When it comes to maintaining the efficiency and longevity of your aquatic power unit, comprehending the intricate assembly of its elements is essential. Each component plays a crucial role in the overall functionality, ensuring optimal performance while navigating the waters. Familiarity with these individual parts not only aids in troubleshooting but also empowers owners to make informed decisions during repairs or upgrades.

Exploring the arrangement of various engine components reveals a world of interconnectivity and precision. From the propulsion system to the ignition setup, every piece is meticulously designed to work harmoniously. This insight can significantly enhance your ability to address potential issues before they escalate, ultimately leading to a more enjoyable boating experience.

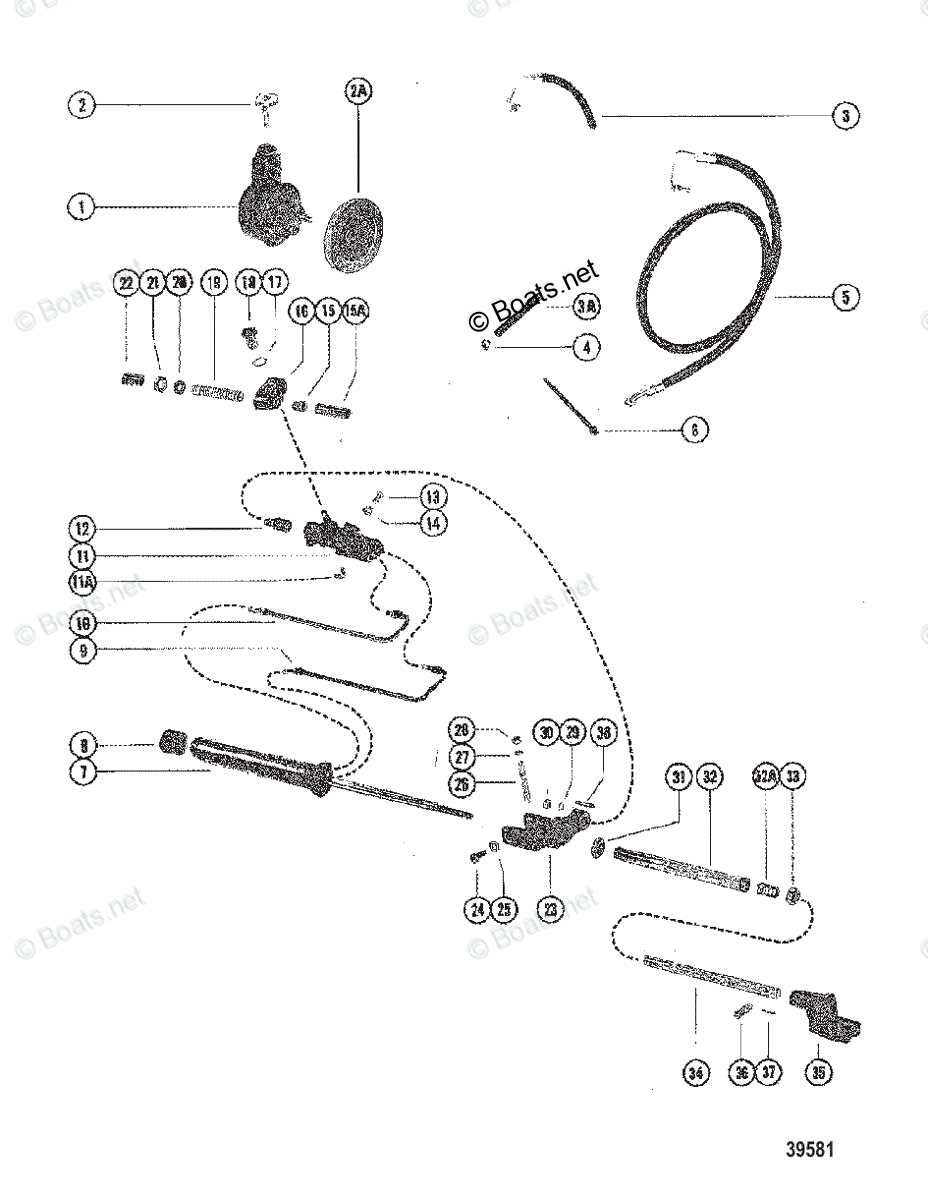

Utilizing detailed schematics of your marine engine serves as a valuable resource for enthusiasts and technicians alike. These visual aids break down complex systems into manageable sections, allowing for a clearer understanding of how each part contributes to the engine’s performance. By referencing these illustrations, you can gain confidence in your maintenance skills and enhance your mechanical knowledge.

Understanding Mercruiser 165 Overview

This section delves into the key aspects of a specific marine engine renowned for its performance and reliability. Designed for various watercraft, this power unit is a favored choice among enthusiasts and professionals alike, offering a blend of efficiency and robust functionality.

The engine features several components that contribute to its overall effectiveness:

- Power Output: Engine capacity is optimized for delivering substantial horsepower.

- Fuel Efficiency: The design ensures minimal fuel consumption while maximizing output.

- Durability: Constructed with high-quality materials to withstand harsh marine environments.

Understanding the configuration and function of each element is crucial for maintenance and enhancement:

- Block: The foundation that houses essential internal components.

- Cylinder Head: Plays a vital role in combustion and airflow management.

- Intake System: Responsible for bringing in air and fuel mixtures efficiently.

- Exhaust System: Ensures proper expulsion of gases, contributing to overall performance.

By familiarizing oneself with these elements, users can ensure optimal performance and longevity of their marine engine, making it a valuable asset on the water.

Key Components of Mercruiser 165

This section focuses on the essential elements that contribute to the performance and efficiency of the engine system. Understanding these components is crucial for maintenance and optimal operation.

Engine Block and Cylinder Head

The engine block serves as the core of the power unit, housing the cylinders where fuel combustion occurs. The cylinder head plays a vital role in sealing the top of the cylinders and facilitating air and fuel intake, ensuring effective combustion.

Fuel Delivery System

This system includes the fuel pump and carburetor, which are responsible for supplying the correct fuel mixture to the engine. Proper functioning of this system is essential for achieving the desired power output and efficiency.

Importance of Parts Diagrams

Understanding the layout and components of a mechanical system is essential for effective maintenance and repair. Visual representations of individual elements not only facilitate easier identification but also enhance the overall comprehension of how each piece interacts within the assembly. This knowledge is crucial for both professionals and enthusiasts alike.

Streamlining Repairs

Having access to a visual guide can significantly streamline the repair process. When working on complex machinery, being able to pinpoint specific components helps technicians quickly diagnose issues. Efficiency is increased when the exact location of each element is clear, reducing the time spent searching for parts and minimizing potential errors.

Enhancing Understanding

These visual aids also play a vital role in education. By illustrating how components fit together, they provide an invaluable resource for learning about system functionality. Newcomers can gain insights into the mechanics involved, fostering a deeper appreciation and understanding of the technology at hand.

Common Issues with Mercruiser 165

Many boat engines face a range of challenges that can affect their performance and longevity. Understanding these common problems can help owners take preventive measures and ensure smoother operations. From overheating to fuel inefficiencies, recognizing early signs of trouble is crucial for maintaining engine health.

Overheating Problems

One frequent issue is overheating, which can be caused by inadequate cooling water supply or blocked passages. Regular maintenance and inspections can help identify potential blockages before they become serious.

Fuel System Issues

Another common challenge involves the fuel system. Issues such as clogged filters or failing pumps can lead to reduced power and efficiency. Timely replacement of filters and regular fuel system checks are recommended.

| Issue | Symptoms | Solutions |

|---|---|---|

| Overheating | High temperature gauge, steam from engine | Check water supply, clean cooling passages |

| Fuel Inefficiency | Poor acceleration, stalling | Replace filters, inspect fuel lines |

Identifying Engine Parts Visually

Recognizing components of a motor can significantly enhance maintenance and troubleshooting skills. By understanding the visual characteristics of each element, enthusiasts and mechanics alike can more easily diagnose issues and ensure proper function. Familiarity with the layout and appearance of key parts contributes to a more efficient repair process and overall engine longevity.

Key Visual Features

Different elements possess unique shapes, sizes, and colors that aid in identification. For instance, the cylinder head typically has a distinct flat surface with multiple bolts, while the oil pan is generally more elongated and may have a darker hue. Noticing these variations allows for quicker assessments during inspections.

Common Components to Recognize

Focus on familiar parts such as the intake manifold, fuel injectors, and exhaust headers. Each component plays a critical role in performance and understanding their visual cues can prevent misdiagnoses. Regular observation during routine checks fosters a deeper connection with the motor’s workings, ultimately leading to more successful repairs.

Parts Diagram Interpretation Techniques

Understanding the intricate layout of mechanical components is crucial for effective maintenance and repair. Mastering the ability to analyze these visual representations can enhance efficiency and accuracy in identifying necessary elements. This section explores methods to effectively decode these illustrations, ensuring a comprehensive grasp of each constituent’s role and relation.

| Technique | Description |

|---|---|

| Familiarization | Acquaint yourself with common symbols and notations used in technical illustrations. |

| Component Grouping | Identify clusters of related elements to understand their interconnections and functionality. |

| Reference Documentation | Utilize accompanying manuals or guides to clarify specific components and assembly processes. |

| Hands-on Practice | Engage in practical disassembly and assembly tasks to reinforce your understanding of the visuals. |

Where to Find Official Diagrams

Accessing reliable visual guides is essential for anyone looking to understand the intricate components of their marine engine. Official resources often provide the most accurate representations, helping enthusiasts and technicians alike to navigate their repairs and maintenance efficiently.

Manufacturer Websites

Visiting the official website of the engine manufacturer is a primary source for high-quality visuals. These sites typically offer downloadable resources, ensuring that users receive the latest updates and accurate schematics for their specific model.

Authorized Dealers and Distributors

Engaging with authorized dealers can also yield beneficial results. Many dealers maintain extensive archives of technical materials and are willing to share detailed images and information with their customers. This route often guarantees access to authentic and up-to-date resources.

Aftermarket vs. OEM Parts Explained

The choice between different types of components can significantly influence performance, durability, and cost. Understanding the distinctions between alternatives available on the market is essential for making informed decisions, especially when it comes to maintenance and repairs. Each option has its own set of advantages and disadvantages that cater to various needs and preferences.

Original components are designed by the manufacturer and typically guarantee compatibility and reliability. They are often made using the same specifications and materials as the original units, ensuring a perfect fit and optimal functionality. However, these items can be more expensive, which might not align with every budget.

On the other hand, third-party offerings can provide a more affordable solution without compromising too much on quality. These alternatives often feature innovative designs or improved materials, which can enhance performance. Nevertheless, buyers should exercise caution, as not all options are created equal. It’s crucial to research the reputation of the manufacturers and check reviews to ensure a reliable choice.

Ultimately, the decision hinges on individual circumstances, including budget constraints, performance expectations, and long-term maintenance plans. Balancing cost with quality is key to achieving the best results, whether opting for original items or exploring alternative solutions.

Maintenance Tips for Mercruiser 165

Regular upkeep is essential for ensuring optimal performance and longevity of your marine engine. By following a few key practices, you can enhance reliability and prevent costly repairs.

Routine Checks

- Inspect the oil levels and change the oil at recommended intervals.

- Examine the cooling system for leaks or blockages.

- Check the fuel system for contaminants and replace filters as needed.

Seasonal Preparation

- Before launching, ensure all electrical connections are clean and secure.

- Flush the engine with fresh water after each use to remove salt and debris.

- Store the engine in a dry environment during off-seasons to prevent corrosion.

Cost-Effective Repair Strategies

When it comes to maintaining and fixing marine engines, implementing budget-friendly approaches can significantly extend their lifespan. Here are several strategies to consider for effective repairs without breaking the bank.

- Conduct Regular Maintenance: Routine checks and minor adjustments can prevent major issues.

- Source Used or Refurbished Parts: Consider high-quality second-hand components to reduce costs.

- Perform DIY Repairs: Familiarize yourself with basic repair techniques to save on labor costs.

- Join Community Forums: Engage with other enthusiasts for advice and resource sharing.

By focusing on these cost-effective methods, you can ensure reliable performance while managing expenses efficiently.

Upgrading Components for Performance

Enhancing the functionality of your marine engine can significantly improve overall efficiency and speed. By carefully selecting and replacing specific elements, you can achieve a notable boost in power and reliability.

- Intake Systems: Consider upgrading to high-performance intake manifolds and carburetors for improved airflow.

- Exhaust Components: Installing performance exhaust systems can reduce backpressure and enhance engine output.

- Ignition Systems: A modern ignition system ensures optimal timing and energy delivery, resulting in better combustion.

- Fuel Delivery: Upgrading fuel pumps and injectors can provide the necessary fuel volume for high-performance applications.

- Cooling Systems: Improved cooling components help maintain optimal operating temperatures during intense usage.

By focusing on these critical areas, you can delve into a more powerful and efficient engine setup, ultimately enhancing your boating experience.

Safety Considerations for Repairs

When undertaking mechanical repairs, prioritizing safety is crucial to ensure a secure environment for both the technician and the equipment. Adhering to best practices can prevent accidents and promote efficiency during the repair process.

Essential Safety Gear

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Use hearing protection when working in noisy environments.

- Ensure proper ventilation when working with chemicals or fuels.

Work Environment Precautions

- Keep your workspace tidy to minimize tripping hazards.

- Ensure tools are in good condition and stored properly when not in use.

- Have a first aid kit readily accessible in case of emergencies.

Resources for Mercruiser Enthusiasts

For those passionate about marine engines, access to quality resources is essential for maintenance, upgrades, and repairs. This section provides a compilation of useful tools, manuals, and online platforms that can enhance your experience and knowledge in the field.

Recommended Online Platforms

| Website | Description |

|---|---|

| BoatTalk | An active forum for discussing issues and sharing tips with fellow boat lovers. |

| MarineParts.com | A comprehensive online store for sourcing various components and accessories. |

| YouTube | Numerous channels dedicated to tutorials and walkthroughs for engine maintenance. |

Manuals and Documentation

Finding manuals and technical documents is crucial for effective troubleshooting. Many manufacturers provide downloadable resources that cover everything from installation to repair procedures. Look for user guides and service manuals specific to your model for the ultimate insights.