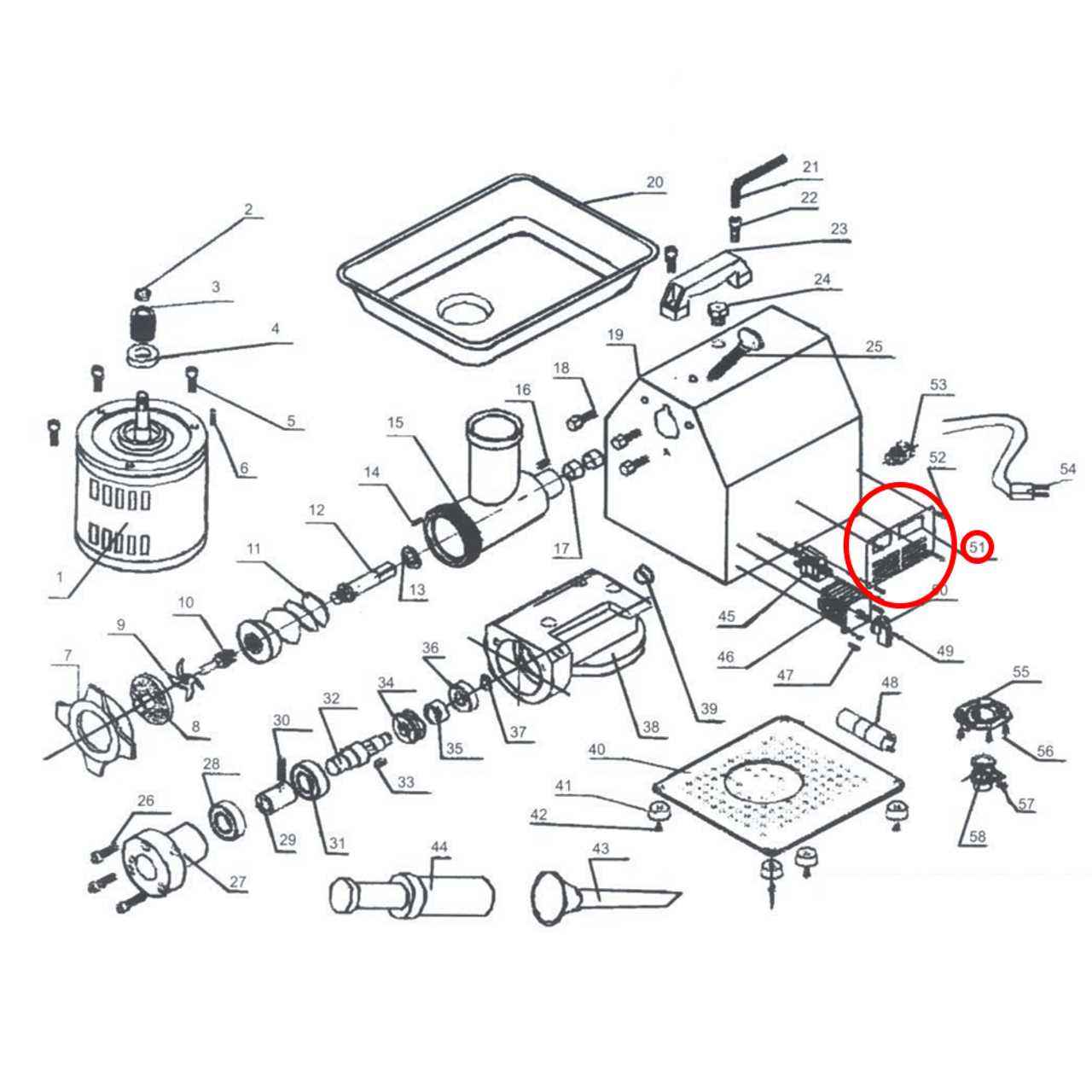

Understanding the internal structure of a food processing device is crucial for anyone looking to maintain, repair, or upgrade their equipment. A comprehensive layout of the various elements can simplify these tasks, making it easier to identify specific components and their roles within the mechanism.

Each section of the device has a dedicated function, and knowing how they interconnect ensures smoother operation and troubleshooting. From the core mechanisms to the smaller auxiliary pieces, having a clear view of the setup helps in better care and efficient use.

Whether you’re performing routine maintenance or addressing specific issues, being familiar with the arrangement of elements will aid in quick diagnostics and effective solutions. This guide will provide an overview of how each part contributes to the overall performance of the unit, enhancing your ability to keep it in top condition.

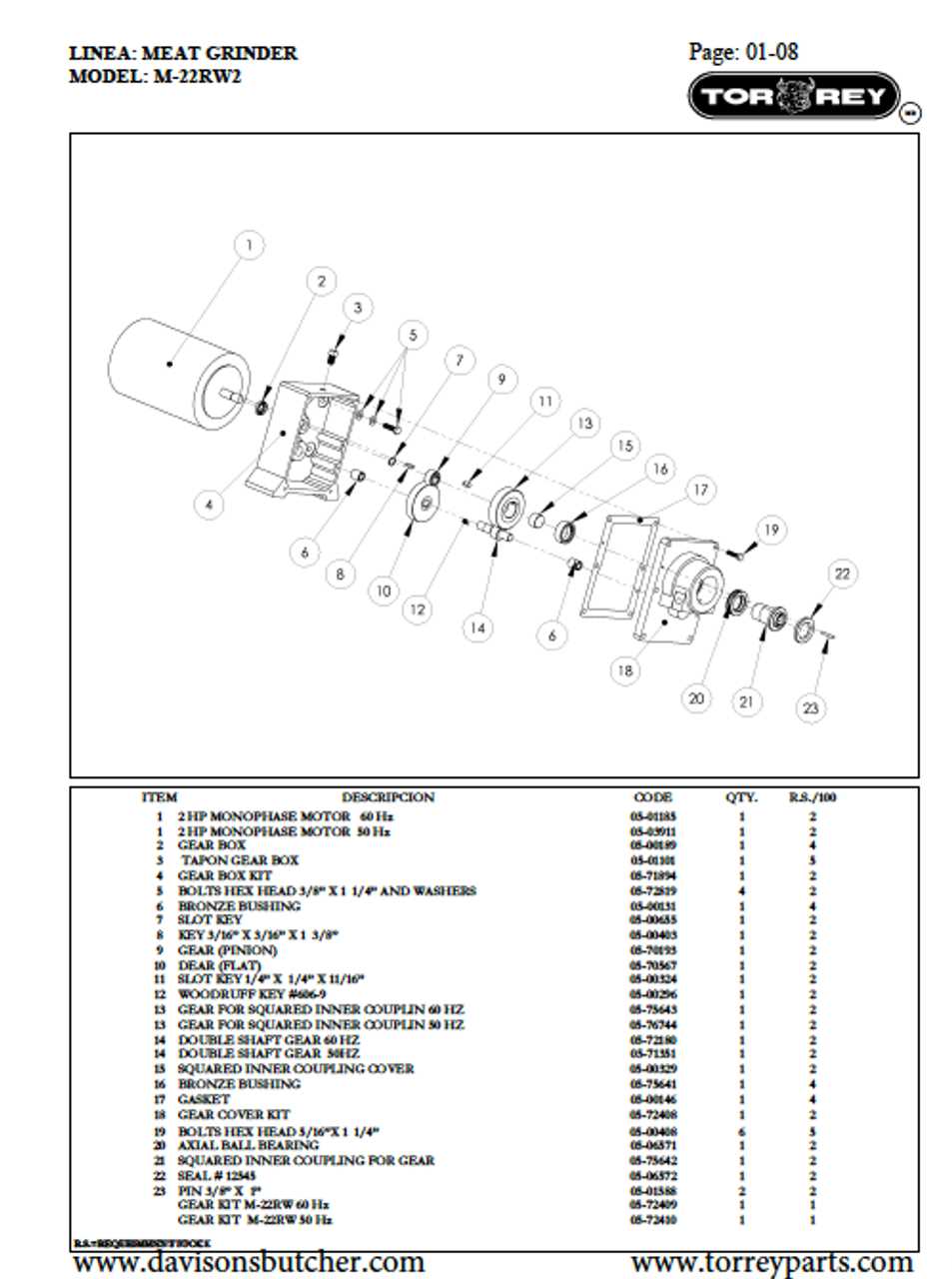

Understanding Meat Grinder Components

Various kitchen devices rely on multiple elements working in unison to achieve efficient performance. This equipment, often found in food preparation, is no exception. By exploring each component, one can better grasp how these devices operate and what ensures their functionality.

Primary Mechanism

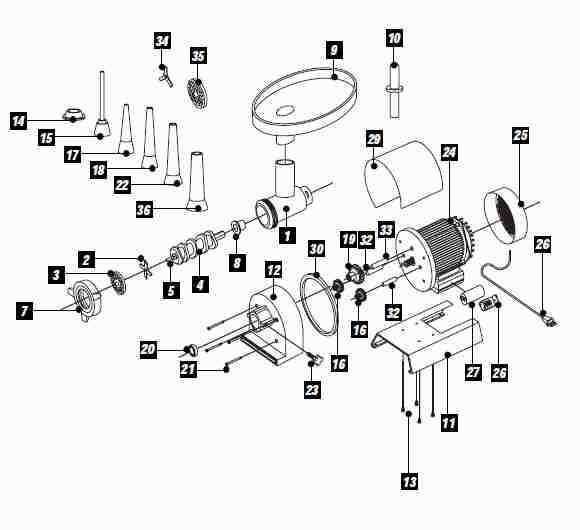

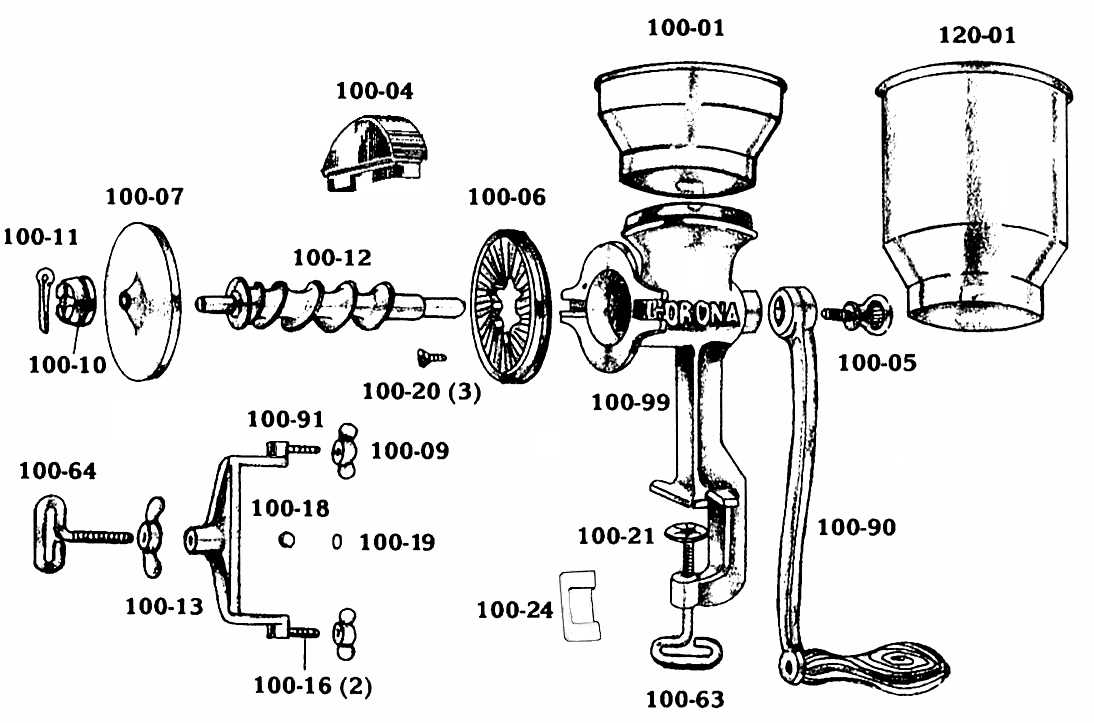

The central unit is responsible for driving the process, ensuring smooth operation. This typically involves a motor or manual handle, which sets everything in motion. The energy or force applied here is transferred through other segments, enabling effective processing.

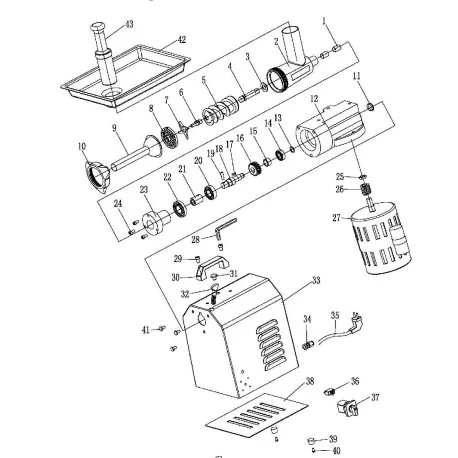

Internal Sections and Attachments

Within the core unit, internal pieces like blades and augers play a crucial role. These are designed to cut, push, and mix substances, guiding them through the device. Additionally, various attachments can be utilized to adapt the system for different tasks, offering greater versatility.

Essential Parts of a Meat Grinder

Understanding the fundamental components of this kitchen device is crucial for efficient operation and maintenance. Each piece plays a specific role, working together to ensure smooth processing and consistent results.

Feeding Mechanism

The feeding mechanism is where the process begins. It allows ingredients to be directed into the device smoothly and safely. Equipped with a sturdy tray, this section ensures that all items are funneled down properly without clogging or jamming.

Cutting and Processing Components

At the core of the device lies the set of blades and discs. These sharp elements are responsible for slicing and cutting the items into desired sizes and textures. The assortment of discs varies, giving users control over the coarseness of the output.

Functions of Different Grinder Elements

Each component of this versatile device has a specific role, ensuring efficient operation and consistent results. Understanding how these elements work together can help users optimize performance and extend the equipment’s longevity.

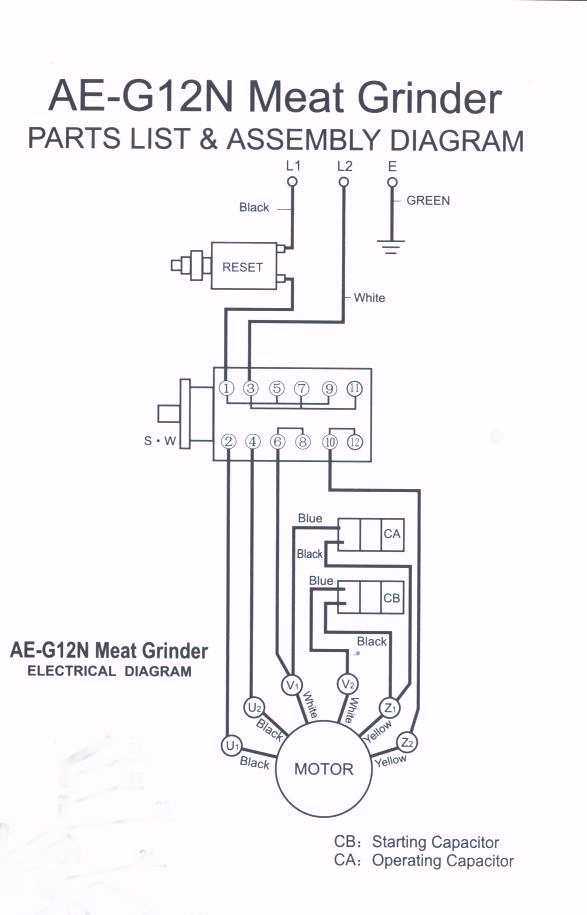

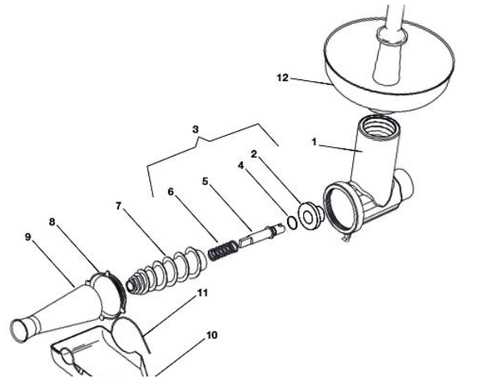

Motor Unit: The core powerhouse, responsible for driving the mechanism and providing the necessary force to process various ingredients. Its power output determines how efficiently the device can handle different textures.

Auger: This spiral-shaped piece moves materials through the machine, pushing them steadily towards the cutting area. Its design ensures a smooth flow, reducing the likelihood of jams and blockages.

Blades: Sharp and precise, these cutters are crucial for achieving consistent textures. Their quality and sharpness directly affect the outcome, ensuring that materials are processed evenly.

Discs: Equipped with different hole sizes, these plates define the final texture of the output. Selecting the right disc can vary the result, from fine to coarse, depending on the desired application.

Hopper: The top compartment where materials are placed before processing. Its design allows for easy feeding, ensuring a continuous flow without manual intervention.

Pusher: A simple but essential tool, enabling users to guide materials safely into the auger without risking contact with moving parts. It provides better control over the process.

Inner Workings of Grinder Mechanisms

Understanding the intricate functionality of food processing appliances reveals a fascinating interplay of various components. Each element plays a crucial role in transforming raw ingredients into finely processed materials, contributing to efficiency and effectiveness in the kitchen.

Key Components and Their Functions

- Feeding Mechanism: This component is responsible for directing the raw materials into the system, ensuring a smooth and consistent flow.

- Cutting Blades: Positioned strategically, these sharp instruments chop and slice the ingredients into desired sizes, facilitating uniformity.

- Mixing Chamber: This area combines ingredients thoroughly, allowing for even distribution of flavors and textures before processing.

- Power Source: Providing the necessary energy, this element drives the entire mechanism, enabling all parts to function harmoniously.

Operational Dynamics

- The process begins with the input of ingredients through the feeding mechanism.

- As the power source activates, the cutting blades engage, breaking down the contents into smaller pieces.

- Subsequently, the mixing chamber ensures a cohesive blend, enhancing the final product’s quality.

- Finally, the processed material is expelled, ready for further culinary applications.

Maintenance Tips for Grinder Parts

Ensuring the longevity and efficiency of your appliance requires consistent care and attention. Regular upkeep not only enhances performance but also prevents potential issues that can arise from neglect. Adopting a proactive approach can save you time and money in the long run.

Routine Cleaning

Thorough cleaning after each use is essential. Residue buildup can affect functionality and lead to unpleasant odors. Disassemble components carefully and wash them with warm, soapy water. Use a soft brush to remove stubborn debris, ensuring that every crevice is free from remnants.

Proper Storage

After cleaning, it is crucial to store the appliance correctly. Keep it in a dry place to prevent rust and corrosion. Avoid stacking heavy items on top, as this can cause damage. Maintaining an organized storage area will also help you quickly access your appliance when needed.

Common Issues with Grinder Components

When utilizing a food processing device, various challenges may arise concerning its individual elements. Understanding these common issues can help in maintaining optimal performance and ensuring longevity. Below are several frequent problems that users encounter with the components of their appliance.

- Clogging: This can occur when food debris accumulates in the mechanism, hindering smooth operation. Regular cleaning can prevent this issue.

- Wear and Tear: Over time, certain components may degrade due to frequent use, leading to diminished efficiency. Regular inspections are essential.

- Misalignment: Parts may become misaligned, causing improper function. Ensuring proper assembly is crucial for effective performance.

- Overheating: Prolonged use can cause overheating, which may affect the integrity of the components. Allowing the device to cool down is advisable.

- Noisy Operation: Unusual sounds can indicate underlying issues with the machinery. Identifying the source of noise can aid in troubleshooting.

By recognizing and addressing these common challenges, users can enhance the performance and durability of their food processing device, ensuring a smoother experience during usage.

How to Replace Grinder Elements

Maintaining the functionality of your food preparation appliance is essential for optimal performance. Over time, certain components may wear out or become damaged, requiring replacement. This guide provides straightforward instructions for effectively swapping out these essential elements, ensuring your device operates smoothly.

Steps for Replacement

- Unplug the appliance to ensure safety during the replacement process.

- Carefully disassemble the unit by removing the outer casing and any protective covers.

- Identify the components that need to be replaced, such as the blades, feed screws, or any other worn elements.

- Using appropriate tools, detach the old components from their positions.

- Install the new elements by following the reverse order of removal. Ensure each part is secured properly.

Maintenance Tips

- Regularly inspect components for signs of wear to avoid sudden failures.

- Clean the device thoroughly after each use to prolong the lifespan of all elements.

- Refer to the manufacturer’s manual for specific guidelines on replacing individual components.

Cleaning Various Grinder Sections

Maintaining cleanliness in different components of a food processing machine is essential for ensuring hygiene and optimal performance. Regularly sanitizing these elements helps prevent contamination and prolongs the equipment’s lifespan. This section outlines effective methods for cleaning the various sections of the appliance.

Essential Cleaning Tools

Before starting the cleaning process, gather the necessary tools and materials to ensure efficiency. The following table lists essential items for effective sanitation:

| Tool | Purpose |

|---|---|

| Brush | For scrubbing hard-to-reach areas |

| Soap solution | For dissolving grease and grime |

| Cloth | For drying and polishing surfaces |

| Disinfectant | For eliminating bacteria and viruses |

Step-by-Step Cleaning Process

Follow these steps to ensure thorough cleaning of all sections:

1. Disassemble the appliance carefully, ensuring all components are separated.

2. Rinse each section under warm water to remove any residual food particles.

3. Apply the soap solution and use the brush to scrub surfaces, focusing on crevices.

4. Rinse again with clean water to remove any soap residue.

5. Wipe down with a cloth and apply a disinfectant to finalize the sanitation process.

6. Allow all components to dry completely before reassembling.

Safety Precautions for Grinder Usage

When operating any equipment designed for processing food, it is essential to prioritize safety to prevent injuries and accidents. Understanding the necessary precautions can significantly reduce risks associated with using such machinery.

Always ensure that the device is securely assembled before use. Check for any loose components or wear that might compromise its functionality. Prior to starting the machine, familiarize yourself with its controls and emergency shut-off features.

It is crucial to keep hands and other body parts away from moving elements during operation. Use appropriate tools for handling food items, avoiding direct contact with sharp components. Wear protective gear, such as gloves and non-slip shoes, to minimize the chance of accidents.

Regular maintenance and cleaning are vital for the longevity of the equipment. Unplug the device before cleaning to avoid accidental activation. Dispose of any waste properly and ensure that the area around the machine is tidy to prevent slips or falls.

Lastly, always supervise the operation when in use, especially if others are nearby. Educate all users on safety practices to create a secure environment for processing food products.

Choosing the Right Grinder Accessories

Selecting the appropriate attachments for your device can greatly enhance its functionality and efficiency. The right accessories not only improve performance but also offer versatility in food preparation. Understanding your needs and the available options is crucial for achieving the best results in your culinary endeavors.

When considering which accessories to incorporate, functionality is paramount. Evaluate what types of dishes you plan to create and choose attachments that facilitate those tasks. For example, if you intend to create a variety of textures, opting for different blades or plates can provide the desired outcome.

Quality is another essential factor. Investing in durable and well-constructed accessories ensures longevity and optimal performance. Check for materials that resist wear and tear, as they will maintain their effectiveness over time.

Lastly, compatibility with your device is vital. Always verify that the selected attachments fit seamlessly with your machine to prevent any operational issues. Taking the time to research and choose wisely will ultimately lead to a more satisfying experience in your kitchen.

Material Types Used in Grinder Parts

Understanding the different materials employed in the components of a processing machine is essential for optimal performance and longevity. The choice of materials can significantly influence the efficiency and durability of the equipment, impacting overall functionality.

Various types of substances are utilized in constructing the elements of such machinery, each with distinct characteristics and benefits:

- Stainless Steel: Renowned for its resistance to corrosion and rust, this material is often favored for its durability and ease of cleaning.

- Aluminum: Lightweight yet strong, aluminum components are popular for their excellent conductivity and affordability.

- Cast Iron: Known for its strength and stability, cast iron offers excellent wear resistance, making it suitable for heavy-duty applications.

- Plastic: Used in non-load-bearing parts, various plastics are lightweight, resistant to corrosion, and cost-effective.

Each material type plays a crucial role in ensuring the reliability and effectiveness of the equipment, contributing to its overall performance in the processing of different substances.