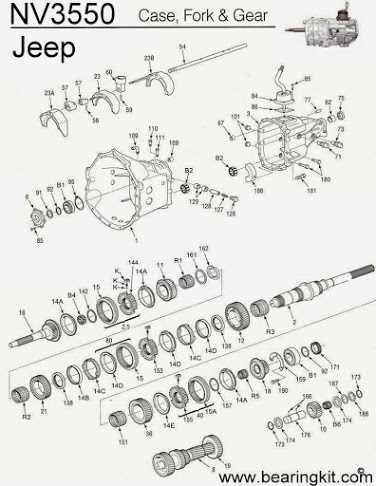

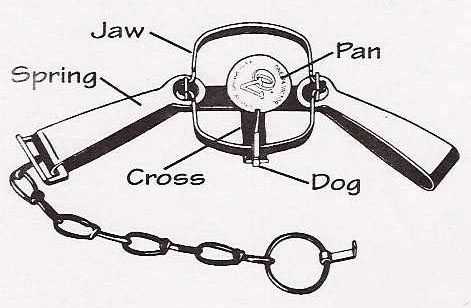

Shift forks – guide the gears during shifts

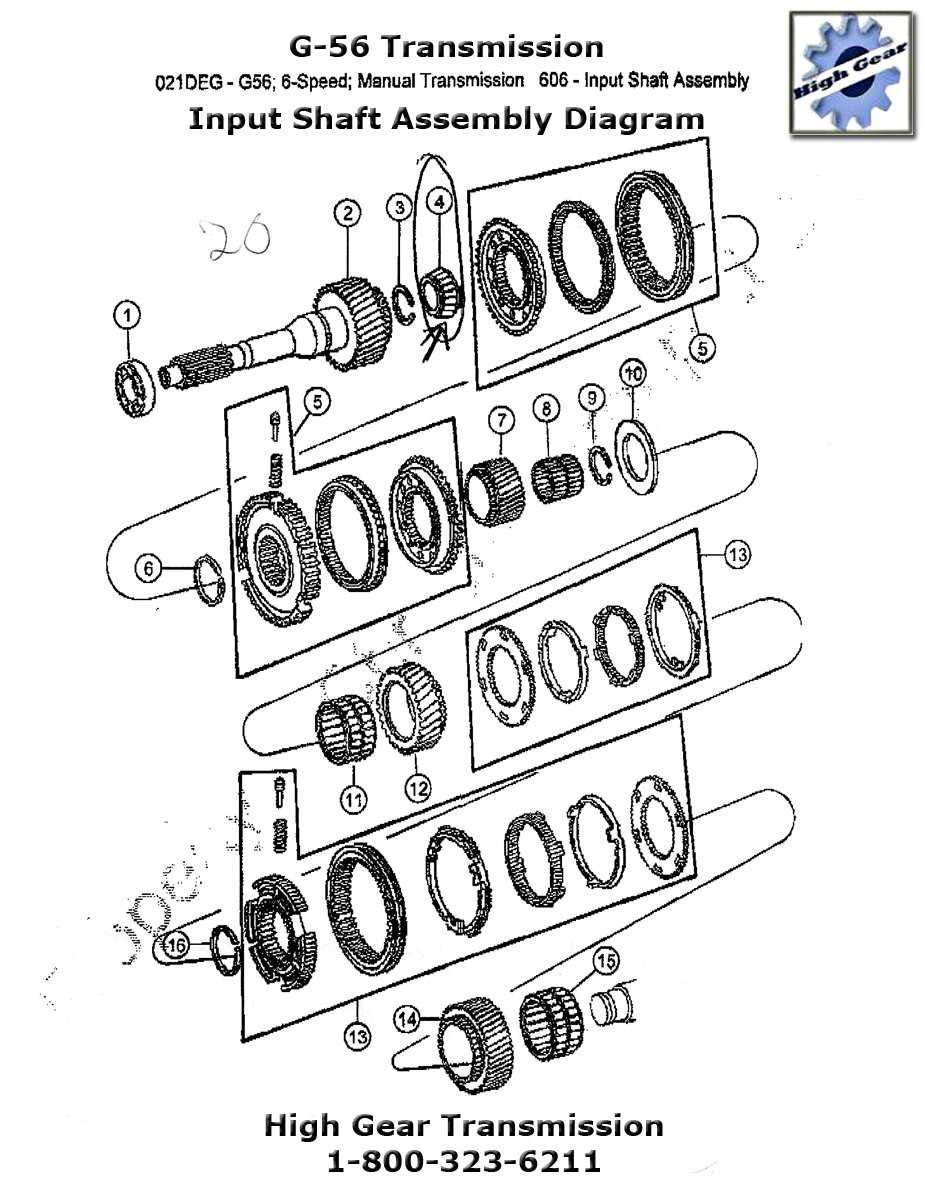

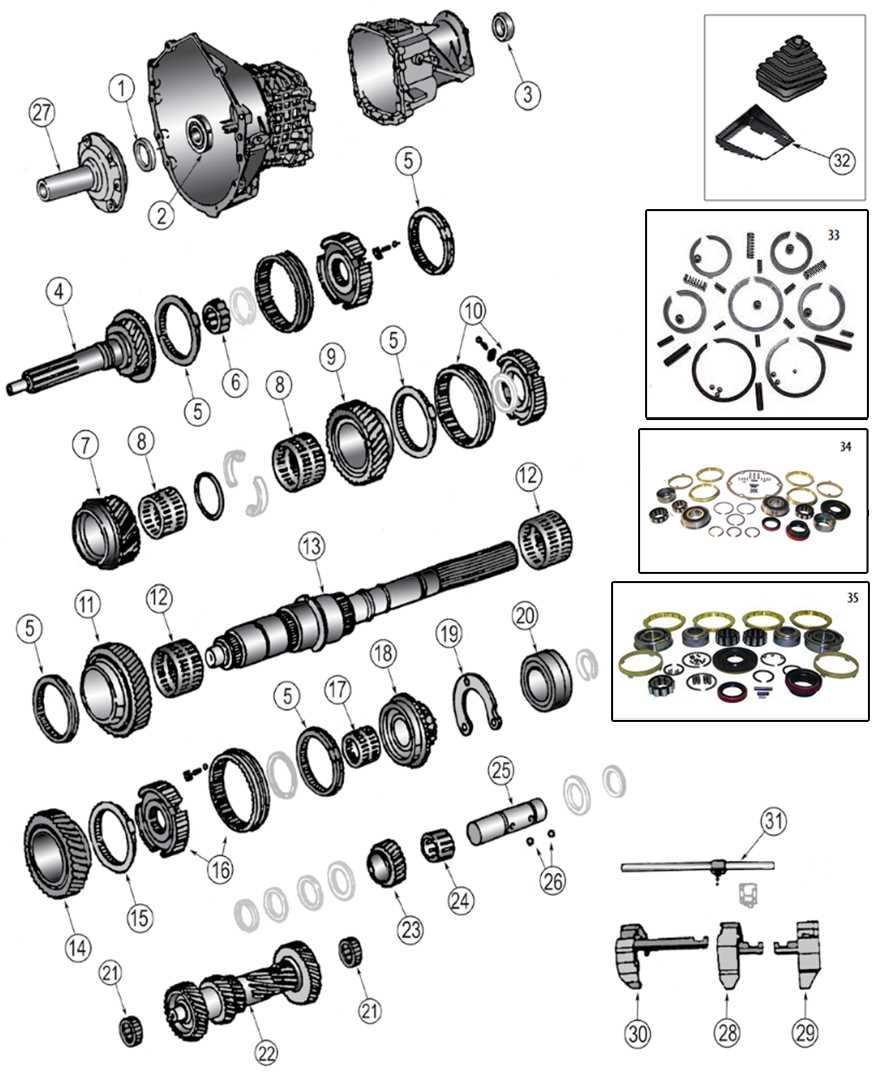

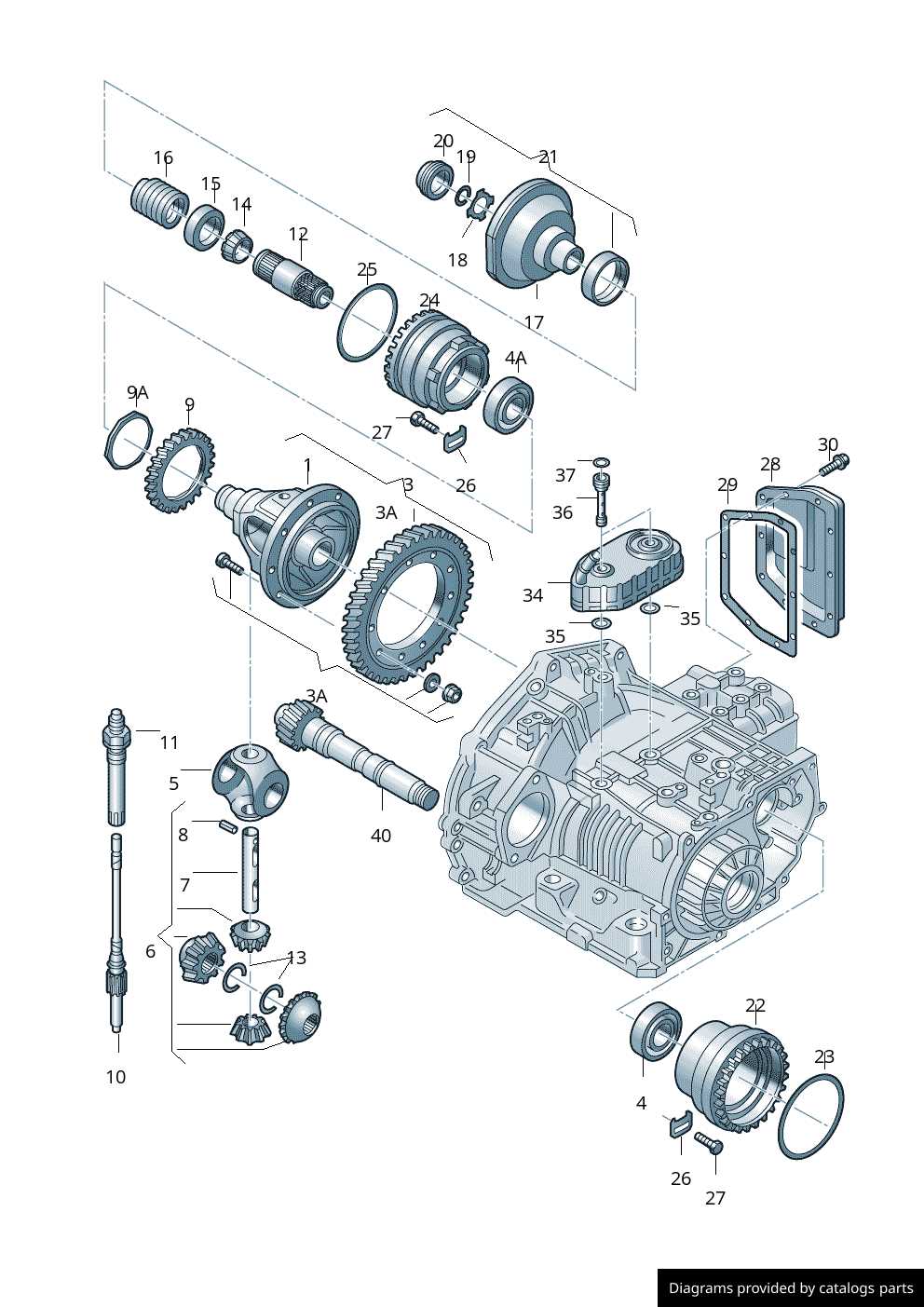

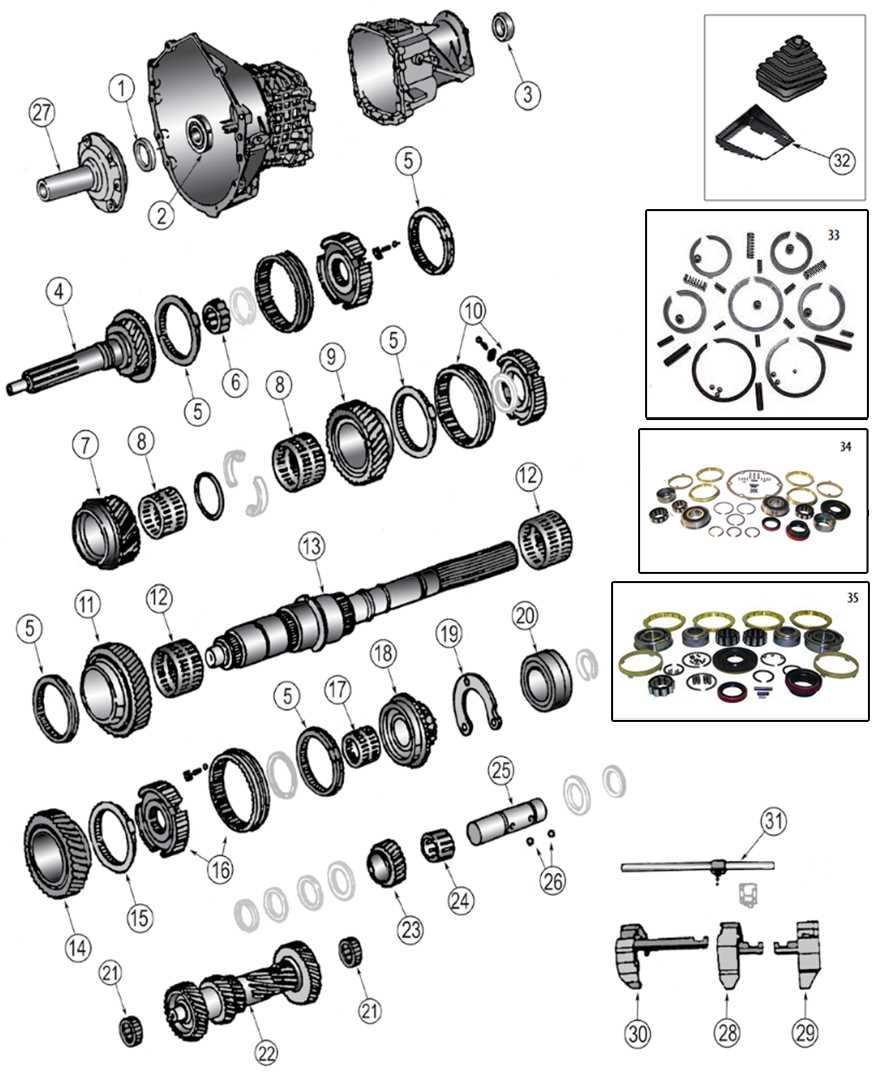

Identifying Key Nv3550 Parts

Understanding the essential components of this transmission system is crucial for anyone working on repairs or upgrades. By familiarizing yourself with the critical elements, you can improve both troubleshooting and maintenance efficiency.

Main Structural Elements

- Gear Assembly: The core of the system, responsible for transferring power and adjusting speed.

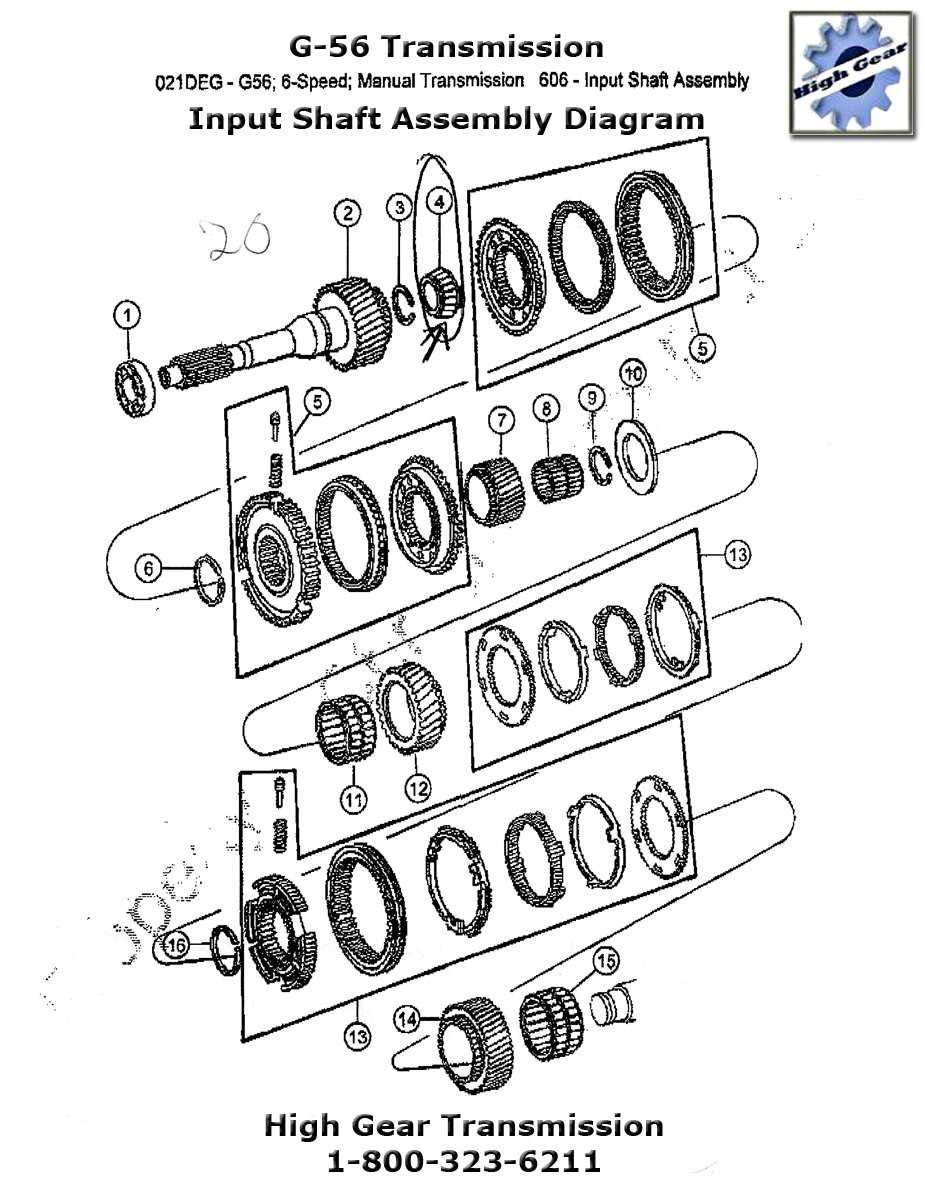

- Input Shaft: Connects to the engine, transmitting torque into the system.

- Output Shaft: Directs power from the transmission to the vehicle’s drivetrain.

Supporting Mechanisms

- Synchronizers: Help smooth gear changes, preventing grinding or wear.

- Bearings: Reduce friction between rotating parts, ensuring smooth operation.

- Seals and Gaskets: Prevent leakage of fluids, maintaining optimal performance.

Gear Ratios and Synchronizers in Nv3550

The balance between gear ratios and synchronizers plays a crucial role in ensuring smooth and efficient shifting. Proper calibration of these components allows for optimized torque transfer and seamless transitions between gears, making it essential for the overall performance of the transmission system. Understanding the interaction between these elements is key to maintaining durability and functionality in various driving conditions.

Importance of Gear Ratios

Gear ratios determine the relationship between engine speed and the speed of the wheels. A well-designed ratio allows for both high acceleration and fuel efficiency. Lower ratios provide more power for towing or off-road driving, while higher ratios contribute to smoother highway driving. Balancing these ratios ensures that the vehicle operates at its peak across different scenarios.

The Role of Synchronizers

Synchronizers are critical in managing the engagement of gears by aligning them to the same speed before they mesh. This prevents grinding and extends the lifespan of the gear system. High-quality synchronizers reduce the effort required to shift and enhance the overall driving experience, providing precise and quick gear changes without damaging the components.

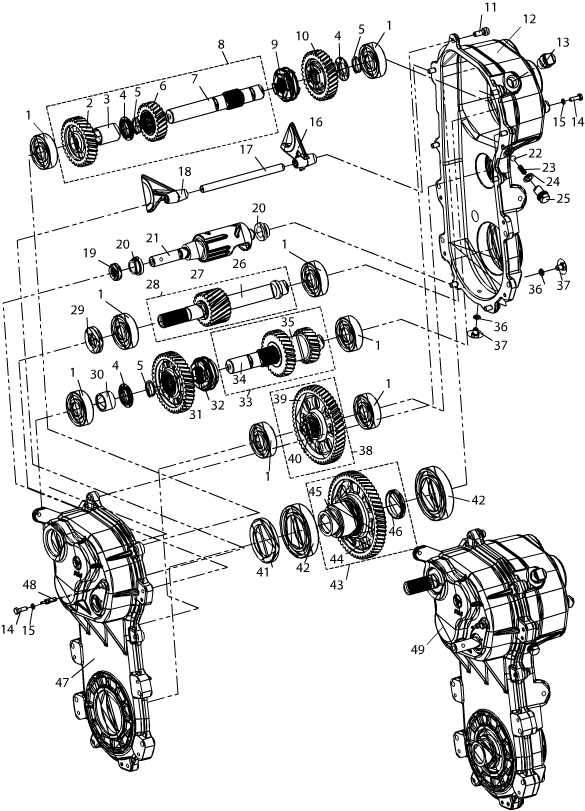

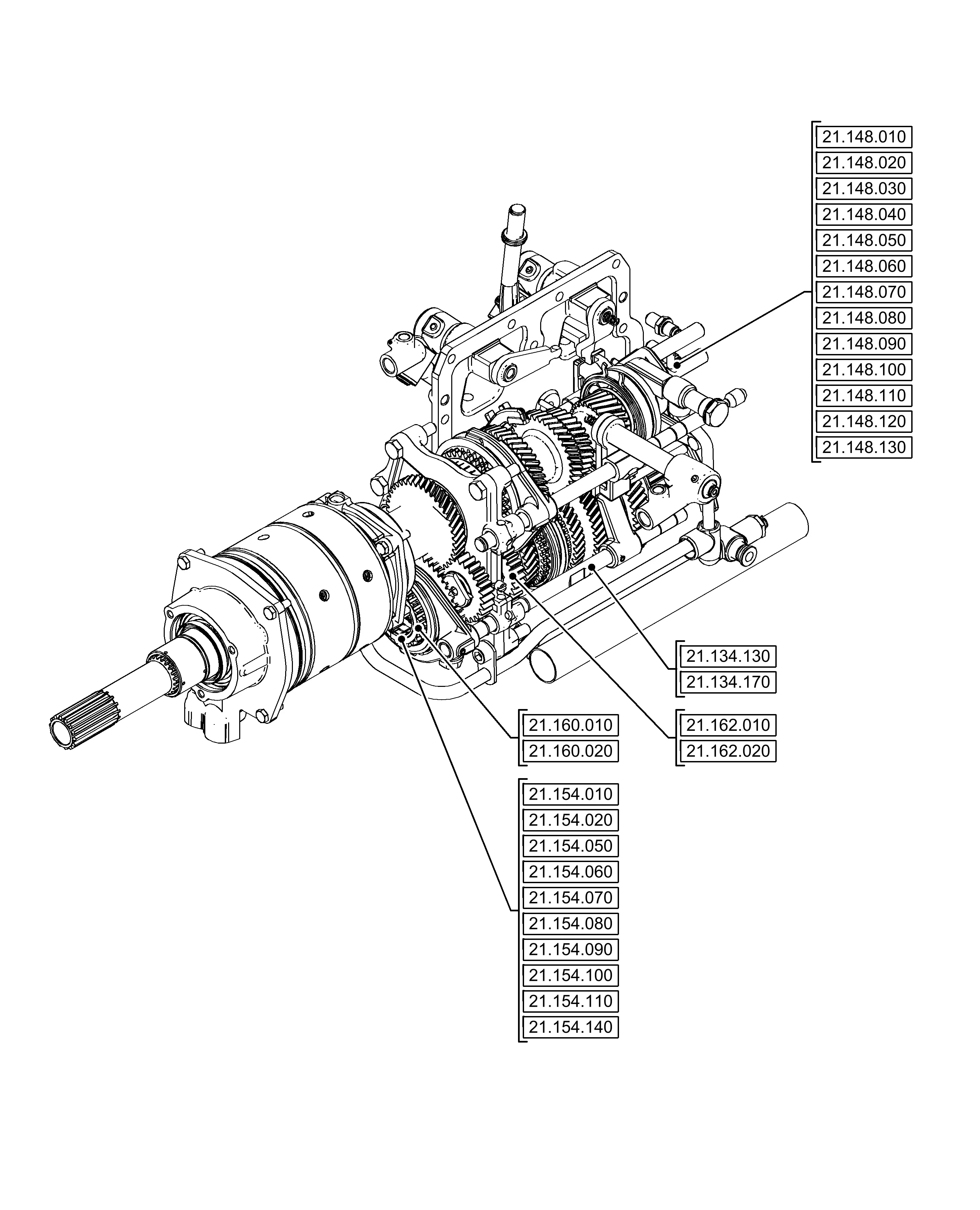

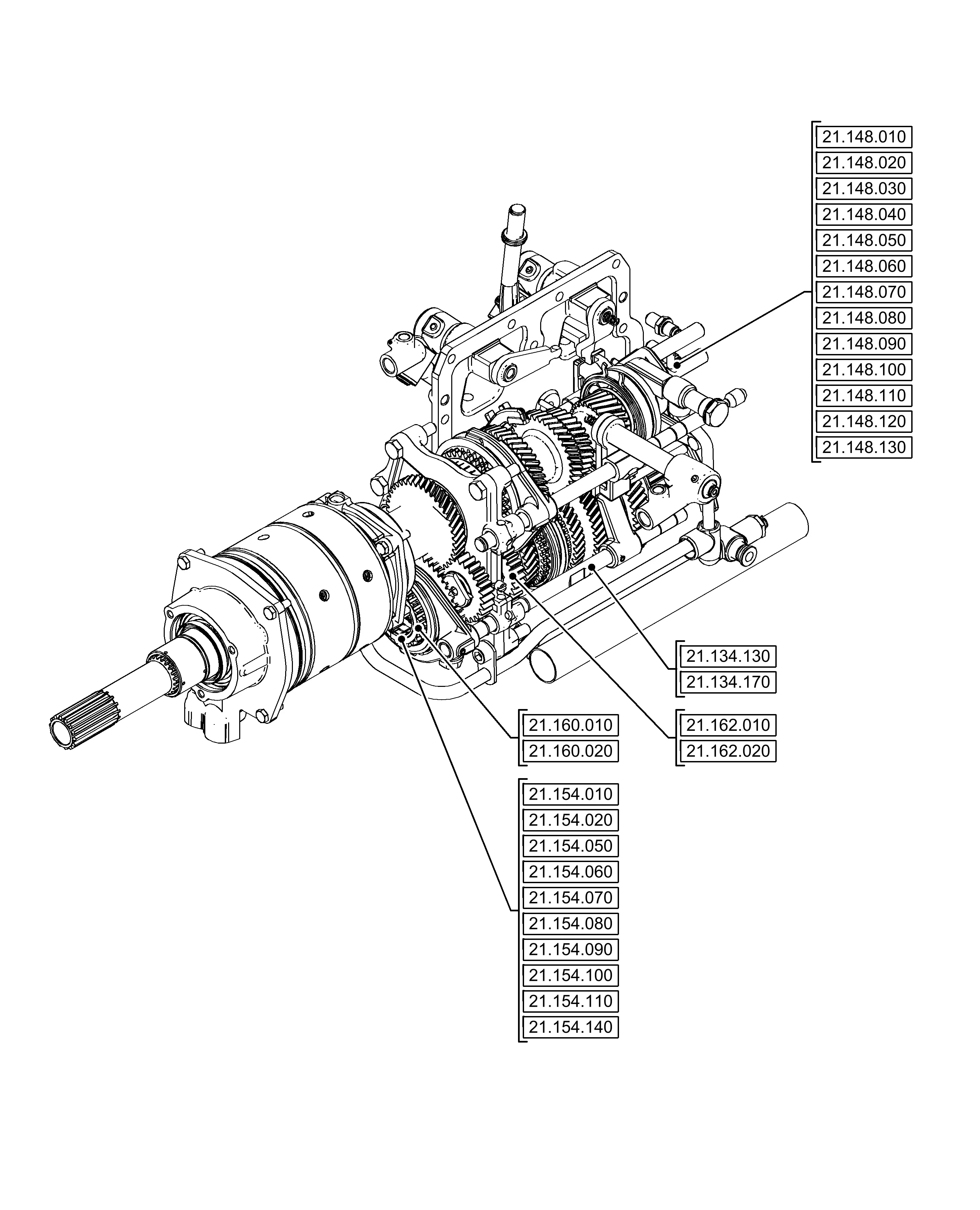

Shifting System in Nv3550 Assembly

The shifting mechanism in this transmission assembly plays a crucial role in facilitating smooth gear transitions. It involves a series of components that work together to ensure precise engagement and disengagement of gears, providing the driver with optimal control over the vehicle’s power delivery. Understanding the functionality and arrangement of these elements is essential for effective maintenance and performance enhancement.

Components of the Shifting Mechanism

At the core of the shifting system is the gear lever, which initiates the change in gears when actuated by the driver. This lever is connected to a series of linkages that transmit motion to the internal components, allowing for the selection of various gear ratios. Synchronizers are also integral to this process, as they facilitate smooth engagement by matching the speeds of the gears before they connect.

Operational Process

When the driver moves the gear lever, it triggers a series of movements within the assembly. The linkages translate the lever’s motion to the shift forks, which then engage the synchronizers. As the gears align, the system ensures that the transition is seamless, minimizing the risk of grinding or damaging the components. Proper alignment and maintenance of these parts are vital for the longevity and efficiency of the entire assembly.

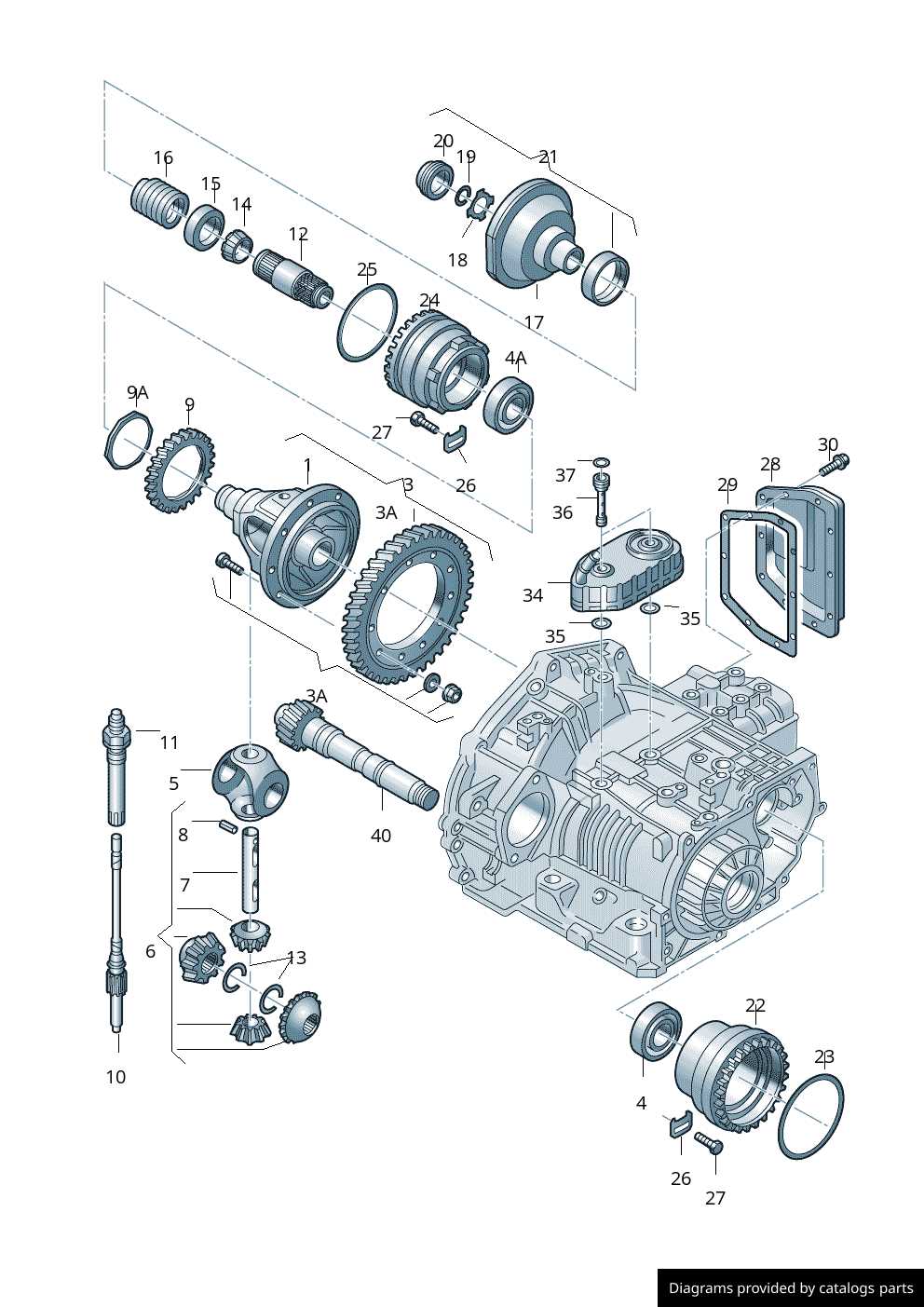

Bearings and Seals in Nv3550 Transmission

In any mechanical assembly, the role of components that facilitate smooth movement and prevent fluid leakage is crucial. These elements not only ensure optimal performance but also contribute significantly to the longevity of the entire system. Understanding their structure and function is essential for effective maintenance and repair.

Bearings are integral to minimizing friction between moving parts, allowing for efficient rotation and movement. Seals, on the other hand, act as barriers to contain lubricants and protect against contaminants. The interplay between these two types of components is vital for the reliable operation of the transmission system.

| Component Type |

Function |

Common Materials |

| Bearings |

Reduce friction and facilitate smooth movement |

Steel, ceramic, plastic |

| Seals |

Prevent fluid leakage and protect against contaminants |

Rubber, silicone, polymer |

Regular inspection and timely replacement of these components can prevent premature wear and potential failure of the system. Proper selection of bearings and seals based on application requirements will enhance performance and durability.

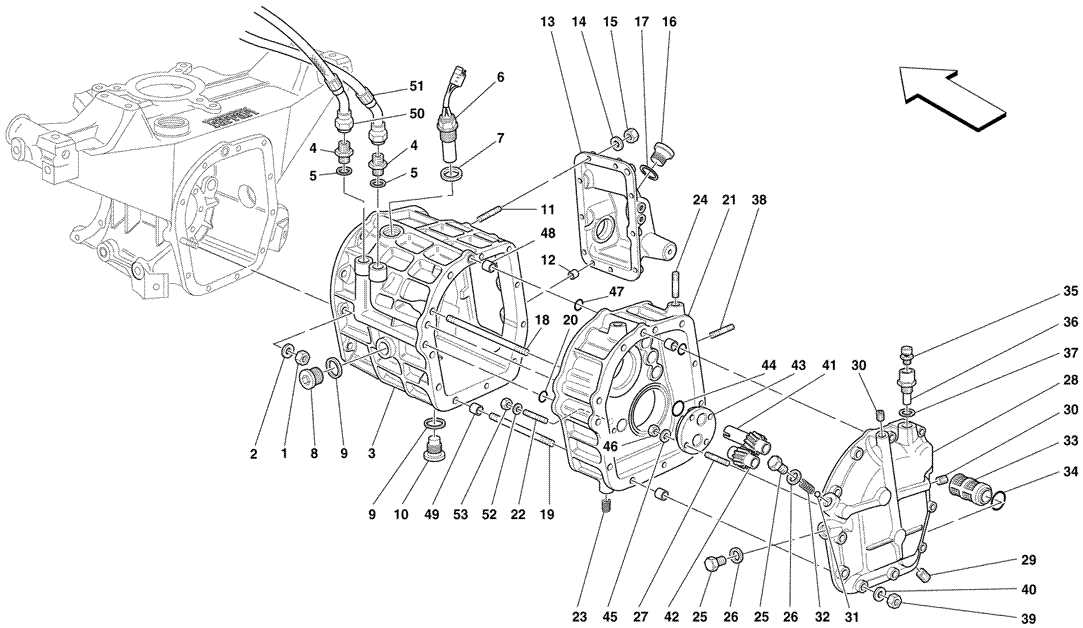

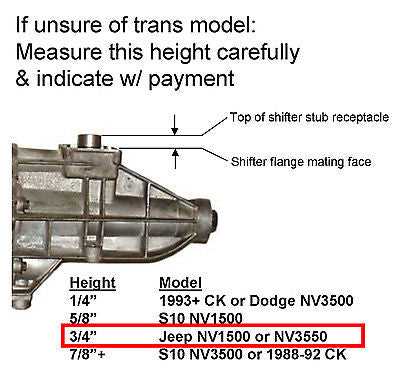

Clutch System and Nv3550 Compatibility

The clutch assembly plays a vital role in the operation of manual transmissions, allowing for smooth gear shifts and vehicle control. Understanding how different components interact within this system is essential for ensuring optimal performance, especially when considering aftermarket options or upgrades.

When assessing compatibility with various transmissions, several factors come into play:

- Pressure Plate: The pressure plate must be compatible with the specific design of the transmission to ensure proper engagement and disengagement.

- Clutch Disc: Choosing the right clutch disc is crucial as it affects torque transfer and the overall feel of the pedal.

- Release Bearing: A suitable release bearing is necessary for smooth operation during gear changes.

- Flywheel: The flywheel should match the clutch system to provide adequate support and durability.

It’s important to note that while many components may appear similar, small differences can significantly impact functionality. Therefore, consulting manufacturer specifications and compatibility charts is advisable before making any modifications or replacements.

Ultimately, ensuring that all elements of the clutch system work harmoniously will enhance both performance and longevity, providing a more enjoyable driving experience.

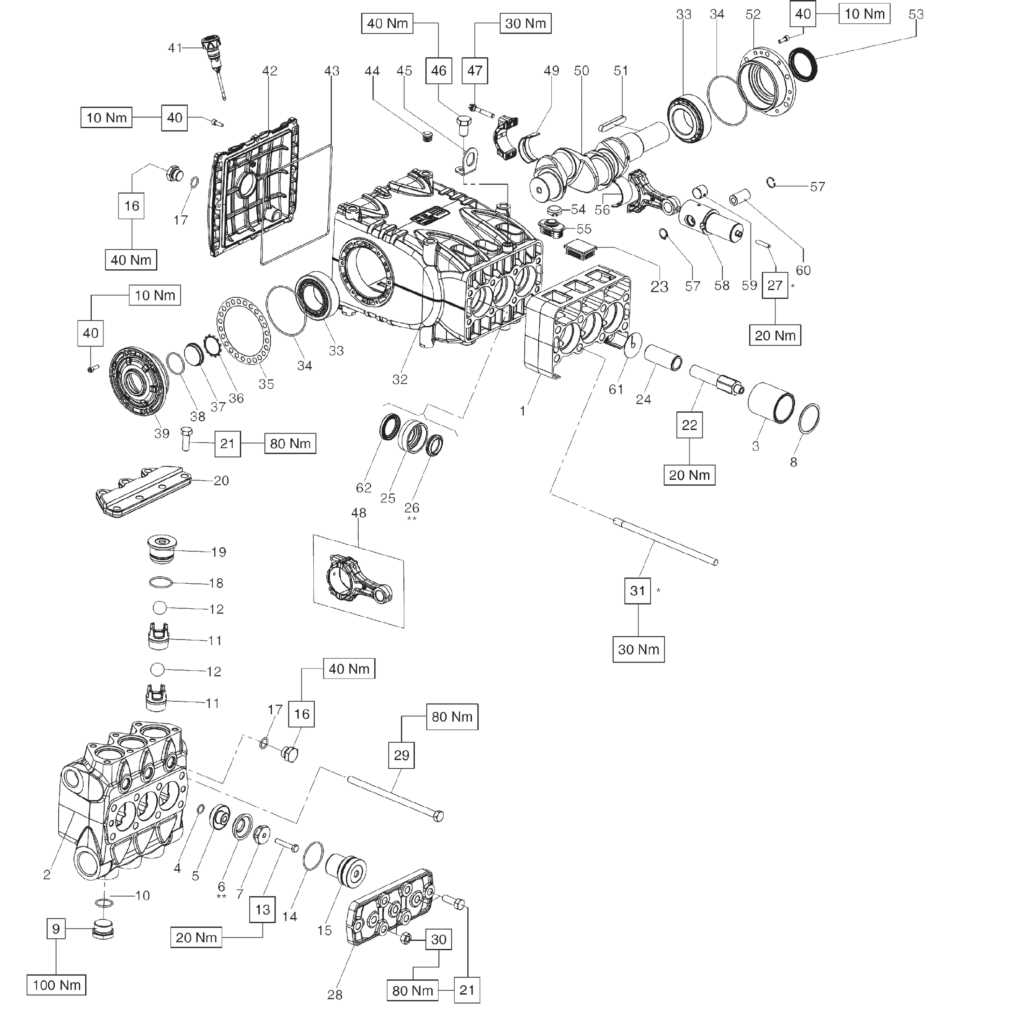

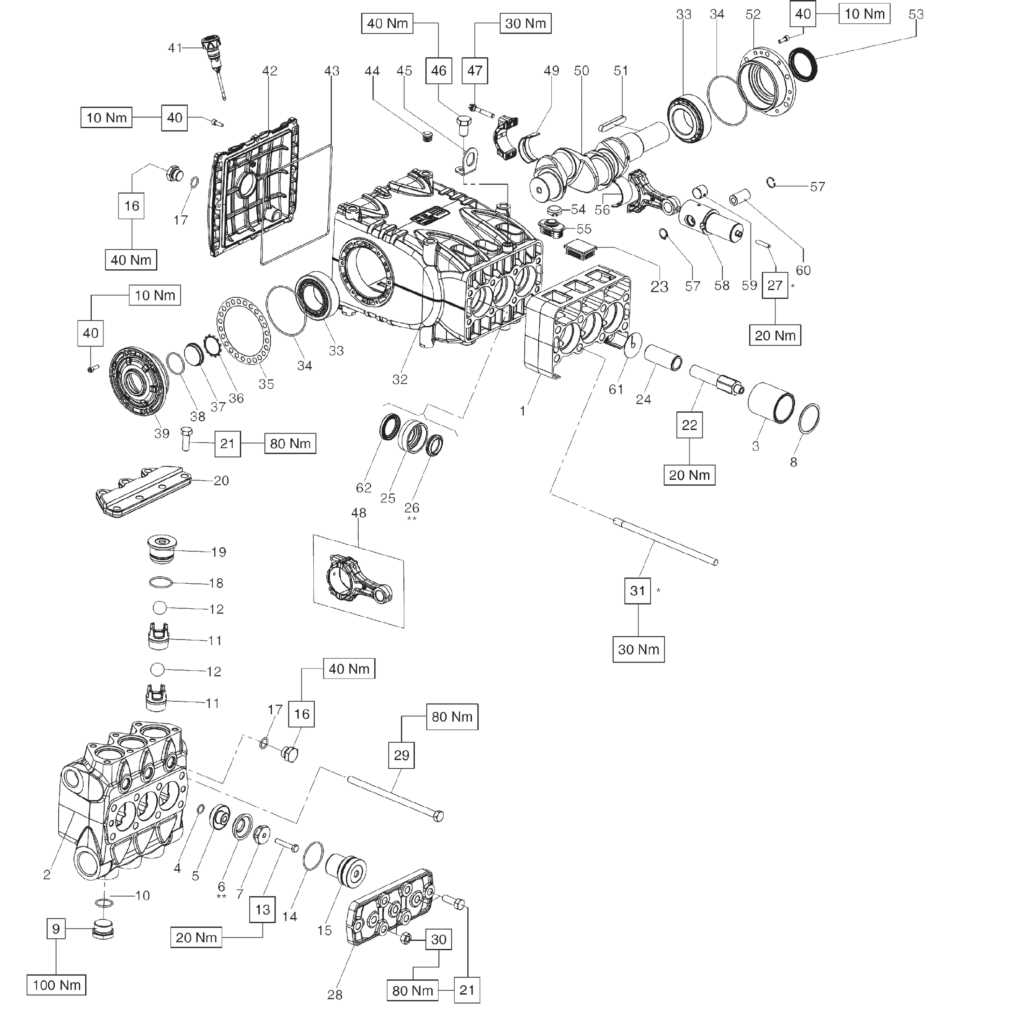

Torque Specifications for Nv3550 Parts

Understanding the appropriate torque settings is crucial for ensuring the longevity and performance of your vehicle’s components. Correctly tightening fasteners prevents issues such as leaks, failures, and misalignments. This section provides essential specifications that should be adhered to when assembling various components.

Below are the recommended torque values for specific components:

- Transmission Case Bolts:

- Shift Fork Bolts:

- Output Shaft Nut:

- Input Shaft Bearing Retainer:

- Mounting Bolts:

Always use a calibrated torque wrench when applying these specifications. Adhering to these values will ensure optimal performance and prevent premature wear or damage to the assembly.

Maintenance Tips for Nv3550 Components

Proper upkeep of automotive transmission components is essential for ensuring optimal performance and longevity. Regular maintenance can prevent premature wear and tear, enhance efficiency, and reduce the risk of costly repairs. Below are some effective strategies to maintain these crucial elements.

Regular Inspections

Conducting routine inspections is vital for identifying potential issues early on. Check for leaks, unusual noises, and any signs of wear. Inspect fluid levels and condition, ensuring they meet manufacturer specifications. Addressing minor problems promptly can prevent them from escalating into major failures.

Fluid Changes

Changing transmission fluid at recommended intervals is crucial for maintaining performance. Old fluid can lose its effectiveness, leading to overheating and increased friction. Use the specified type of fluid to ensure compatibility with the components. Regular fluid replacement contributes to smoother operation and extends the life of the system.

Common Nv3550 Transmission Issues

Automotive enthusiasts and mechanics alike often encounter various challenges related to a specific manual gearbox. Understanding these common complications is crucial for effective troubleshooting and maintenance. This section delves into prevalent problems that may arise, along with potential solutions to enhance the performance and reliability of the transmission system.

Common Problems

Several issues can manifest within the transmission assembly, affecting its efficiency and operation. Below are some of the most frequently reported concerns:

| Issue |

Description |

Possible Solutions |

| Shifting Difficulties |

Drivers may experience resistance or grinding noises while shifting gears. |

Check fluid levels and quality; adjust linkage if necessary. |

| Fluid Leaks |

Transmission fluid may leak from seals or gaskets, leading to low fluid levels. |

Inspect and replace faulty seals or gaskets; top off fluid levels. |

| Overheating |

Excessive heat can cause performance degradation and damage. |

Ensure proper cooling; check for blockages in the cooling system. |

| Noisy Operation |

Unusual noises during operation can indicate internal wear or damage. |

Inspect internal components for wear; consider rebuilding or replacing. |

Conclusion

Addressing these common transmission issues promptly can prevent further complications and prolong the lifespan of the assembly. Regular maintenance and vigilant observation are essential to ensure smooth operation and reliable performance.

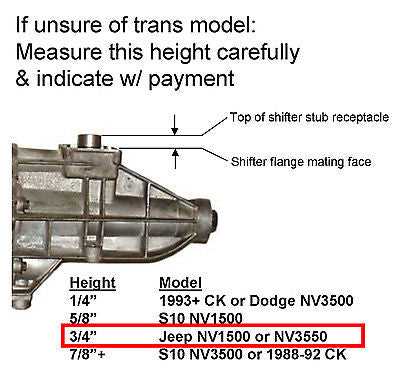

Replacement Guide for Nv3550 Parts

This section provides an essential overview for those looking to source components for their manual transmission system. Understanding the various elements that may need replacement is crucial for maintaining optimal performance and reliability.

When considering replacements, it’s important to identify the specific components that are most susceptible to wear and tear. Common areas of concern often include synchronizers, bearings, and seals, which play a vital role in the overall functionality of the assembly.

Additionally, one should take into account the compatibility of new components with existing systems. Ensuring that parts meet quality standards and specifications will enhance durability and performance. A thorough assessment of options available in the market will also aid in making informed decisions.

Regular maintenance and timely replacement can prevent more significant issues down the line, making it essential to stay vigilant about the condition of each component. By following this guide, you will be better equipped to manage the upkeep of your transmission system effectively.