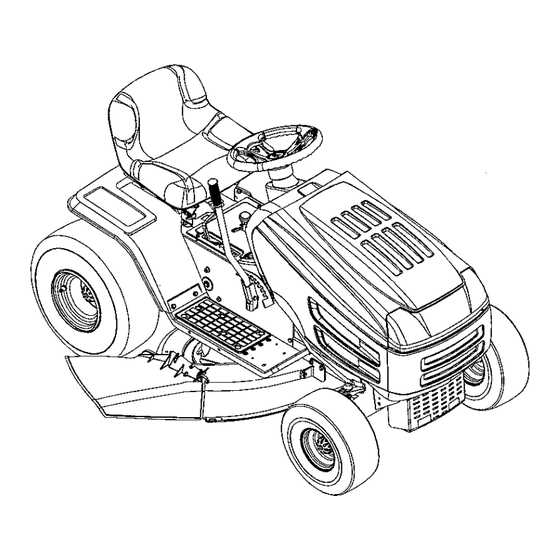

In the realm of outdoor power equipment, having a clear visual representation of individual elements is essential for effective maintenance and repair. This section delves into the intricacies of understanding the configuration of various mechanisms within these machines, providing valuable insights for users and technicians alike.

By examining the arrangement of essential components, one can gain a deeper comprehension of how each part contributes to the overall functionality of the device. This knowledge not only facilitates easier troubleshooting but also enhances the efficiency of any repair processes undertaken.

Moreover, familiarizing oneself with the organization of these elements empowers users to make informed decisions when it comes to replacements or upgrades. A well-structured overview serves as a reliable reference, ensuring that all necessary aspects are considered when working on equipment.

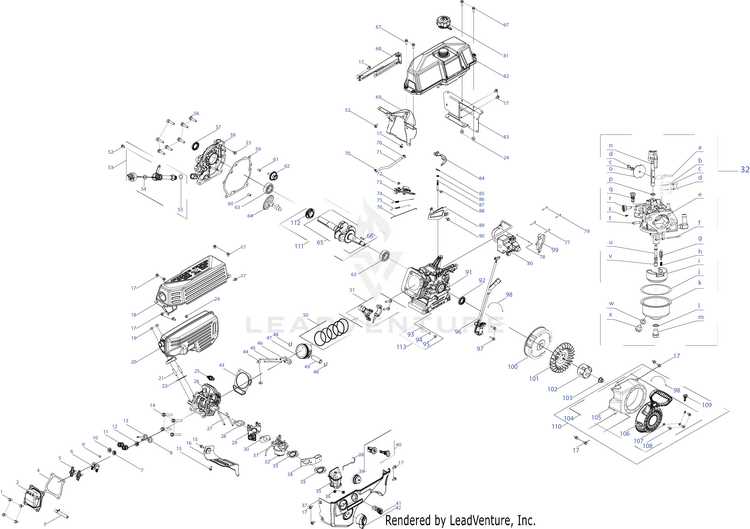

This section aims to provide a comprehensive overview of the various components and their interrelationships within a specific machine framework. Understanding these elements is crucial for effective maintenance and repair, allowing users to identify parts easily and enhance their operational efficiency. Each component plays a vital role, contributing to the overall functionality of the equipment.

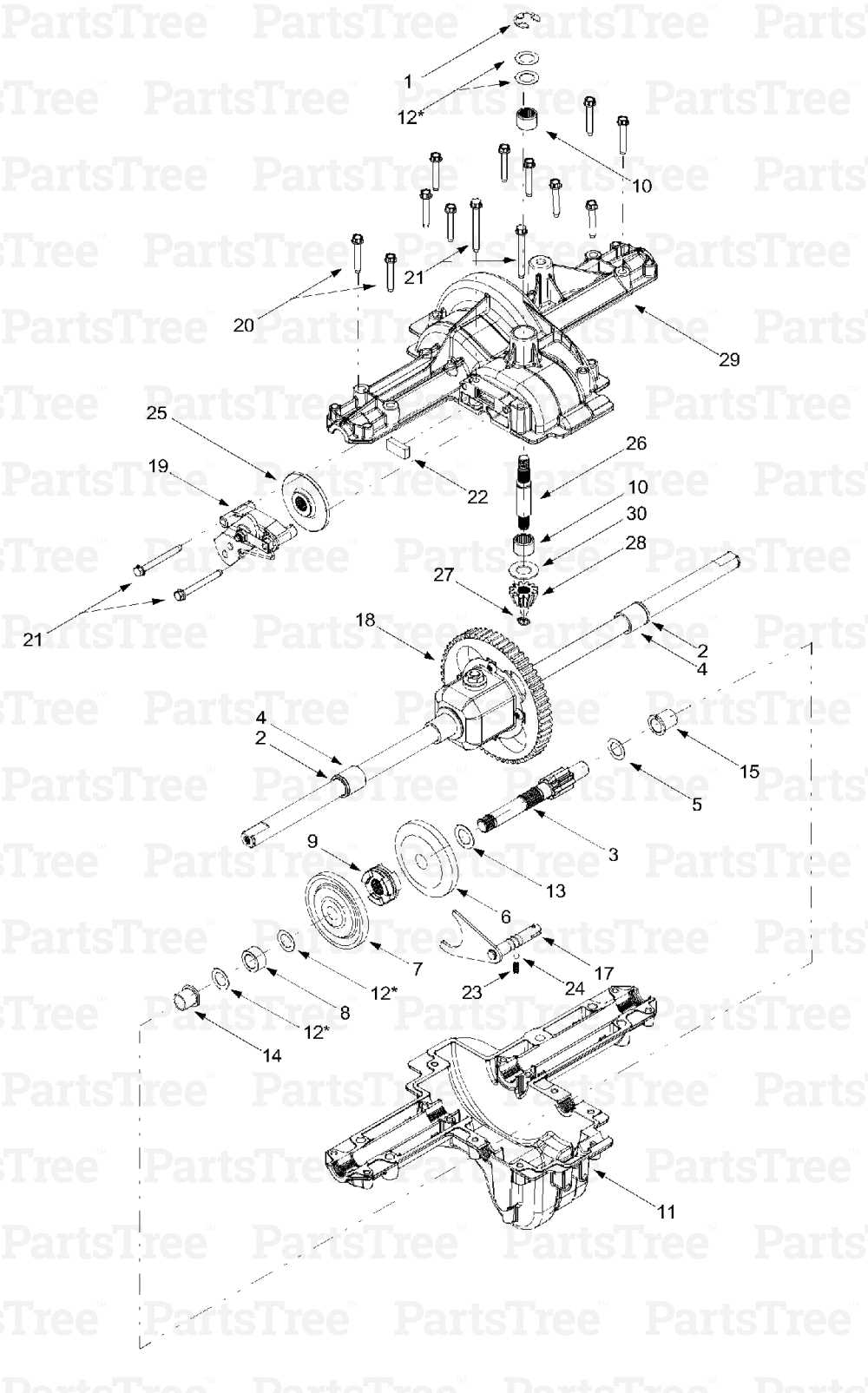

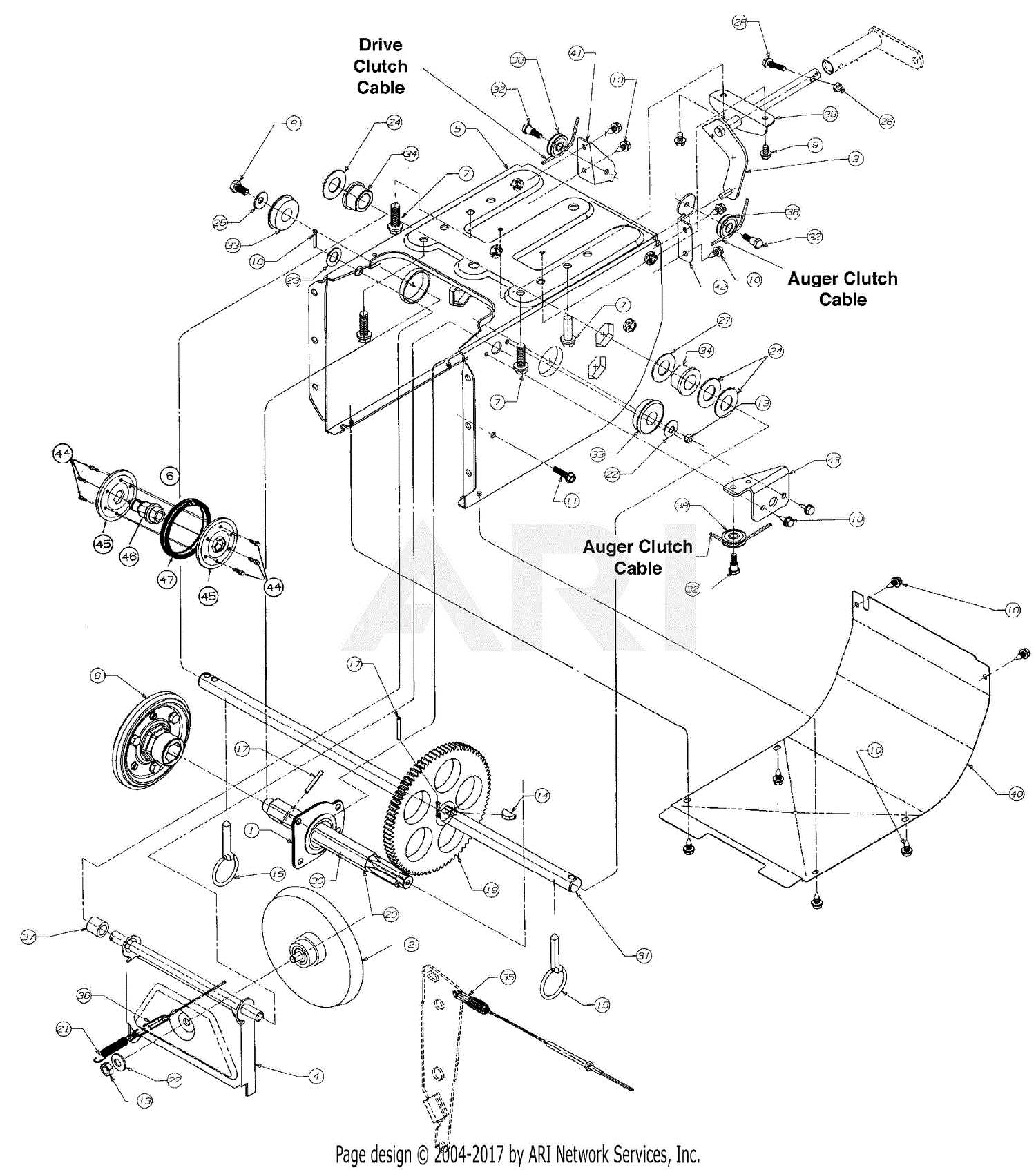

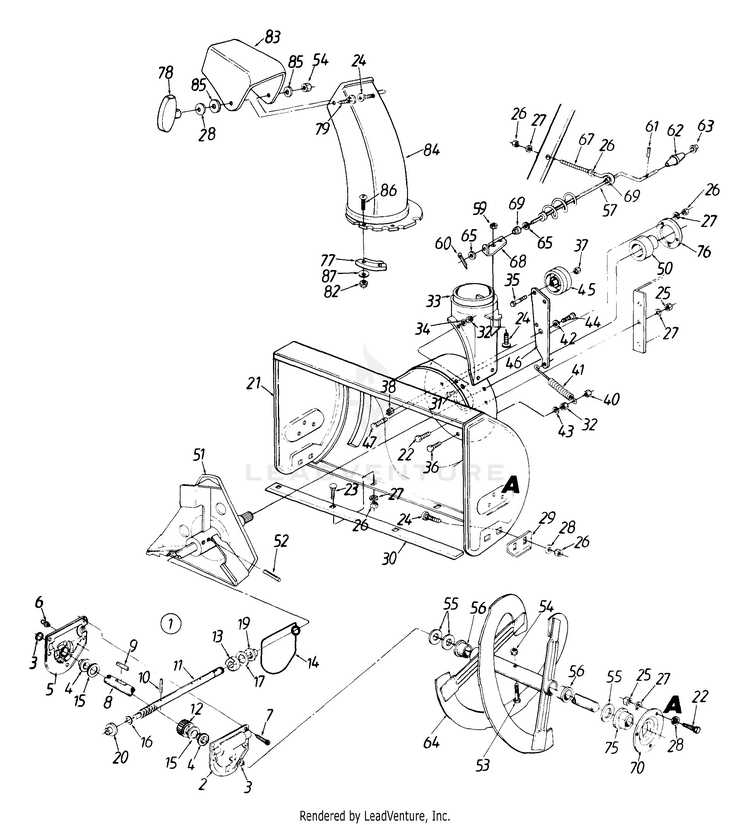

Component Identification

Identifying each individual piece is the first step in grasping the complete structure. Each section is labeled to simplify the recognition process, ensuring that users can pinpoint the necessary parts without confusion.

Assembly Overview

An overview of how each element fits together offers valuable insights into the assembly process. Recognizing the arrangement aids in both assembly and disassembly, facilitating smoother operations.

Understanding these visual representations allows users to:

- Locate specific components quickly.

- Understand the relationships between different parts.

- Enhance repair skills and maintenance practices.

Effective utilization of these resources can lead to improved performance and longevity of the equipment.

Importance of Accurate Parts Identification

Correct identification of components is crucial in maintaining and repairing various machinery. Understanding the specific requirements of each element ensures optimal performance and longevity of the equipment. Misidentification can lead to significant inefficiencies, increased costs, and potential damage, ultimately affecting productivity.

Enhancing Maintenance Efficiency

When individuals accurately recognize the necessary components, they can streamline maintenance processes. This precision allows for quicker repairs and replacements, minimizing downtime. By utilizing the right elements, operators can ensure that their machinery runs smoothly, which is essential for meeting operational goals.

Reducing Operational Risks

Identifying the correct components also plays a vital role in safety. Using inappropriate or incorrect elements can pose serious hazards to both the machinery and the operator. Ensuring that every part meets the required specifications mitigates risks, contributing to a safer working environment.

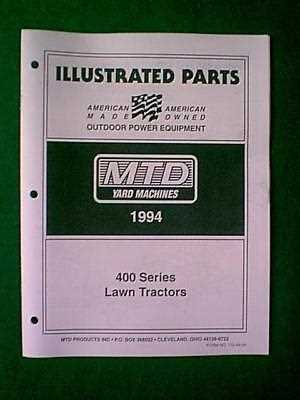

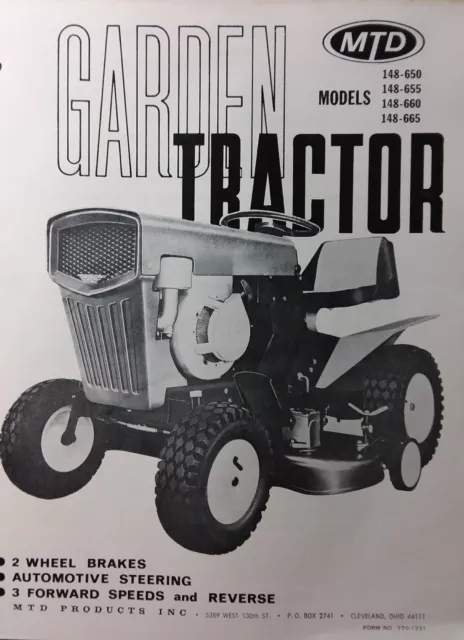

Common Components in MTD Equipment

In various types of outdoor machinery, certain elements play crucial roles in ensuring efficient operation and longevity. Understanding these fundamental components helps users maintain and troubleshoot their equipment effectively.

Engines serve as the heart of any machine, providing the necessary power for operation. They vary in size and capacity, influencing performance and suitability for different tasks.

Blades are essential for cutting and trimming tasks. Their design and material quality affect the effectiveness and durability, making them a key focus for maintenance.

Wheels and Tires contribute to mobility and stability, impacting how the equipment navigates various terrains. Proper inflation and tread depth are vital for optimal performance.

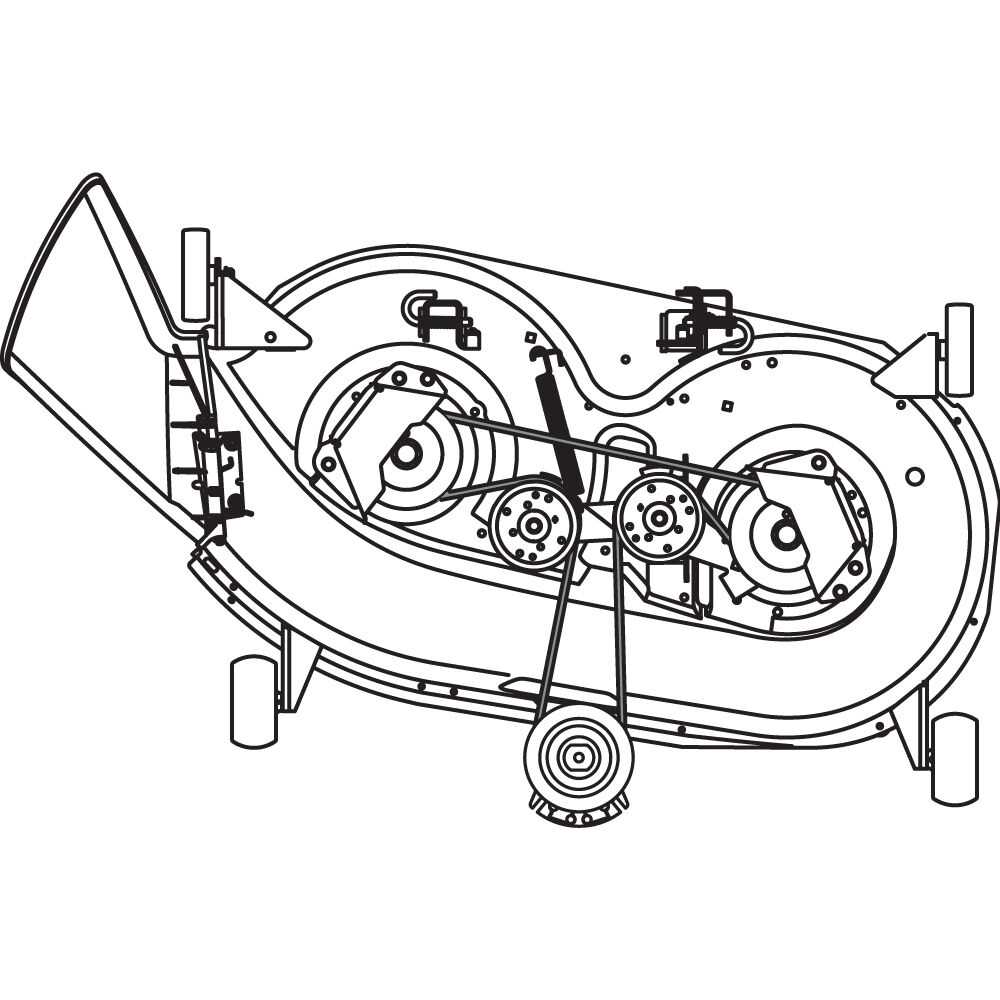

Belts and Cables facilitate the transfer of power and control signals between different components, ensuring smooth operation. Regular inspection for wear and tension is crucial for reliable function.

Frames and Chassis provide structural integrity and support for all other components. A sturdy frame enhances durability and can withstand the rigors of outdoor use.

Each of these elements plays a pivotal role in the overall functionality of outdoor machinery, making awareness of their condition and maintenance essential for users.

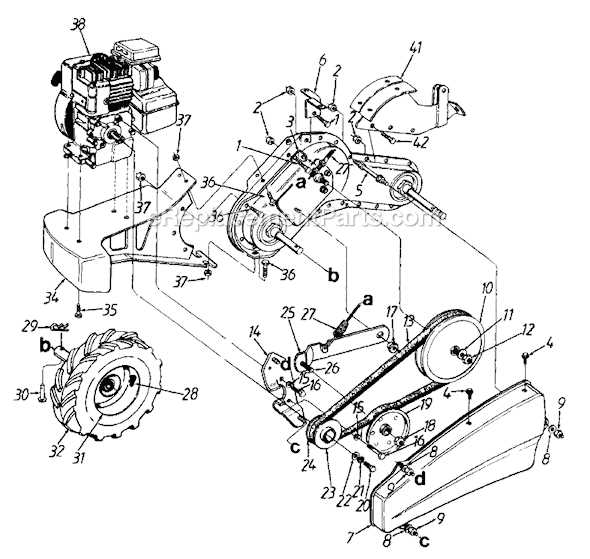

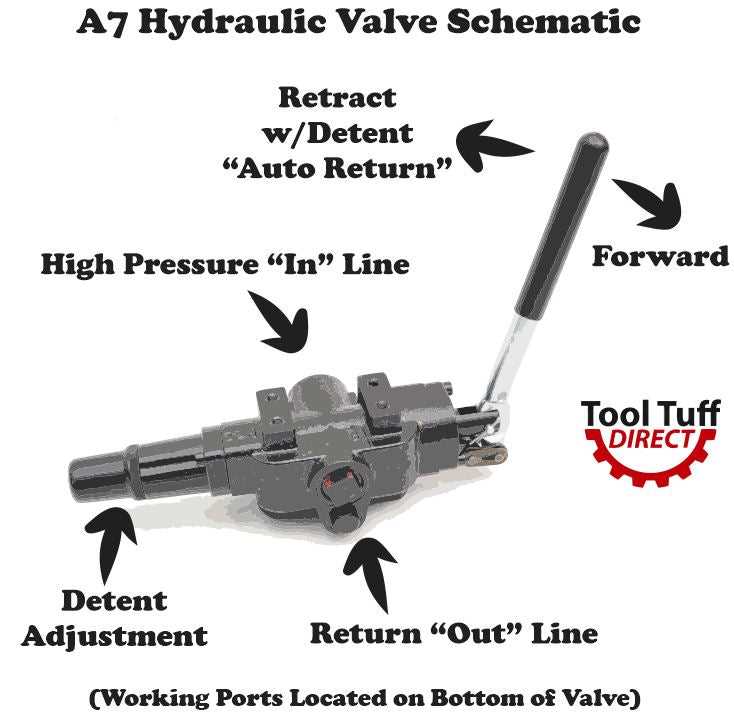

How to Read MTD Diagrams Effectively

Understanding technical illustrations is crucial for effective maintenance and repair tasks. Mastering these visual representations allows users to identify components and their relationships, ensuring successful troubleshooting and assembly. By following a structured approach, one can enhance comprehension and efficiency when dealing with complex schematics.

Key Steps for Effective Interpretation

- Familiarize with Symbols: Different shapes and icons represent specific components. Take time to learn what each symbol signifies.

- Follow the Flow: Most visuals are arranged to guide the reader through a logical sequence. Pay attention to the direction of lines and connections.

- Utilize a Legend: Many illustrations include a legend or key that explains symbols and color codes. Refer to it frequently.

Tips for Better Understanding

- Practice Regularly: The more you engage with these representations, the easier it becomes to decipher them.

- Cross-Reference Information: Use manuals or online resources to clarify details about specific components.

- Take Notes: Document any observations or questions as you study to reinforce learning and facilitate future reference.

Locating Replacement Parts for MTD

Finding suitable components for outdoor equipment can be a straightforward process when you know where to look. Various resources are available that provide detailed information on compatible replacements, ensuring optimal performance and longevity for your machinery.

Online Resources

The internet is a valuable tool for sourcing components. Numerous websites offer comprehensive catalogs and search features that allow users to find specific items quickly. These platforms often include user manuals, detailed descriptions, and sometimes even customer reviews to assist in making informed decisions.

Local Suppliers

Visiting local suppliers or authorized dealers can also yield positive results. These establishments often have knowledgeable staff who can help identify the required items based on your equipment’s specifications. In addition, they may have stock on hand, allowing for immediate purchases.

| Resource Type | Advantages |

|---|---|

| Online Retailers | Wide selection, convenience, detailed information |

| Local Dealers | Expert advice, immediate availability, support |

| Manufacturer Websites | Official specifications, compatibility checks, warranty information |

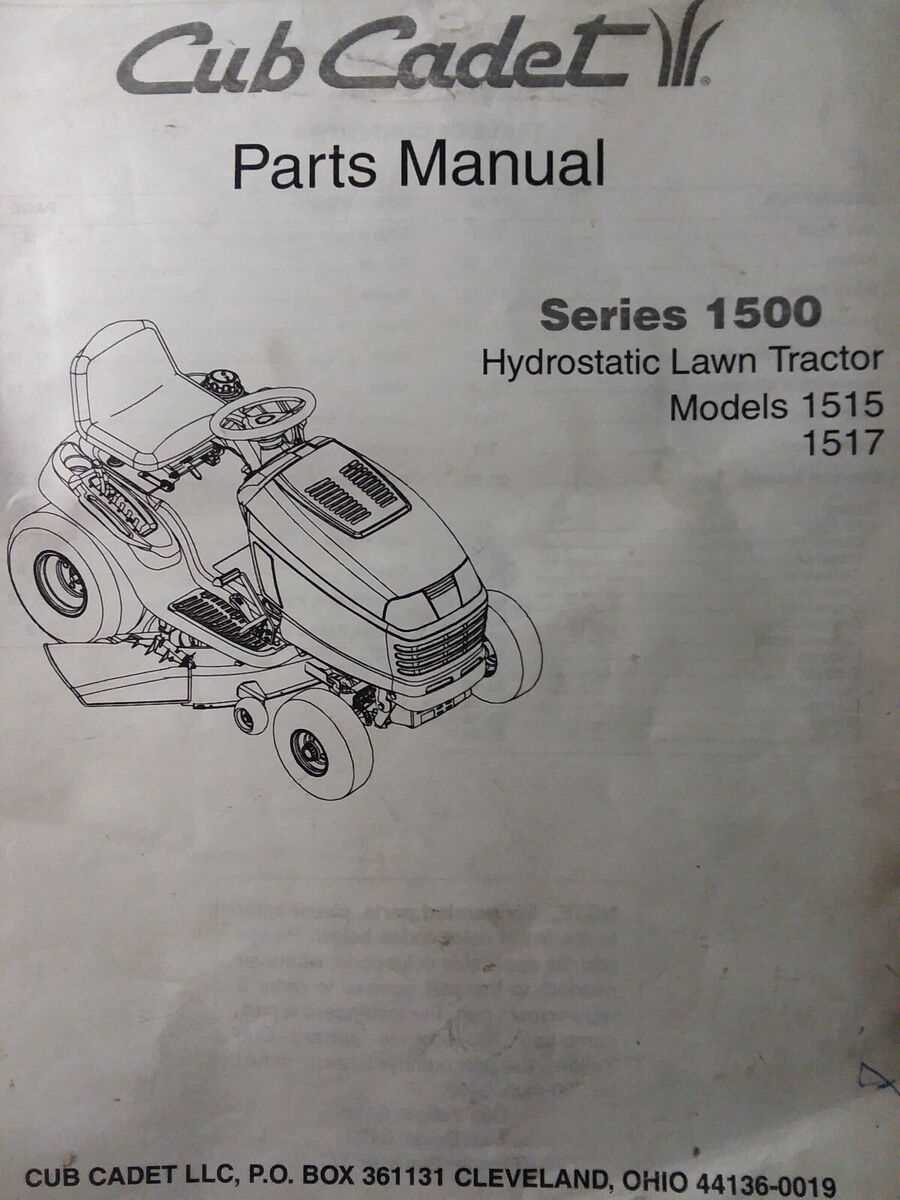

Benefits of Using OEM Parts

Utilizing original components in machinery maintenance ensures optimal performance and longevity. These elements are specifically designed for seamless compatibility with your equipment, enhancing overall efficiency. The advantages of choosing these components over generic alternatives are numerous and significant.

- Quality Assurance: OEM components are manufactured to stringent standards, ensuring they meet the required specifications and performance levels.

- Perfect Fit: These components are tailored for specific models, guaranteeing easy installation and reliable operation.

- Enhanced Durability: The use of high-quality materials contributes to the longevity of the machinery, reducing the frequency of replacements.

- Warranty Coverage: Many manufacturers offer warranties on their original components, providing peace of mind and protection for your investment.

- Increased Resale Value: Machines maintained with original components typically retain their value better than those using aftermarket alternatives.

Incorporating these elements into maintenance practices is an investment in reliability and performance, leading to greater satisfaction and fewer issues over time.

Identifying Model Numbers and Specifications

Understanding the identification of model numbers and their associated specifications is essential for effective maintenance and repair of equipment. This knowledge aids users in selecting the correct components and ensuring compatibility. Various methods exist to locate this information, making it accessible to both novice and experienced individuals.

Where to Find Model Numbers

- Check the owner’s manual for detailed information.

- Look for identification stickers on the equipment, often located on the frame or engine.

- Search online databases and manufacturer websites for model information.

Understanding Specifications

Specifications provide crucial details regarding dimensions, capabilities, and compatibility with various components. Familiarity with these specifications enables users to:

- Ensure proper fitting of components.

- Assess performance characteristics.

- Compare different models for optimal selection.

Seasonal Maintenance and Parts Checklist

Regular upkeep of your equipment is crucial for optimal performance throughout the year. A systematic approach to seasonal care ensures longevity and efficiency, minimizing unexpected breakdowns. This guide provides an essential overview of tasks and components to inspect, helping maintain smooth operation.

Inspection of Essential Components: Begin by examining the crucial elements that impact functionality. Check for wear and tear on belts and blades, ensuring they are free from damage. Replace any parts that show signs of deterioration to prevent further complications.

Fluid Levels: Regularly monitor and top off all necessary fluids, including oil and fuel. Proper lubrication is vital to maintain engine health, while clean fuel prevents performance issues.

Cleaning: Remove debris and buildup from all surfaces, focusing on air filters and cooling systems. Keeping these areas clean enhances airflow and cooling efficiency, extending the life of your machinery.

Battery Maintenance: Inspect the battery for corrosion and ensure secure connections. A charged and well-maintained battery is essential for reliable starts and overall performance.

Final Checklist: Before the season begins, ensure all maintenance tasks are completed. Document any parts that were replaced or serviced, and create a timeline for future inspections to maintain a proactive maintenance routine.

Common Issues and Part Failures

In machinery, various complications can arise due to wear and tear, leading to malfunctions or complete breakdowns. Understanding these common challenges is essential for effective maintenance and timely repairs.

Here are some frequent problems encountered:

- Engine Difficulties: Issues such as stalling or difficulty starting can arise from fuel system blockages or electrical failures.

- Transmission Problems: Slipping gears or unresponsive controls may indicate worn components or fluid leaks.

- Blade Malfunctions: Dull or damaged cutting elements can hinder performance and require replacement for optimal efficiency.

- Electrical Failures: Malfunctioning lights or starting systems often stem from faulty wiring or dead batteries.

To mitigate these problems, regular inspections and preventive measures are crucial. Here are some effective strategies:

- Conduct routine checks on critical systems.

- Replace worn components promptly.

- Keep the equipment clean and well-lubricated.

- Ensure proper storage and handling practices to avoid unnecessary damage.

By recognizing these common issues and implementing preventive maintenance, users can enhance the longevity and reliability of their machinery.

How to Source Aftermarket Components

Finding reliable replacements for specific mechanical components can enhance the performance and longevity of your equipment. Aftermarket alternatives often provide a cost-effective solution while maintaining quality and functionality. This section explores practical steps to effectively acquire these replacements, ensuring you make informed choices.

Research Options

Begin your search by gathering information about the available alternatives. Consider the following sources:

- Online retailers specializing in aftermarket components

- Local hardware or repair shops

- Forums and community groups focused on equipment maintenance

Evaluate Quality and Compatibility

Before making a purchase, ensure the replacement components meet your needs:

- Check reviews and ratings from other users.

- Verify that the components are compatible with your existing equipment.

- Inquire about warranties or return policies to safeguard your investment.

By following these guidelines, you can successfully navigate the aftermarket landscape and find suitable replacements for your machinery. This proactive approach will help you maintain optimal performance and extend the lifespan of your equipment.

DIY Repairs Using Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and troubleshooting. By utilizing visual representations of the various elements, individuals can identify issues and facilitate repairs without needing professional assistance. This approach empowers users to take control of their equipment, saving time and money.

Benefits of Visual References

Visual guides provide clarity when dealing with complex machinery. They help in pinpointing specific sections that require attention, ensuring that repairs are conducted accurately. This method reduces the likelihood of errors, enabling users to follow a step-by-step process, which can be especially beneficial for those new to DIY repairs.

Tips for Successful Repairs

Before starting any repair work, ensure you have all necessary tools at hand. Refer to visual guides carefully to familiarize yourself with each component’s location and function. Take your time during the repair process, double-checking each step to avoid mistakes. If uncertain, consider seeking advice from online forums or instructional videos to enhance your understanding and execution of the repair.

Online Resources for MTD Parts Information

Accessing detailed information about various components and their specifications is crucial for effective maintenance and repairs. Numerous online platforms provide valuable resources to assist users in identifying and obtaining the necessary items for their equipment. These websites offer various tools, including schematics, guides, and part availability, enhancing the overall service experience.

Manufacturer Websites

Official manufacturer sites are among the most reliable sources for detailed information. They typically feature comprehensive catalogs that include detailed illustrations, specifications, and compatibility information. Users can easily navigate these platforms to find the exact components required for their machinery.

Online Retailers and Marketplaces

Reputable online retailers often provide extensive listings of available components along with user reviews and ratings. These platforms not only facilitate the purchase process but also offer insights into the quality and performance of the items. Comparing options across different retailers can ensure users find the best deals and reliable replacements.