In any mechanical device, a clear understanding of its configuration is essential for effective operation and maintenance. Knowing how various elements interact and function together can significantly enhance performance and longevity. This knowledge is crucial for anyone looking to optimize the functionality of their equipment.

Exploring the internal structure provides valuable insights into the specific roles each element plays within the assembly. This exploration aids in troubleshooting and ensures that users can perform repairs with confidence. Additionally, a thorough grasp of the setup facilitates better decision-making regarding upgrades or replacements, leading to improved efficiency.

By examining the comprehensive representation of each segment, individuals can better appreciate the intricacies involved in the design. Understanding these connections is vital for anyone engaged in maintenance, ensuring that they can address any issues that arise effectively.

Understanding the roles of individual elements within a complex assembly is crucial for optimal performance and maintenance. Each part contributes uniquely to the overall operation, ensuring efficiency and reliability. By examining the functionality of these elements, users can gain insights into how to troubleshoot issues and enhance the longevity of the equipment.

Key Elements and Their Roles

- Motor: The heart of the device, converting electrical energy into mechanical power.

- Gearbox: This component regulates speed and torque, facilitating the appropriate power transfer to the working end.

- Switch: A vital control mechanism, allowing users to start or stop operations easily.

- Housing: Protects internal components from dust and damage, contributing to the device’s durability.

Importance of Each Element

Each component serves a specific purpose that influences the overall functionality. Understanding these roles can lead to better maintenance practices:

- Regular inspection of the motor ensures efficient performance and avoids overheating.

- Monitoring the gearbox helps maintain the correct torque settings, preventing wear and tear.

- Ensuring the switch is functioning correctly can prevent unexpected shutdowns or malfunctions.

- Maintaining the housing protects internal mechanisms, prolonging the life of the tool.

Common Issues and Repair Solutions

Understanding frequent problems and their remedies can enhance the longevity and performance of your equipment. Many users encounter similar challenges, which can often be resolved with simple troubleshooting steps. Below are some typical issues faced and suggested solutions for effective maintenance.

-

Insufficient Power:

This can result from various factors such as a faulty power source or worn-out components.

- Check the power outlet for functionality.

- Inspect cords and plugs for any damage.

- Replace any defective parts as needed.

-

Overheating:

Excessive heat can lead to equipment failure if not addressed promptly.

- Ensure proper ventilation during operation.

- Clean any dust or debris from vents and fans.

- Limit continuous usage to prevent overheating.

-

Noise Issues:

Unusual sounds often indicate underlying mechanical problems.

- Examine all moving parts for wear or damage.

- Lubricate parts that require it to reduce friction.

- Replace any broken components to restore normal operation.

-

Inconsistent Performance:

Fluctuations in performance can hinder efficiency.

- Regularly check and clean filters.

- Inspect connections for any loose or corroded contacts.

- Adjust settings as per manufacturer specifications for optimal results.

By addressing these common issues with the outlined solutions, users can significantly improve the functionality and lifespan of their tools. Regular maintenance is essential for avoiding more significant problems down the line.

Identifying Compatible Replacement Parts

Finding suitable substitutes for your equipment is essential for maintaining its functionality and performance. Understanding the compatibility of various components ensures that repairs are effective and that your device operates smoothly. The process involves identifying specifications and features that align with the original setup, allowing for seamless integration.

Start by consulting the manufacturer’s specifications, as they often provide detailed information about the necessary attributes of each component. This includes dimensions, materials, and performance standards that replacements should meet. Additionally, online resources and forums can offer valuable insights from other users who have successfully replaced similar elements.

When sourcing replacements, prioritize reputable suppliers who offer authentic or high-quality aftermarket options. Checking reviews and product ratings can help ensure that the items are reliable. By being diligent in your search, you can prolong the life of your equipment and maintain optimal functionality.

Importance of Regular Maintenance Practices

Regular upkeep of tools and machinery is essential for ensuring optimal performance and longevity. Consistent maintenance not only enhances the efficiency of equipment but also prevents unexpected failures that can lead to costly repairs or replacements. By implementing routine checks and servicing, users can identify potential issues before they escalate, ultimately saving time and resources.

Moreover, adhering to maintenance schedules fosters a safer working environment. Well-maintained equipment reduces the risk of accidents and malfunctions, promoting overall productivity. Investing time in regular care not only extends the lifespan of tools but also enhances user confidence in their reliability and performance.

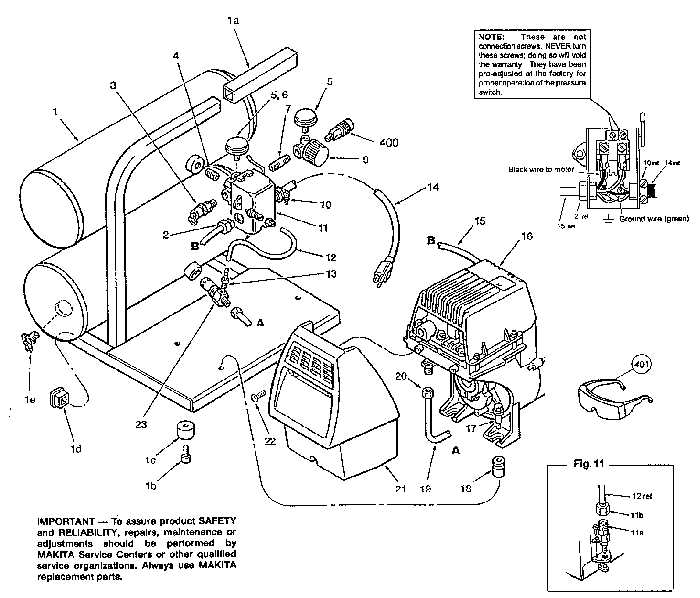

How to Interpret the Parts Diagram

Understanding the layout of components is crucial for effective maintenance and repair. A well-structured visual representation allows users to identify each element’s function and its relationship with other pieces. By familiarizing yourself with this schematic, you can streamline repairs and enhance your equipment’s longevity.

To effectively decode the visual representation, follow these key steps:

| Step | Description |

|---|---|

| 1 | Examine the overall layout to get a sense of the component arrangement. |

| 2 | Identify each section and note the labeled elements for reference. |

| 3 | Cross-reference the illustration with your service manual for detailed insights. |

| 4 | Use the visual guide to assist in disassembly and reassembly during repairs. |

By following these steps, you can enhance your understanding of the component layout and improve your overall repair experience.

Tools Required for Assembly and Disassembly

Proper assembly and disassembly of equipment necessitate a range of tools to ensure efficiency and precision. Utilizing the right instruments can simplify the process, minimize the risk of damage, and enhance safety. Below is a list of essential tools that facilitate these tasks effectively.

Essential Hand Tools

When working on equipment, several hand tools are indispensable for both assembly and disassembly. These tools provide the necessary leverage and grip required for manipulating components.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening nuts and bolts. |

| Screwdriver Set | Essential for driving screws in various sizes. |

| Pliers | Helpful for gripping, twisting, and cutting wire. |

| Hex Key Set | Used for fasteners with hexagonal sockets. |

Power Tools and Equipment

In addition to hand tools, certain power tools can significantly expedite the assembly and disassembly processes, especially for larger components.

| Tool | Purpose |

|---|---|

| Drill | Utilized for making holes and driving screws quickly. |

| Impact Driver | Ideal for loosening stubborn screws and bolts. |

| Angle Grinder | Used for cutting and grinding metal components. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

Tips for Safe Operation of the Equipment

Ensuring the safe use of tools and machinery is essential for both efficiency and the prevention of accidents. Understanding operational protocols and adhering to safety measures significantly reduces the risk of injury and equipment damage. Following a few key guidelines can enhance your safety while working with heavy-duty machinery.

Pre-Operational Checks

- Inspect the equipment for any visible damages or wear before use.

- Ensure that all safety guards are in place and functioning properly.

- Check the power source for any issues or irregularities.

- Familiarize yourself with the operating manual to understand specific safety requirements.

Safe Operating Practices

- Wear appropriate personal protective equipment, including goggles and gloves.

- Keep the work area clean and free from obstructions to prevent accidents.

- Do not bypass safety features; these are designed to protect the user.

- Maintain a firm grip on the equipment and be aware of your surroundings while operating.

- Turn off and unplug the machine when not in use or when changing accessories.

Where to Purchase Genuine Parts

Acquiring authentic components for your tools is essential to ensure their optimal performance and longevity. When seeking replacements, it is crucial to source them from reputable suppliers to guarantee quality and compatibility. Here are some recommended avenues for finding genuine replacements:

- Authorized Dealers: Visit local authorized retailers that specialize in tool sales. These establishments typically carry a range of original components and can assist with specific requirements.

- Official Websites: Many manufacturers offer online stores where you can directly purchase authentic items. This option ensures you receive products that meet the manufacturer’s standards.

- Specialized Online Retailers: Various online platforms focus on providing genuine items for tools. Look for sites with positive reviews and customer feedback to ensure reliability.

- Tool Repair Shops: Local repair shops often have access to authentic components and can help source what you need while providing expert advice.

- Manufacturer Customer Support: Contact the manufacturer’s customer service for assistance in locating specific components. They can guide you to reliable sources or provide ordering options.

By exploring these options, you can confidently acquire the necessary replacements to keep your equipment functioning effectively.

FAQs About the MAC5501G Model

This section addresses common inquiries regarding this specific tool model, offering clarity and detailed information for users. It is essential to understand the features, maintenance, and troubleshooting aspects to maximize the efficiency and longevity of the equipment.

Common Questions and Answers

| Question | Answer |

|---|---|

| What is the power rating of this tool? | The device typically operates at a power rating of 550 watts, making it suitable for various applications. |

| How often should I perform maintenance? | Regular maintenance should be performed every 50 hours of usage to ensure optimal performance and prevent wear. |

| Is there a warranty available? | Yes, this model usually comes with a standard warranty that covers manufacturing defects for a specified period. |

| Can I use it for commercial purposes? | This tool is designed for both residential and light commercial use, making it versatile for various tasks. |

Maintenance Tips

To ensure the longevity of the tool, regularly check for wear on essential components and keep the device clean. Use appropriate lubricants where necessary and store it in a dry place to prevent corrosion.