For anyone working with high-performance equipment, having a clear understanding of the internal structure and individual components is essential. Knowing how each part fits together ensures optimal functionality and smooth operation. This guide provides an overview of how to navigate the intricate details of these powerful machines.

Maintenance and repairs become significantly easier when you can visualize the layout and recognize the role of each element. Whether you are a professional technician or a DIY enthusiast, being familiar with the assembly allows for efficient troubleshooting and upgrades.

Each machine is made up of interconnected units that work harmoniously. A detailed look into these elements can help identify any issues and facilitate the process of finding suitable replacements. This understanding can be invaluable for both regular use and emergency repairs.

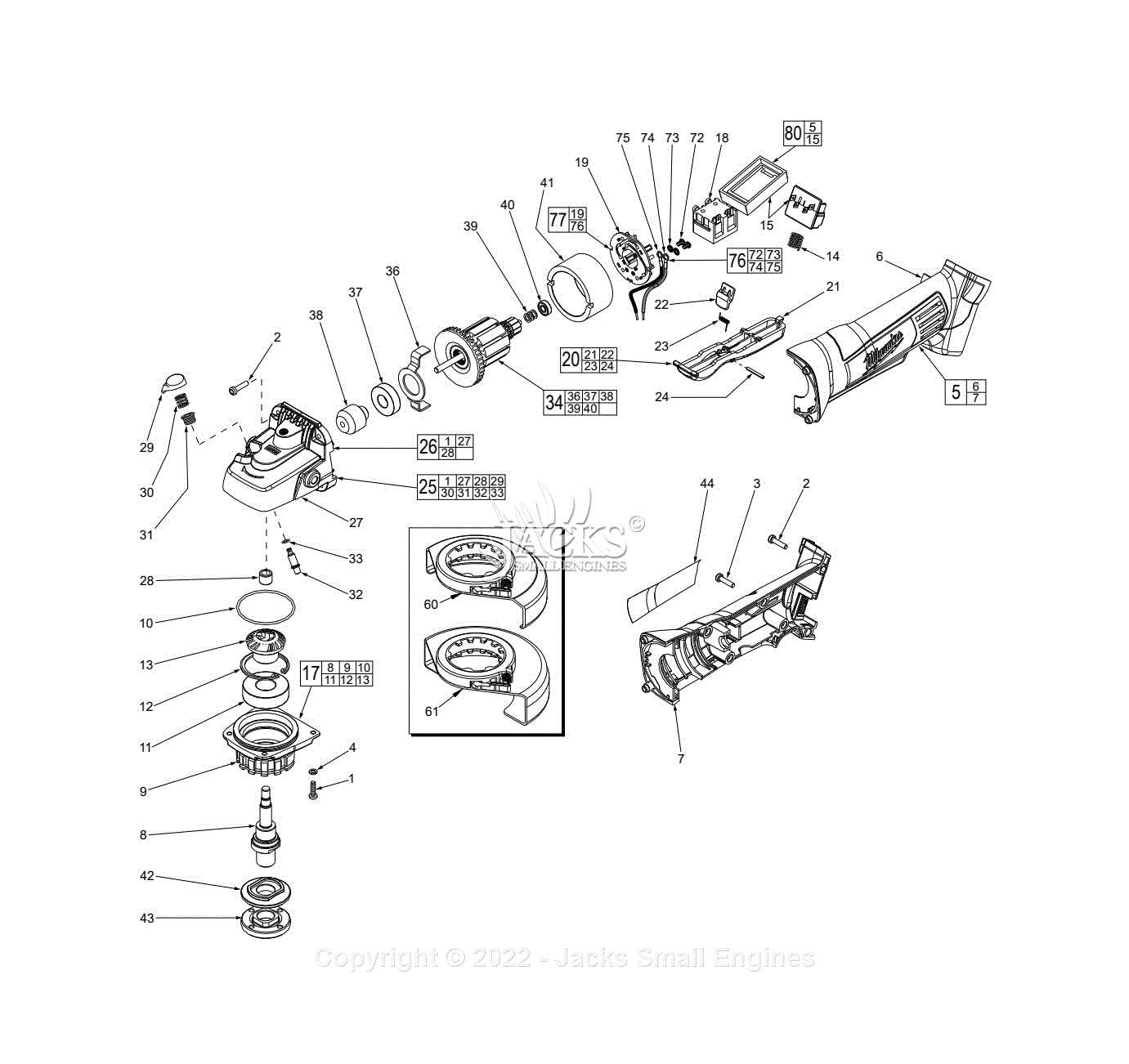

Understanding the Milwaukee 2804-20 Parts Diagram

To fully comprehend how a powerful tool operates, it’s essential to explore its key components and how they interact. A clear breakdown of each piece of the machine allows users to better understand its functionality and perform maintenance or repairs more efficiently.

| Component | Function |

|---|---|

| Motor | Drives the movement and power of the tool |

| Gearbox | Transfers power from the motor to the driving mechanism |

| Trigger | Controls the activation and speed of the tool |

| Battery | Provides portable power for operation |

| Chuck | Holds the bit or attachment in place during use |

Overview of Key Components

Understanding the essential elements of a tool helps in both its maintenance and efficient operation. These primary components play crucial roles in ensuring optimal performance, durability, and ease of use. Each part contributes to the overall functionality and makes the tool more adaptable to various tasks.

- Motor: The driving force behind the tool’s power, responsible for converting electrical energy into mechanical motion.

- Chuck: This part holds the attachments securely, allowing for smooth operation when drilling or driving.

- Battery: Supplies the necessary power, providing mobility without the need for a direct electrical connection.

- Gearbox: Responsible for transmitting power from the motor to the tool’s working parts, often allowing for variable speeds.

- Handle: Designed for comfort and control, it ensures stable operation during extended use.

Each of these key elements works in tandem to deliver the performance and functionality expected from high-quality power tools. Proper care and understanding of these parts contribute to extending the tool’s lifespan and maximizing its efficiency.

How to Identify Parts in the Diagram

Understanding how to recognize components in a visual schematic is essential for effective maintenance and repair. By familiarizing yourself with the layout and key features, you can easily pinpoint each element and ensure proper assembly or replacement.

Follow these steps to correctly identify components in the layout:

- Locate the Legend or Key: Most illustrations will have a legend or key that explains the symbols and numbers used to represent various elements.

- Identify the Reference Numbers: Each part typically has a reference number next to it. Cross-reference these numbers with the corresponding list of components for more details.

- Examine the Shape and Structure: Pay attention to the shape, size, and orientation of each component. This can help you determine its function within the assembly.

- Use Color Coding (if available): Some schematics use color to distinguish between different types of components. Identify these colors to simplify the process of recognizing parts.

- Check for Annotations: Many diagrams will include additional notes or arrows to highlight specific features or important aspects of the components.

By carefully analyzing the visual layout and using the provided references, you can accurately identify each element and gain a better understanding of how everything works together.

Common Issues with Milwaukee 2804-20 Parts

When using power tools, it’s common to encounter issues related to specific components over time. These challenges can range from mechanical failures to wear and tear on critical elements, affecting overall performance. Identifying and addressing these problems promptly can prevent further damage and ensure the tool operates efficiently.

Frequent Wear and Tear

One of the most common issues arises from the gradual degradation of moving components. As parts endure regular use, friction can lead to reduced efficiency and potential malfunction. Regular maintenance and proper storage can significantly extend the lifespan of these crucial elements.

Electrical Failures

Electrical components, such as connectors and wiring, are prone to damage due to exposure to dust, moisture, or incorrect usage. These failures can interrupt the functioning of the tool, leading to unexpected shutdowns or poor performance. Keeping electrical connections clean and ensuring proper insulation can help prevent these issues.

Step-by-Step Guide to Disassembly

Proper disassembly of power tools requires careful attention to detail and methodical steps. Following this guide will help you break down the tool in a safe and organized manner, ensuring all components are handled correctly and ready for maintenance or repair.

Preparation

Before starting the disassembly process, ensure you have all the necessary tools and workspace organized. This will allow for smooth handling of each part without causing damage.

- Gather essential tools such as screwdrivers, pliers, and a socket set.

- Wear protective gear such as gloves and safety glasses.

- Make sure your workspace is clean and well-lit to avoid losing small components.

Disassembly Process

Follow these steps carefully to ensure proper disassembly:

- Disconnect the tool from any power source to avoid electrical hazards.

- Remove any outer casing by unscrewing the fasteners. Set the screws aside in an organized manner.

- Carefully take out the internal parts, starting with the most accessible components.

- Check for any additional screws or clips securing internal mechanisms, and gently remove them without forcing any parts.

- Keep track of all removed components and their order for easy reassembly later.

Following this guide ensures that each part is safely removed and prepared for any necessary repair or maintenance. The key is to stay organized and take your time during the process.

Replacement Parts and Their Compatibility

When maintaining or upgrading your tool, it is essential to ensure the replacement components are fully compatible with the model in question. Selecting the right replacements not only ensures optimal performance but also contributes to the longevity of the equipment. Understanding the specifications and matching them to the original build is key to preserving efficiency and safety.

| Component | Compatible Models | Key Features |

|---|---|---|

| Motor Assembly | Various Cordless Drill Models | High torque, efficient energy consumption |

| Chuck | Universal 1/2″ Hex | Durable, quick-release mechanism |

| Battery Pack | Li-ion 18V | Long-lasting, fast recharging capability |

| Brushes | Compatible with brushed motor systems | Enhanced durability, smooth operation |

Tools Needed for Maintenance

Proper maintenance of power tools requires a few essential instruments to ensure longevity and optimal performance. These tools allow for accurate inspections, cleaning, and repairs to keep the equipment running smoothly. Having the right set of tools on hand makes the process more efficient and prevents potential damage during upkeep.

Basic Equipment

To begin, you will need a selection of basic tools, such as screwdrivers, wrenches, and pliers. These are essential for disassembling and reassembling various parts of the tool. A multi-bit screwdriver can be especially useful for handling screws of different sizes and types.

Specialized Tools

For more advanced repairs, you may need torque wrenches or a precision tool set to ensure parts are tightened to the manufacturer’s specifications. These tools are critical for maintaining the tool’s efficiency and safety, preventing over-tightening or under-tightening of screws and bolts.

Visual Aid for Easy Repairs

Clear visual guides play a crucial role in simplifying the repair process. These resources help users quickly identify individual components, ensuring accurate repairs without unnecessary confusion. With a visual reference, even complex maintenance tasks can be tackled efficiently.

Benefits of Visual Guides

- Provides clear, step-by-step instructions

- Minimizes mistakes by highlighting crucial parts

- Enhances understanding of the overall assembly

- Speeds up the troubleshooting and repair process

How to Use Visual References Effectively

- Begin by locating the specific area of focus in the visual guide.

- Compare the diagram with the actual device to identify any worn or damaged parts.

- Use the visual aid to follow proper disassembly and reassembly steps.

- Ensure all parts are correctly aligned before reassembling the device.

Exploring the Function of Each Part

Understanding the individual components of a tool is essential for grasping how it operates efficiently. Each element plays a specific role, contributing to the overall performance and durability of the device. From the motor to the housing, all parts work together seamlessly to ensure the tool functions optimally.

Power Source is the heart of the mechanism, providing the necessary energy to drive the entire system. This unit, often a battery or corded power supply, initiates the tool’s movement, converting electrical energy into mechanical force.

Motor is the driving force behind the movement, transforming the electrical energy into rotational power. It is carefully designed to withstand heavy use while maintaining a balance between speed and torque.

Gearbox plays a pivotal role in controlling the speed and torque output, allowing users to adjust the power for different tasks. This section ensures that the power generated by the motor is effectively transmitted to the working parts of the tool.

Chuck serves as the connection point for attachments, holding the tool bit securely during operation. Its ability to quickly change tools or bits adds versatility and ease of use to the device.

Handle and Housing provide structural integrity, ensuring that all internal components are securely encased. The design of the handle also affects the tool’s ergonomics, impacting user comfort and control during extended periods of use.

Safety Considerations During Repairs

When conducting repairs on power tools, it is crucial to prioritize safety to prevent accidents and ensure proper functionality. Adhering to basic safety principles protects both the person performing the maintenance and the tool itself, preventing potential harm and extending the equipment’s lifespan.

Preparation and Proper Equipment

Before starting any repair, ensure you have the right tools and personal protective equipment (PPE). Wearing safety goggles, gloves, and closed-toe shoes reduces the risk of injury. Additionally, having a clean and organized workspace will help avoid unnecessary hazards.

Disconnection and Power Source Safety

Always disconnect the power supply before performing any work. This simple step eliminates the risk of electric shock or accidental activation. If working with cordless equipment, remove the battery to ensure it is completely isolated from any power source.

Note: Regularly check the condition of your tools and maintain them according to the manufacturer’s recommendations to avoid wear-related hazards.

Where to Find Authentic Parts

When looking for high-quality replacement components for your tool, it’s essential to ensure you’re sourcing them from trusted and reliable outlets. Genuine items not only offer superior performance but also contribute to the longevity and safety of your equipment. Choosing the right place to purchase these elements is crucial for maintaining the efficiency of your machinery.

Authorized Retailers

One of the best places to start is through authorized sellers. These retailers often carry original parts directly from the manufacturer and ensure you’re getting components that match your tool’s specifications.

- Official brand stores and websites

- Certified local dealers

- Reputable online platforms with a strong reputation

Online Marketplaces

Several trusted online platforms offer a wide range of genuine replacements. When purchasing from these sites, always verify that the seller has positive reviews and that the items are labeled as authentic.

- Popular e-commerce platforms with user ratings

- Specialized online retailers offering direct manufacturer connections