Every complex machine relies on the harmony of individual elements to function effectively. When it comes to construction equipment, knowing how different sections interact and where each element fits can make a significant difference in maintenance and repair. In this section, we’ll explore how these elements come together to ensure smooth operation.

Each component serves a specific role, and understanding the layout is crucial for anyone involved in upkeep or assembly. Whether you are looking to replace a specific part or simply need to familiarize yourself with the structure, knowing how everything is arranged provides a clear path forward.

By carefully reviewing the arrangement of key sections, you can ensure that every element is in its proper place

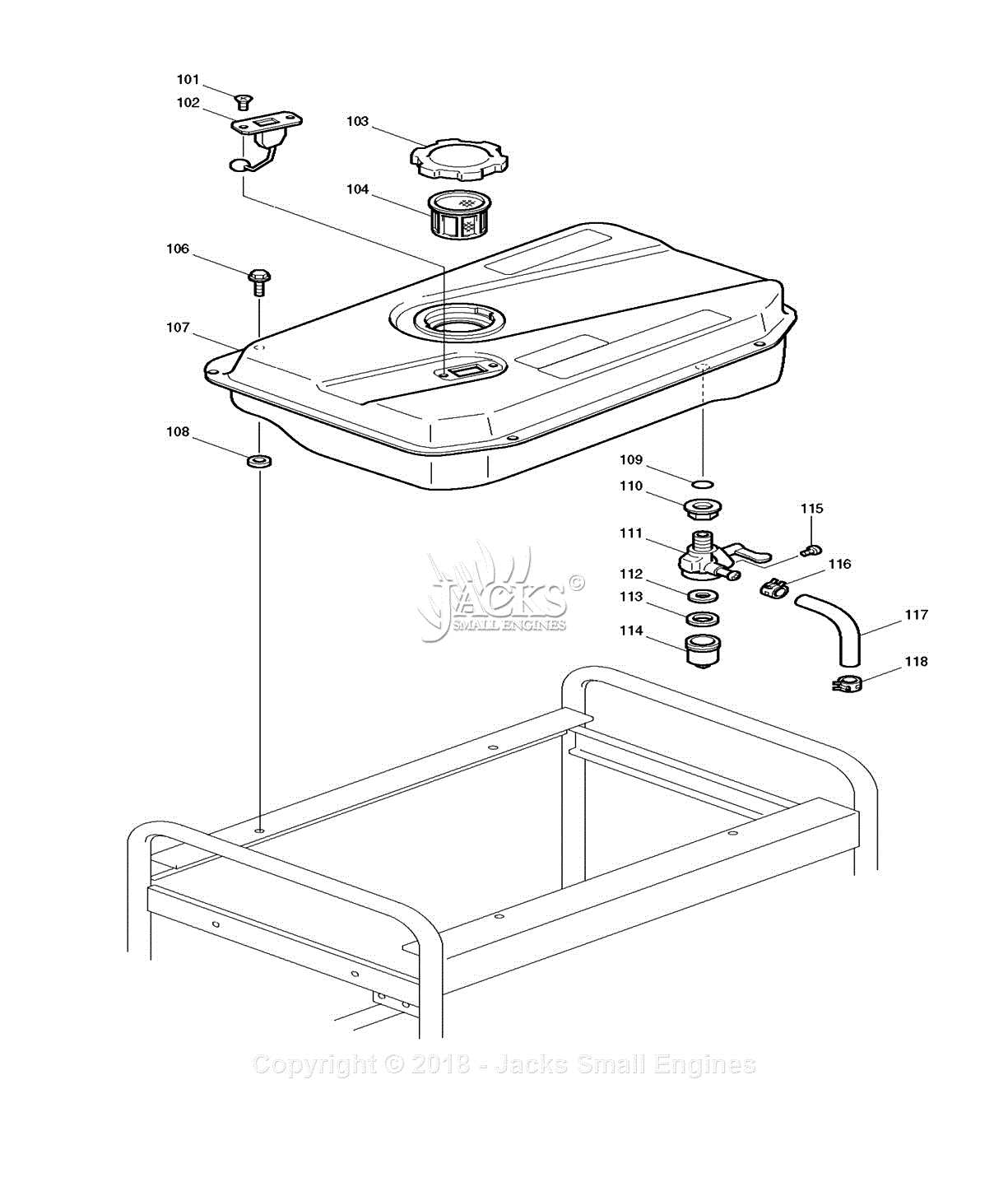

Key Components of the MTX70HD

The device consists of several integral elements that work together to ensure smooth and efficient operation. These components are carefully designed to enhance performance and reliability, making them essential for its functionality. Below, we explore some of the critical parts that contribute to the overall structure and utility of the equipment.

Engine and Power Source

The motor is the heart of the equipment, providing the necessary energy to drive its operations. Whether gasoline-powered or electric, this component ensures consistent power delivery, which is vital for performance in various conditions.

- Fuel tank or battery for energy supply

- Exhaust system for heat management

- Cooling mechanism to prevent overheating

Operational Mechanisms

Understanding the Engine Assembly

The core component of any machine lies in its central mechanical structure, responsible for driving performance and functionality. The engine, as a key feature, plays a critical role in powering the overall operation. By examining how its individual sections work together, one can gain insights into the mechanisms behind smooth, efficient performance. Each section has a unique role in ensuring the stability and strength of the entire system.

| Component | Description | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power Unit | This section generates the energy required to activate the moving parts, ensuring a stable and continuous operation. | ||||||||||||||||||||||

| Cooling System | Designed to maintain optimal temperatures during heavy use, preventing overheating and ensuring long-term reliability. |

| Component | Description |

|---|---|

| Power Distribution Unit | Distributes electrical power to different sections of the system. |

| Control Module | Manages the operation of various components and systems. |

| Connecting Cables | Facilitate communication and power transfer between components. |

| Fuses and Breakers | Provide protection against overloads and electrical faults. |

| Sensors | Monitor system parameters and provide feedback for adjustments. |

Maintaining an organized electrical system is crucial for preventing failures and ensuring longevity. Regular inspections and updates to the configuration can significantly enhance performance and mitigate risks associated with electrical malfunctions.

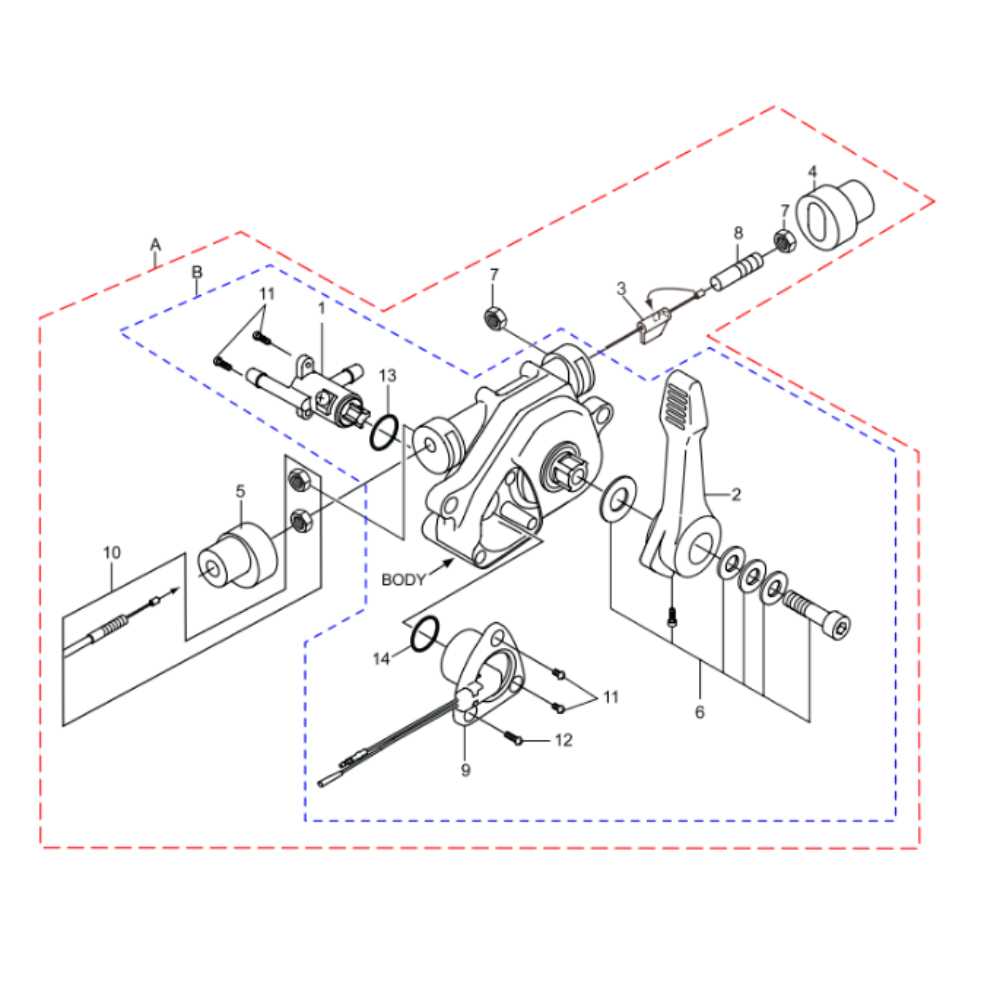

Clutch and Drive Systems

The efficiency of any mechanical system relies heavily on its engagement and power transfer mechanisms. These components play a critical role in ensuring smooth operation and effective control of motion. Understanding how these systems function can significantly enhance performance and longevity.

Key Components

At the heart of these systems are various elements that work together to facilitate seamless transitions between power and movement. The primary components include the actuator, pressure plate, disc, and flywheel. Each part has its unique function, contributing to the overall effectiveness of the drive system.

| Component | Function |

|---|---|

| Actuator | Controls the engagement and disengagement of the clutch. |

| Pressure Plate | Applies pressure to the clutch disc, ensuring proper engagement. |

| Disc | Friction surface that transmits power between the engine and transmission. |

| Flywheel | Provides a mounting surface and aids in stabilizing engine speed. |

Maintenance Considerations

Regular maintenance of these systems is crucial for optimal performance. Ensuring that components are free from wear and tear can prevent costly repairs and downtime. It’s advisable to follow a scheduled inspection and replacement plan to maintain the integrity of the entire system.

Air Filter and Intake Design

The design of air filtration and intake systems is crucial for optimizing engine performance and efficiency. These components ensure that the air entering the engine is clean and properly channeled, allowing for effective combustion. A well-engineered intake system can significantly enhance airflow while minimizing contaminants, contributing to better power output and reduced emissions.

Key Considerations for Air Filtration

When designing air filtration systems, several factors must be taken into account. The size and material of the filter play essential roles in determining airflow resistance and filtration effectiveness. Additionally, the placement of the filter within the intake pathway can influence how efficiently air is drawn into the engine. It’s vital to strike a balance between adequate filtration and maximum airflow to achieve optimal engine performance.

Intake System Configuration

The configuration of the intake system greatly impacts engine responsiveness and torque characteristics. Smooth bends and appropriate duct diameters facilitate uninterrupted airflow, enhancing overall performance. Various intake designs, including cold air intakes and short ram systems, can also affect engine temperature, which is crucial for maintaining efficiency. An effective intake system design incorporates these elements to ensure that the engine receives the best possible air supply.

Hydraulic Elements and Functions

Hydraulic systems are integral to the efficient operation of various machinery, utilizing fluid dynamics to transmit power. These systems consist of several critical components, each serving a unique purpose that contributes to the overall functionality and performance. Understanding the roles of these elements is essential for optimizing system operation and ensuring reliability.

Hydraulic Pumps play a vital role by converting mechanical energy into hydraulic energy, enabling fluid movement through the system. These pumps generate flow, creating pressure that drives the operation of other components.

Actuators, such as hydraulic cylinders and motors, convert hydraulic energy back into mechanical energy. They are responsible for performing specific tasks, such as lifting, pushing, or rotating, based on the application’s requirements.

Valves control the flow and direction of the hydraulic fluid, allowing for precise operation of the system. These components can regulate pressure, ensuring that the system operates within safe limits, and can direct the flow to different parts of the machinery as needed.

Filters are essential for maintaining system integrity by removing contaminants from the hydraulic fluid. Clean fluid is crucial for preventing wear and tear on components, thus prolonging the lifespan of the system.

Understanding these hydraulic components and their functions is key to troubleshooting, maintenance, and enhancing the efficiency of any hydraulic system. Proper knowledge enables operators and technicians to identify potential issues, optimize performance, and ensure safe operation.

Maintenance Tips for Key Parts

Proper upkeep of essential components is vital for ensuring optimal performance and longevity of your equipment. Regular maintenance not only helps in preventing unexpected breakdowns but also enhances overall efficiency. Here are some valuable tips to consider when caring for critical elements.

- Regular Inspection: Frequently check key elements for signs of wear and tear. Early detection can prevent more significant issues down the line.

- Clean Components: Keep essential parts clean to avoid dirt accumulation that can hinder performance. Use appropriate cleaning agents and methods suitable for the material.

- Lubrication: Apply suitable lubricants to moving parts to reduce friction and wear. Ensure to follow the manufacturer’s recommendations for the type of lubricant.

- Check Fasteners: Regularly inspect screws, bolts, and nuts for tightness. Loose fasteners can lead to instability and potential damage.

- Follow Service Intervals: Adhere to the recommended service schedule for maintenance tasks. Consistent servicing helps maintain the functionality of critical components.

By implementing these practices, you can significantly extend the life of important elements and maintain the reliability of your machinery.