The effectiveness of any snow-clearing apparatus relies heavily on the precision of its individual elements and their assembly. A comprehensive overview of these components aids users in grasping how each part contributes to the overall functionality and efficiency of the equipment. Knowledge of these elements is essential for maintenance and repair, ensuring optimal performance during harsh winter conditions.

In examining the intricate relationship between these components, one can appreciate the engineering behind the design. Each piece serves a specific purpose, working in harmony to facilitate the removal of accumulated precipitation. This collective understanding enhances the user’s ability to troubleshoot issues and execute necessary repairs, ultimately extending the lifespan of the machinery.

With a detailed exploration of these crucial elements, operators can make informed decisions regarding upgrades and replacements. Familiarity with the assembly not only empowers users but also fosters a greater appreciation for the technology that supports effective winter maintenance.

Overview of Monroe Snow Plow Systems

This section provides a comprehensive look at various equipment designed for managing winter weather challenges. These systems are engineered to enhance efficiency and effectiveness in clearing surfaces, ensuring safe and accessible routes during adverse conditions.

Each setup consists of multiple components that work in harmony, including hydraulic systems, control mechanisms, and mounting brackets. Understanding the configuration of these elements is essential for optimal performance and maintenance. The reliability of the entire assembly hinges on the quality and compatibility of individual parts.

Regular inspection and maintenance of these systems are crucial for longevity and functionality. Users should familiarize themselves with the operational features and troubleshooting techniques to ensure seamless performance throughout the winter season. By mastering these systems, operators can improve their handling and responsiveness in various snow management scenarios.

Key Components of Snow Removal Equipment

Effective winter maintenance relies on a variety of essential elements that work in harmony to ensure efficiency and reliability. Understanding these critical components is vital for anyone involved in managing icy conditions, as each part contributes to the overall functionality of the system.

Blade Assembly

The blade assembly serves as the primary interface with the ground, designed to effectively clear and direct the accumulated material. This component is engineered for optimal durability, allowing it to withstand harsh conditions while maintaining its shape and effectiveness. Regular inspection and maintenance of this part are crucial to ensure it operates smoothly throughout the season.

Hydraulic System

The hydraulic system plays a pivotal role in maneuverability, facilitating the adjustment of the blade angle and height. This mechanism ensures that operators can easily adapt to varying conditions, enhancing both performance and safety. Proper maintenance of hydraulic fluids and components is essential to prevent malfunctions and ensure longevity.

Understanding Hydraulic Mechanisms in Plows

Hydraulic systems play a crucial role in the operation of various equipment, enhancing efficiency and control. These mechanisms utilize fluid pressure to facilitate movement and power, making them indispensable in tasks requiring heavy lifting and precision. By harnessing the properties of fluids, these systems enable smooth operation and adaptability to different working conditions.

At the core of hydraulic systems is the principle of Pascal’s Law, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. This principle allows operators to exert force from a distance, making tasks more manageable. Components such as pumps, cylinders, and valves work in harmony to create a seamless flow of hydraulic fluid, translating operator input into mechanical movement.

In many configurations, hydraulic cylinders serve as the primary actuators, converting hydraulic energy into linear motion. The design of these cylinders determines their efficiency and responsiveness. Additionally, the choice of hydraulic fluid is essential for maintaining system integrity and ensuring optimal performance. Regular maintenance and proper fluid management are vital to prevent wear and tear, ensuring longevity and reliability.

Moreover, the versatility of hydraulic systems allows for customization, accommodating various attachments and enhancing the overall functionality of the equipment. Understanding these mechanisms can lead to improved operation and maintenance practices, ultimately enhancing productivity in challenging environments.

Common Wear Parts and Maintenance Tips

Regular upkeep and timely replacement of essential components are crucial for ensuring optimal performance and longevity of your equipment. Understanding which elements are prone to wear can help prevent costly repairs and enhance efficiency during operation.

Identifying Key Components

Many mechanisms incorporate several components that experience wear due to constant use and exposure to harsh conditions. These typically include cutting edges, hydraulic hoses, and springs. Regular inspection of these elements will allow for early detection of issues, facilitating a smoother operation and reducing downtime.

Maintenance Practices

Routine checks should be performed to identify signs of wear, such as cracks or significant deterioration. Keeping lubrication up to date is also essential, as it reduces friction and prolongs the lifespan of moving parts. Additionally, ensuring that all connections are tight and free from corrosion will contribute to the reliability and safety of the equipment.

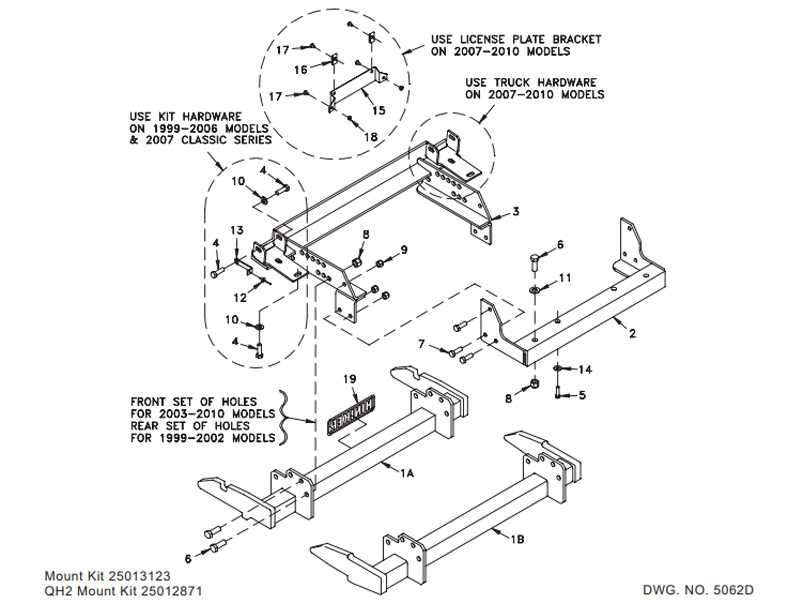

Identifying Model-Specific Parts

Understanding the unique components tailored to each model is crucial for proper maintenance and repairs. Variations between designs can influence the compatibility and performance of certain elements. This section explores how to differentiate these components and ensure they match specific models for efficient functionality.

Key Differences Between Variants

Each version may have distinct configurations, which can include variations in size, shape, or mounting styles. Recognizing these distinctions helps in selecting the right items that fit perfectly with the existing setup, avoiding mismatched elements that could cause issues during assembly or operation.

Reference Table for Model Variations

| Model | Unique Component | Compatibility Note |

|---|---|---|

| Series A | Hydraulic Adapter | Requires specific hose fittings for optimal connection. |

| Series B | Mounting Bracket | Designed for heavier loads, not compatible with lighter setups. |

| Series C | Control Unit | Includes advanced electronic features, not suitable for older models. |

This table highlights key distinctions between models, ensuring that each component alig

Exploring Electrical Systems in Plows

Understanding the intricate setup of power connections and control mechanisms is crucial for maintaining efficient operations in various types of heavy-duty attachments. The coordination of wiring and components ensures that every movement is precisely controlled, providing operators with reliable and responsive functionality.

Key Components and Their Roles

Several elements make up the electrical configuration of these attachments. Control modules serve as the brain of the setup, processing commands and sending signals to different components. Relays and fuses protect the system by managing the flow of current, preventing overloads that could cause damage. Properly installed wiring harnesses connect all these elements, ensuring seamless communication between the controls and the mechanical parts.

Maintaining System Integrity

Regular inspections and timely maintenance of the electrical network are essential for preventing malfunctions. Checking for signs of wear, such as frayed cables or loose connections, helps maintain the integrity of the setup. Additionally, ensuring that all connectors are secure and free from corrosion can significantly extend the lifespan of the entire system, promoting consistent and effective performance during demanding operations.

How to Read Parts Diagrams

Understanding schematic representations can simplify maintenance and repairs. These visual guides illustrate the relationship between various components, making it easier to pinpoint what needs attention or replacement. With the right approach, one can quickly interpret these layouts, ensuring accurate identification and proper assembly of each piece.

The first step is to familiarize yourself with the symbols and labels often found in these illustrations. They are usually numbered or named, correlating to a list that describes each element in detail. Recognizing these identifiers helps in locating specific components without confusion.

| Symbol | Meaning |

|---|---|

| Circles | Often denote connectors or pivot points between elements. |

| Arrows | Indicate the direction of movement or flow, helping to visualize the dynamic function. |

| Solid Lines | Represent rigid connections or structural links between components. |

| Dashed Lines | Highlight optional connections or pathways that are not always active. |

By analyzing these visual cues, one can effectively map out the relationships between elements, making assembly or disassembly a smoother process. Matching the visual information to rea

Comparison of Different Plow Models

Various models of equipment for winter road management present unique features that cater to different needs and environments. Understanding these distinctions can help in selecting the most effective option for diverse terrains and conditions.

| Model | Design Feature | Ideal Terrain | Maintenance Requirements | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model A | Enhanced curved frame for improved clearing efficiency | Urban and residential areas | Moderate, with seasonal adjustments | |||||||||

| Model B | Reinforced blade edges for durability | Rural roads and open fields | High, due to heavy-duty use | |||||||||

| Model C | Lightweight structure for easy maneuverability | Narrow paths and tight spaces | Low, with occasional checks | |||||||||

| Model D |

| Criteria | Description |

|---|---|

| Manufacturer Certification | Ensure that the supplier provides certified products, as this guarantees adherence to industry standards and durability. |

| Warranty | Check for a warranty or guarantee period. This often reflects the confidence in the quality and reliability of the item. |

| Material Quality | Look for replacements made from robust materials that can withstand harsh conditions and extend the lifespan of your equipment. |

| Customer Reviews | Reading feedback from other users can provide insight into the longevity and performance of the replacement options. |

| Cost vs. Value | While affordability is important, consider the long-term value that authentic options bring to your machinery. |

By carefully evaluating these aspects, one can make an informed decision, ensuring that their investment contributes to efficient operation and reduced

FAQs About Monroe Plow Components

In this section, we address common inquiries regarding the various elements and functionality of a well-known winter road maintenance tool. Understanding how each piece interacts with the rest is crucial for optimal performance and maintenance.

What Are the Key Components?

The core elements include a blade, hydraulic system, and control mechanisms. The blade serves as the primary interface with the surface, while the hydraulic setup ensures smooth lifting and lowering. Control systems allow operators to adjust settings for different conditions. These components work together to ensure efficiency and durability.

How Do You Maintain These Parts?

Regular upkeep includes checking fluid levels, inspecting for wear, and ensuring that connections remain secure. This helps extend the lifespan of each element, preventing common issues such as leaks or loss of responsiveness in the hydraulic system. Proper storage during off-season periods can also prevent corrosion and other forms of damage.