In the world of outdoor equipment, familiarity with your machine’s inner workings can significantly enhance its performance and longevity. Knowing the various elements that make up your chainsaw not only empowers you to maintain it effectively but also helps in troubleshooting issues when they arise. This understanding is essential for any user aiming to keep their tool in top condition.

Visual representation of the individual elements provides clarity and aids in comprehending how each piece contributes to the overall functionality. Whether you’re looking to replace a worn-out section or simply wanting to familiarize yourself with your tool, having a comprehensive overview can make the process straightforward and manageable.

Additionally, grasping the arrangement of these components can facilitate better assembly and disassembly, leading to a more efficient maintenance routine. With the right knowledge, you’ll be well-equipped to tackle any task with confidence and ensure your equipment operates smoothly for years to come.

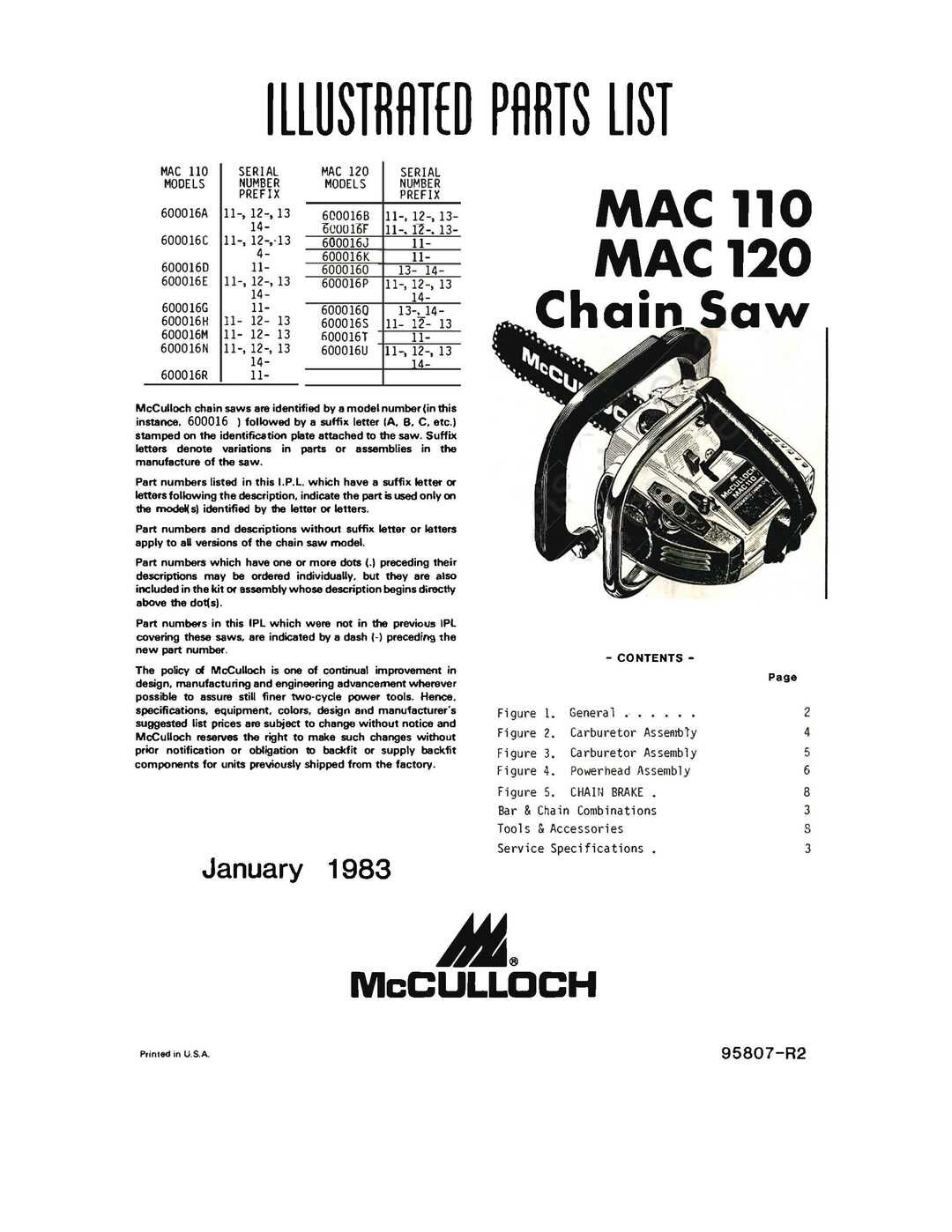

Mcculloch Mac 110 Overview

This section provides a comprehensive examination of a classic chain saw model renowned for its durability and performance. Designed for both casual users and professionals, it features a robust engine that delivers reliable power while remaining lightweight and easy to handle.

Key Features: The device is equipped with an efficient cutting system that ensures swift and precise operation. Its ergonomic design enhances user comfort, allowing for extended use without fatigue. The construction is made from high-quality materials, ensuring longevity and resilience against wear and tear.

Maintenance Tips: Regular upkeep is essential to maintain optimal performance. This includes routine checks of the cutting mechanism, fuel system, and overall condition of the equipment. Keeping it clean and well-lubricated will significantly extend its lifespan.

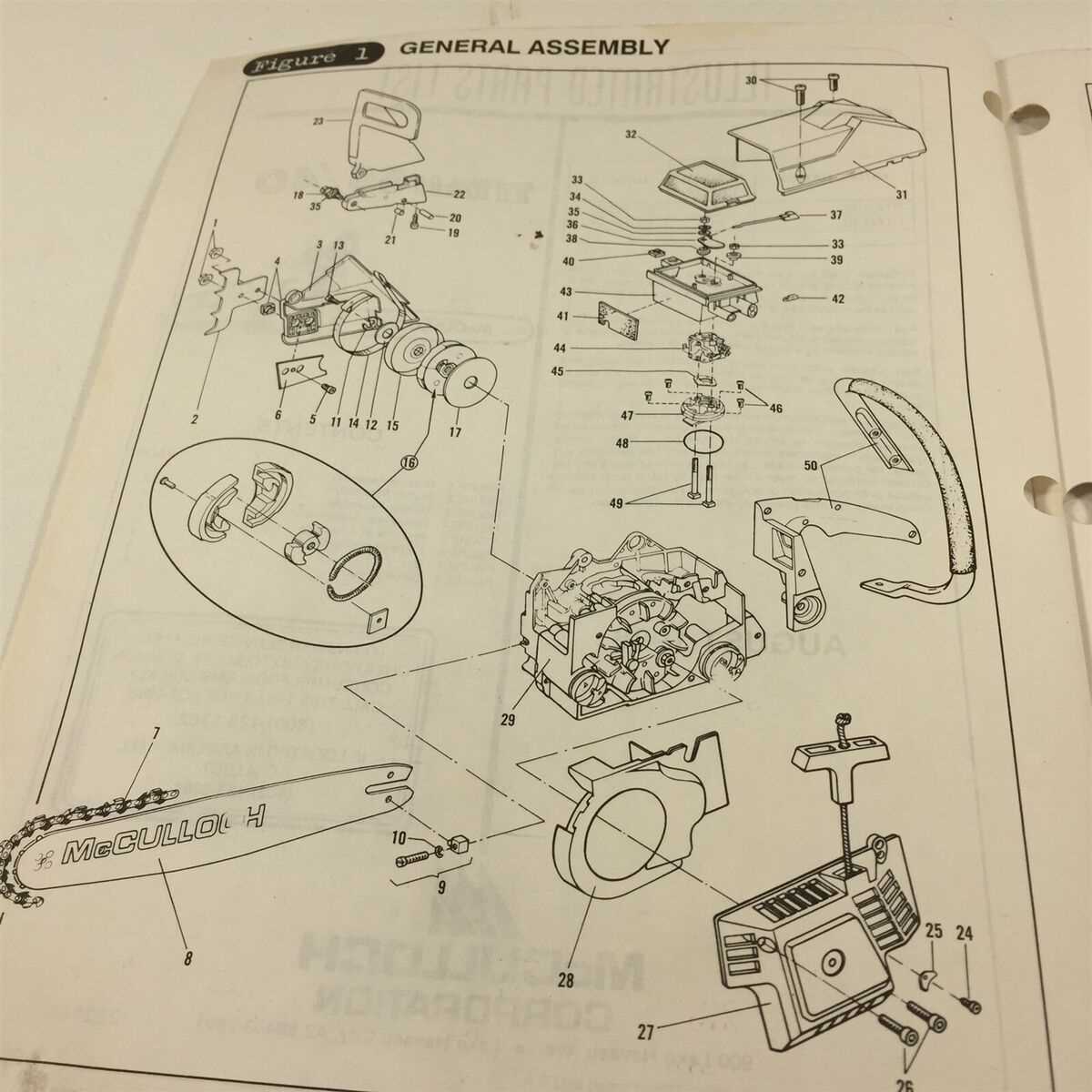

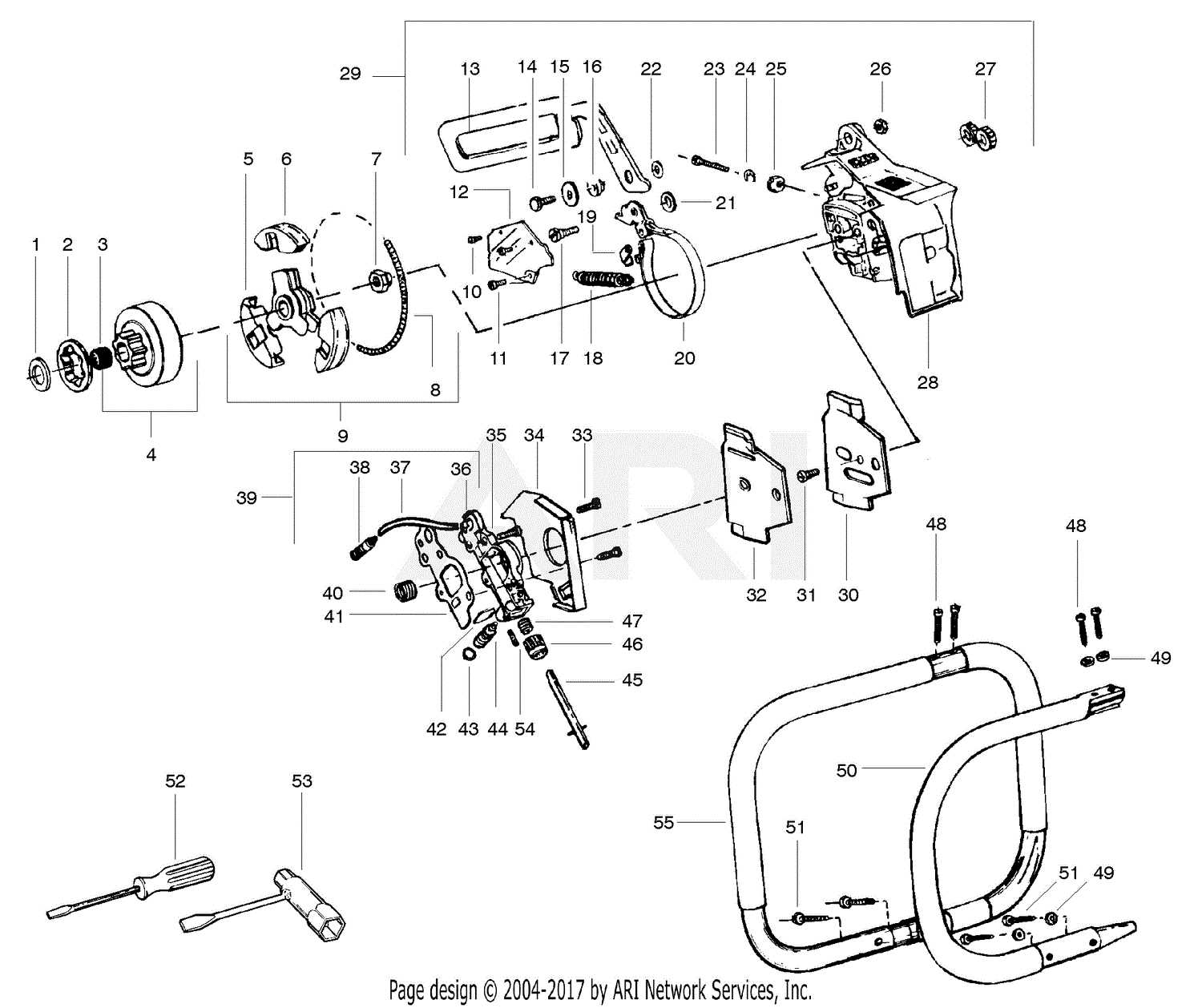

Understanding Parts Diagrams

Visual representations of components serve as essential tools for grasping the intricacies of machinery. They provide clarity by illustrating how each element interacts within the larger system. These visuals can simplify maintenance, repair, and assembly processes, making them invaluable resources for both novices and experienced technicians.

By examining these schematics, one can delve into the relationships between various elements, ultimately enhancing problem-solving abilities. Recognizing individual pieces and their functions is crucial for effective troubleshooting and ensures that all parts are correctly aligned for optimal performance.

Moreover, familiarity with these illustrations fosters confidence in handling equipment, empowering users to undertake repairs or modifications with greater ease. As such, understanding these visual aids is a fundamental step in mastering the machinery at hand.

Essential Components of Mac 110

Understanding the fundamental elements of a chainsaw is crucial for its effective maintenance and operation. Each component plays a vital role in ensuring the tool functions smoothly and efficiently, making it important for users to be familiar with them. Below are the key elements that contribute to the performance and reliability of this equipment.

Core Parts

- Engine: The heart of the tool, providing the necessary power to operate the cutting chain.

- Bar: The elongated metal piece where the chain loops around, guiding it during cutting tasks.

- Chain: The serrated loop that does the cutting; it needs regular sharpening for optimal performance.

- Fuel System: Includes the tank and lines that supply the engine with the required fuel mixture.

- Ignition System: Responsible for starting the engine and ensuring it runs efficiently.

Additional Elements

- Clutch: Engages and disengages the chain from the engine, allowing for safe operation.

- Air Filter: Protects the engine by filtering out debris and contaminants from the air intake.

- Oiler: Lubricates the chain and bar to reduce friction and wear during operation.

- Handle: Provides control and maneuverability, ensuring user safety and comfort.

- Safety Features: Includes mechanisms like the chain brake and throttle lock to enhance user protection.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of your equipment. Regular maintenance not only enhances functionality but also extends the life of your machinery. By adopting a few simple practices, you can prevent issues and keep your device running smoothly.

Routine Checks

- Inspect all moving parts for wear and tear.

- Clean air filters to ensure optimal airflow.

- Check for loose screws and tighten as necessary.

Lubrication and Storage

- Apply appropriate lubricants to reduce friction.

- Store in a dry, sheltered area to avoid rust.

- Cover the equipment when not in use to protect from dust.

Common Issues and Solutions

When operating a chainsaw, users may encounter several common problems that can hinder performance. Understanding these issues and their solutions can enhance efficiency and prolong the life of the equipment.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Empty fuel tank, clogged filter, faulty spark plug | Refill fuel, clean or replace filter, check and replace spark plug |

| Excessive Vibration | Loose parts, damaged chain, unbalanced bar | Tighten screws, inspect and replace chain, adjust bar |

| Poor Cutting Performance | Dull chain, incorrect tension, improper angle | Sharpen chain, adjust tension, check cutting angle |

| Overheating | Blocked air intake, dirty air filter | Clear air intake, clean or replace filter |

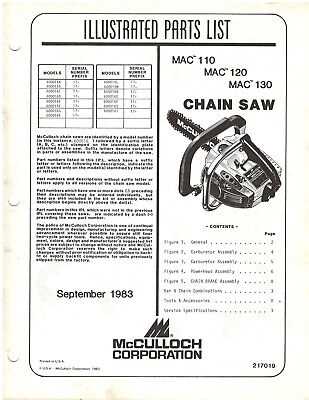

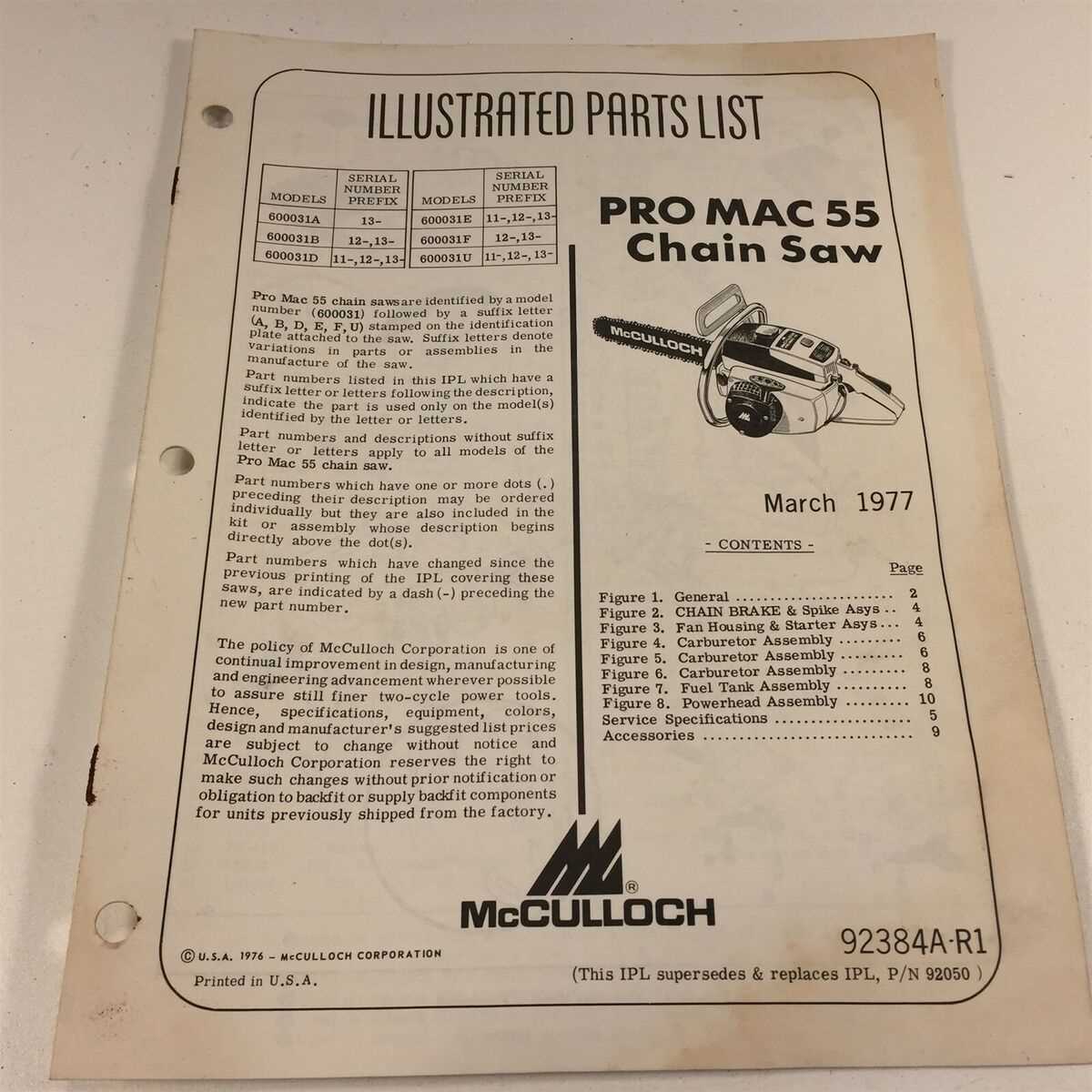

How to Identify Replacement Parts

Understanding how to pinpoint the correct components for your machinery is essential for maintaining optimal performance. Accurate identification ensures that you select the right items for repairs or upgrades, avoiding compatibility issues and enhancing the lifespan of your equipment.

Consult the Manufacturer’s Resources

One of the most reliable methods for finding the necessary components is to refer to the manufacturer’s resources. Look for official documentation, such as user manuals or online catalogs, which often include detailed information about each element, including specifications and compatibility notes. This information can be invaluable when determining what you need to replace.

Utilize Online Forums and Communities

Engaging with online forums and communities can provide additional insights. Experienced users often share their knowledge about specific components and alternatives. Be sure to ask for recommendations based on your model and needs, as this can lead to discovering hard-to-find items or even improved substitutes.

Tools Required for Repairs

Proper maintenance and repair of equipment necessitate a set of essential tools. Having the right instruments on hand not only simplifies the repair process but also enhances efficiency and safety. Below is a list of tools that are vital for effective repairs.

Basic Tools

- Screwdrivers (flathead and Phillips)

- Wrenches (adjustable and fixed)

- Pliers (needle-nose and regular)

- Socket set

- Utility knife

Specialized Equipment

- Torque wrench

- Fuel line clamp

- Multimeter

- Grease gun

- Safety goggles and gloves

Equipping yourself with these tools will ensure you are prepared to delve into repairs with confidence and achieve the ultimate results.

Safety Precautions During Maintenance

When undertaking maintenance on machinery, prioritizing safety is crucial to prevent accidents and ensure effective operation. Adhering to specific guidelines can significantly reduce risks associated with mechanical work.

Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, to safeguard against potential hazards. Additionally, ensure the equipment is powered down and disconnected from any power sources before beginning maintenance tasks to avoid accidental starts.

Maintaining a clean and organized workspace is essential. Remove any clutter that could cause slips or falls, and keep tools within reach. Be mindful of sharp edges and hot surfaces, as these can pose serious risks during handling and adjustments.

Lastly, consult the manufacturer’s guidelines and technical manuals for specific safety instructions related to the equipment you are working on. Regularly reviewing these protocols can provide critical insights for safe operation and maintenance practices.

Where to Find Authentic Parts

When maintaining or repairing outdoor machinery, sourcing genuine components is crucial for optimal performance and longevity. Authentic replacements ensure compatibility and reliability, allowing users to avoid potential issues that may arise from substandard alternatives. Whether you are restoring a vintage model or keeping a current one running smoothly, knowing where to look is essential.

One of the best places to start is the official manufacturer’s website. Here, you can often find a dedicated section for accessories and replacements, complete with detailed specifications. Authorized dealers are another reliable source, as they typically offer certified items that meet the original standards of quality. Additionally, checking with local retailers who specialize in outdoor equipment can yield valuable options.

Online marketplaces also provide a vast array of choices. Reputable platforms often feature verified sellers who stock genuine components. Always look for customer reviews and ratings to gauge the authenticity of the items offered. Furthermore, joining online forums or communities dedicated to machinery can connect you with fellow enthusiasts who might have insights on where to procure high-quality replacements.

In summary, whether through official channels or trusted online resources, taking the time to find authentic components will enhance the performance and durability of your equipment, ensuring that it serves you well for years to come.

Upgrades for Enhanced Performance

Enhancing the functionality of your machine can lead to remarkable improvements in efficiency and output. By focusing on specific modifications, you can significantly boost its overall performance and longevity.

Power Enhancements: Consider upgrading the engine components to achieve greater horsepower. A high-performance carburetor can improve fuel delivery, resulting in better acceleration and responsiveness.

Weight Reduction: Utilizing lightweight materials for certain parts can reduce overall weight, enhancing maneuverability and ease of use. This allows for improved handling and less fatigue during operation.

Cooling System: Installing an upgraded cooling system can prevent overheating, ensuring consistent performance during extended use. Enhanced airflow and efficient heat dissipation are key factors.

Safety Features: Adding advanced safety features not only protects the user but can also enhance performance by allowing for more aggressive operation without compromising safety.

Incorporating these upgrades will help you delve deeper into the potential of your equipment, achieving ultimate efficiency and effectiveness.