In the realm of power tools, a comprehensive grasp of the individual elements that comprise a specific instrument is essential for effective maintenance and repair. Each component plays a crucial role in the overall functionality, contributing to the tool’s performance and longevity. Familiarity with these elements allows users to troubleshoot issues more efficiently and ensure optimal operation.

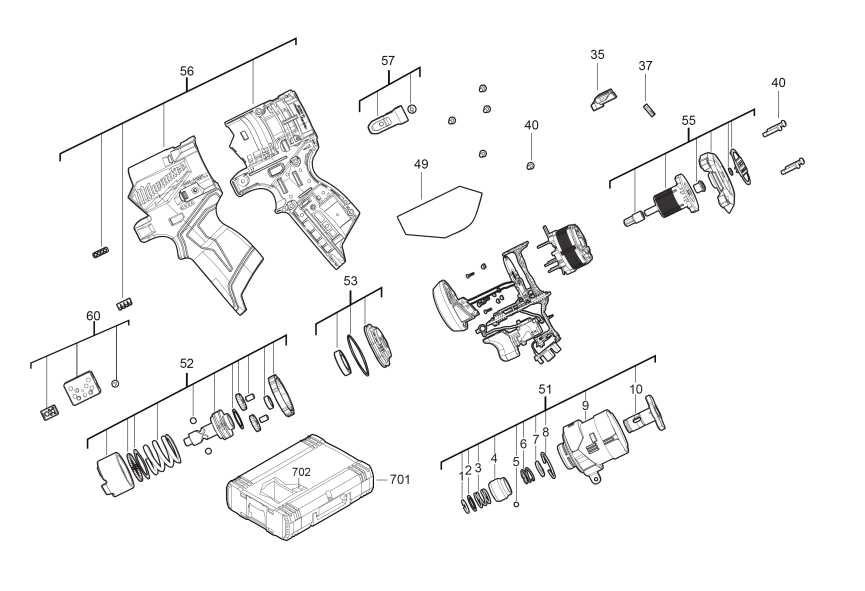

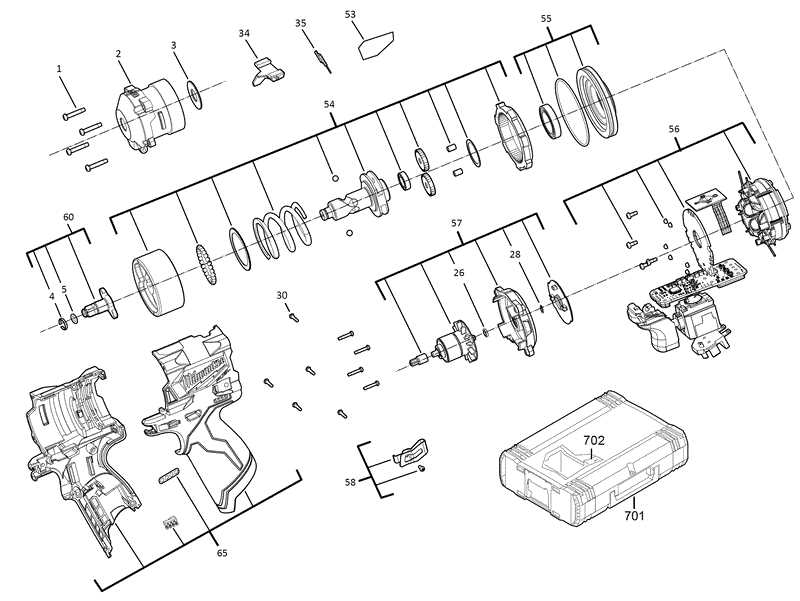

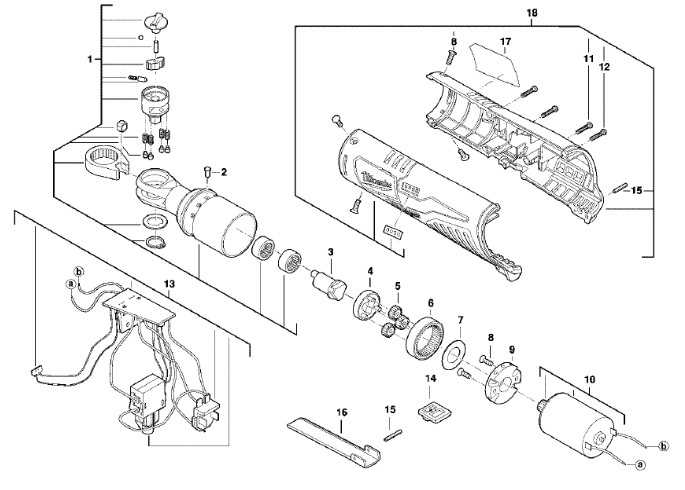

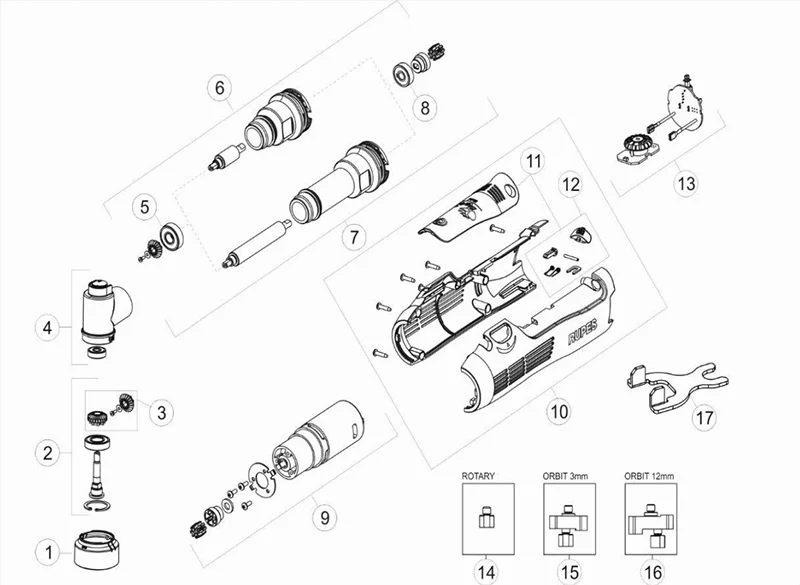

Visual aids serve as invaluable resources, providing clear representations of each segment. They facilitate a better understanding of how parts interconnect and function together. By analyzing these illustrations, one can quickly identify components, enhancing the ability to diagnose problems and execute repairs with precision.

Whether one is a seasoned professional or a novice enthusiast, knowledge of the intricate details of tool mechanisms is indispensable. Gaining insight into the various segments not only boosts confidence but also empowers individuals to handle tasks with greater proficiency. This exploration of the structural elements ultimately leads to improved usage and maintenance practices.

This section provides a comprehensive overview of a specific tool known for its efficiency and compact design. Ideal for both professionals and DIY enthusiasts, it exemplifies precision engineering and ease of use. Understanding the components that contribute to its functionality is essential for maintenance and effective application in various tasks.

To facilitate a better understanding, the following table outlines the key components, their functions, and common issues associated with each:

| Component | Function | Common Issues |

|---|---|---|

| Gear Mechanism | Transforms motor rotation into torque | Wear and tear leading to slipping |

| Trigger | Controls the power supply | Malfunction or unresponsiveness |

| Battery | Powers the device for operation | Decreased capacity over time |

| Housing | Protects internal components | Cracks or damage from impact |

| Socket Adapter | Allows attachment of various tools | Wear leading to poor fit |

Key Features of the Ratchet

The tool under discussion stands out for its innovative design and functionality, making it a valuable addition to any toolbox. Its essential characteristics contribute to enhanced performance and ease of use, catering to both professionals and enthusiasts alike.

One of the most notable aspects is its compact size, allowing for access to tight spaces where traditional tools may struggle. This feature is particularly advantageous when working in confined areas, ensuring efficiency without compromising on power.

Additionally, the durable construction guarantees longevity, enabling it to withstand rigorous use. The materials used in its manufacture provide excellent resistance to wear and tear, ensuring reliability over time.

Another significant feature is its ergonomic design, which enhances user comfort during operation. The carefully crafted grip minimizes fatigue, making it ideal for extended use without discomfort.

Lastly, the inclusion of a high-speed mechanism allows for swift and effective adjustments, significantly reducing the time spent on tasks. This efficiency is a game-changer for those who value productivity and effectiveness in their work.

Understanding Parts and Components

Grasping the various elements and their roles is essential for anyone looking to maintain or repair a tool. Each component plays a crucial part in the overall functionality and performance, making it vital to recognize their interconnections and purposes.

In this section, we will explore the key features and functions of the individual elements. Understanding these will enhance your knowledge and enable you to tackle any maintenance tasks with confidence.

- Drive Mechanism: The core of any tool, facilitating the rotation and motion necessary for effective operation.

- Housing: The outer shell that protects the internal components from dust and damage, ensuring durability.

- Trigger: This element allows for easy control over the tool’s activation and deactivation, providing user convenience.

- Battery System: Powers the device, ensuring sufficient energy supply for extended use.

- Gear System: Enhances torque and speed, critical for efficient functioning.

Each of these components works in harmony to deliver optimal performance. Familiarity with them is crucial for effective troubleshooting and repairs.

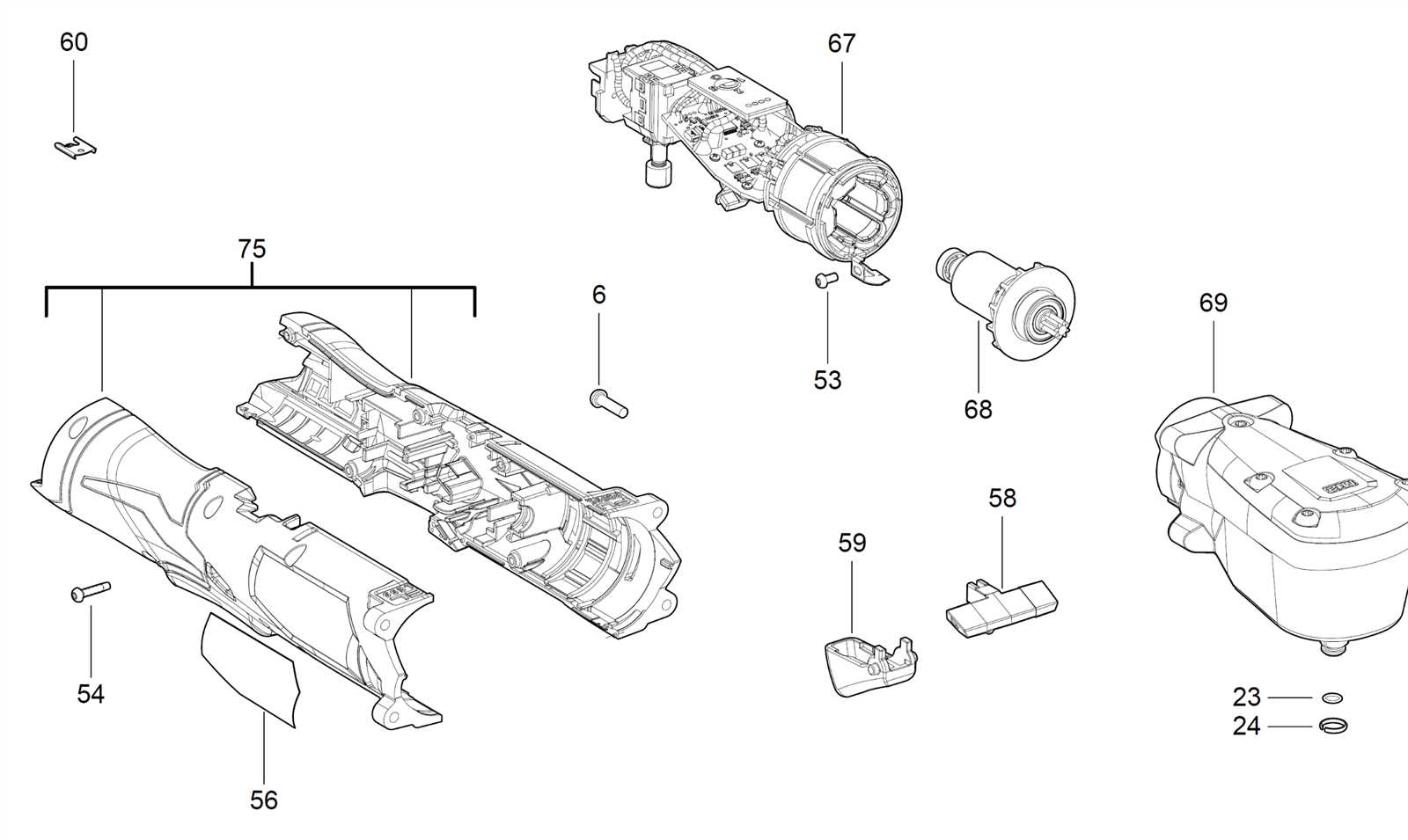

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and assembly. This guide provides insights into interpreting these illustrations, allowing users to identify and locate each element with ease.

Initially, focus on the overall layout. Typically, the components are arranged in a systematic manner, with related parts grouped together. Each section may correspond to a specific function or mechanism, aiding in visual comprehension.

Next, familiarize yourself with the accompanying labels. These notations often include reference numbers that correlate with a list of items. Pay attention to these annotations, as they provide crucial information regarding the specifications and compatibility of each element.

Additionally, note the scale and orientation used in the illustration. Understanding the dimensions will assist in visualizing how each component interacts within the entire assembly. This awareness is crucial for ensuring a successful installation or repair process.

Lastly, consult the reference list to verify the parts’ details. This comparison ensures that you are equipped with the correct components for your tasks. By mastering these techniques, you will enhance your proficiency in managing and utilizing various tools effectively.

Common Issues and Solutions

This section addresses frequent problems encountered with a specific type of tool and offers effective remedies. Understanding these common challenges can enhance the user experience and extend the lifespan of the equipment.

Frequent Operational Failures

One of the most typical issues users face is the failure to engage or disengage properly. This can stem from inadequate lubrication or the accumulation of debris. Regular maintenance, including cleaning and applying appropriate lubricants, can resolve this issue and ensure smooth functionality.

Battery Performance Issues

Another common concern involves battery life and performance. Users may notice a decline in power output or a failure to hold a charge. To mitigate this, it’s essential to follow proper charging practices and store the battery in optimal conditions. Additionally, replacing an aging battery can restore the tool’s efficiency.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your tools requires regular care and attention. By following a few simple maintenance practices, you can significantly extend the lifespan of your equipment and enhance its efficiency. This section outlines essential techniques to keep your tools in excellent working condition.

Regular Cleaning

Cleaning your equipment after each use is crucial to prevent dirt and debris buildup. Use a soft brush or cloth to remove any grime, and ensure that moving parts remain free from obstructions. Regular cleaning not only helps maintain functionality but also prevents corrosion and wear over time.

Proper Lubrication

Applying the right lubricant to moving components is vital for smooth operation. Ensure you use a lubricant compatible with your tools, and apply it according to the manufacturer’s recommendations. This practice reduces friction, minimizes wear, and enhances performance, ensuring your tools operate efficiently for years to come.

Replacement Parts Availability

Access to suitable components for tools is essential for maintaining optimal performance and longevity. When a device requires a specific element, it’s vital to identify where to source these replacements effectively. Numerous suppliers offer a wide range of suitable items to ensure that users can easily restore functionality.

Online Retailers are a convenient option, providing a vast selection of components that can be delivered directly to your doorstep. Many reputable websites specialize in tool accessories, making it easy to find the necessary elements without the hassle of visiting physical stores.

Local Hardware Stores may also stock essential items for various tools. Engaging with knowledgeable staff can assist in locating the right component or alternative solutions that fit your requirements. Additionally, many stores can place special orders for specific items not typically in stock.

Furthermore, contacting authorized service centers can provide access to original components that guarantee compatibility and reliability. These centers often have comprehensive catalogs and can advise on the best options for replacements based on the specific model.

Comparing Models in the M12 Series

The diverse lineup within this tool series showcases various models, each designed to cater to specific needs and preferences of users. Understanding the unique features and functionalities of each variant can greatly enhance the efficiency and effectiveness of tasks at hand.

For instance, while some models prioritize compactness and portability, others may focus on delivering higher torque or longer battery life. Evaluating these differences allows users to select the most suitable option based on their particular applications and work environments.

Moreover, variations in design and ergonomic considerations can significantly impact user comfort and control during operation. By comparing aspects such as weight, handle design, and trigger sensitivity, individuals can make informed choices that align with their operational style.

Ultimately, a thorough assessment of the different models available in this series can lead to improved performance and satisfaction, ensuring that each user finds the right fit for their tool collection.

Tools for Disassembly and Assembly

Effective disassembly and assembly of mechanical components require a selection of appropriate tools tailored to facilitate these processes. Utilizing the right instruments not only enhances efficiency but also ensures the integrity of the components throughout their handling. Whether for maintenance or repair, a well-equipped toolkit can significantly streamline tasks and improve outcomes.

Essential Instruments

Key instruments for these tasks include screwdrivers, wrenches, and pliers. Each tool serves a specific purpose, allowing for the manipulation of various fasteners and fittings. For instance, precision screwdrivers enable access to intricate screws in compact spaces, while adjustable wrenches accommodate a range of bolt sizes, ensuring a secure grip without damaging surfaces.

Specialized Equipment

In addition to basic hand tools, specialized equipment such as torque wrenches and impact drivers play a vital role in achieving optimal results. A torque wrench ensures that fasteners are tightened to the manufacturer’s specifications, preventing over-tightening and potential damage. Meanwhile, impact drivers provide enhanced power for loosening stubborn bolts, making them indispensable for challenging tasks.

Warranty Information and Support

This section provides essential details regarding the guarantee coverage and assistance available for your tool. Understanding the terms of warranty and the support options can enhance your experience and ensure proper use of the equipment.

Coverage Details

The warranty typically includes repairs or replacements for defects in materials and workmanship under normal use. Coverage duration may vary, so it’s important to refer to the specific documentation that accompanies your tool.

Support Options

For any issues or inquiries, various support channels are available. You can reach out to customer service through phone, email, or visit the official website for online assistance.

| Support Channel | Contact Information |

|---|---|

| Customer Service Phone | (800) 123-4567 |

| Email Support | [email protected] |

| Website | www.example.com |

User Reviews and Experiences

This section highlights the thoughts and feedback from users regarding their encounters with a specific tool designed for mechanical applications. It serves to provide insights into the performance, reliability, and usability of the equipment, showcasing a variety of perspectives that potential buyers may find valuable.

Many users have expressed satisfaction with the tool’s efficiency and ease of use. They appreciate its lightweight design, which allows for extended periods of operation without causing fatigue. Several reviewers noted the convenience of its compact size, making it an ideal choice for tight spaces where traditional tools may struggle.

However, some users reported concerns regarding durability, particularly under heavy use. While many found the tool to perform admirably for light to medium tasks, there were instances where others felt it could benefit from improved sturdiness. Overall, feedback indicates a blend of positive experiences with a few caveats, making it essential for prospective users to consider their specific needs and expectations.