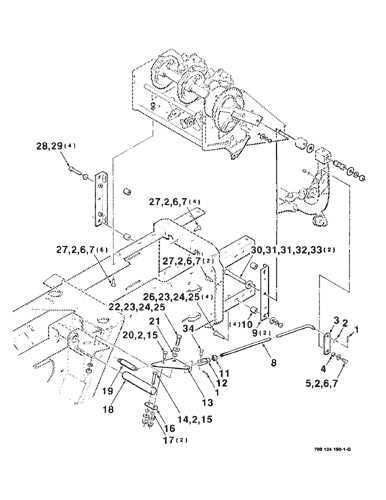

Understanding how various elements come together in machinery can significantly aid in maintenance and repair. When working with agricultural equipment, it is essential to familiarize yourself with the arrangement of different mechanical elements. This knowledge allows for efficient troubleshooting, ensuring that each element operates as intended.

The assembly of agricultural machinery involves numerous interconnected components that contribute to the overall functionality of the equipment. By examining the structural layout, users can gain insight into how each element interacts with the others, making it easier to replace or repair specific components when necessary.

Detailed diagrams and explanations of each section help users pinpoint specific areas of interest, whether for routine checks or more extensive repairs. With a clear understanding of how everything fits together, you can minimize downtime and maximize operational efficiency.

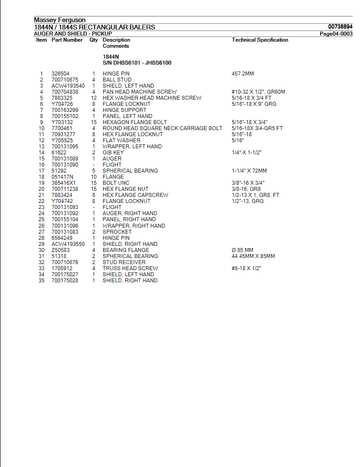

Understanding Massey Ferguson Baler Components

Efficient agricultural machinery relies on a series of crucial elements that ensure smooth operation and productivity in the field. Each mechanical piece serves a specific purpose, contributing to the overall performance of the equipment. These interconnected elements allow for the seamless collection, compression, and packaging of material, simplifying essential farming tasks.

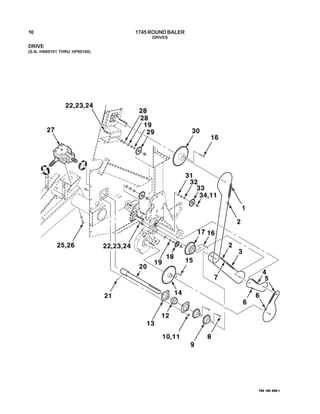

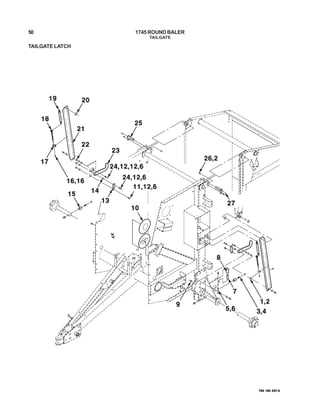

Key mechanical sections are designed to work in unison, from the intake system to the release mechanism. Drive assemblies and compression chambers are particularly important for handling large quantities of material, while precision components manage material flow and uniformity.

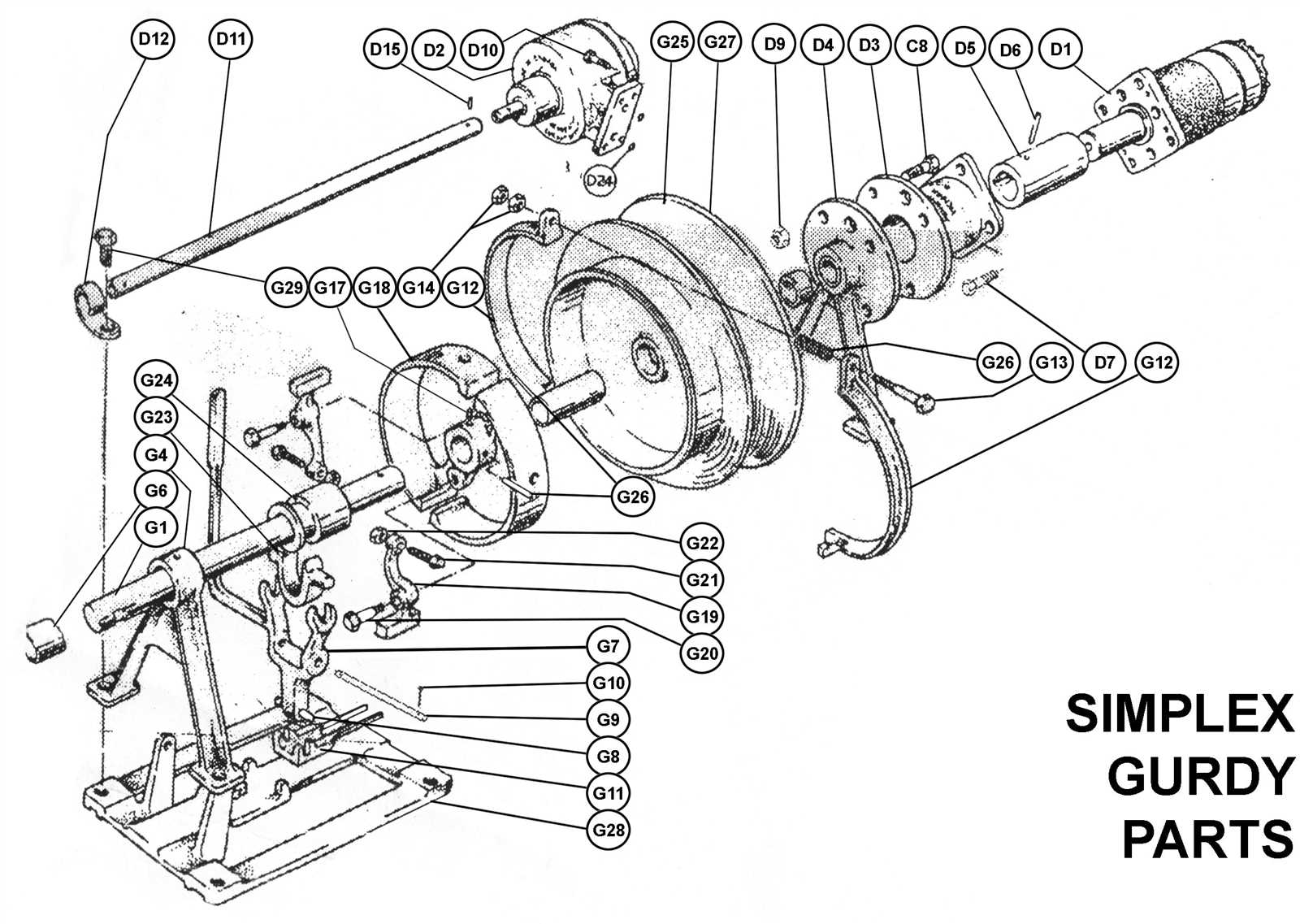

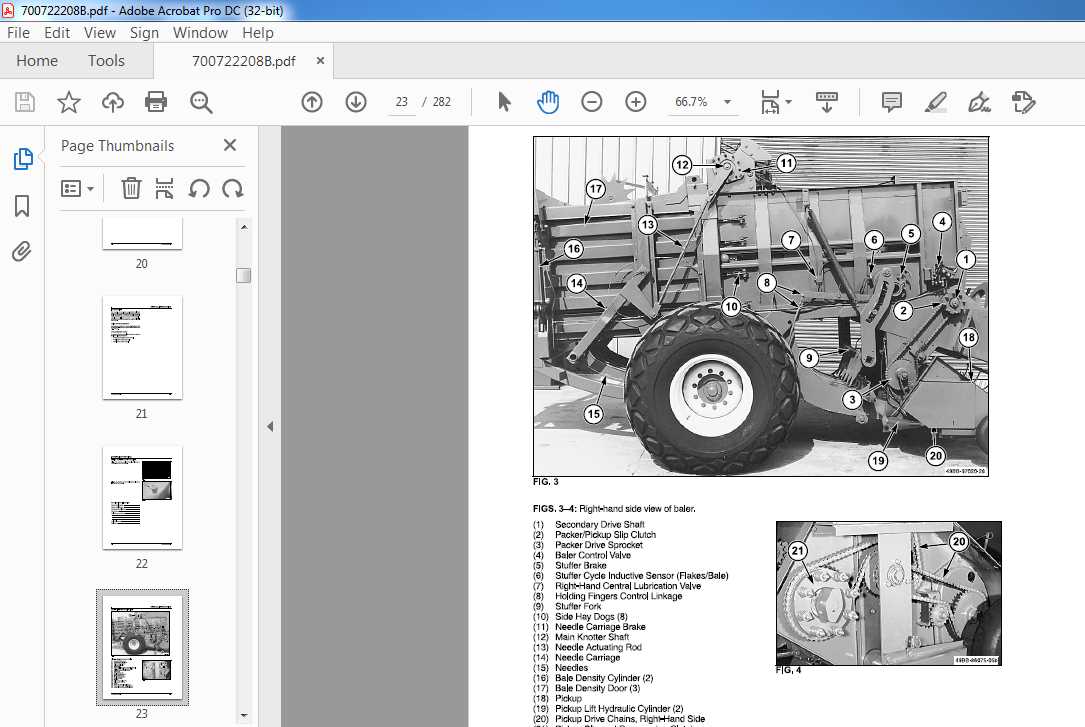

Key Diagrams for Baler Repairs

When working on maintaining or restoring agricultural equipment, visual aids play a crucial role in understanding the intricate connections and components. These essential schematics help identify specific elements and their alignment within the overall mechanism, ensuring that repairs are done accurately and efficiently.

Clear illustrations allow for quick reference to critical areas, reducing the risk of errors during assembly or replacement processes. Whether you are dealing with mechanical alignments or electrical systems, having access to detailed representations can save time and effort, guiding you through each step of the repair.

How to Identify Crucial Baler Parts

Recognizing key components in your agricultural equipment is essential for maintaining its functionality and efficiency. By understanding how these elements work together, you can prevent potential malfunctions and keep your machinery running smoothly.

| Component | Description | Function | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pickup Mechanism | This assembly gathers material from the field. | Ensures proper feeding of crops into the machine. | ||||||||||||||||||||||||

| Tying System | A system responsible for

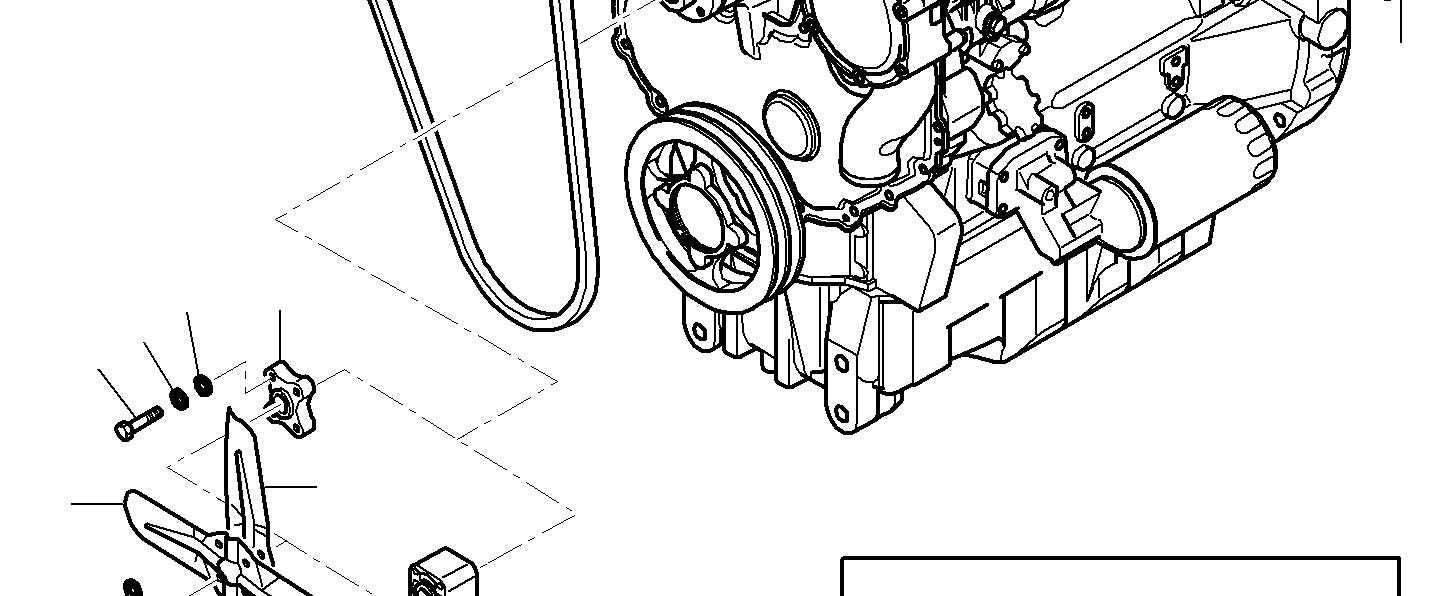

Guide to Belt and Roller MechanismsThe functioning of agricultural machines often depends on the efficient interaction between belts and rollers. These components work together to drive the internal processes, ensuring smooth operation and consistent performance. Understanding their role and configuration is crucial for maintaining and optimizing the equipment. Belt systems are typically responsible for transferring motion between various parts, providing the necessary force to keep the mechanisms in sync. Rollers, on the other hand, help guide materials through the system, ensuring a steady and uniform movement. Both elements must be properly aligned and maintained for optimal functionality. Comprehensive View of Knotter AssemblyThe knotter mechanism plays a crucial role in ensuring smooth operation during the tying process. Its assembly is designed to reliably secure materials by creating strong, consistent ties, making it an essential part of agricultural machinery. Main Components and Their Functions

Understanding the various elements of the knotter system helps in maintaining efficient operation. Key components include gears, needles, and hooks, all working together to produce tight and dependable knots.

Troubleshooting Common Baler Component Issues

When operating agricultural machinery, encountering issues with various components is a common challenge. Identifying and resolving these problems is crucial for maintaining efficiency and ensuring smooth operation. This section will outline typical issues and their solutions to help operators effectively manage equipment performance. Identifying Mechanical FailuresMechanical failures can arise from wear and tear, improper maintenance, or inadequate lubrication. Symptoms such as unusual noises, decreased efficiency, or jamming may indicate underlying mechanical issues. Regular inspections and timely replacements of worn components are essential to prevent significant breakdowns and prolong the equipment’s lifespan. Electrical System Troubleshooting

Electrical problems can significantly impact functionality and operation. Common symptoms include malfunctioning sensors, erratic performance, or complete power loss. Checking wiring connections, fuses, and relays should be the first step in diagnosing electrical issues. Ensuring a secure and clean electrical system will help mitigate these challenges. Replacing Worn Out Baler Elements

Maintaining optimal performance in agricultural equipment requires timely replacement of components that show signs of wear. Identifying and addressing these deteriorated elements is crucial for ensuring efficiency and longevity. Regular inspections can help pinpoint parts that need attention, minimizing downtime and enhancing overall productivity. Identifying Worn Components

Before proceeding with replacements, it is essential to recognize the signs of wear in various components. Common indicators include unusual noises, decreased functionality, and visible damage. Conducting a thorough examination can aid in identifying parts that require replacement. Replacement Process Overview

The process of swapping out old components generally involves several key steps:

Hydraulic System Layout and FunctionThe hydraulic mechanism is a vital component in various agricultural machines, facilitating efficient operation through the use of fluid power. This system allows for precise control of different functions, ensuring smooth and effective performance during various tasks. Understanding the configuration and workings of the hydraulic system is essential for optimal operation and maintenance. Key elements of this system include: Each component plays a critical role in ensuring the efficiency and effectiveness of the hydraulic system. Regular inspection and maintenance are crucial to prevent issues and prolong the lifespan of the equipment. Understanding Twine and Needle OperationsThe processes involving string and stitching tools are crucial in the functioning of hay and forage machinery. These operations ensure that harvested material is securely bound, allowing for efficient handling and transportation. A clear comprehension of how these components interact can significantly enhance operational efficiency and reduce maintenance needs. Role of Twine in BindingString serves as the primary medium for securing gathered material. Its proper tension and alignment are essential for achieving effective binding. Incorrect use can lead to issues such as slippage or breakage, resulting in wasted material and time. Needle Mechanism FunctionalityThe stitching tool plays a vital role in the tying process, facilitating the insertion of string through gathered material. Understanding the movement and mechanics of this tool is essential for troubleshooting and ensuring smooth operation. Regular inspection and maintenance can prevent operational failures, thus enhancing overall productivity. Maintaining theRegular upkeep of agricultural machinery is crucial for ensuring optimal performance and longevity. By following appropriate maintenance practices, operators can minimize breakdowns and enhance efficiency. This section outlines essential maintenance tasks to keep your equipment functioning smoothly. Key Maintenance Tasks

By adhering to these maintenance tasks, operators can enhance the reliability and effectiveness of their machinery, leading to improved agricultural productivity. |