Historical firearms are fascinating pieces of engineering that showcase the evolution of weaponry through the ages. They consist of various essential elements that work together to create a functional and precise tool. Whether used for hunting, sport, or historical reenactments, these devices require a deep understanding of their structure to ensure proper use and maintenance.

Each section of these firearms serves a unique purpose, contributing to the overall performance. From the ignition system to the barrel, every element must function seamlessly for optimal results. By exploring the specific features and how they interconnect, enthusiasts can gain a deeper appreciation of these remarkable inventions.

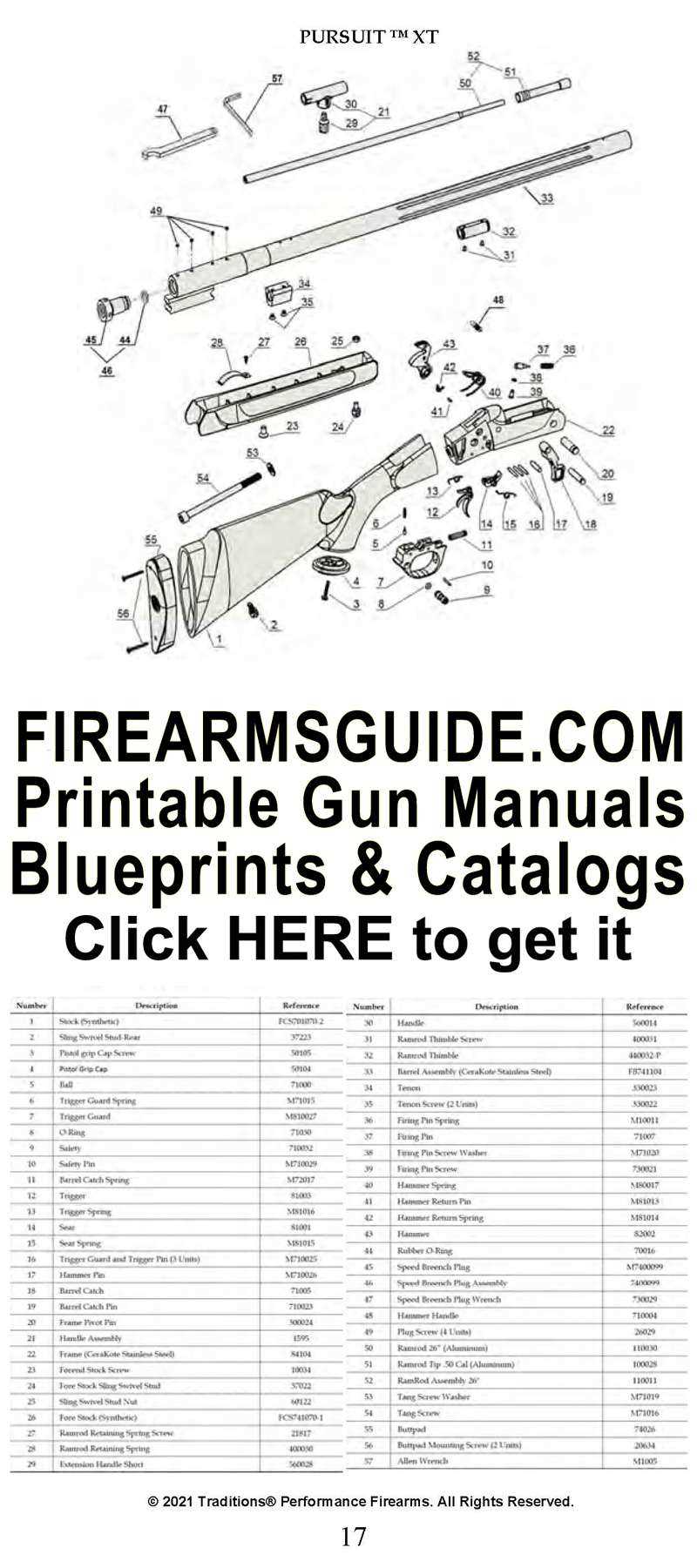

Understanding the various elements of these devices is key to preserving their functionality and

Understanding the Muzzleloader Mechanism

The structure of this type of firearm relies on a set of key components working together to ensure precise operation. Each element has a specific function, contributing to the overall performance and accuracy. By understanding the roles these components play, one can appreciate the intricate design and craftsmanship that go into these weapons.

Key Functional Elements

Several critical elements combine to make the firearm function efficiently. These include the ignition system, which initiates the firing process, and the loading chamber, where the ammunition is placed. Both systems must operate in harmony to provide consistent results.

Operational Dynamics

The firing process begins when the ignition system triggers, sending energy through to the projectile. The propulsion creates the force needed to launch the ammunition. Each step in the process is essential for the

Components Essential for Proper Firing

The correct functioning of a traditional firearm relies on a precise combination of key elements. Each piece plays a vital role in ensuring smooth and safe operation, allowing for effective discharge when everything is assembled properly. Understanding the interaction between these components is crucial for achieving consistent performance.

The ignition system is at the core of proper firing, providing the necessary spark to ignite the charge. It needs to work seamlessly with the firing mechanism to guarantee the release of energy. Another critical aspect is the containment of the propellant, which must be securely held to prevent any misfires or accidents.

The loading process also requires careful attention. The right tools and materials ensure that the projectile is seated properly, allowing for a smooth exit when the shot is fired. Without precise alignment and secure placement, the accuracy and safety of the shot can be compromised.

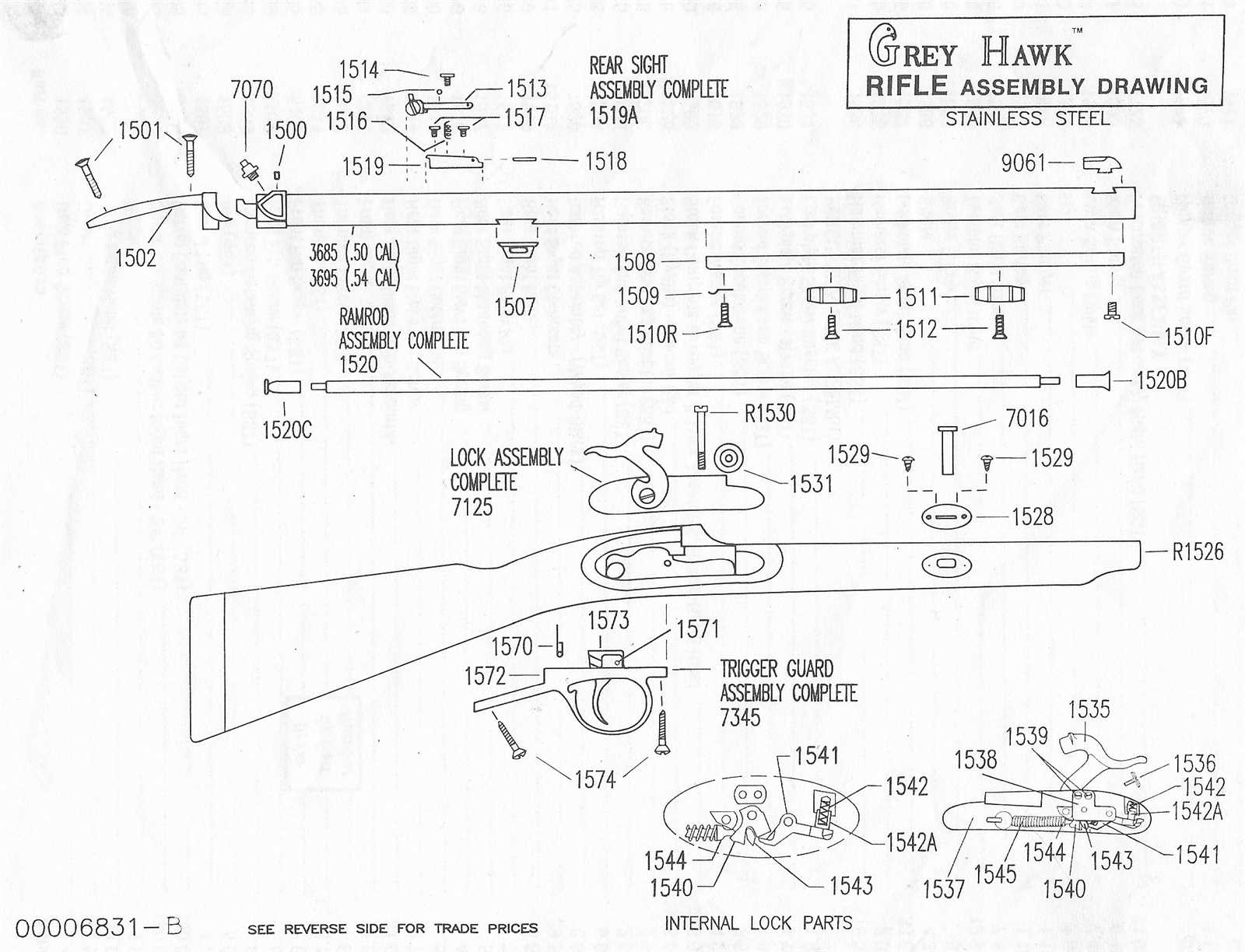

The Role of the Barrel in Accuracy

The precision and consistency of a firearm are heavily influenced by the design and quality of its barrel. It serves as the path through which the projectile travels, meaning even minor imperfections can affect the overall performance. By carefully considering aspects such as length, material, and internal rifling, one can significantly improve the reliability of each shot.

A well-constructed barrel ensures that the bullet follows a stable and predictable trajectory. This is achieved through proper balance between internal dimensions and surface smoothness, reducing any potential for unwanted deviations. As a result, the barrel is one of the most critical components for achieving consistent precision.

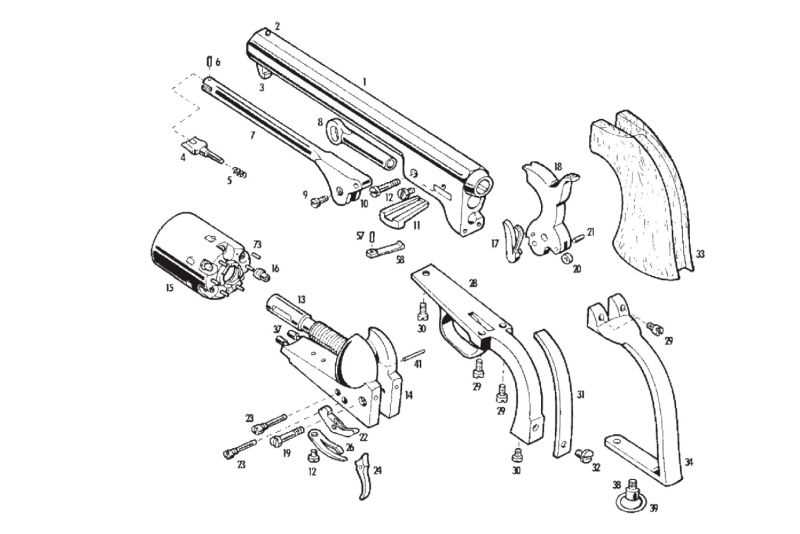

Trigger Assembly and Its Function

The trigger mechanism is a vital element in ensuring precise and controlled firing. It plays a crucial role in the overall operation, directly influencing how and when the internal components are engaged. Understanding its purpose and the details of its structure helps in appreciating the intricacy behind accurate performance.

Main Components of the Trigger Mechanism

- Trigger – The part pressed by the user to initiate the firing sequence.

- Sear – A lever that holds the firing pin in place until the trigger is pulled.

- Spring – Provides the tension needed for the sear to release, ensuring reliable operation.

Function in the Firing Process

When the trigger is pulled, the mechanism engages various internal elements. The spring compresses, allowing the sear to release its hold on the firing component. This

How the Lock System Works

The mechanism that controls the discharge of a firearm is a critical component of its operation. This system ensures that the weapon fires when triggered, while also preventing accidental discharge. Understanding its function is essential for safety and efficiency during use.

Trigger Mechanism

The trigger mechanism is responsible for releasing the hammer or striker, initiating the firing process. When the user pulls the trigger, it sets off a series of actions within the system, eventually causing the ignition of the charge.

Safety Features

Modern lock systems often

Ramrod Usage for Loading Ammunition

The ramrod is an essential tool in the loading process of black powder firearms. Its primary function is to ensure that the projectile and the propellant are securely seated within the barrel. Proper utilization of this implement can greatly enhance the efficiency and safety of the loading procedure.

Ensuring Proper Seating

When loading ammunition, it is crucial to use the ramrod to push the bullet firmly against the charge. This not only maximizes accuracy but also prevents any potential misfires. A well-seated projectile ensures that the combustion occurs evenly, resulting in optimal performance.

Maintaining Safety

In addition to improving accuracy, utilizing the ramrod correctly also promotes safety. It helps to prevent the accumulation of residue that could lead to blockages. Regularly inspecting the ramrod for signs of wear and ensuring it is clean can significantly reduce risks during shooting.

Importance of the Breech in Safety

The breech plays a crucial role in the overall security and functionality of firearm systems. Its design and construction significantly influence how effectively and safely the weapon operates. Understanding its importance helps ensure proper handling and reduces the risk of accidents during use.

Structural Integrity

A well-designed breech contributes to the structural integrity of the firearm. It withstands the high pressures generated during discharge, preventing catastrophic failures. Proper materials and craftsmanship are essential for maintaining safety standards.

Loading and Firing Mechanism

The breech also facilitates the loading and firing mechanism, impacting the overall performance of the firearm. An effective breech ensures that ammunition is secured correctly, minimizing the chances of misfires or other operational issues.

| Aspect | Significance |

|---|---|

| Material Quality | Prevents structural failure under pressure |

| Design Precision | Enhances operational reliability |

| Maintenance | Ensures long-term safety and performance |

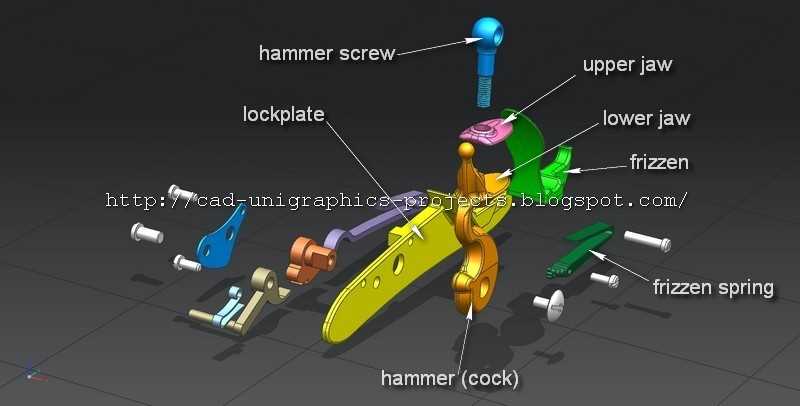

Differences in Hammer Designs

The variety in firing mechanism structures significantly influences performance and user experience. Different designs serve specific functions and offer unique advantages, impacting both the operation and maintenance of the device.

Traditional hammers typically feature a simple, single-piece construction that allows for straightforward operation. Their design emphasizes reliability and ease of use, making them popular among enthusiasts who appreciate classic functionality.

Modern variations, on the other hand, often incorporate advanced materials and engineering techniques. These hammers may include adjustable components or enhanced features that facilitate precision firing. Such innovations cater to those who prioritize accuracy and versatility in their shooting experience.

Another notable distinction lies in the weight and balance of the hammer. Heavier designs can provide more momentum during the firing process, while lighter options may enhance maneuverability and reduce fatigue during extended use. Users often choose based on their individual shooting style and preferences.

Ultimately, understanding the differences in hammer configurations allows users to select the best option for their specific needs, whether they seek tradition or innovation in their firing mechanisms.

Powder Chamber and Its Purpose

The powder chamber plays a crucial role in the functionality of firearms that rely on black powder or similar propellant substances. This essential component serves as a dedicated space where the charge is securely housed before ignition, ensuring optimal performance during firing.

Designed to contain the propellant, the chamber is engineered to withstand the high pressures generated during the combustion process. Its construction often features materials that can endure extreme conditions, providing safety and reliability. By facilitating a controlled environment for ignition, the chamber contributes to the accuracy and efficiency of the projectile’s launch.

Furthermore, the design of the powder chamber can vary based on the specific type of firearm, impacting the overall mechanics of how the weapon operates. Understanding its function is vital for enthusiasts and users alike, as it enhances both maintenance practices and firing precision.

The Stock: Stability and Comfort

The stock of a firearm plays a crucial role in ensuring a steady and enjoyable shooting experience. It serves as the main point of contact between the shooter and the weapon, influencing handling, aim, and overall comfort. A well-designed stock not only enhances stability but also minimizes fatigue during extended use, making it an essential component for both novice and experienced marksmen.

Importance of Design

The design of the stock affects various factors, including grip, balance, and recoil absorption. An ergonomic shape can help maintain a natural wrist position, which is vital for precision. Moreover, materials used in construction can significantly impact weight and durability, contributing to the overall shooting experience.

Types of Stocks

| Type | Description |

|---|---|

| Wooden | Offers a traditional aesthetic and good shock absorption. |

| Synthetic | Lightweight and resistant to weather conditions; often more durable. |

| Adjustable | Allows customization of length and comb height for better fit. |

In conclusion, selecting the right stock is paramount for achieving optimal performance. Whether prioritizing aesthetics, weight, or adjustability, understanding the implications of different designs can lead to a more rewarding shooting experience.

Cleaning Tools for Muzzleloaders

Maintaining the longevity and performance of your firearm requires a selection of appropriate cleaning implements. Proper care is essential for ensuring optimal functionality and safety during use. This section will outline various essential tools that facilitate the cleaning process and contribute to the upkeep of your equipment.

One of the primary instruments needed is a cleaning rod, which allows for effective scrubbing of the barrel. Paired with various brushes, these rods help eliminate fouling and residue accumulated after use. Additionally, patches and jags are crucial for applying solvents and removing debris from the interior surfaces.

Another important tool is the ramrod, designed for ease of use and efficiency. Often made from sturdy materials, it ensures that cleaning processes are both thorough and manageable. Moreover, a good solvent is necessary to break down stubborn residues, making it easier to maintain your gear.

Lastly, a cleaning kit that includes small tools like picks and brushes can be invaluable for accessing tight spots and ensuring that all components are properly serviced. By utilizing the right tools, you can significantly enhance the performance and reliability of your firearm.

Maintenance of Muzzleloader Parts

Ensuring the longevity and reliability of your firearm requires regular upkeep and attention. Proper care involves understanding the different components and implementing effective cleaning and maintenance routines. By following recommended practices, you can enhance performance and extend the lifespan of your equipment.

Routine Cleaning

Regular cleaning is crucial for preventing buildup that can impair functionality. After each use, components should be thoroughly inspected and cleaned to remove residues. Utilize appropriate solvents and brushes to reach intricate areas, ensuring that all traces of fouling are eliminated.

Inspection and Lubrication

Frequent inspections help identify any signs of wear or damage. Pay close attention to moving elements and connections, as these areas are prone to wear over time. Additionally, applying suitable lubricants to specified points can facilitate smooth operation and prevent rusting.