Understanding the internal structure and the various elements that compose a cooling system is crucial for ensuring its longevity and proper functioning. When you have a clear picture of how different segments are arranged and interact, it becomes much easier to troubleshoot issues or carry out maintenance tasks.

In this section, we will explore the layout of various sections and explain their functionality within the cooling mechanism. Whether you’re looking to perform routine upkeep or fix a specific issue, having a detailed understanding of the system’s construction is essential for smooth operation.

Key sections of cooling units often include components that manage airflow, temperature regulation, and energy efficiency. Knowing where these essential elements are located helps in diagnosing potential problems before they escalate. Let’s dive deeper into the specific areas that require attention and offer insights into maintaining these essential systems.

Components Overview

This section provides a detailed exploration of the various elements that make up the cooling system. Each element plays a crucial role in ensuring the efficient and reliable operation of the equipment, contributing to both performance and longevity.

Cooling Unit: The central feature of the system, responsible for maintaining the internal temperature. This unit utilizes a sophisticated process to keep contents cool, even in fluctuating external conditions.

Control Panel: The interface that allows users to manage temperature settings and monitor the overall functionality. This panel is designed for ease of use, with clear indicators and responsive controls.

Thermostat: A key component that regulates temperature by activating or deactivating the cooling process as needed. It ensures that the desired internal environment is consistently maintained.

Ventilation System: Efficient airflow is critical to the proper operation of the cooling equipment. This system helps dissipate heat, preventing overheating and maintaining stable performance.

Each of these components works in harmony to deliver a reliable and efficient cooling experience, ensuring the appliance performs optimally across various conditions.

Key Features of Norcold N811 Model

This cooling appliance is designed to provide reliable and efficient performance, making it a top choice for those seeking functionality and ease of use. Its design prioritizes energy efficiency and convenience, ensuring long-lasting performance in a variety of settings.

- Energy-efficient cooling system that minimizes power consumption while maintaining optimal temperatures.

- Spacious interior layout, allowing for the storage of a variety of items without compromising space.

- Advanced temperature control settings that offer users the ability to customize cooling levels.

- Durable construction materials that ensure longevity and resistance to wear and tear over time.

- Compact and versatile design, ideal for fitting into different environments without taking up excessive space.

With a focus on both performance and ease of use, this cooling unit delivers all the essential features needed for everyday convenience and efficiency.

Understanding the Cooling Unit Assembly

The cooling unit is an essential component responsible for maintaining the desired temperature within refrigeration systems. Its primary function involves efficiently transferring heat out of the cooling chamber to keep stored items at optimal conditions. Understanding how the components of this assembly work together ensures smoother operation and longevity.

Main Components of the Cooling Unit

The assembly consists of several interconnected parts, each playing a crucial role in the cooling process. These components are designed to work in unison to achieve efficient heat transfer and temperature regulation.

- Evaporator: This part absorbs heat from inside the cooling chamber, allowing the temperature to drop.

- Condenser: After the heat is absorbed, the condenser releases it outside the system, helping maintain the interior’s coolness.

- Heat Exchanger: Facilitates the movement of heat between the refrigerant and the surrounding air or liquid

How to Identify Control Board Parts

The control system within many devices includes a central board responsible for managing various functionalities. Understanding how to recognize its components can help with troubleshooting and ensuring optimal performance. By familiarizing yourself with the layout, you can easily locate and identify key elements that are crucial for operation and maintenance.

Main Components Overview

At the core of the control unit, certain elements are commonly found across various models. These include power regulation circuits, signal processors, and connectors that link the board to other parts of the system. Power regulators ensure that voltage levels remain consistent, while signal processors handle communication between the board and the device’s operational mechanisms. Understanding these components is essential for diagnosing potential issues.

Identifying Specific Elements

Each section of the board plays a distinct role, with visual markers such as labels or distinct shapes making it easier to identify. For example, connectors are typically located near the edges and can be recognized by their multiple pins. Capacitors and resist

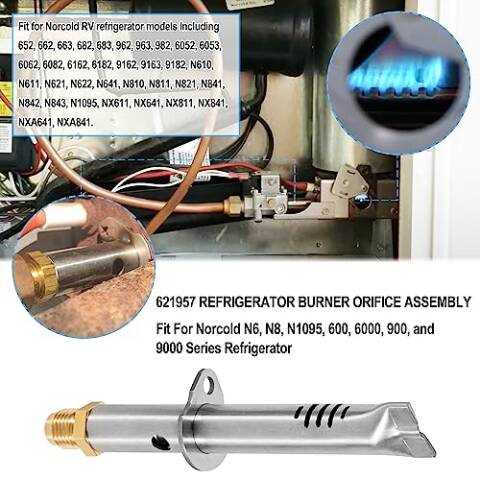

Guide to Burner and Gas Valve Components

The burner and gas valve system plays a crucial role in the overall performance of gas-powered appliances. This section will provide a comprehensive overview of the key elements involved in managing fuel flow and ignition, ensuring optimal heat production and safety. Understanding these components is essential for maintaining the functionality and efficiency of the device.

Main Burner Assembly

The main burner is responsible for producing the flame that generates heat. It consists of a nozzle where the fuel is released and ignited. Proper alignment and cleaning of the burner are essential to ensure an even flame and to prevent blockages that could hinder performance.

Gas Valve Mechanism

The gas valve controls the flow of fuel to the burner. This critical component regulates the amount of gas released based on the appliance’s settings. A well-functioning gas valve ensures that fuel is delivered efficiently, maintaining the right balance between heat

Recognizing Thermistor and Sensor Functions

Understanding the roles of temperature sensors and thermistors is essential for maintaining optimal performance in refrigeration systems. These components play crucial roles in monitoring and regulating temperature, ensuring that the unit operates within the desired range. By accurately sensing temperature variations, they help maintain food preservation and energy efficiency.

Key Functions of Thermistors

Thermistors are temperature-sensitive resistors that change their resistance based on temperature fluctuations. They are commonly used in various applications to provide precise temperature readings. In refrigeration units, thermistors relay critical information to the control system, allowing for adjustments that ensure consistent cooling. Their rapid response time makes them ideal for detecting even minor temperature changes, contributing to the overall reliability of the system.

Importance of Temperature Sensors

Temperature sensors, often integrated with control circuits, monitor the internal environment of cooling appliances. They provide real-time data, which is vital for effective temperature management. By detecting temperature shifts, these sensors enable the system to react accordingly, preventing potential malfunctions or spoilage. The accurate functioning of these sensors is vital for the longevity of refrigeration equipment, as they help maintain optimal conditions for food storage.

Exploring the Power Supply Circuit Layout

The power supply circuit is a crucial component in any electrical system, serving as the backbone that ensures the smooth operation of various devices. Understanding its layout can provide insights into how energy is distributed and regulated throughout the system, contributing to both efficiency and reliability.

Typically, the power supply configuration consists of several key elements, including transformers, rectifiers, and voltage regulators. Each part plays a specific role in converting and managing electrical energy. For instance, transformers adjust voltage levels to meet the requirements of different components, while rectifiers convert alternating current (AC) to direct current (DC).

Furthermore, the circuit layout often features protective mechanisms to prevent damage from overloads or short circuits. Fuses and circuit breakers are essential safety devices that interrupt the flow of electricity in case of abnormal conditions, safeguarding both the equipment and the user.

Understanding the arrangement of these components can aid in troubleshooting and maintenance, allowing for quicker identification of issues that may arise. A well-organized power supply layout not only enhances performance but also ensures a longer lifespan for the overall system.

Common Issues with the Door Assembly

The door assembly of a refrigeration unit plays a crucial role in maintaining the internal temperature and efficiency. However, various problems can arise that affect its functionality and performance. Understanding these issues can help in troubleshooting and ensuring the longevity of the appliance.

Frequent Problems

- Misalignment: A common issue occurs when the door is not properly aligned, leading to gaps that allow cold air to escape. This can result in inefficient cooling and increased energy consumption.

- Seal Damage: Worn or damaged seals can prevent the door from closing securely, compromising the unit’s ability to maintain the desired temperature.

- Hinges Wear: Over time, the hinges may become loose or damaged, causing difficulty in opening and closing the door smoothly.

Troubleshooting Tips

- Inspect the door alignment and adjust it as needed to ensure a tight fit.

- Examine the seals for any signs of wear or damage, and replace them if necessary.

- Check the hinges for looseness and tighten or replace them if they show signs of wear.

By addressing these common issues, users can enhance the performance of their refrigeration unit and prolong its lifespan.

Fan and Airflow System Explained

The cooling mechanism of a refrigeration unit relies heavily on the effective circulation of air. This process is vital for maintaining optimal temperatures within the storage space, ensuring that the items stored remain fresh and properly preserved. A well-designed airflow system not only enhances the performance of the cooling unit but also improves energy efficiency and reduces wear on components.

At the heart of this system is the fan, which plays a crucial role in promoting air movement. It draws in air from the surroundings and facilitates the distribution of cool air throughout the compartment. By creating a consistent flow, the fan helps to regulate temperature and prevents hotspots from forming within the unit.

Understanding the components and functionality of the airflow system can aid in troubleshooting and maintenance. Below is a table that outlines the key elements involved in the airflow mechanism:

Component Function Fan Circulates air to maintain consistent temperatures. Air Ducts Guide airflow to various sections within the storage area. Vents Allow for the intake and exhaust of air, promoting airflow. Filters Trap dust and debris, ensuring clean air circulation. In conclusion, the fan and airflow system is an integral aspect of refrigeration technology, contributing significantly to the efficiency and effectiveness of temperature regulation. Proper understanding and maintenance of these components can lead to enhanced performance and longevity of the cooling unit.

Detailed Look at Interior Shelving Parts

Exploring the interior shelving components of a refrigerator system reveals their essential roles in optimizing storage and organization. Understanding the functionality and structure of these elements can enhance user experience and ensure efficient usage of space.

Key Components of Interior Shelving

- Support Brackets: These crucial elements provide stability and strength to the shelving units, allowing them to bear weight securely.

- Glass Shelves: Transparent surfaces that maximize visibility, enabling users to easily locate items while also contributing to the aesthetic appeal.

- Adjustable Racks: These versatile features offer customization options, allowing users to modify shelf heights according to their storage needs.

- End Caps: These protective elements prevent items from slipping off the edges, ensuring a safer and more organized interior.

Benefits of Quality Shelving

- Improved organization of stored items, making it easier to find essentials.

- Enhanced storage capacity through adjustable features, accommodating various sizes of products.

- Increased durability, ensuring that shelves withstand daily use without warping or breaking.

- Aesthetic enhancement, contributing to an overall pleasing interior design.

Investing in high-quality shelving components not only improves functionality but also elevates the overall user experience by creating a well-organized and visually appealing environment.

Maintenance Tips for Seals and Gaskets

Proper upkeep of seals and gaskets is essential for ensuring the efficient operation of various appliances. These components are crucial in preventing leaks and maintaining optimal performance. Regular attention can prolong their lifespan, reduce the need for replacements, and enhance the overall functionality of your system.

Regular Inspection

Conduct routine checks to identify any signs of wear, cracks, or damage. Look for areas where the seal might be compressing or deforming, as this could indicate that it needs replacement. Keeping an eye on these components can help you catch issues early, preventing larger problems down the line.

Cleaning and Lubrication

Maintaining cleanliness around seals and gaskets is vital. Use a gentle cleaning solution to remove any debris or buildup that may affect their performance. Additionally, applying a suitable lubricant can enhance flexibility and effectiveness, ensuring a tight seal and preventing deterioration over time.

Installation Guide for the Norcold N811 Refrigerator

This section provides a comprehensive overview of the installation process for your refrigerator model. Proper installation ensures optimal performance and longevity of the unit, allowing you to enjoy reliable cooling in your mobile or stationary space.

Before you begin, it is crucial to gather all necessary tools and materials. Follow these steps to facilitate a smooth installation:

- Ensure that the installation area is clean and free from debris.

- Check the dimensions of the refrigerator and the designated space to confirm a proper fit.

- Gather tools such as a screwdriver, level, and adjustable wrench.

Once you have prepared the area and gathered your tools, proceed with the following steps:

- Positioning the Unit:

- Carefully lift the refrigerator into the designated space.

- Ensure that it is level by using a level tool.

- Connecting the Power Supply:

- Locate the electrical connection point.

- Securely connect the power wires, ensuring proper insulation and safety measures are followed.

- Ventilation Setup:

- Ensure that the unit is installed with adequate airflow around it.

- Check that ventilation openings are not blocked.

After completing these steps, double-check all connections and ensure that everything is securely in place. Once satisfied, you can power on the unit and monitor its performance to confirm successful installation.

Safety Precautions for Handling Refrigerator Parts

When working with cooling appliances, it is essential to prioritize safety to prevent accidents and ensure proper functionality. Understanding how to manage components carefully can significantly reduce the risk of injury and damage.

Always Disconnect Power: Before starting any maintenance or repairs, ensure that the unit is unplugged from the electrical outlet. This will help prevent electrical shocks and short circuits.

Wear Protective Gear: It is advisable to wear gloves and safety goggles while handling different elements. This protective equipment can safeguard you from sharp edges and hazardous materials.

Work in a Well-Ventilated Area: Ensure that you are in a space with adequate airflow. This is particularly important when dealing with refrigerants or cleaning substances that may release harmful fumes.

Handle with Care: Components should be treated delicately to avoid breakage. Dropping or mishandling them can lead to injuries or further damage to the appliance.

Follow Manufacturer Guidelines: Always consult the manufacturer’s recommendations for safe handling procedures. Adhering to these instructions can help ensure that all actions taken are compliant with safety standards.

Dispose of Materials Properly: When replacing any elements, ensure that old or damaged materials are disposed of in accordance with local regulations. This is crucial for both safety and environmental considerations.