The proper function and efficiency of equipment heavily rely on the arrangement and interaction of individual elements. This guide provides a clear overview of how essential pieces come together, ensuring optimal performance and smooth operation.

Focusing on the structure and role of each component, this section explores the detailed configuration that makes the system work seamlessly. The relationship between these elements is crucial for reliability and functionality in various applications.

By familiarizing yourself with the layout and positioning of critical sections, you’ll gain a deeper understanding of the system’s overall functionality. This knowledge is important for maintaining performance, making adjustments, or troubleshooting potential issues.

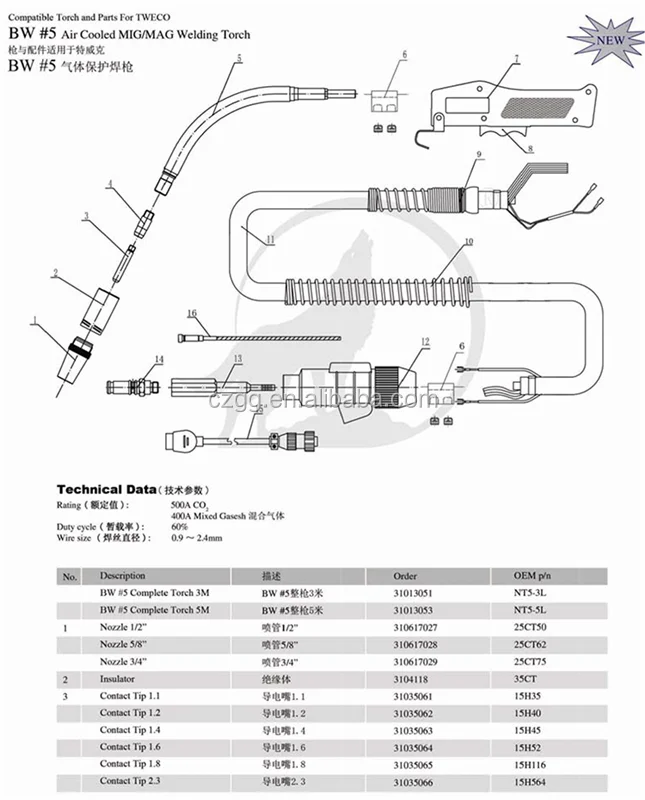

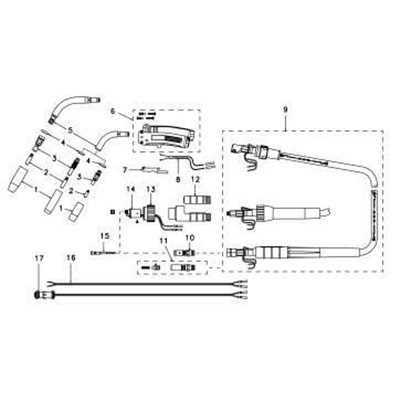

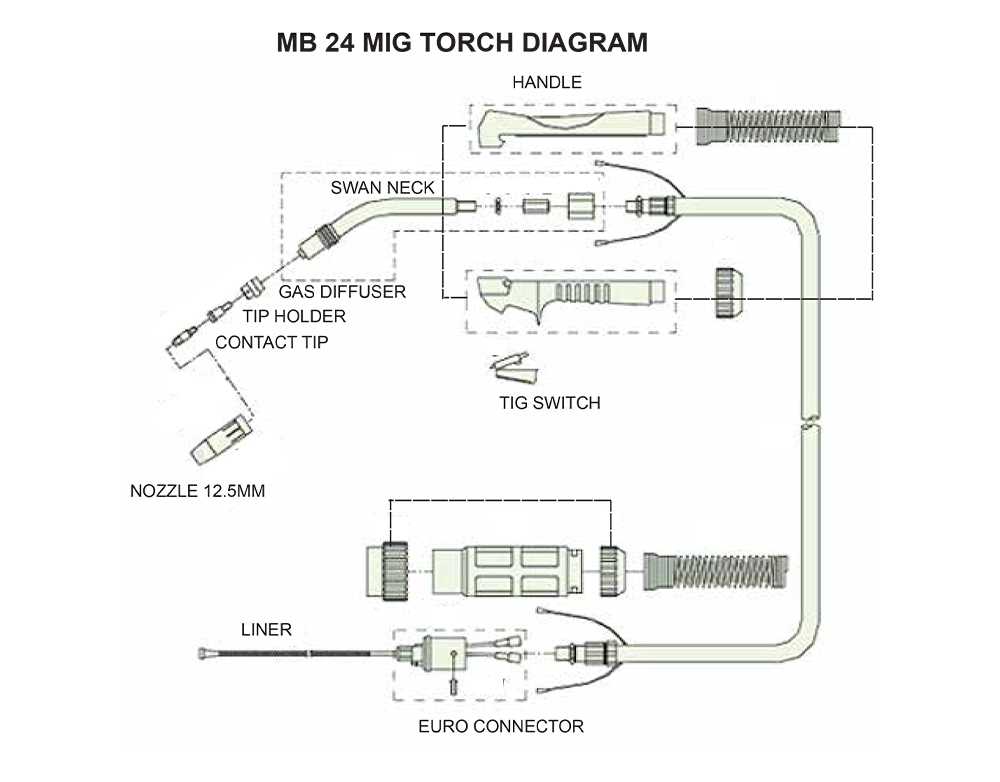

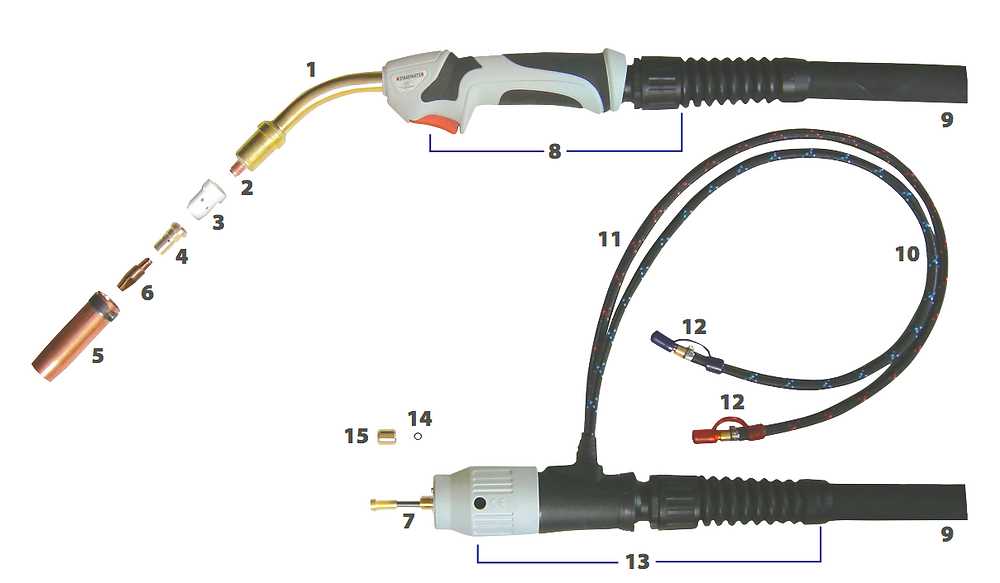

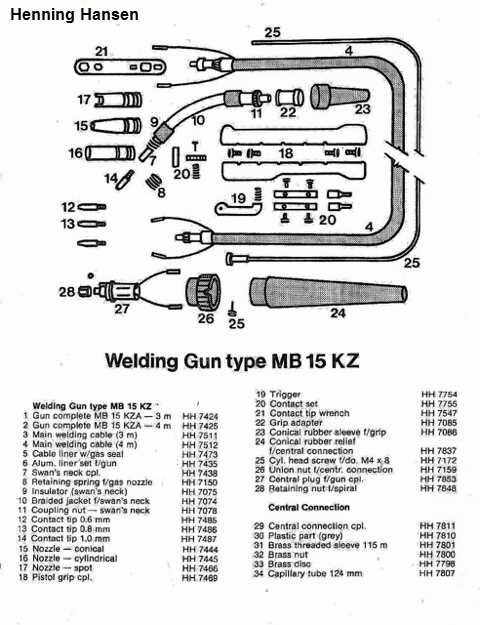

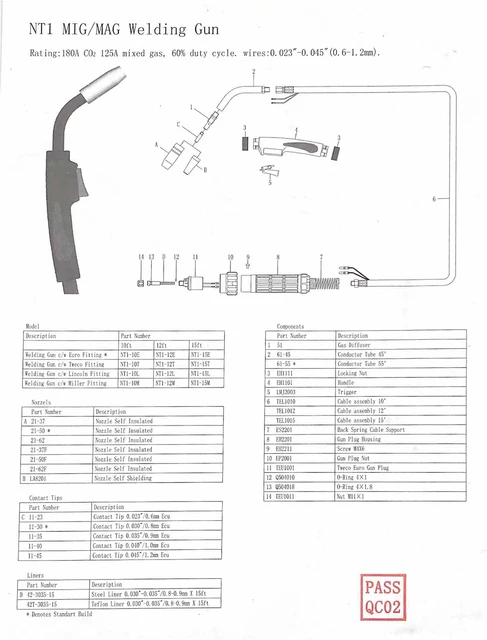

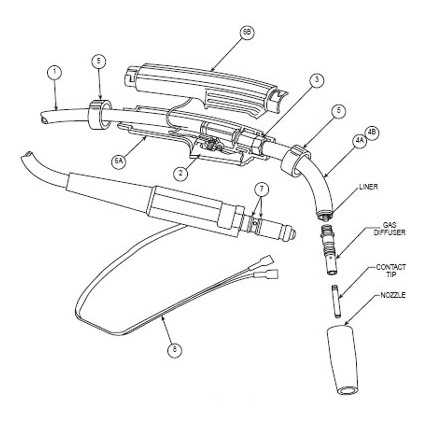

Mig Gun Components Overview

Understanding the essential elements of this tool is key to ensuring proper function and performance. Each part of the system contributes to its overall efficiency and longevity, working together to deliver precise and controlled results. The components are designed to handle various tasks, making it important to recognize their role in the whole structure.

Nozzle plays a crucial role in directing the flow, ensuring accurate delivery and preventing unwanted interference. It shields other parts from excessive exposure, helping maintain the system’s performance.

Contact tip serves as a critical point of contact, where the actual transfer occurs. It allows smooth transmission, ensuring consistency in the process.

Additionally, cable assembly connects the different sections, enabling seamless interaction between the elements. It ensures that everything works in harmony, providing flexibility and control during use.

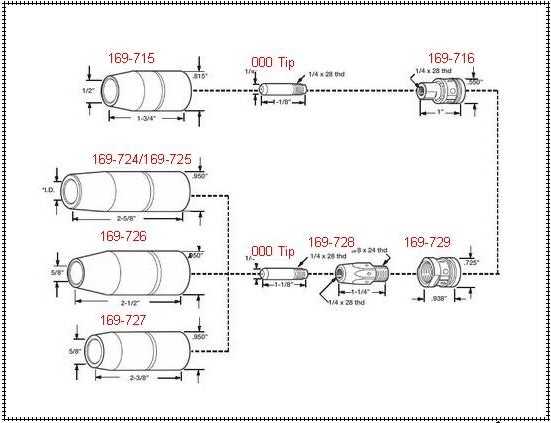

Understanding the Nozzle Functionality

The nozzle plays a critical role in ensuring efficient performance during the welding process. Its primary function revolves around guiding essential elements to the right location, helping maintain consistency and precision in the work. A well-functioning nozzle improves the overall flow and reduces interference from unwanted external factors.

One key aspect of the nozzle’s function is to create a protective shield that keeps the environment stable. This ensures that the process proceeds smoothly without disruptions. Additionally, the nozzle’s design helps prevent excess buildup, contributing to its longevity and reliability.

Key Features of Contact Tips

Contact tips play an essential role in ensuring the efficiency and accuracy of various equipment. They act as the final point where energy is transferred, making them crucial for smooth operation and optimal performance. Understanding their features can help in choosing the right type for your needs.

Durability and Material

- Wear Resistance: A high-quality contact tip is designed to withstand frequent use and maintain its functionality over time.

- Material Composition: The most common materials used include copper and alloys, each providing distinct advantages in conductivity and heat resistance.

Size and Compatibility

- Precision Fit: It’s essential that the contact tip matches the size of the equipment for consistent and reliable results.

- Adaptability: Different sizes and thread types are available, ensuring compatibility with a wide range of applications.

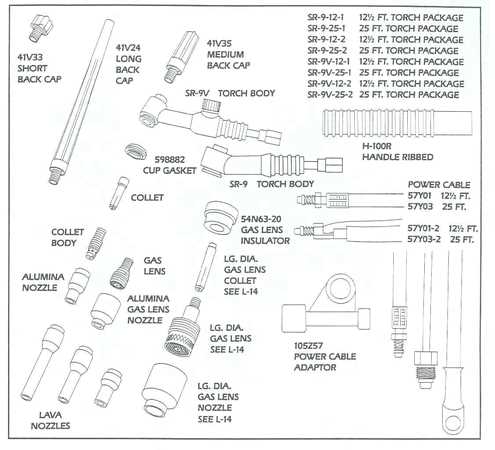

- Activation Point: This is the specific area where engagement occurs, allowing the user to initiate action.

- Lever System: A series of levers may be involved in the mechanism, providing leverage to enhance performance.

- Spring Assembly: Springs play a vital role in returning the mechanism to its original position after activation.

- Examine the overall configuration to locate the activation point.

- Observe the lever system for any visible movement during operation.

- Check for the presence of springs, ensuring they are intact and functional.

Gas Diffuser Role in Welding

The function of the gas diffuser is crucial in ensuring smooth and efficient welding. It helps control the flow of shielding gas, creating an environment that supports clean, strong welds. Without proper gas distribution, the quality of the weld can be compromised due to contamination from the surrounding atmosphere.

A properly working gas diffuser evenly distributes the gas across the welding area, preventing issues such as oxidation and porosity. Its role is to maintain consistency in gas coverage, which directly affects the stability and strength of the weld bead.

| Feature | Purpose | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gas Flow Control | Ensures steady shielding gas distribution. | ||||||||||||||||||

| Prevents Contaminants | Minimizes exposure to atmospheric elements. | ||||||||||||||||||

| Weld Stability |

Importance of the Liner in PerformanceThe liner plays a crucial role in ensuring smooth operation and maintaining optimal performance. Its primary function is to guide the material through the system without obstruction, reducing friction and wear. When the liner is well-maintained, it significantly enhances the overall efficiency, making the entire process more reliable and consistent. Impact on Efficiency and Durability

A well-functioning liner helps minimize disruptions, which can lead to a more consistent flow and improved durability of the components. Proper alignment and condition of the liner directly affect the longevity and precision of the equipment, preventing issues such as blockages or overheating. Maintenance and CareRegular inspection and maintenance of the liner are essential to keep it in top condition. Replacing the liner when signs of wear appear ensures sustained performance, minimizing downtime and the risk of failures. This simple upkeep practice can greatly extend the life of the entire system. Identifying the Trigger MechanismThe trigger mechanism is a crucial component that facilitates the initiation of a process within various systems. Understanding its design and function can greatly enhance efficiency and safety during operation. This section will explore the key elements that define the trigger mechanism and how to recognize its components. Key Elements of the Mechanism

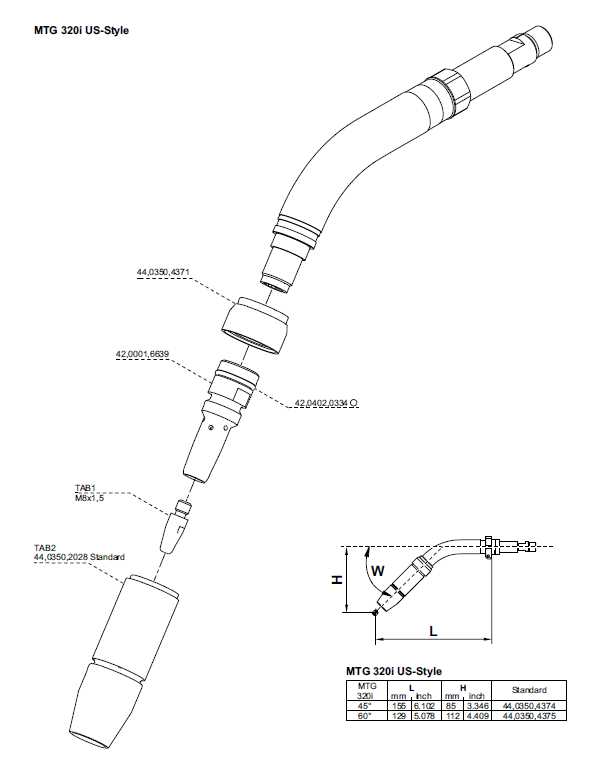

Several critical features characterize the mechanism: Steps for IdentificationTo effectively identify the trigger mechanism, follow these steps: Recognizing these features can aid in understanding the functionality and maintenance requirements of the system. Exploring the Swanneck StructureThe swanneck structure plays a crucial role in the functionality of various machinery. This unique design features a distinct curvature that enhances the overall performance and efficiency of the system. Understanding its anatomy is essential for anyone looking to gain deeper insights into the mechanics behind its operation. Understanding the Design and Function

At its core, this design is engineered to facilitate smooth movement and connectivity within the mechanism. The curvature allows for optimal alignment, ensuring that forces are distributed evenly. This not only improves the durability of the component but also minimizes wear and tear over time. The structural integrity of this design is paramount, making it a key focus for engineers and technicians alike. Applications and Benefits

The swanneck structure is utilized in various applications, ranging from industrial machines to specialized tools. Its advantages include increased efficiency and reliability, which are critical for achieving high performance in demanding environments. By investing time in understanding this structure, operators can enhance their troubleshooting skills and improve maintenance practices, ultimately leading to a longer lifespan for the equipment. Shielding Gas Flow and ControlThe proper management of protective gas is essential for achieving high-quality welds in various applications. Understanding how this gas is delivered and controlled can significantly impact the welding process and the overall results. An efficient flow of shielding gas not only protects the weld area from contamination but also influences the stability and appearance of the weld. Importance of Shielding Gas FlowMaintaining an appropriate flow rate of protective gas is crucial. If the flow is too low, the weld may be exposed to atmospheric contamination, leading to defects such as porosity and weak joints. Conversely, excessive gas flow can create turbulence, causing inconsistent shielding and potential weld flaws. Thus, a balanced flow rate ensures optimal protection during the welding operation. Control Mechanisms

Various mechanisms can be employed to regulate the flow of protective gas effectively. Manual valves allow for direct adjustment, while automated systems can offer precise control based on real-time monitoring of welding conditions. Monitoring systems are essential for ensuring that the gas flow remains consistent throughout the welding process, adapting to any changes in conditions that may arise. Ultimately, understanding the dynamics of protective gas management plays a vital role in enhancing weld quality and operational efficiency. Maintaining the Mig Gun CableEnsuring the longevity and efficiency of your welding equipment requires regular attention to the connecting cable. This component plays a crucial role in delivering power and controlling the welding process, making it essential to keep it in optimal condition. Regular maintenance can help prevent operational issues and enhance performance. Inspecting for Wear and Damage

Regularly check the cable for any signs of fraying, cracking, or other forms of wear. Damaged areas can lead to electrical failures or affect the quality of the welding. Address any issues promptly to maintain a safe working environment and avoid further complications. Cleaning and Proper Storage

Keeping the cable clean is vital for its functionality. Remove any dust, debris, or spatter that may accumulate over time. Additionally, store the cable properly when not in use, ensuring it is coiled correctly to prevent kinks or knots. This practice helps prolong its life and maintain optimal performance. Wear and Tear of Consumables

The longevity and efficiency of certain items in welding applications are significantly influenced by their exposure to intense conditions. Over time, these components experience degradation due to repeated use, high temperatures, and contact with various materials. Understanding the factors that contribute to their deterioration is essential for maintaining optimal performance. Regular inspection and maintenance play a crucial role in extending the lifespan of these items. Users should be vigilant for signs of wear, such as discoloration, irregular shapes, or decreased functionality. Promptly replacing worn components not only enhances the quality of work but also ensures safety during operations. In addition, selecting high-quality replacements can make a noticeable difference in performance. Investing in durable alternatives often leads to better results and reduces the frequency of necessary replacements. Thus, maintaining a proactive approach to consumables management is vital for achieving consistent outcomes in welding tasks. Proper Assembly of Mig Gun Parts

Assembling the components of a welding tool is crucial for ensuring optimal performance and efficiency. Each element plays a vital role in the overall functionality of the apparatus, and understanding how to correctly put them together can greatly impact the quality of the work produced. Before beginning the assembly process, it’s essential to gather all necessary components and familiarize yourself with their specific functions. This preparatory step helps to streamline the assembly, reducing the risk of errors and ensuring a more effective workflow.

After ensuring all components are securely assembled, it’s advisable to conduct a thorough inspection. This helps identify any loose connections or potential issues before the tool is put to use, ensuring a smooth and safe operation. |