The intricate machinery used in modern agriculture comprises various components that work in harmony to ensure optimal performance. A thorough grasp of these elements is essential for effective maintenance and troubleshooting. This section delves into the key elements that comprise these agricultural devices, highlighting their functions and interconnections.

By familiarizing oneself with the layout and specifications of these components, operators can significantly enhance their understanding of the equipment. This knowledge aids in identifying potential issues and facilitates timely repairs, ultimately leading to improved efficiency and productivity in the field.

In this exploration, we will examine the structure and arrangement of critical components, providing insights into their respective roles within the machinery. Recognizing the importance of each part will empower users to make informed decisions regarding repairs and replacements, contributing to the longevity and reliability of their agricultural tools.

Key Features of the Oliver 550

The remarkable qualities of this agricultural machinery make it an essential asset for farmers seeking efficiency and reliability. This equipment stands out due to its robust construction, innovative design, and user-friendly operation, ensuring that it can tackle a variety of tasks with ease.

Robust Construction

Crafted from high-quality materials, this machinery is designed to withstand the rigors of fieldwork. Its durable frame ensures longevity, allowing it to endure harsh conditions without compromising performance.

User-Friendly Operation

The intuitive controls and ergonomic design facilitate seamless operation, making it accessible for both novice and experienced operators. This aspect significantly enhances productivity, allowing users to focus on their tasks rather than troubleshooting complex systems.

| Feature | Description |

|---|---|

| Powerful Engine | Delivers exceptional performance and efficiency for various agricultural applications. |

| Versatile Attachments | Compatible with a wide range of implements to enhance functionality. |

| Advanced Technology | Incorporates modern innovations for improved operation and monitoring. |

| Compact Design | Allows for maneuverability in tight spaces while maintaining stability. |

Importance of Accurate Parts Diagrams

Precise visual representations of components play a crucial role in various fields, particularly in machinery maintenance and repair. These illustrations serve as a vital reference for technicians and engineers, enabling them to identify, locate, and replace elements effectively. When clarity and accuracy are prioritized, it significantly enhances the efficiency of repair processes and minimizes the risk of errors.

Enhanced Understanding of Assembly

Well-crafted visuals provide a comprehensive overview of how individual components fit together. This understanding aids technicians in comprehending the overall structure and functionality of the equipment. Moreover, clear depictions facilitate smoother assembly and disassembly, reducing the time spent troubleshooting issues.

Streamlining Maintenance Processes

Accurate visuals are essential for streamlining maintenance routines. When personnel can quickly reference high-quality illustrations, they can perform inspections and repairs more efficiently. This leads to improved operational uptime and overall productivity, ensuring that machinery remains in optimal working condition.

Common Issues with Oliver 550 Parts

Maintenance and repair of agricultural machinery often reveal a range of challenges that operators may encounter over time. Understanding these difficulties is crucial for ensuring optimal performance and longevity of equipment. Below are some frequently observed problems that may arise with various components of a particular tractor model, along with possible solutions.

Worn Components

Many mechanical parts experience wear due to regular use, leading to reduced efficiency. Identifying these worn elements early can prevent further damage and costly repairs. Regular inspections are essential to detect signs of fatigue or degradation.

Misalignment Issues

Misalignment between different assemblies can result in inefficient operation and increased strain on the machinery. Ensuring that all components are properly aligned is vital for maintaining optimal performance and reducing the risk of premature failure.

| Issue | Description | Recommended Action |

|---|---|---|

| Worn Gears | Reduced effectiveness and potential slippage | Regularly inspect and replace as needed |

| Hydraulic Leaks | Loss of hydraulic fluid can lead to decreased performance | Check seals and hoses for damage; replace as necessary |

| Overheating | Excessive heat can cause component failure | Ensure proper cooling system function and regular fluid changes |

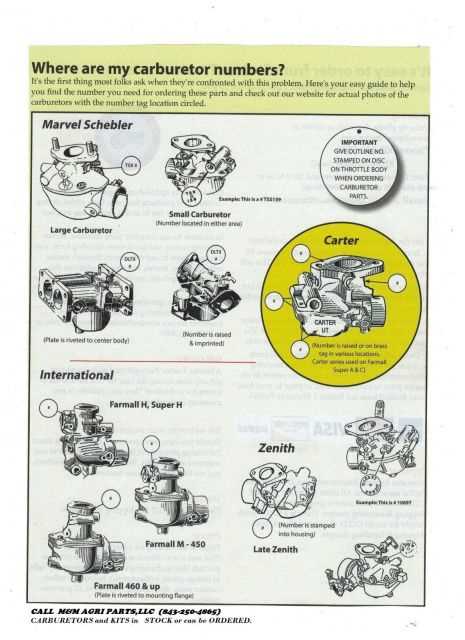

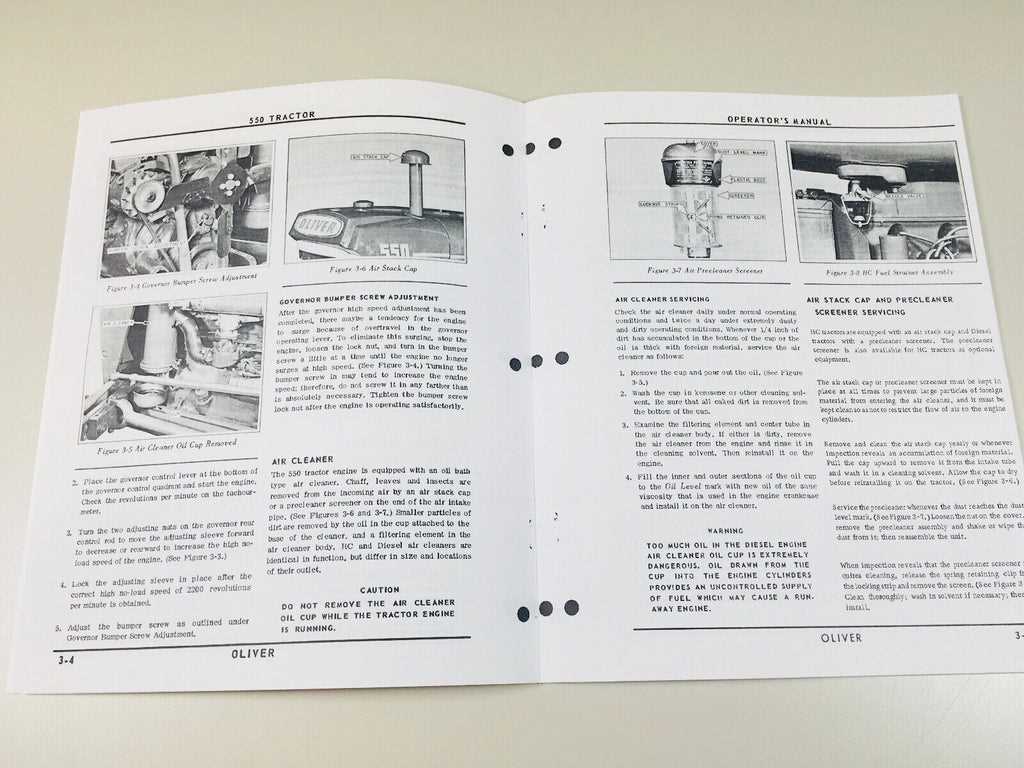

How to Read Parts Diagrams

Understanding assembly illustrations is essential for anyone involved in maintenance or repair tasks. These visual guides provide a comprehensive overview of components and their interconnections, enabling users to navigate complex systems effectively. Familiarity with the elements depicted in these representations facilitates a smoother troubleshooting process.

To effectively interpret these illustrations, one should focus on the following key aspects:

| Element | Description |

|---|---|

| Symbols | Various shapes or icons represent different components, each with specific functions. |

| Labels | Textual annotations often accompany symbols, providing names or part numbers for easy identification. |

| Lines | Connecting lines illustrate relationships and pathways between different elements, indicating how they interact. |

| References | Some diagrams may include reference numbers linking to detailed descriptions or exploded views. |

By paying attention to these features, individuals can efficiently decipher assembly illustrations, leading to improved understanding and execution of repair or assembly tasks.

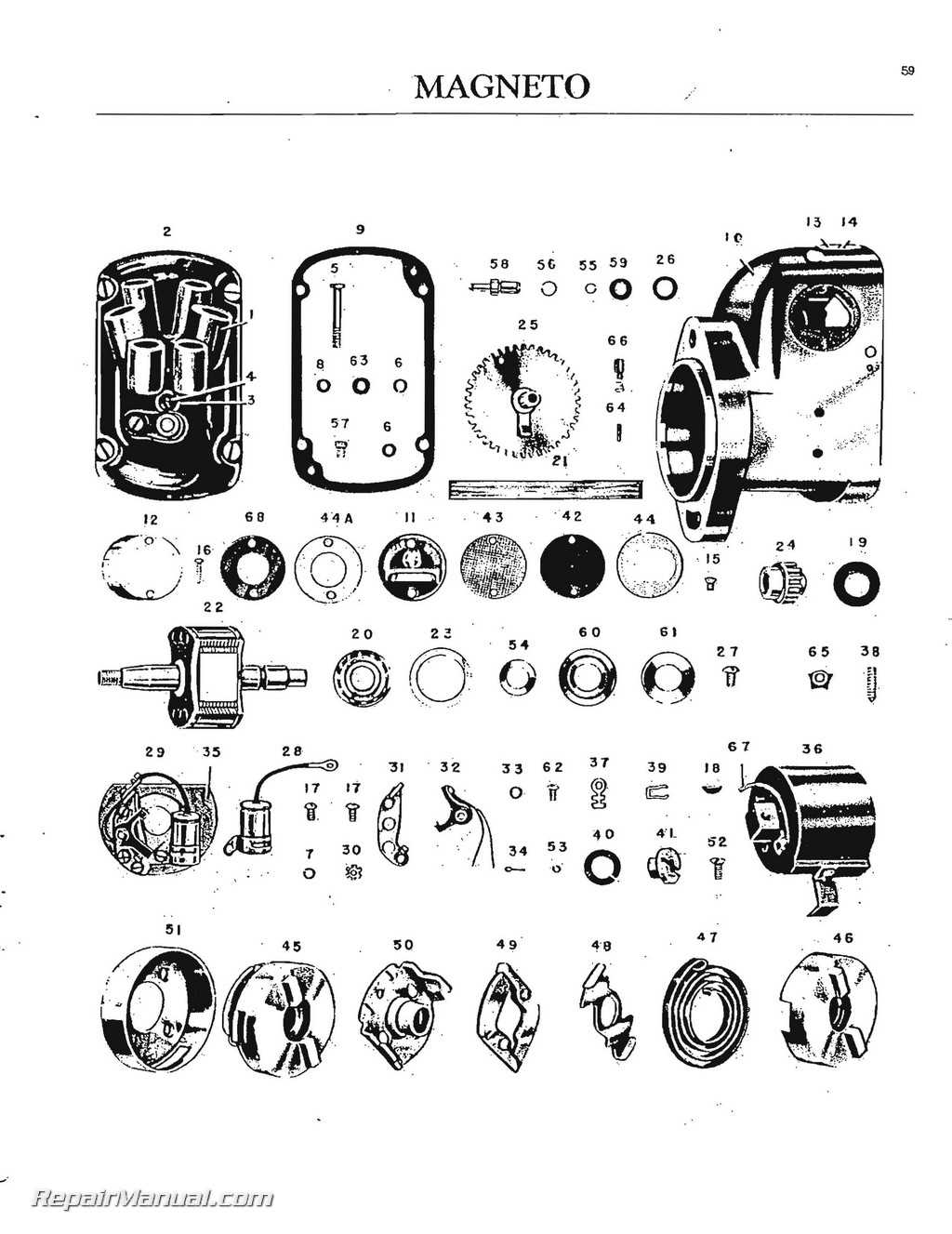

Identifying Components in the Diagram

Understanding the various elements depicted in a visual representation is crucial for effective maintenance and repairs. Each section within this illustration serves a specific purpose, contributing to the overall functionality of the machinery. Familiarity with these individual components enables operators and technicians to perform troubleshooting and replacements more efficiently.

Key Elements and Their Functions

To grasp the operational significance of each part, it’s essential to categorize them according to their roles. Below is a concise table outlining some of the primary components commonly found in such visual aids, along with their respective functions:

| Component Name | Function |

|---|---|

| Drive Shaft | Transfers power from the engine to the working mechanisms. |

| Gearbox | Modulates torque and speed between the engine and output. |

| Hydraulic Pump | Generates hydraulic pressure to operate various attachments. |

| Control Panel | Facilitates user interaction for monitoring and adjustments. |

Interpreting the Visual Representation

When examining the visual representation, it’s vital to note the interconnectedness of the components. Each element is strategically placed to demonstrate how they interact, which is key for diagnosing issues and ensuring optimal performance. Properly interpreting these visuals enhances the ability to manage repairs effectively.

Maintenance Tips for Oliver 550

Regular upkeep is essential for ensuring the longevity and optimal performance of any machinery. This section highlights effective strategies and practices to maintain your equipment in excellent condition, thus enhancing its reliability and efficiency.

Following a systematic approach to maintenance can prevent costly repairs and downtime. Here are some fundamental tips to keep your machinery running smoothly:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Checks | Weekly | Inspect oil and coolant levels; refill or change as necessary to avoid overheating and ensure smooth operation. |

| Filter Replacements | Every 200 hours | Change air, fuel, and oil filters to maintain optimal performance and prevent contaminants from damaging internal components. |

| Belts and Hoses Inspection | Monthly | Check for wear, cracks, or leaks and replace as needed to avoid failure during operation. |

| Greasing Points | Every 50 hours | Lubricate all necessary points to reduce friction and wear on moving parts, ensuring smooth operation. |

| Visual Inspection | Before Each Use | Conduct a thorough visual check for any signs of damage or leaks that may need immediate attention. |

Implementing these maintenance practices will contribute significantly to the efficiency and durability of your machinery. Keeping detailed records of maintenance activities can also help track the condition of your equipment over time.

Finding Replacement Parts Easily

Locating suitable components for machinery can be a straightforward task when you know where to look. Various resources are available that cater specifically to enthusiasts and professionals seeking to restore or maintain their equipment. By utilizing online platforms, local suppliers, and specialized forums, individuals can efficiently identify and acquire the necessary items.

Online Resources

The internet provides a plethora of options for sourcing essential components. Here are some useful strategies:

- Visit dedicated websites that specialize in machinery components.

- Utilize search engines to find specific items by inputting relevant keywords.

- Check online marketplaces that offer both new and refurbished items.

Local Suppliers and Communities

In addition to online resources, local suppliers and community networks can be valuable for finding components:

- Explore local hardware stores or specialty shops that may stock relevant items.

- Engage with local farming or machinery clubs where members might share insights on sourcing.

- Attend trade shows or expos to connect with suppliers directly and see products firsthand.

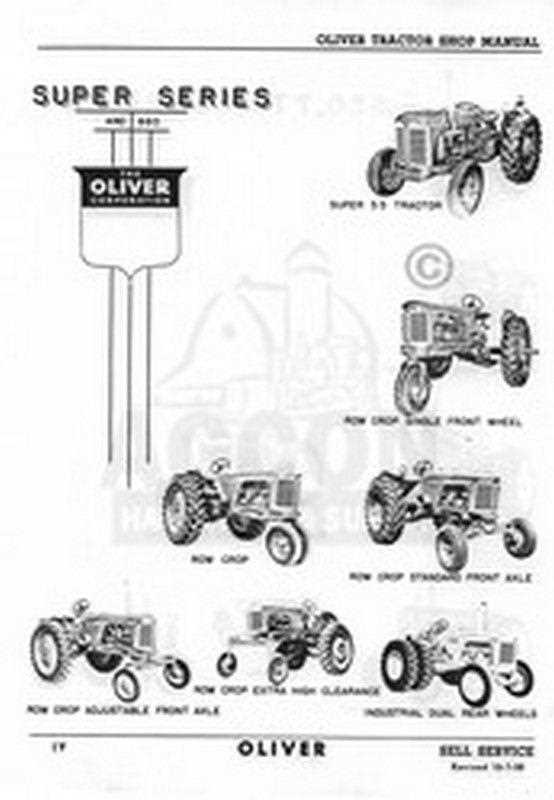

Historical Context of Oliver Tractors

The evolution of agricultural machinery has significantly shaped modern farming practices. The development of robust, reliable vehicles revolutionized crop production, enabling farmers to increase efficiency and reduce labor. Among these pioneering designs, certain manufacturers stood out for their innovative approaches and contributions to the industry.

The Rise of American Agriculture

In the late 19th and early 20th centuries, the demand for efficient farming solutions surged as the United States transitioned into a major agricultural powerhouse. This period saw the emergence of numerous companies dedicated to creating machinery tailored to the needs of farmers. Innovations in technology and design played a crucial role in enhancing productivity on farms across the nation.

Impact on Modern Farming Techniques

As time progressed, these agricultural vehicles evolved, incorporating advanced features that improved their functionality. Manufacturers focused on durability, ease of use, and adaptability, which were essential for farmers facing diverse environmental conditions. The legacy of these early innovators continues to influence contemporary agricultural practices, highlighting the importance of historical developments in shaping today’s farming landscape.

Popular Modifications for the Oliver 550

Enhancing the functionality and performance of agricultural machinery is a common practice among enthusiasts and professionals alike. Numerous upgrades can be made to improve efficiency, adaptability, and overall user experience. Below are some notable adjustments that can significantly transform the operation of these robust vehicles.

Engine Upgrades: One of the most sought-after modifications involves enhancing the engine’s output. By replacing the standard carburetor with a performance model or adjusting the fuel delivery system, operators can achieve improved power and torque. This not only increases productivity but also enhances the capability to handle heavier loads.

Transmission Enhancements: Modifying the transmission system can lead to smoother gear shifts and better handling of various terrains. Implementing a high-performance clutch or upgrading to a more advanced transmission model ensures optimal power transfer and efficiency, making the equipment more versatile in different agricultural applications.

Front-End Loader Integration: For those seeking to boost productivity in material handling, integrating a front-end loader is a popular choice. This addition allows for easy lifting and transporting of bulk materials, saving time and effort on the field.

Wheel and Tire Upgrades: Choosing the right wheels and tires can greatly impact traction and stability. Upgrading to wider tires or those designed for specific conditions can enhance grip and control, ensuring safer and more effective operations in challenging environments.

Implementing these modifications can breathe new life into agricultural machinery, allowing for tailored performance that meets the specific needs of the user. These enhancements contribute to a more efficient workflow, ultimately leading to better results in various farming tasks.

Expert Recommendations for Repairs

When it comes to maintaining and restoring agricultural machinery, having reliable guidance is essential. Expert insights can significantly enhance the efficiency and longevity of equipment. Proper evaluation and strategic interventions play a crucial role in achieving optimal performance.

Assessing the Condition

Before embarking on any repair task, it’s important to thoroughly assess the equipment’s condition. Consider the following steps:

- Conduct a visual inspection for any visible wear or damage.

- Check fluid levels and ensure there are no leaks.

- Test operational components to identify any irregularities.

Utilizing Quality Components

When replacing components, opt for high-quality alternatives to ensure durability and performance. Recommendations include:

- Source parts from reputable suppliers to guarantee compatibility.

- Consult with experienced technicians for advice on suitable replacements.

- Prioritize original equipment manufacturer (OEM) parts whenever possible.

Resources for Oliver Tractor Enthusiasts

For those passionate about vintage agricultural machinery, a wealth of information and support exists to enhance knowledge and foster community. Whether you’re seeking repair manuals, restoration tips, or forums for discussion, these resources are invaluable for anyone looking to deepen their understanding of these classic machines.

Online Communities

- Tractor Forums: Numerous online platforms allow enthusiasts to connect, share experiences, and seek advice on maintenance and restoration.

- Social Media Groups: Facebook and other social networks host groups dedicated to vintage tractors, where members share insights, photos, and project updates.

- Dedicated Websites: Numerous websites specialize in vintage machinery, offering articles, guides, and resources tailored to specific models and brands.

Literature and Publications

- Restoration Guides: Books focusing on restoration techniques provide step-by-step instructions and valuable insights into the intricacies of older machinery.

- Magazines: Subscriptions to agricultural and vintage machinery magazines keep readers updated on trends, events, and innovations in the field.

- Technical Manuals: Original service manuals and reprints are essential for anyone involved in maintenance or restoration projects, detailing specifications and procedures.