In this section, we delve into detailed illustrations that outline the inner workings of a popular espresso machine model. These diagrams serve as invaluable resources for both enthusiasts and professionals seeking a comprehensive understanding of machine functionality.

Visual representations within these schematics elucidate the intricate interplay of components responsible for delivering a perfect cup of espresso. Each part’s role and placement are meticulously depicted, aiding in diagnostics and troubleshooting.

By examining these diagrams, one gains insights into the engineering precision behind espresso machine design, fostering a deeper appreciation for the craftsmanship involved in creating such devices.

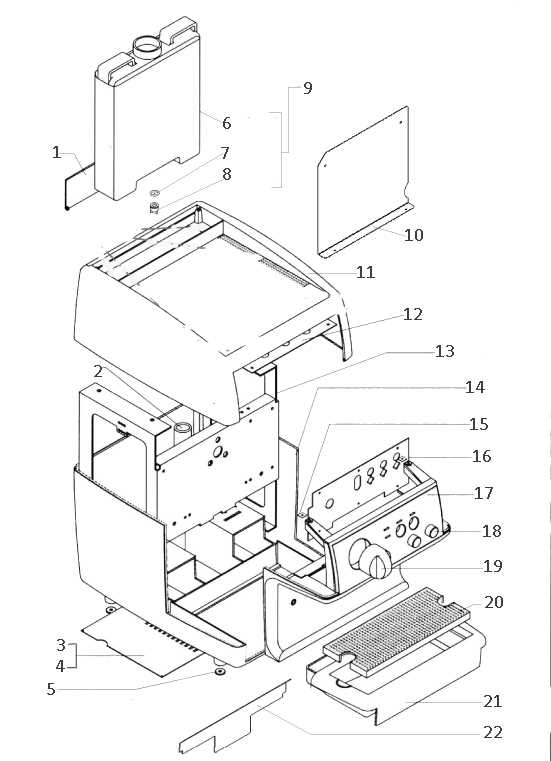

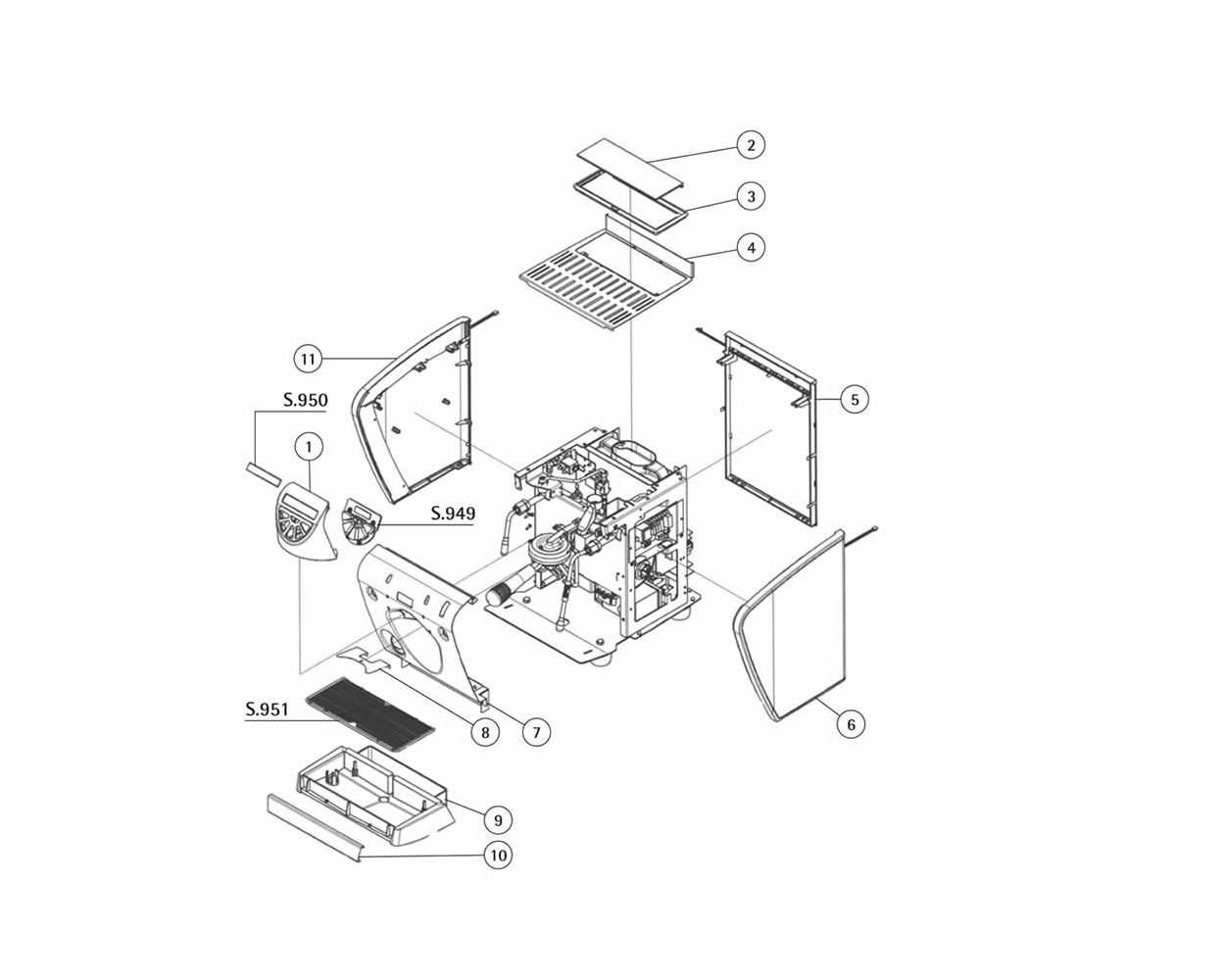

This section will provide a comprehensive overview of a popular espresso machine known for its reliability and performance in the coffee brewing industry. Understanding the various components and their functions is essential for both maintenance and optimal operation. This guide aims to simplify the intricate assembly of the machine, enabling users to grasp its structure and the role of each element.

| Component | Description | Function |

|---|---|---|

| Boiler | The heating element responsible for producing steam and hot water. | Essential for brewing espresso and steaming milk. |

| Group Head | The part where coffee is brewed. | Holds the coffee basket and controls water flow. |

| Pump | Creates the pressure needed to extract coffee. | Delivers water through the coffee grounds. |

| Water Tank | Reservoir for fresh water. | Supplies water to the machine. |

| Steam Wand | Used for frothing milk. | Creates steam for milk texturing. |

Importance of Accurate Parts Diagram

Having a precise representation of components is crucial for the effective maintenance and repair of machinery. Such illustrations provide users with the necessary information to identify and understand the function of each element, facilitating informed decisions during servicing. A well-structured visual guide can significantly enhance efficiency and reduce the likelihood of errors.

Clarity in maintenance tasks is one of the primary benefits of accurate representations. Technicians can quickly locate the required components, minimizing downtime and expediting repairs. Furthermore, this clarity helps in training new staff, allowing them to familiarize themselves with the equipment more efficiently.

Moreover, properly labeled visual aids ensure that users can easily communicate issues and solutions. This is especially beneficial in collaborative environments, where team members must work together to address technical challenges. Ultimately, having a detailed illustration supports not only individual proficiency but also enhances overall operational effectiveness.

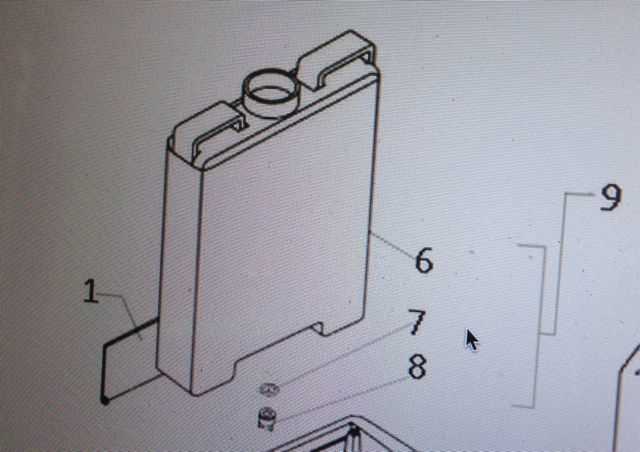

Common Components of the Oscar Model

This section explores the essential elements found in a well-known espresso machine model. Understanding these components is crucial for proper maintenance and optimal performance. Each part plays a significant role in the machine’s functionality, contributing to the overall brewing process.

Main Functional Elements

- Boiler: The primary heating unit responsible for maintaining the desired water temperature for brewing.

- Group Head: The part where the coffee is extracted, directly interacting with the coffee grounds.

- Portafilter: A detachable handle that holds the coffee grounds during the brewing cycle.

- Steam Wand: A tool used to froth and heat milk for various beverages.

Supporting Mechanisms

- Pressure Gauge: Monitors the pressure during extraction, ensuring optimal brewing conditions.

- Water Reservoir: The storage area for water, feeding the boiler and enabling multiple brewing cycles.

- Control Panel: The interface that allows the user to operate and adjust settings on the machine.

- Drip Tray: Collects excess water and coffee, keeping the workspace tidy and clean.

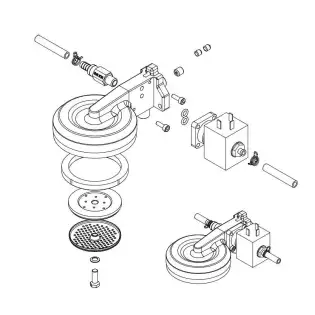

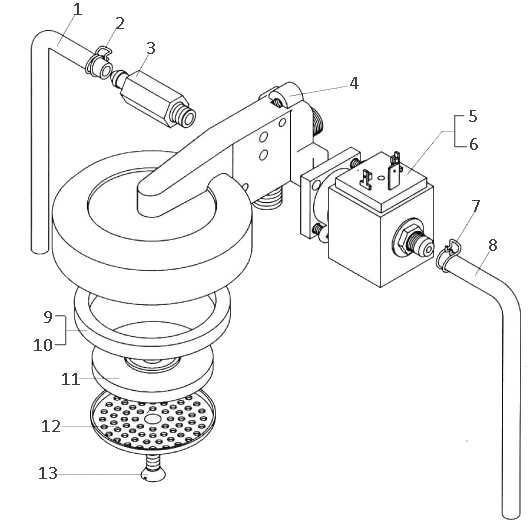

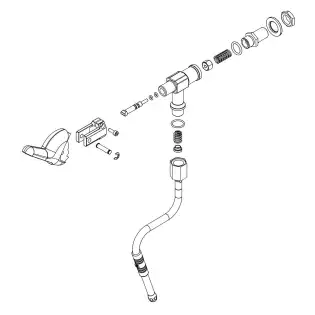

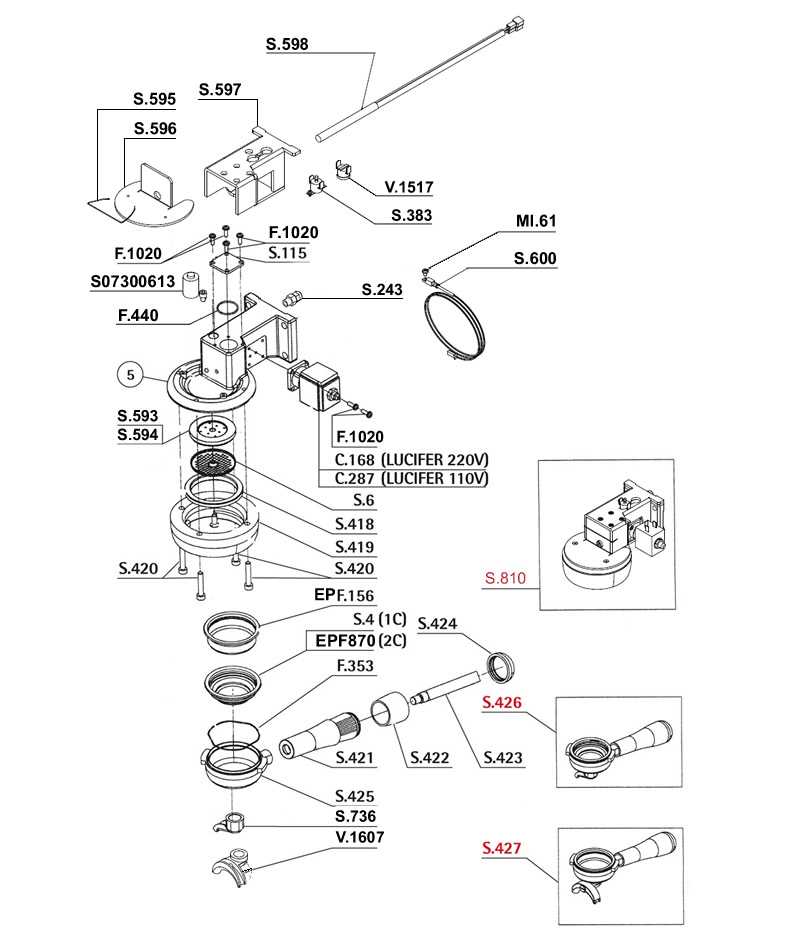

Understanding the Brew Group Assembly

The brew group assembly is a crucial component of any espresso machine, playing a vital role in the extraction process. This assembly encompasses various elements that work together to ensure optimal brewing performance. By understanding its structure and functionality, users can better appreciate how to maintain and troubleshoot their equipment effectively.

Key Components of the Brew Group

At the heart of the brew group assembly are several essential parts that contribute to its overall efficiency. Familiarity with these components can aid in recognizing potential issues and performing routine maintenance. Below is a summary of the main parts involved:

| Component | Description |

|---|---|

| Brew Head | The part where coffee is extracted and brewed under pressure. |

| Filter Basket | A receptacle that holds the coffee grounds during brewing. |

| Shower Screen | Distributes hot water evenly over the coffee grounds. |

| Piston | Creates pressure to push water through the coffee grounds. |

Maintenance Tips for Longevity

Regular maintenance of the brew group assembly is essential for ensuring its longevity and consistent performance. Cleaning and inspecting each component will prevent clogs and build-up, which can adversely affect the quality of the espresso. Users are advised to follow a routine cleaning schedule and replace worn-out parts as necessary.

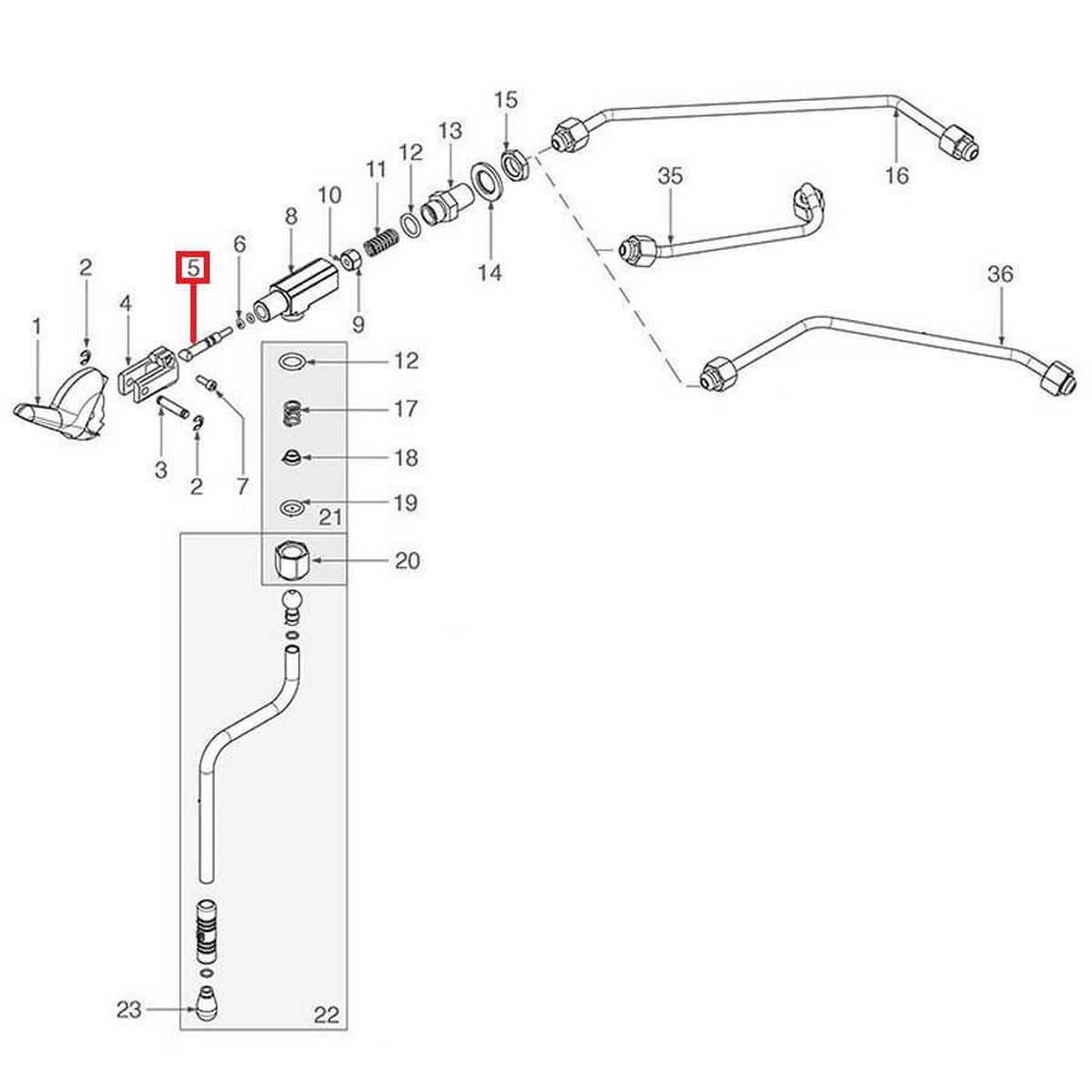

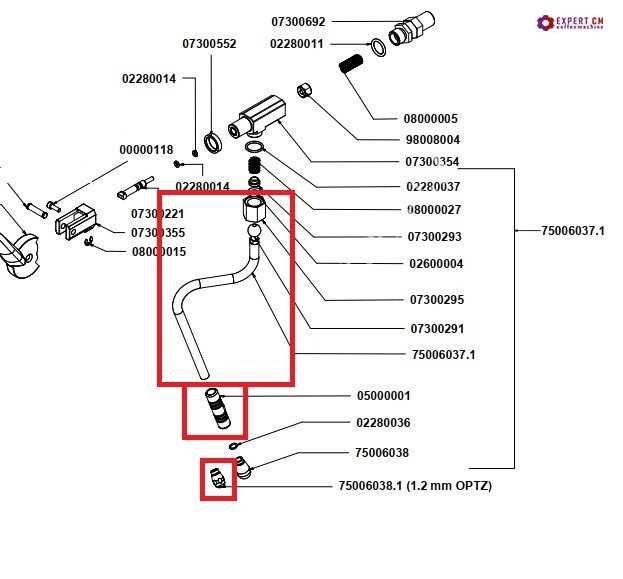

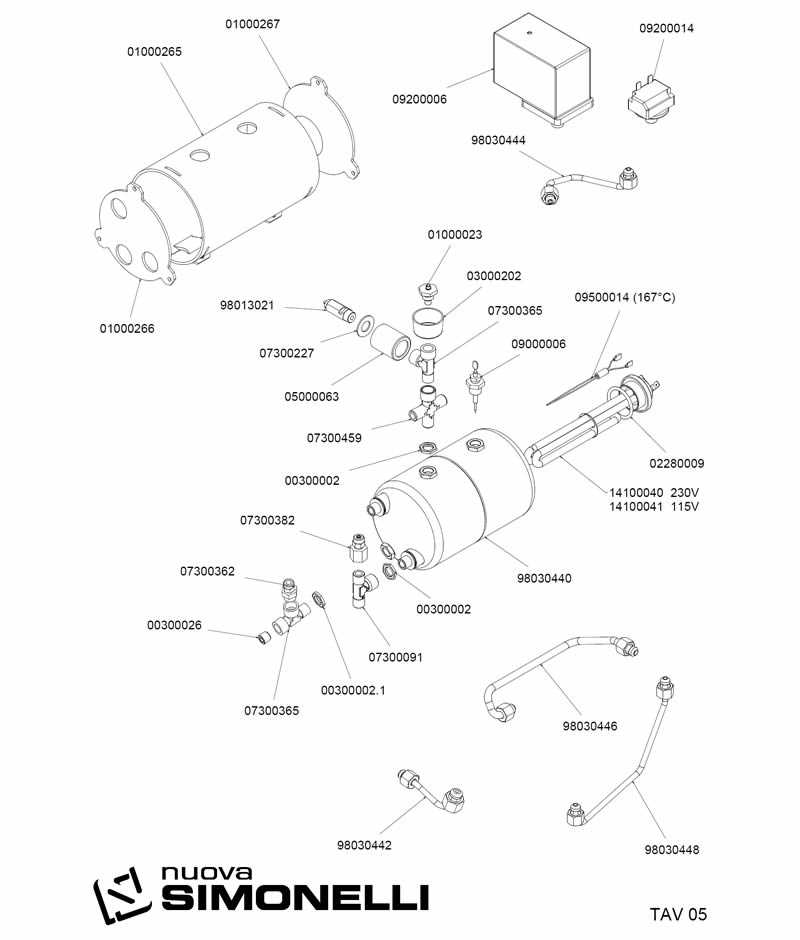

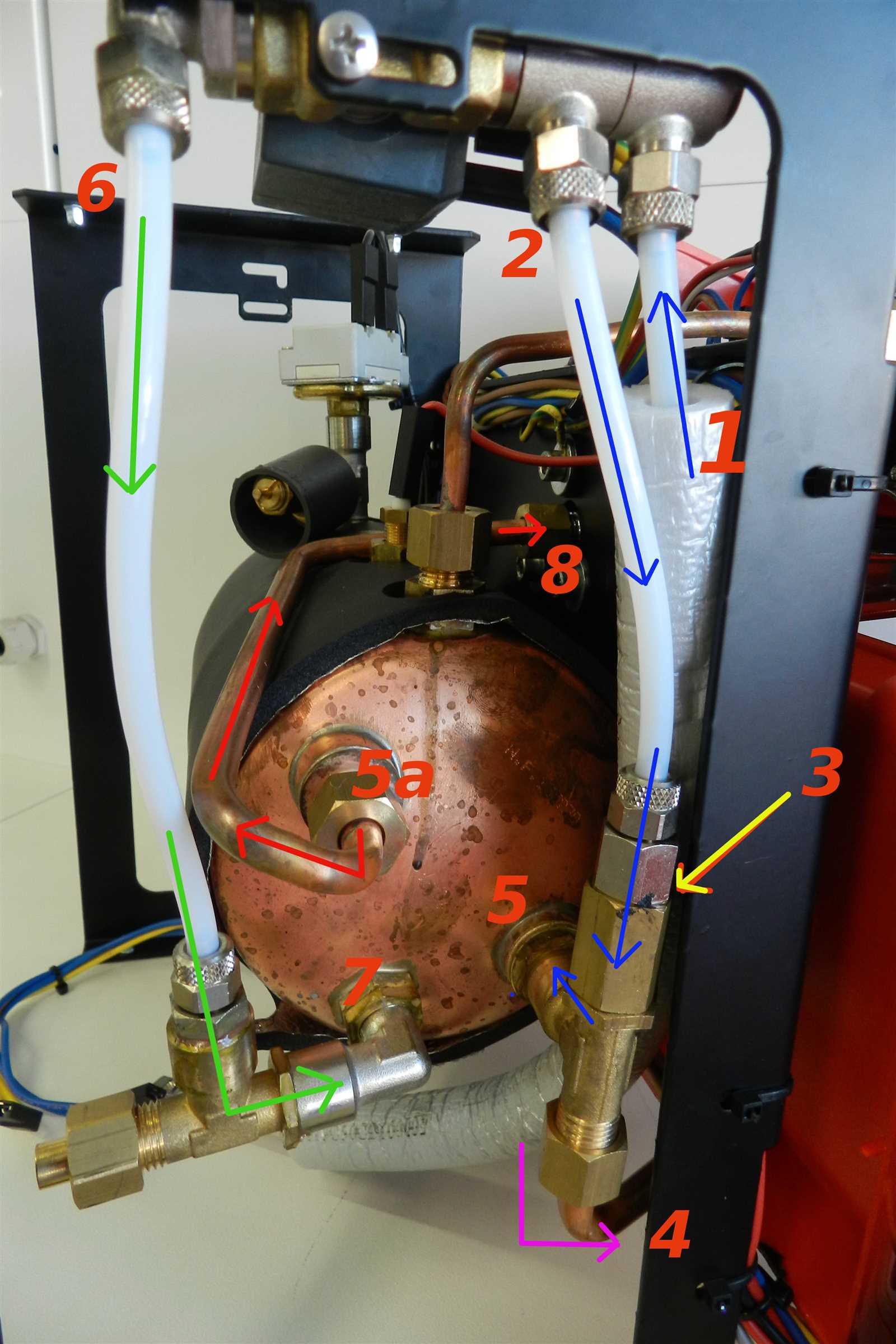

Exploring the Water Circulation System

The water circulation system is a vital component in espresso-making machines, ensuring that hot water flows efficiently through the brew group and extraction process. This system is designed to optimize the brewing temperature and maintain consistent pressure, which are crucial for producing high-quality beverages. Understanding its various elements can greatly enhance the maintenance and troubleshooting of the machine.

At the heart of this system lies the pump, which draws water from the reservoir and pushes it through a series of channels. These channels are engineered to minimize resistance and ensure a smooth flow, allowing for optimal extraction of flavors. Additionally, various fittings and valves regulate the pressure and prevent backflow, ensuring that water only moves in the intended direction.

| Component | Function |

|---|---|

| Pump | Draws water from the reservoir and creates pressure. |

| Heating Element | Heats water to the ideal brewing temperature. |

| Valves | Control the flow of water and maintain pressure. |

| Hoses | Transport water between components. |

| Group Head | Where water is directed for brewing. |

By regularly inspecting and maintaining the water circulation components, users can ensure that their machines operate efficiently and consistently produce high-quality drinks.

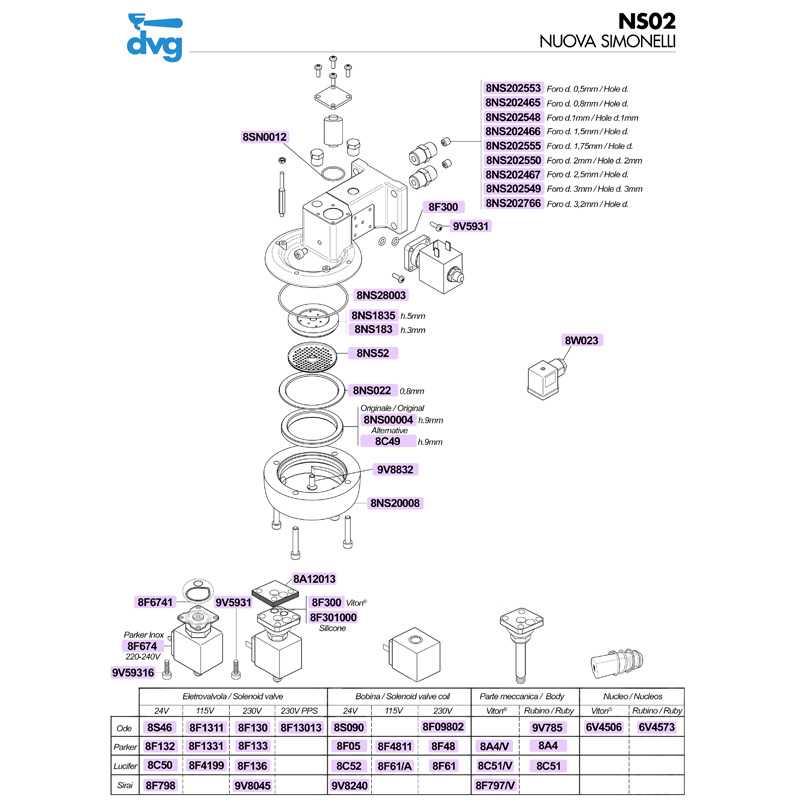

Electrical Parts and Their Functions

This section explores the various components responsible for the electrical operations within the espresso machine. Understanding these elements is essential for effective maintenance and troubleshooting, as they play a crucial role in the overall performance of the device.

The control board serves as the brain of the machine, managing all operations and ensuring proper communication between different components. It regulates the heating element, which is vital for maintaining the desired temperature of the water used in brewing.

Another key component is the pump, which generates the necessary pressure to extract flavors from the coffee grounds. This part is crucial for delivering a rich and balanced espresso. Additionally, the temperature sensor monitors the heat levels, providing feedback to the control board to maintain optimal brewing conditions.

Wiring and connectors are essential for facilitating electrical flow between various components. Properly functioning connections ensure reliable operation and minimize the risk of electrical failures. Each of these elements contributes significantly to the efficient functioning of the espresso machine.

Identifying Maintenance Items for Longevity

Effective upkeep of equipment is crucial for ensuring its durability and optimal performance over time. Regular maintenance not only enhances functionality but also prevents costly repairs and replacements. By recognizing key components that require attention, users can prolong the lifespan of their machines and maintain consistent operation.

Routine checks and servicing of vital elements, such as seals, filters, and cleaning mechanisms, play a significant role in preserving efficiency. Implementing a structured maintenance schedule allows for early detection of wear and tear, ensuring that all parts are in peak condition. Furthermore, using quality replacements and adhering to manufacturer guidelines can significantly impact overall reliability and performance.

Additionally, training personnel on proper usage and care practices can lead to improved longevity. Understanding the intricacies of the machinery, including its operational limits and common issues, empowers users to make informed decisions about maintenance tasks. A proactive approach not only mitigates potential breakdowns but also enhances the overall user experience.

How to Interpret the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and troubleshooting. This guide will help you decipher the various elements illustrated in the schematic, enabling you to identify each segment and its function within the larger assembly.

Key Symbols and Labels

Each component is typically denoted by specific symbols or numbers, which correspond to a legend or key. Familiarizing yourself with these notations is crucial for accurate identification. Common symbols may include circles for connectors, squares for housing units, and lines for electrical pathways.

Reading the Layout

The arrangement of parts often follows a logical flow, reflecting the operational sequence of the device. By examining the layout, you can trace how each component interacts with others, providing insights into potential issues and repair strategies.

| Symbol | Description |

|---|---|

| ◯ | Connector |

| □ | Housing unit |

| ── | Electrical pathway |

| Δ | Adjustment point |

Common Issues and Replacement Parts

In any machine, wear and tear over time can lead to various malfunctions, necessitating the need for certain components to be replaced. Understanding the typical problems that arise can help users identify solutions quickly and efficiently. Regular maintenance and timely replacements are key to ensuring optimal performance and longevity of the equipment.

Frequent Malfunctions

Among the most prevalent issues are inconsistent brewing temperatures and pressure fluctuations. These problems can stem from faulty heating elements or malfunctioning pressure regulators. Identifying these symptoms early can prevent further damage and ensure a smooth operation.

Essential Components for Replacement

To address these common issues, it is crucial to have access to reliable components. Heating elements and pressure regulators are vital for maintaining proper functionality. Additionally, gaskets and filters play a significant role in preserving the integrity of the machine. Ensuring that these components are readily available will facilitate quicker repairs and enhance overall efficiency.

Finding Authentic Nuova Simonelli Parts

When it comes to maintaining your espresso machine, sourcing genuine components is crucial for ensuring optimal performance and longevity. Identifying trustworthy suppliers and understanding the significance of using original items can greatly impact the quality of your brews. This section will guide you through the process of acquiring authentic replacements for your equipment.

Identifying Reliable Suppliers

Begin your search by exploring authorized dealers and specialized retailers. These establishments often provide a comprehensive range of original components, ensuring compatibility with your device. Additionally, they can offer valuable insights and recommendations for your specific needs.

Importance of Genuine Components

Using authentic items ensures not only the efficiency of your machine but also its safety. Counterfeit or substandard replacements can lead to malfunction and damage, potentially voiding any existing warranties. Prioritizing genuine components safeguards your investment and enhances the overall brewing experience.

Tips for Efficient Parts Replacement

When it comes to replacing components in a coffee machine, efficiency is key. Ensuring that the process is smooth not only saves time but also minimizes potential issues during reassembly. This section provides valuable insights on how to streamline the replacement process, making it easier for both novice and experienced technicians.

Preparation is Essential

Before beginning any replacement task, proper preparation can greatly enhance efficiency. Gathering all necessary tools and components in advance reduces the chances of interruptions during the process. Consider the following items:

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove and install screws |

| Wrench | For loosening and tightening nuts |

| Replacement Components | To ensure correct functioning |

| Cleaning Supplies | To keep the machine in optimal condition |

Follow a Systematic Approach

Adopting a methodical approach during the replacement process can prevent mistakes. It is beneficial to document the steps taken, which can serve as a useful reference for future tasks. Additionally, keeping components organized and labeled can significantly reduce confusion and facilitate a seamless replacement experience.