In this section, we delve into the inner workings of a widely recognized cutting tool, breaking down its structure and key elements. Whether you’re an experienced technician or just beginning your journey in the world of power tools, understanding the intricacies of this machine can greatly enhance your efficiency and precision on various projects.

Each mechanical element plays a critical role in ensuring that the device functions smoothly, offering durability and optimal performance over time. From the sturdy frame to the precision-driven mechanism, every component is essential for proper operation, and understanding how these parts work together is crucial for maintenance and repairs.

Throughout this article, we will examine various structural pieces and how they interact to create a seamless cutting experience. By exploring each segment, you’ll gain valuable insights into how to maintain and troubleshoot common issues, ensuring that your tool remains in peak condition.

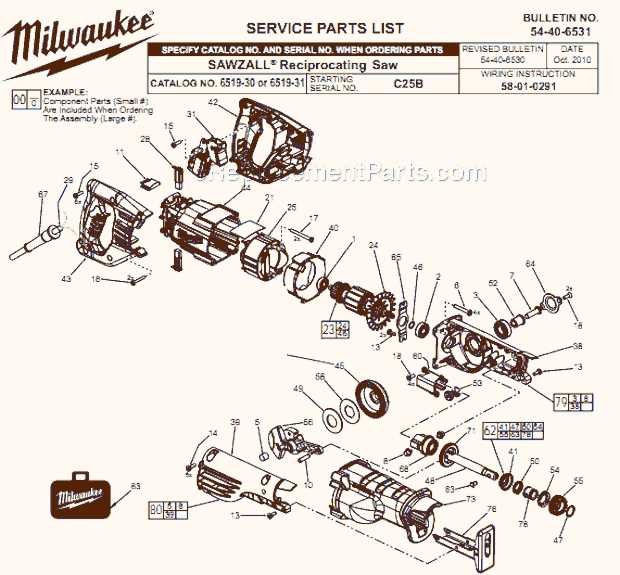

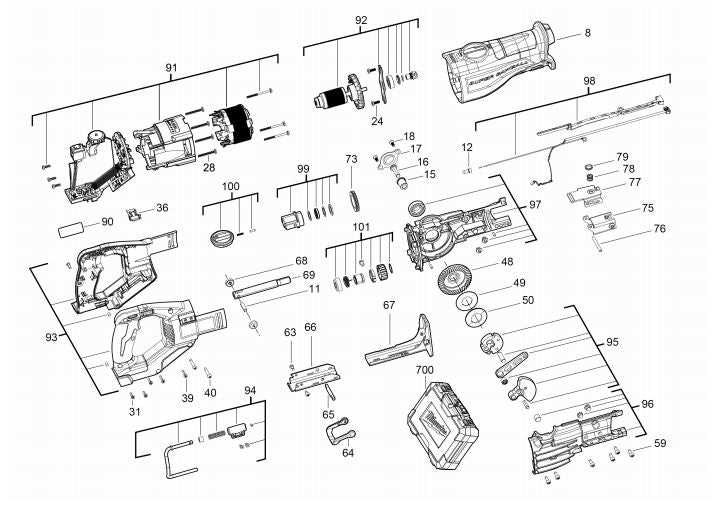

Understanding Key Components of a Sawzall

To achieve optimal performance and longevity in any cutting tool, it’s essential to understand the core elements that contribute to its functionality. Each section plays a crucial role in ensuring smooth operation, stability, and precision. Knowing these elements will help with maintenance, troubleshooting, and enhancing efficiency during use.

- Blade Mechanism: The cutting blade is one of the most critical parts. It operates through a back-and-forth motion, delivering sharp, clean cuts through various materials.

- Motor: The motor provides the necessary power to drive the cutting mechanism. High-performance motors ensure quick and accurate cuts even through tougher surfaces.

- Grip Handle: The ergonomic handle is designed to reduce user fatigue while maintaining control during operation, especially in prolonged use or tight spaces.

- Trigger Switch: The trigger is responsible for activating and controlling the speed of the blade, allowing users to adjust the speed as needed for different materials.

- Shoe Plate: The adjustable shoe plate provides stability during cutting by resting on the surface, ensuring accurate cuts and protecting the blade from excessive wear.

- Variable Speed Control: Some models feature a speed control dial, enabling users to choose between slower, more controlled cuts or faster, more aggressive cutting based on the task.

By understanding these essential components, you can effective

Exploring the Internal Mechanism of Reciprocating Saws

The inner workings of a reciprocating saw involve various components that operate in harmony to deliver powerful cutting action. Understanding how these elements interact helps in diagnosing issues and improving performance. This section offers insight into the primary elements of the tool’s mechanism and their functions, helping to clarify the complexities of its operation.

Key Components and Their Functions

The core mechanism revolves around a motor-driven system that converts rotary motion into the back-and-forth motion of the blade. Below is a breakdown of the essential elements involved in this transformation process:

| Component | Function | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor | Provides the initial rotary motion that powers the tool. | ||||||||||||||||||||||||||||||

| Crankshaft | Transforms rotary motion into linear motion for the blade. | ||||||||||||||||||||||||||||||

| Blade Clamp | Secures the cutting blade in place, ensuring stability during use. | ||||||||||||||||||||||||||||||

| Reciprocating Mechanism | Enables the back-and-forth movement essential for cutting. | ||||||||||||||||||||||||||||||

| Housing | Identifying Crucial Replacement Parts for Repairs

When it comes to maintaining efficient functionality of your equipment, recognizing which components need attention is key to ensuring long-term durability and performance. Understanding the role of each element and when it requires replacement can prevent unnecessary breakdowns and costly repairs. Recognizing Wear and TearRegular use naturally leads to wear on various components, which can affect overall efficiency. Identifying signs of degradation early allows for timely replacements, avoiding further damage to connected elements. Look for cracks, excessive friction, or reduced performance as indicators of worn-out components. Essential Components to Monitor

|