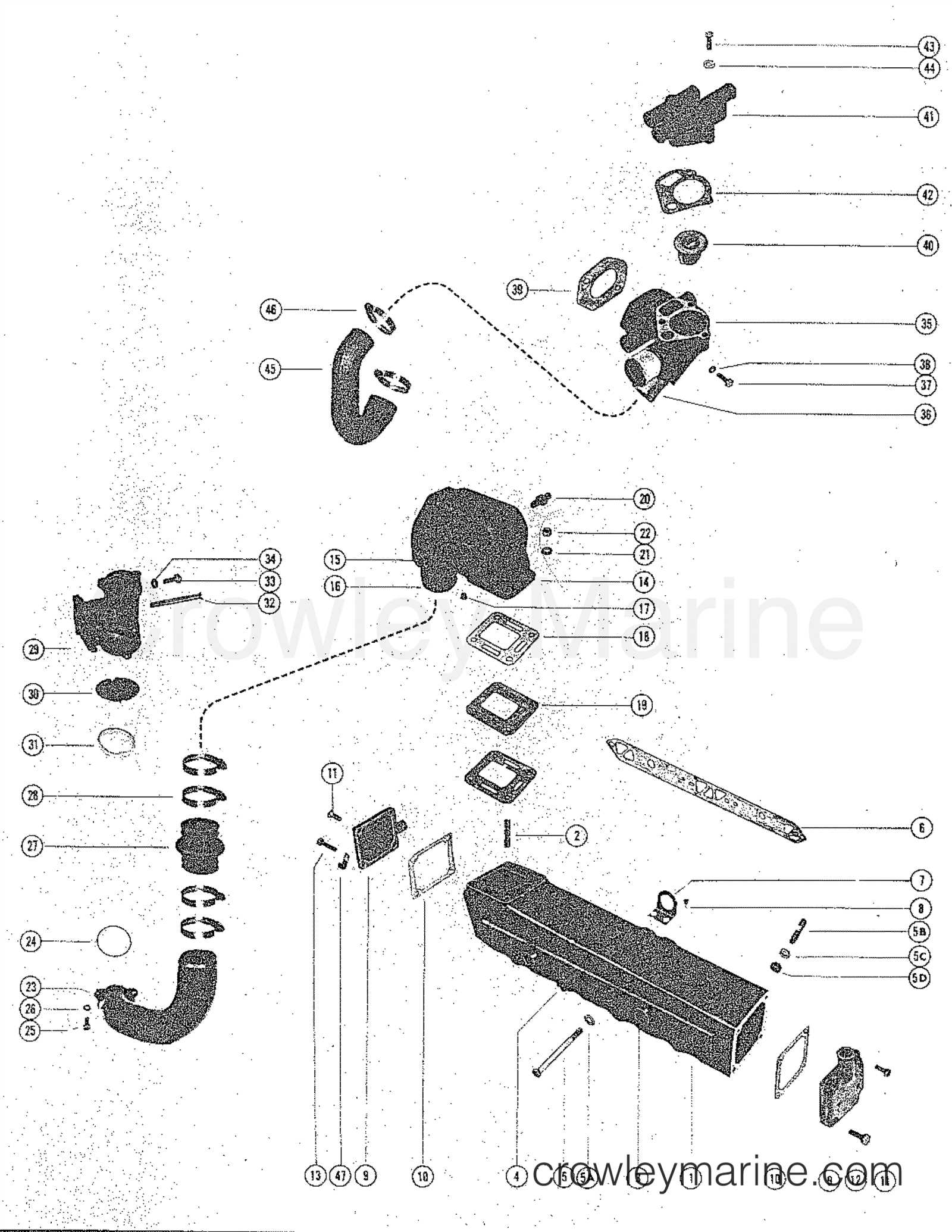

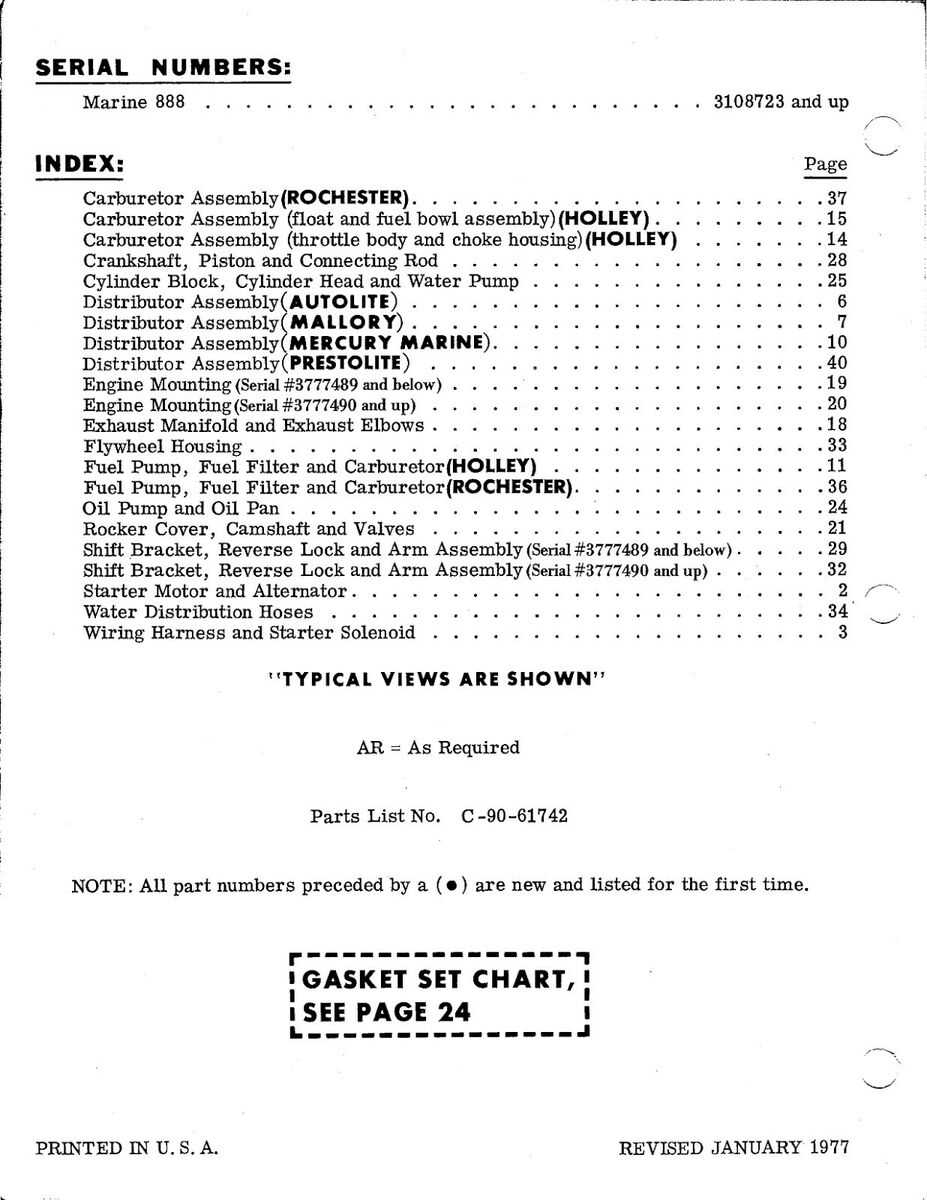

The intricate design of marine propulsion systems requires a thorough understanding of their individual elements and how they interact. This section delves into the essential components of a specific engine model, illustrating their configurations and relationships. A comprehensive overview of these elements is crucial for effective maintenance and repairs.

By examining the structural arrangement of various mechanical components, enthusiasts and technicians can gain insights into optimal performance and troubleshooting. Visual representations serve as invaluable tools for identifying specific parts and their functions, making it easier to navigate the complexities of engine servicing.

Moreover, grasping the layout enhances one’s ability to source replacements or upgrades, ultimately contributing to a more efficient operation. Understanding these details not only aids in problem-solving but also fosters a deeper appreciation for the engineering behind marine technology.

This section provides a comprehensive look at the various elements that constitute a specific marine propulsion system. Understanding these components is essential for both maintenance and troubleshooting, as each part plays a critical role in the overall functionality and efficiency of the engine. By breaking down the system into its individual parts, users can gain insight into how each element contributes to optimal performance on the water.

Key Elements of the Engine

The engine assembly includes several vital components that work together to ensure smooth operation. Familiarity with these parts allows for better understanding and effective handling during repairs.

Importance of Proper Maintenance

Regular maintenance of the engine components is crucial for longevity and performance. Neglecting any part can lead to significant issues that may affect the entire system’s efficiency.

| Component | Function | Maintenance Tips |

|---|---|---|

| Engine Block | Houses the internal components and maintains structural integrity. | Regularly inspect for cracks and corrosion. |

| Cylinder Head | Encases the combustion chamber and contains valves. | Check for leaks and ensure proper sealing. |

| Oil Pan | Holds the engine oil needed for lubrication. | Change oil regularly to prevent buildup. |

| Intake Manifold | Distributes air and fuel to the engine cylinders. | Clean to avoid blockages and ensure efficient airflow. |

| Exhaust Manifold | Channels exhaust gases away from the engine. | Inspect for leaks and clean to prevent overheating. |

Understanding Engine Assembly Parts

The core of any marine propulsion system relies on a well-coordinated arrangement of mechanical components. These elements work together seamlessly to ensure smooth operation and efficient power delivery. By exploring the structure and roles of each element, one gains a clearer perspective on how they contribute to overall functionality.

Within the assembly, various mechanical elements are interconnected, creating a balanced flow of energy. Key elements focus on the transformation of energy, enabling the propulsion system to deliver a steady and reliable performance. Each segment plays a role in maintaining stability, cooling, and precise movement, essential for the longevity of the system.

Understanding the individual functions and connections between these components allows for better maintenance and optimization. Proper alignment and care of each element ensure the entire system operates at peak efficiency, reducing wear and extending the lifespan of the mechanism.

Key Systems in Mercruiser 888

In this section, we explore the core mechanisms that drive the overall functionality of this marine propulsion unit. These elements work together to ensure efficient power delivery, smooth navigation, and reliable performance in various conditions.

Propulsion System

The primary force behind movement, this system converts the engine’s power into forward momentum. It relies on a combination of power generation and transmission components, ensuring that thrust is delivered to the propeller with minimal loss of energy.

Cooling Mechanism

This crucial feature prevents overheating during extended use. By circulating water through specific channels, it helps maintain optimal temperature levels, ensuring durability and reducing wear on essential components. The balance between heat exchange and fluid flow is key to maintaining long-term performance.

Fuel Delivery Setup

Responsible for ensuring a steady supply of energy, this setup manages the flow of fuel to the engine. Precision in mixing air and fuel is critical, allowing the unit to operate smoothly across varying speeds and loads. This system plays a vital role in achieving efficiency and maintaining smooth operations.

Exploring the Cooling System Design

The cooling system in marine propulsion is essential for maintaining optimal temperature levels during operation. It ensures that various components remain within a suitable thermal range, preventing overheating and ensuring efficient performance. Understanding the design of this system helps in recognizing how heat is managed and dispersed.

Key Components and Flow

This cooling system features various elements working in harmony to circulate and regulate the temperature of the engine. It typically includes pathways for water flow, heat exchangers, and pumps that work together to maintain steady cooling. The system directs cool water through specific channels, absorbing excess heat and allowing it to be expelled through an exhaust.

Efficiency and Maintenance Insights

Maintaining the cooling system’s efficiency is crucial for prolonged engine life. Regular inspections and servicing of the water passages and heat exchangers help to avoid blockages and ensure smooth operation. By understanding the overall design and its maintenance needs, users can prevent potential issues and optimize the cooling process.

Fuel Delivery Components Explained

The system that supplies energy to an engine involves several key elements, each playing a vital role in maintaining optimal performance. These components work together to ensure a consistent flow, adjusting to various conditions and demands of the motor.

Fuel Pump is a crucial element that initiates the process. It moves the liquid from the tank towards the engine, ensuring a steady pressure. This helps maintain a balanced supply, even during rapid acceleration or shifts in speed.

Filters are essential in keeping the flow clean. They remove impurities and unwanted particles that could disrupt the smooth operation of the entire mechanism. Regular maintenance of these elements is key to prolonging the lifespan of the system.

The injectors manage the precise delivery into the combustion chamber. They control the quantity and timing, adapting to the engine’s requirements. This precision is crucial for achieving the right balance between power and efficiency.

Lastly, the regulator maintains the pressure within the system, ensuring that the flow remains stable and prevents any fluctuations that could impact performance. This balance helps in achieving smooth operation, avoiding surges or drops in power output.

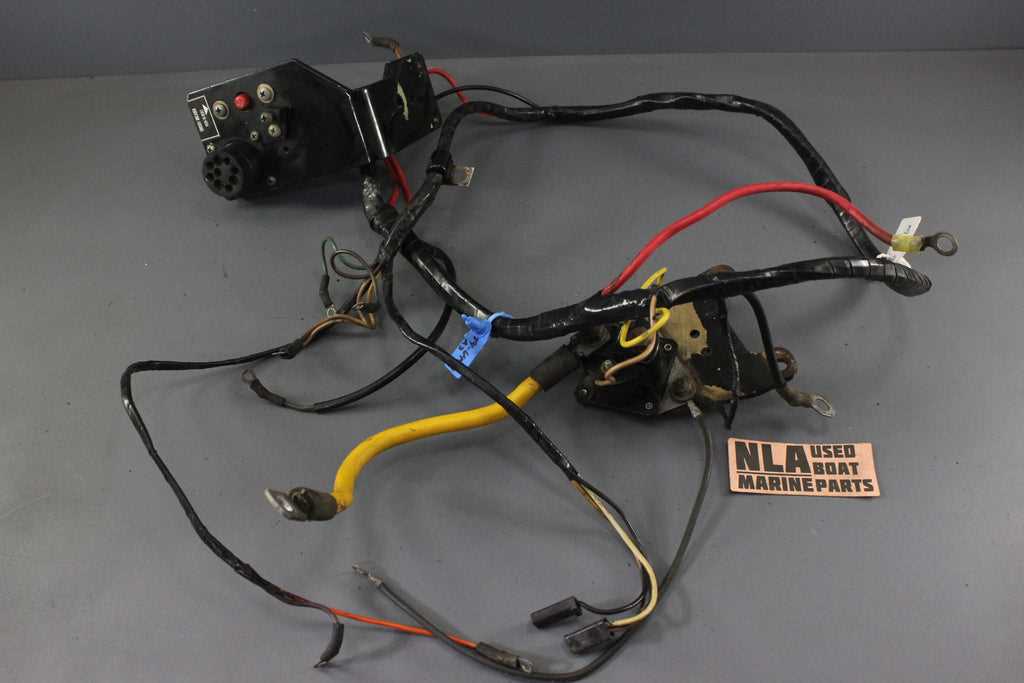

Essential Electrical Parts and Wiring

The electrical system in any marine engine setup plays a critical role in ensuring smooth functionality and reliability. This network of wires and key components allows various elements to operate in harmony, providing the power needed for different operations. Understanding these components and their connections is crucial for maintaining efficiency and avoiding potential issues during use.

One of the fundamental elements is the power distribution unit, which channels energy to various systems. It ensures that each component gets the required current, avoiding overloads. Additionally, various connectors and fuses serve as safety mechanisms, preventing electrical faults and ensuring stable performance.

Another essential component is the ignition setup, which starts the engine reliably. This system involves switches, coils, and spark-producing devices that work together to initiate the operation. Properly arranged connections and regular maintenance can significantly improve the overall reliability of the engine’s ignition.

Lastly, the battery and its associated connections are vital for providing initial power and maintaining the flow of energy during operation. Regular checks and ensuring solid connections help in maintaining the overall performance of the electrical system, preventing downtime and ensuring that all elements function as intended.

Drive System and Propeller Details

The drive mechanism plays a crucial role in ensuring the efficient movement of the vessel through water. It is designed to convert power into motion, optimizing the performance for a smooth and reliable experience on the water. Understanding the essential components and their functions is key to maintaining proper operation and achieving optimal speed and control.

| Component | Description |

|---|---|

| Transmission Unit | Transfers power from the engine, allowing adjustments in speed and direction while maintaining stability during navigation. |

| Propeller | Transforms rotational energy into forward or reverse thrust, influencing the vessel’s acceleration and overall handling in various water conditions. |

| Driveshaft | Connects the power source to the propeller, ensuring consistent energy flow and seamless movement even at higher speeds. |