The proper arrangement of mechanical and structural elements is crucial for maintaining the efficiency and safety of any watercraft. Ensuring that every element is correctly placed allows for smoother operation and easier troubleshooting when issues arise. By having a clear view of how different elements are positioned and connected, boat owners and technicians can more easily address maintenance needs.

In this guide, we will explore how the various components come together in a cohesive system. Knowing where each part is located and how it functions within the larger framework ensures smoother repairs, efficient performance, and better overall understanding of your watercraft’s structure.

Whether you are a boat enthusiast or a professional, having detailed knowledge of component placement can significantly simplify any repairs or upgrades. This insight into the layout helps you make informed decisions during the maintenance process, keeping your vessel in optimal condition for longer periods.

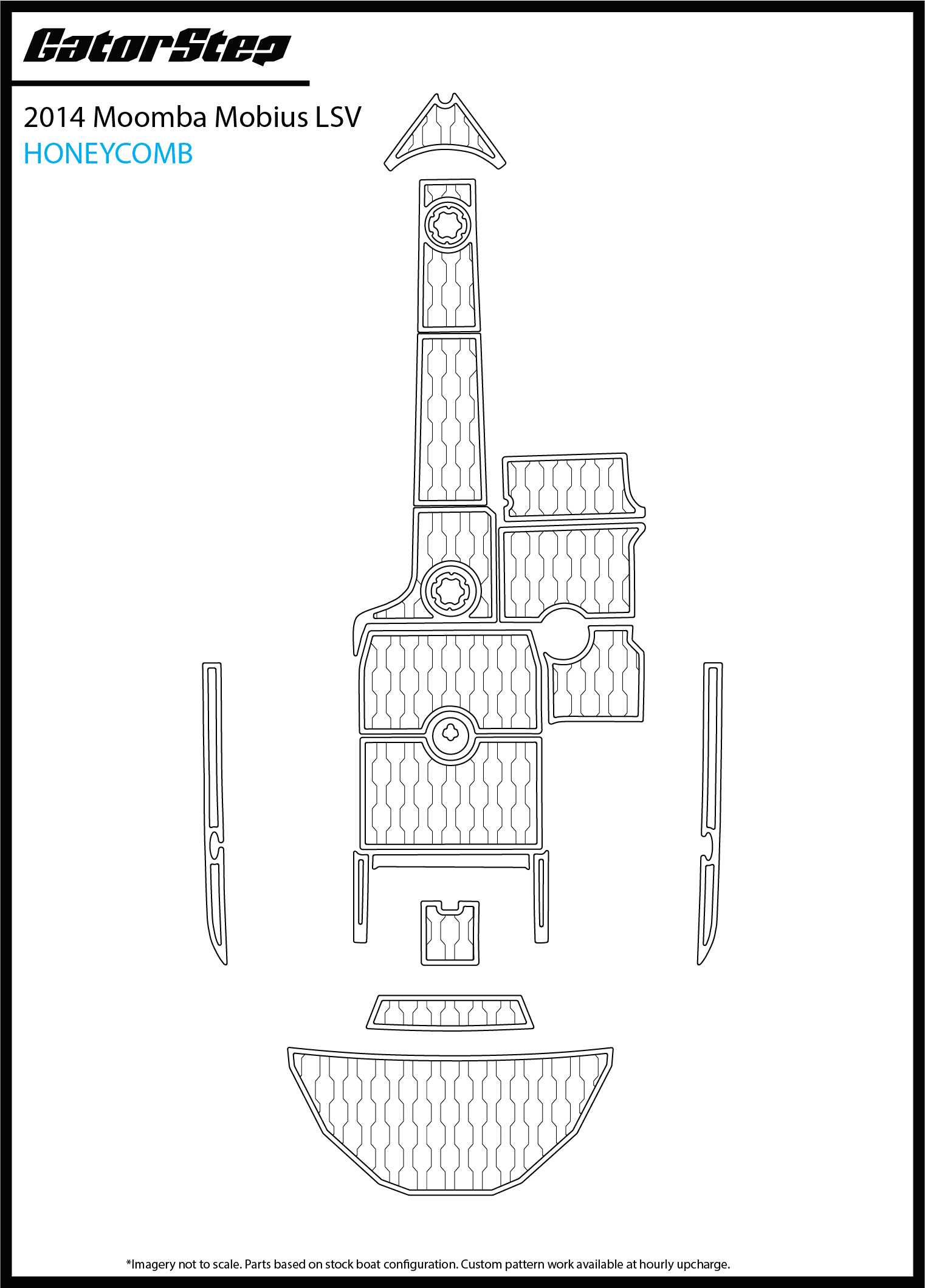

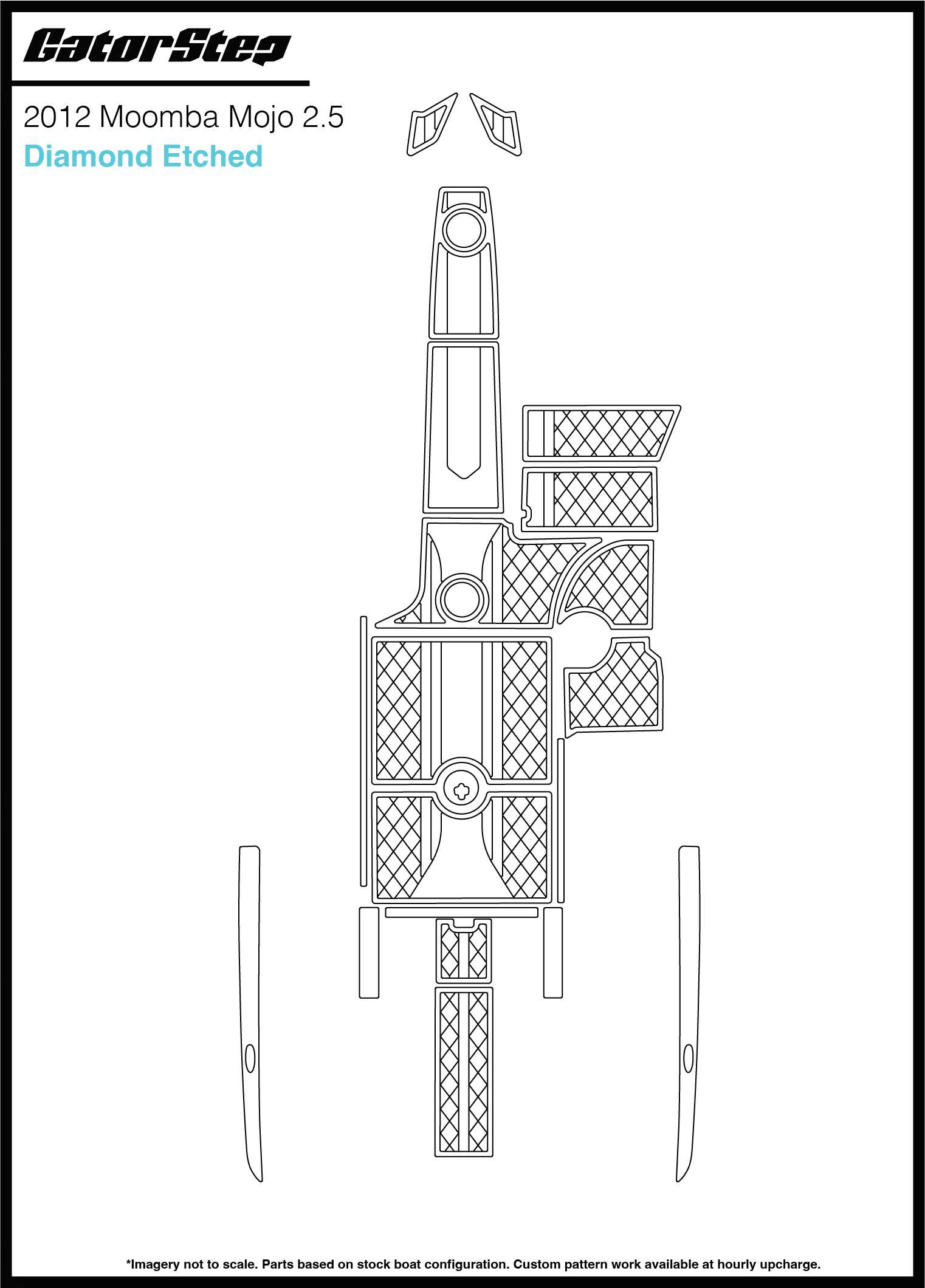

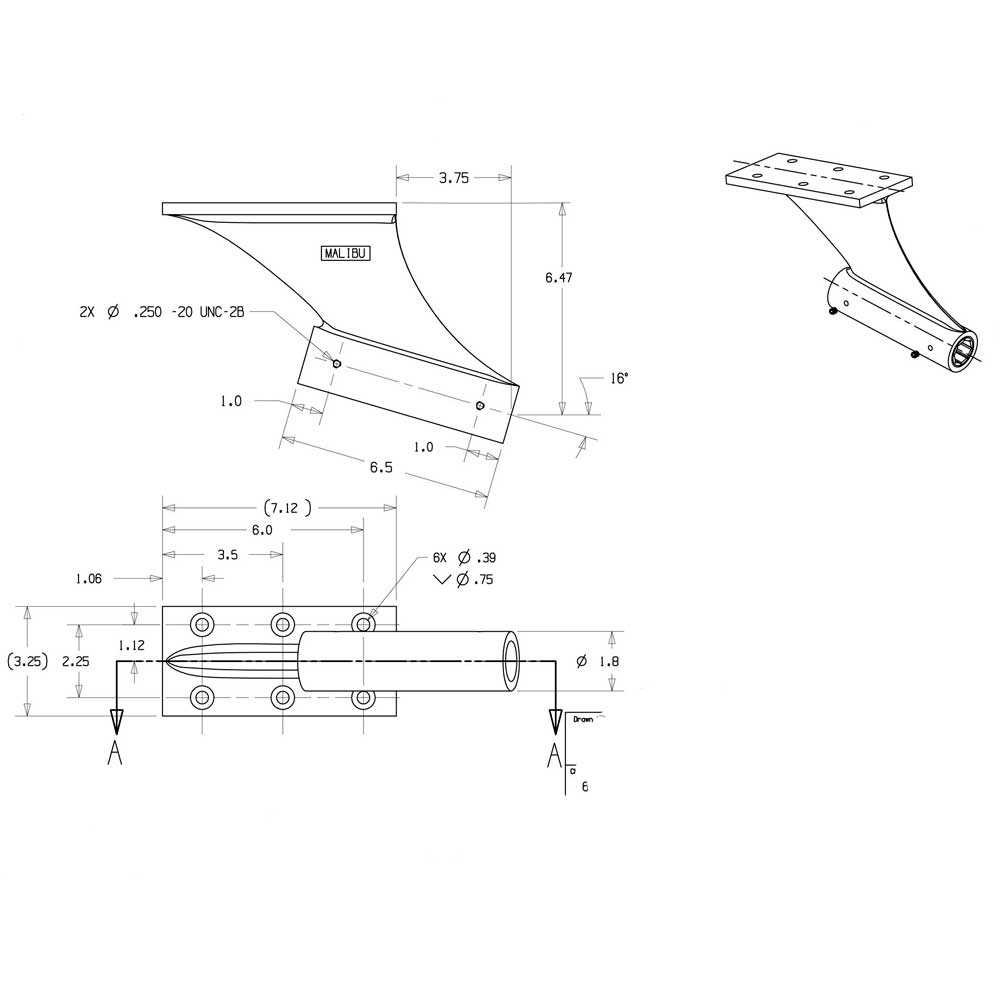

Moomba Parts Diagram Overview

In this section, we’ll explore the structure and components that make up the essential system of a well-functioning vessel. Each element plays a crucial role in ensuring optimal performance and longevity, working together in harmony.

Let’s break down the different components, highlighting their key functions and how they interact:

- Core framework: The backbone of the entire system, providing support and stability.

- Control mechanisms: These are responsible for navigation and the overall operability of the vehicle.

- Power units: The driving force behind the system, ensuring smooth operation and propulsion.

- Auxiliary components: Smaller, but vital, these elements support the main units, ensuring everything runs efficiently.

Understanding the layout of these systems helps in maintenance and troubleshooting, allowing for smoother operation and a longer lifespan of the craft.

Key Components of Moomba Boats

The key elements of these watercraft are designed to provide durability, performance, and comfort. Each vessel is built with precision and attention to detail, ensuring smooth operation and ease of handling on the water. Understanding the primary structures that make up these boats can help in maintaining them and ensuring a long-lasting, high-quality experience.

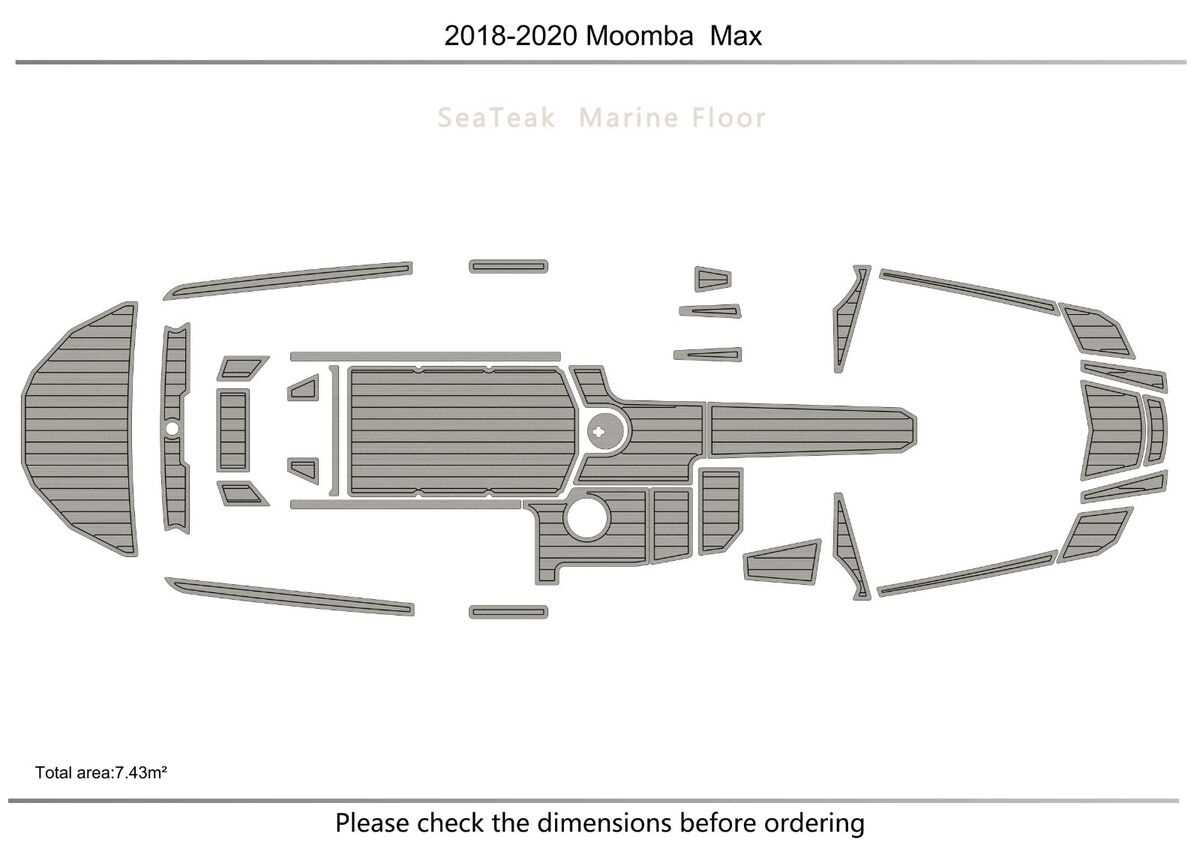

Hull Design and Structure

The hull is the foundation of any boat, providing stability and buoyancy. Crafted to withstand varying water conditions, it ensures that the vessel remains steady, even at high speeds. The materials used in the construction of the hull offer both strength and lightness, which improves fuel efficiency and handling.

Engine and Propulsion System

At the core of every vessel is its propulsion system. Equipped with powerful, reliable engines, these systems deliver the necessary thrust to navigate through various water conditions. The design of the engine compartment ensures easy access for maintenance, while the propulsion system optimizes speed and control.

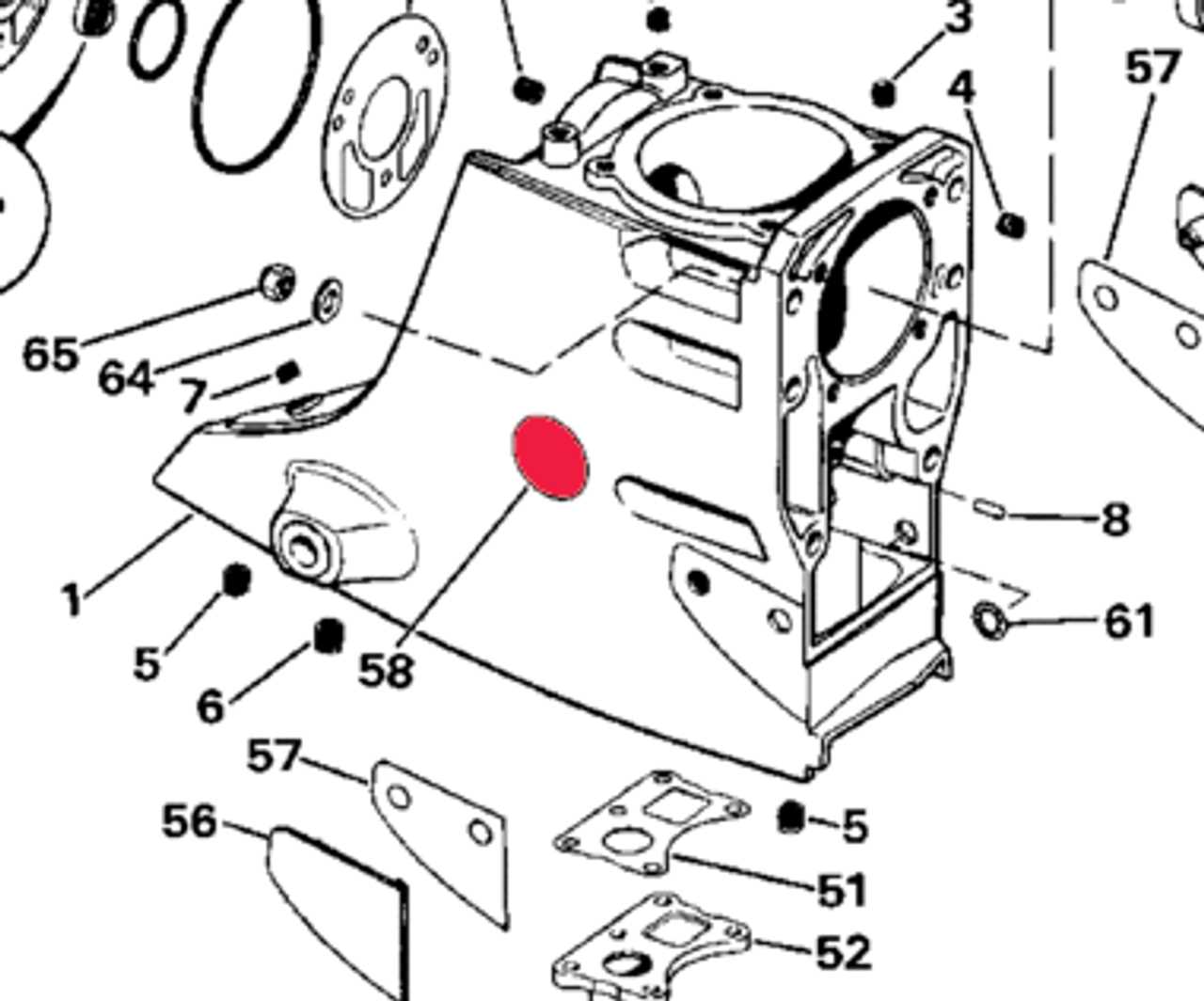

Understanding Engine Parts in Moomba

Recognizing the key components of a boat’s engine system is crucial for ensuring its smooth operation. A basic understanding of how the mechanical elements interact allows for better maintenance and troubleshooting when necessary.

Key Components of the Engine

Several primary components work together to generate the necessary power. These include the combustion unit, transmission, and cooling systems, all playing a vital role in the overall performance.

| Component | Function | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Combustion Unit | Responsible for igniting fuel to create energy that powers the boat. | ||||||||||||||||||||

| Transmission | Transfers the generated power to the propeller for movement. | ||||||||||||||||||||

| Cooling System | Maintains o

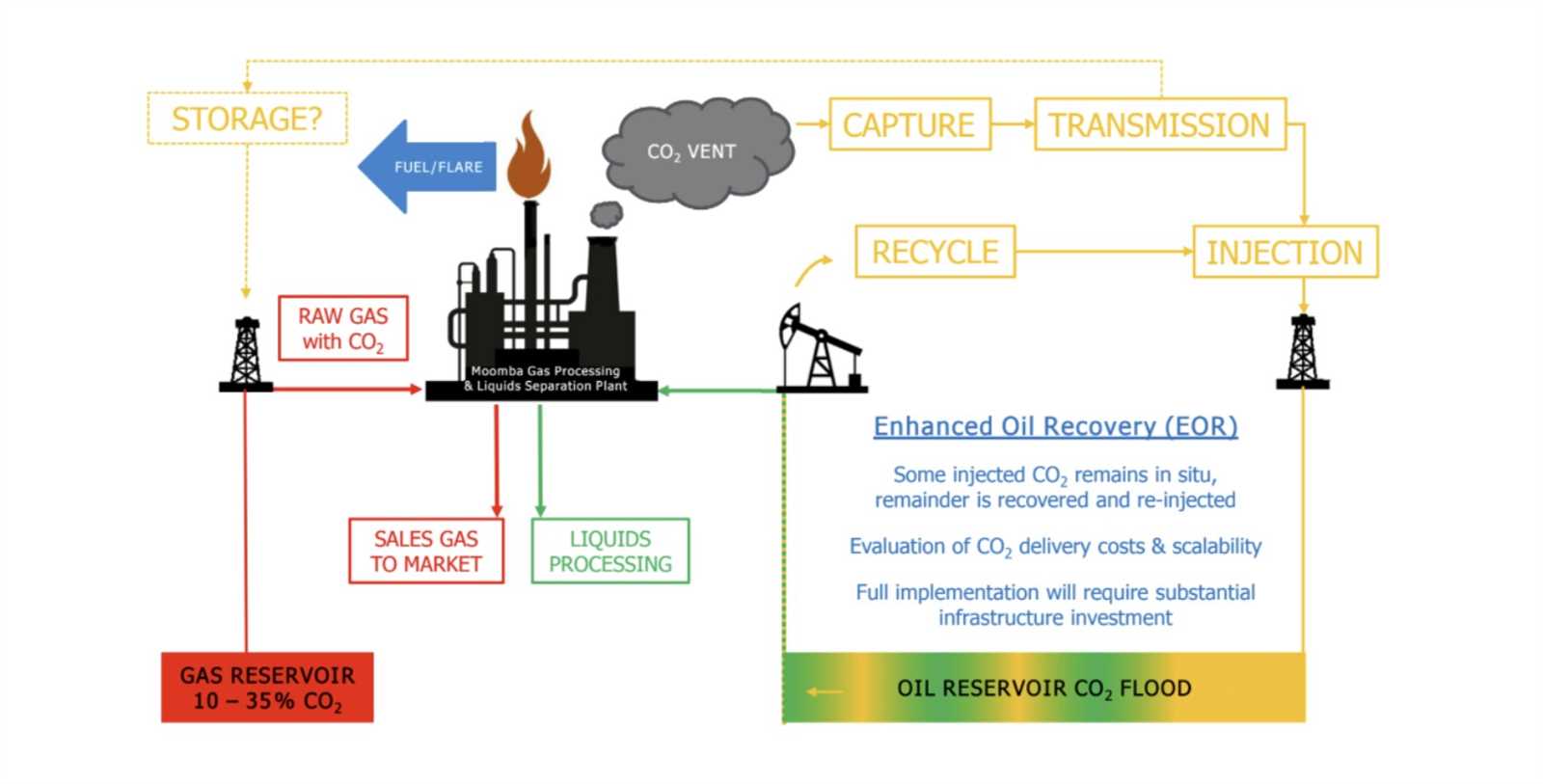

Common Electrical System LayoutThe typical configuration of an electrical system in watercrafts includes various interconnected components that ensure efficient power distribution and control. Understanding this layout is essential for maintaining and troubleshooting the system effectively. The arrangement generally encompasses the main power source, a network of wiring, and various control units that regulate electricity flow to key functions. Power Generation: The system often starts with a generator or battery, which serves as the primary energy provider. This power source delivers electricity to the entire setup through a network of circuits. Wiring Network: The wiring acts as the arteries of the electrical structure, transferring energy to different parts of the vessel. These wires are designed to handle various loads, ensuring safety and performance. Control Panels: Located centrally, control units manage the distribution of electricity to important areas, such as lighting, navigation, and onboard systems. These panels allow the operator to oversee and control Hull Structure and Design DiagramsUnderstanding the structure and design of a vessel’s hull is crucial for ensuring durability, stability, and performance in various water conditions. This section provides an overview of the construction principles that shape the framework of the hull, emphasizing how specific elements contribute to both the vessel’s strength and hydrodynamic efficiency. Core Elements of the Hull

The hull’s design involves multiple interconnected components that form the base of the boat. These elements are meticulously designed to support the vessel’s weight, ensure balanced buoyancy, and withstand external pressures. Key factors such as material selection and structural reinforcements play a vital role in the long-term reliability of the hull. Internal and External FeaturesWhile the exterior of the hull primarily focuses on streamlining and reducing drag, internal structures provide reinforcement and distribute forces evenly across the boat. Below is a table summarizing the essential components involved in the hull design process.

Conclusion

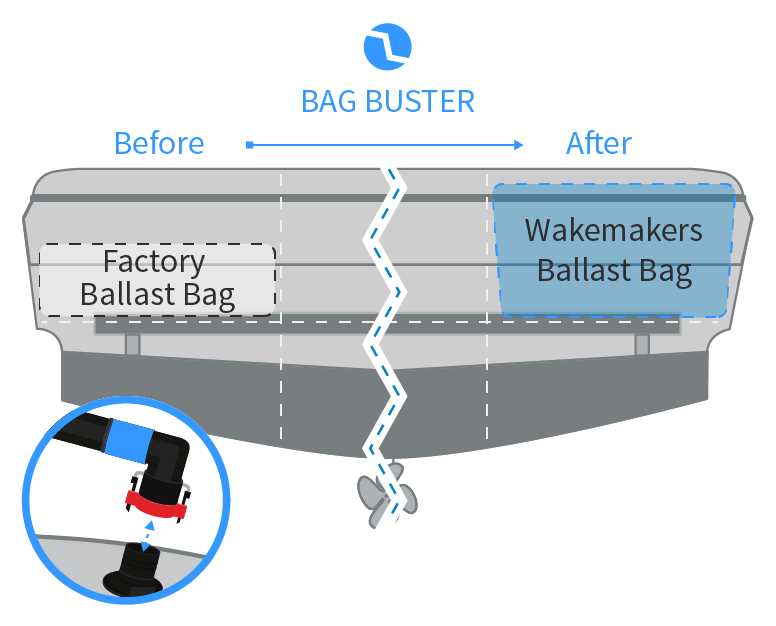

By adhering to these maintenance guidelines, you can ensure that your watercraft operates smoothly and safely. Regular checks and timely repairs will help avoid costly issues and enhance your enjoyment on the water. Best Practices for Part Replacement

Replacing components in any system requires careful consideration to ensure optimal performance and longevity. Following recommended guidelines can greatly enhance the effectiveness of the process, minimize downtime, and ultimately save on costs. This section will outline key strategies to adopt when undertaking the replacement of various elements. Assessing CompatibilityBefore proceeding with any substitutions, it is essential to evaluate the compatibility of the new components with existing systems. This includes checking specifications, sizes, and performance ratings to avoid potential issues. Utilizing manufacturer recommendations can provide valuable insights into suitable replacements that will function harmoniously within the overall framework. Regular Maintenance ChecksImplementing routine maintenance checks can prevent unexpected failures and extend the life of various components. Regular inspections allow for the identification of wear and tear, making it possible to address concerns before they escalate into more significant problems. Keeping a detailed log of maintenance activities can also aid in planning future replacements more effectively. |