentation is often provided alongside visual representations. This reference guide contains descriptions, specifications, and other relevant information about each part. Cross-referencing the visual with the list enhances understanding and ensures accurate identification of components.

| Component | Description | Common Issues |

|---|---|---|

| Base | Foundation of the assembly. | Stability problems. |

| Motor | Powers the operation of the device. | Overheating, noise issues. |

| Blade | Cutting tool used in the assembly. | Dullness, damage. |

Maintenance Tips for Longevity

Ensuring the durability of your tools requires consistent care and attention. By adopting effective maintenance practices, you can significantly extend the lifespan and efficiency of your equipment.

Regular Cleaning: After each use, it’s crucial to clean the tool thoroughly. Remove dust, debris, and any residue to prevent buildup that can affect performance.

Proper Storage: Store your equipment in a dry, cool place. Utilizing protective cases or racks can shield them from moisture and accidental damage.

Routine Inspections: Periodically check all components for wear and tear. Identifying issues early allows for timely repairs, preventing further damage.

Lubrication: Apply lubricant to moving parts regularly. This minimizes friction and enhances the overall functionality of the tool.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for specific maintenance procedures. Adhering to these guidelines ensures optimal performance and safety.

Implementing these simple yet effective practices can lead to improved reliability and extended use of your tools, making them a worthy investment for any project.

Where to Find Replacement Parts

When it comes to maintaining your tools, locating the right components is essential for ensuring optimal performance and longevity. Numerous sources are available to help you acquire the necessary items, whether for routine maintenance or specific repairs.

Online Retailers

One of the most convenient ways to find components is through various online platforms. Websites specializing in tool accessories often provide detailed catalogs that allow you to search by model or type. Be sure to check customer reviews and ratings to ensure reliability before making a purchase.

Local Hardware Stores

Visiting nearby hardware shops can also be beneficial. Many of these stores carry a selection of items for popular tools, and knowledgeable staff can assist you in finding what you need. Additionally, local suppliers may offer the advantage of immediate availability without shipping delays.

Comparing Models: LS1016L vs Others

When evaluating different tools in the same category, it’s essential to examine the unique features and specifications that each model offers. This comparison aims to highlight the distinctions and advantages of a particular model in relation to its counterparts, aiding users in making informed decisions based on their specific needs.

Key Features to Consider

Each tool comes with a variety of attributes, such as cutting capacity, weight, and power source, which can greatly impact performance. Understanding these characteristics can help users identify which model is best suited for their projects. For instance, some models may excel in portability, while others might provide enhanced cutting precision.

Performance and Efficiency

Performance varies significantly among different options, influencing their efficiency and usability. It’s crucial to assess how each model handles various tasks, such as making angled cuts or operating under heavy load. Users often find that certain features contribute to smoother operation and reduced fatigue during prolonged use.

Assembly Instructions for New Parts

This section provides essential guidance for properly assembling new components in your equipment. Understanding the steps involved is crucial to ensure that everything functions seamlessly and safely. By following these instructions, you can enhance the efficiency and longevity of your tool.

Preparation Steps

Before beginning the assembly, ensure that you have all necessary tools and components ready. It’s important to work in a clean, organized space to avoid misplacing any parts. Reviewing the user manual for specific details related to your equipment can also be beneficial.

Assembly Process

Start by identifying each component and its corresponding location in the assembly. Follow the sequence of steps carefully to ensure everything fits together correctly. If you encounter resistance or any issues during assembly, double-check the alignment and orientation of the parts.

| Step | Action |

|---|---|

| 1 | Gather all necessary tools and components. |

| 2 | Ensure the workspace is clean and organized. |

| 3 | Identify each part and its position in the assembly. |

| 4 | Carefully follow the assembly sequence as outlined. |

| 5 | Double-check the alignment if any resistance occurs. |

Safety Precautions During Repairs

When conducting maintenance or fixing tools, it is essential to follow specific safety guidelines to prevent accidents and injuries. Ensuring a secure working environment is key to minimizing risks while handling equipment.

Protective Gear: Always wear the necessary protective clothing, such as gloves, safety goggles, and appropriate footwear, to shield yourself from potential hazards.

Power Off: Before starting any repair, make sure the equipment is fully powered off and unplugged to avoid any accidental activation during the process.

Proper Tools: Use the right tools designed for the task to avoid causing damage to the equipment or risking personal injury. Incorrect tools can lead to malfunctions or accidents.

Work Area: Maintain a clean and organized workspace. This reduces

Customer Reviews on LS1016L Performance

Feedback from users provides valuable insights into the efficiency and reliability of this tool. Many customers share their experience, highlighting key aspects such as accuracy, ease of use, and overall functionality. These opinions help potential buyers make informed decisions based on real-world performance.

Precision and Accuracy

Users frequently commend the tool for its exceptional precision during operation. Whether cutting through different materials or making complex angles, the accuracy consistently meets expectations. Professionals particularly value how well it maintains stability and delivers smooth results.

Ease of Use and Durability

Another common theme in reviews is the ease of use. Even those new to similar tools appreciate how intuitive