When working on any mechanical system, it’s crucial to have a clear understanding of its core elements and how they interact with each other. Whether you’re performing routine maintenance or addressing specific issues, being familiar with the arrangement of each element can make the process more efficient and less prone to errors.

Each mechanical system is made up of several key elements, all of which play a vital role in its operation. Identifying these sections and understanding their placement is the first step in ensuring smooth functionality. From propulsion systems to smaller internal mechanisms, knowing where everything fits is essential for both repairs and upgrades.

In this overview, we will explore the most important elements found in typical setups. By gaining a deeper insight into these components, you’ll be better equipped to handle various operational needs, ensuring both efficiency and reliability.

Overview of Mercruiser Alpha One Generation One

The drivetrain system discussed here is renowned for its reliability and efficiency in various marine applications. It has been a key choice for boating enthusiasts due to its performance and longevity, providing a solid foundation for watercraft propulsion. This setup combines durability and ease of maintenance, making it a popular selection among boat owners.

Key Features

- Robust design with a focus on high efficiency

- Simplified maintenance for improved longevity

- Compatible with a wide range of watercraft engines

Maintenance Considerations

Regular upkeep is essential to ensure the optimal performance of this marine system. Its design allows for straightforward inspections, which helps identify wear and tear early on. Routine checks, such as lubrication and alignment, can significantly extend its operational life.

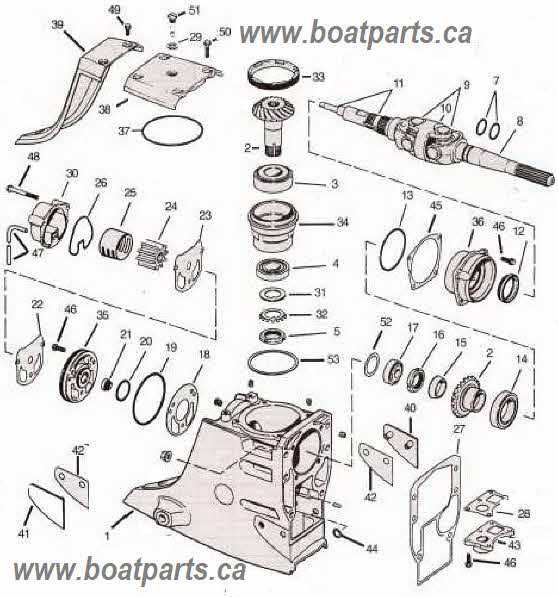

Key Components in the Alpha One System

This section covers the essential mechanical elements that form the backbone of the propulsion and steering system. These components are crucial for ensuring smooth operation, durability, and performance during various maritime activities.

Primary Mechanical Elements

- Drive Shaft – Connects the engine to the propeller, transferring power efficiently while maintaining alignment and minimizing vibration.

- Propeller – Responsible for converting rotational force into forward motion, crucial for the vessel’s speed and maneuverability.

- Gimbal Bearing – Supports the drive shaft, allowing it to rotate freely and maintain stability during operation.

Steering

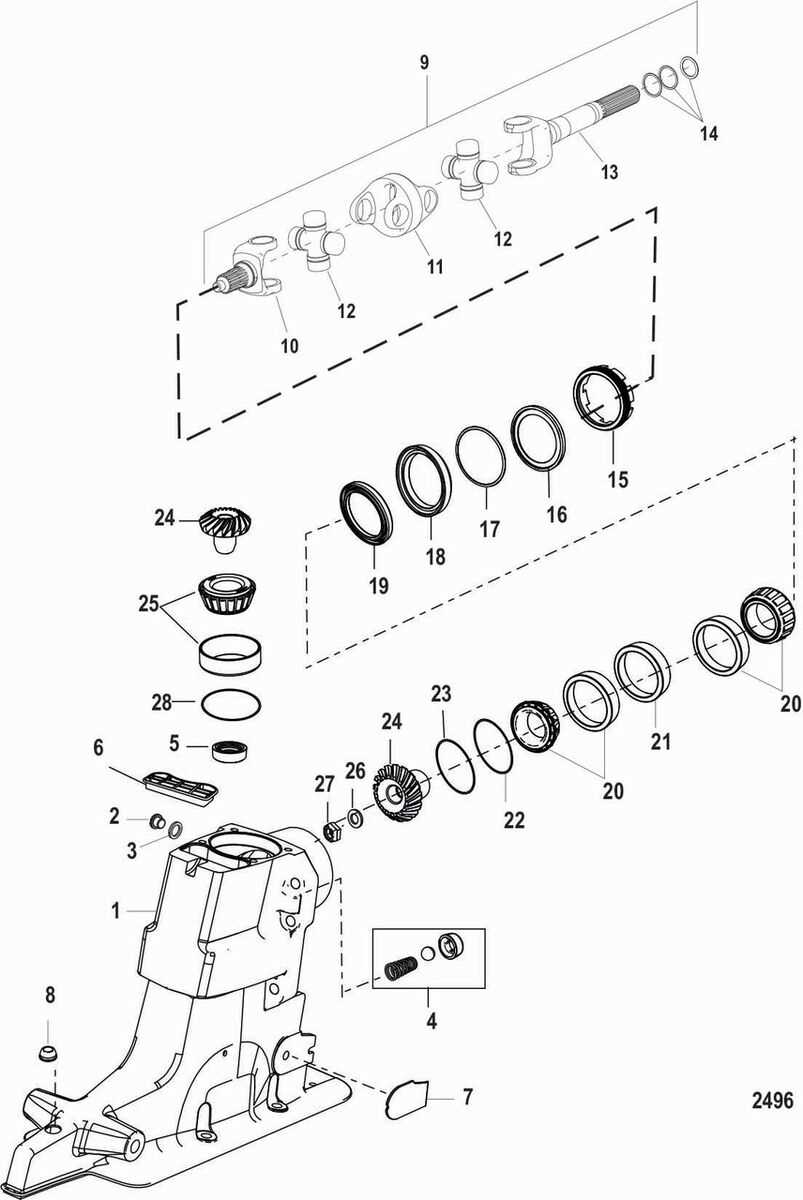

Understanding the Gear Housing Assembly

The gear housing assembly plays a critical role in ensuring smooth and efficient transmission of power to the propeller. By containing and protecting key components, it allows for proper engagement and transfer of rotational force, enabling propulsion. This section will focus on the elements that make up this system and how they interact to deliver optimal performance.

Key Components of the Assembly

The assembly consists of several vital elements such as the driveshaft, propeller shaft, and pinion gears. These components work in tandem to convert engine power into motion, while also ensuring durability and reliability. Proper lubrication within the casing is essential to maintain these parts in good condition, preventing wear and corrosion.

Maintenance and Troubleshooting

Regular inspection and servicing are essential to keep the assembly functioning effectively. Checking for signs of wear, proper gear alignment, and sufficient lubrication can prevent common issues such as overheating or inefficient power transfer. Any abnormal noises or vibrations should

Maintenance Tips for Propeller and Shaft

Regular upkeep of the components involved in watercraft propulsion is essential to ensure long-lasting performance and prevent damage. Maintaining these crucial parts can help avoid unnecessary repairs and extend the life of the equipment. Below are some practical tips for caring for these elements.

- Inspect regularly: Routine checks can help identify damage or wear early. Look for dents, cracks, or any distortion in the blades.

- Lubricate the shaft: Proper lubrication prevents corrosion and ensures smooth movement. Be sure to use marine-grade lubricants.

- Check for debris: Remove any fishing lines, seaweed, or other debris that may become wrapped around the shaft or blades.

- Balance the prop

Examining the Water Pump Mechanism

The water pump plays a crucial role in ensuring proper engine cooling by maintaining the circulation of liquid through various internal channels. Understanding the inner workings of this essential component can help identify potential issues that might arise during operation and improve overall system reliability.

Main Components and Their Functions

The system consists of several key parts, including the impeller, housing, and seals. The impeller is responsible for pushing liquid through the system, while the housing ensures proper containment and direction of flow. Seals prevent leaks and ensure that fluid stays within the designated paths.

Maintenance and Troubleshooting

Regular maintenance, such as inspecting the condition of the impeller and seals, is vital to prevent overheating or system failure. Common issues, like wear on the impeller or cracks in the housing, c

Steering and Trim System Breakdown

The steering and trim assembly is crucial for maintaining control and stability in various aquatic conditions. This system allows the operator to maneuver the vessel effectively while adjusting the angle of the drive unit to optimize performance and fuel efficiency. Understanding the components involved in this setup is essential for effective maintenance and troubleshooting.

The steering mechanism typically comprises a helm, steering cables, and a tiller or steering wheel. Each component plays a vital role in ensuring smooth navigation. The helm translates the operator’s movements into cable motion, which then directs the drive unit’s position.

In addition to steering, the trim system allows for adjustments to the angle of the drive unit relative to the water surface. This feature can enhance speed, fuel efficiency, and overall handling. Key elements of the trim assembly include trim cylinders, hydraulic lines, and a trim pump. The trim cylinders actuate the drive unit’s angle, while the hydraulic pump generates the necessary pressure for operation.

Regular inspection and maintenance of these systems are paramount for optimal performance. Signs of wear or malfunction can lead to decreased handling capabilities and potential safety hazards. Keeping the steering and trim assembly in top condition ensures a safe and enjoyable boating experience.

Lubrication Points for Optimal Performance

Proper maintenance is essential for the longevity and efficiency of any marine engine system. Identifying and regularly servicing key lubrication points can significantly enhance performance and prevent wear and tear. This section highlights the crucial areas that require attention to ensure smooth operation and reduce the risk of mechanical failures.

Key Areas to Focus On

Prioritize lubrication in the following critical components:

- Drive Shaft: Regularly grease the drive shaft to minimize friction and protect against corrosion.

- U-Joints: Ensure that universal joints are adequately lubricated to facilitate smooth movement and reduce strain on connected parts.

- Gimbal Bearing: Apply lubricant to the gimbal bearing to support the engine’s pivoting motion and prolong its life.

Recommended Lubricants

Selecting the right type of lubricant is vital for optimal performance. Use high-quality marine-grade grease designed for saltwater environments to ensure maximum protection against corrosion and wear. Regularly check and replace lubricants as necessary to maintain the effectiveness of these components.

By diligently attending to these lubrication points, you can significantly enhance the operational efficiency and lifespan of your marine engine system.

Cooling System Parts and Functions

The cooling system in marine engines plays a vital role in maintaining optimal operating temperatures, ensuring efficiency and longevity. Each component is essential for regulating heat, preventing overheating, and enabling the engine to perform at its best. Understanding these elements is crucial for effective maintenance and troubleshooting.

Key components of the cooling system include:

- Water Pump: This component circulates coolant throughout the system, drawing in water from the surrounding environment.

- Thermostat: Regulates the flow of coolant, opening and closing to maintain the desired temperature range.

- Heat Exchanger: Transfers heat from the engine coolant to the incoming water, allowing for efficient cooling.

- Hoses: Flexible tubes that carry coolant between different components, ensuring a seamless flow.

- Coolant Reservoir: Holds excess coolant and provides a supply to the system as needed, maintaining pressure and preventing air locks.

Each of these elements works in harmony to manage heat effectively. Regular inspection and maintenance of these components help prevent malfunctions and prolong the life of the engine.

Common Issues with Drive Assembly

The drive assembly is crucial for optimal performance in marine propulsion systems. Understanding the typical problems that may arise can help in maintaining the longevity and functionality of the unit. From mechanical failures to lubrication concerns, various factors can impact the effectiveness of the assembly.

One prevalent issue is the wear and tear of the gears and bearings. Prolonged use without proper maintenance can lead to grinding noises and diminished performance. Regular inspection of these components is essential to identify any signs of damage early on.

Another common concern involves the sealing components, which can degrade over time. Inadequate sealing may result in water ingress, leading to corrosion and potential failure of internal parts. Ensuring that seals are intact and replacing them as needed can prevent costly repairs.

Furthermore, improper alignment during installation can cause uneven wear and strain on the assembly. It is vital to follow manufacturer specifications and guidelines to guarantee accurate alignment and proper function.

Lastly, insufficient lubrication is a critical issue that can lead to overheating and component failure. Regularly checking and maintaining appropriate lubricant levels will help avoid these problems and ensure smooth operation.

Identifying Electrical Connectors and Wiring

Understanding the various electrical connectors and wiring configurations is essential for maintaining and troubleshooting marine propulsion systems. Proper identification ensures reliable connections, preventing electrical failures that can lead to significant issues on the water.

Common Connector Types

Different types of connectors are utilized in marine systems, each designed for specific applications. These include plug-and-socket types, terminal blocks, and circular connectors. Recognizing the features of these connectors, such as pin configurations and locking mechanisms, aids in proper installation and repair.

Wiring Color Codes

Another critical aspect is the wiring color codes, which help in identifying functions and ensuring correct connections. Common standards, such as using red for positive voltage and black for ground, simplify troubleshooting processes. Adhering to these codes not only enhances safety but also promotes efficient maintenance practices.