When maintaining or troubleshooting a specific type of generator, a clear understanding of its individual components is essential. This knowledge not only enhances the efficiency of repairs but also ensures the longevity of the machine. Familiarity with the layout and function of each element can greatly aid in diagnosing issues and performing effective maintenance.

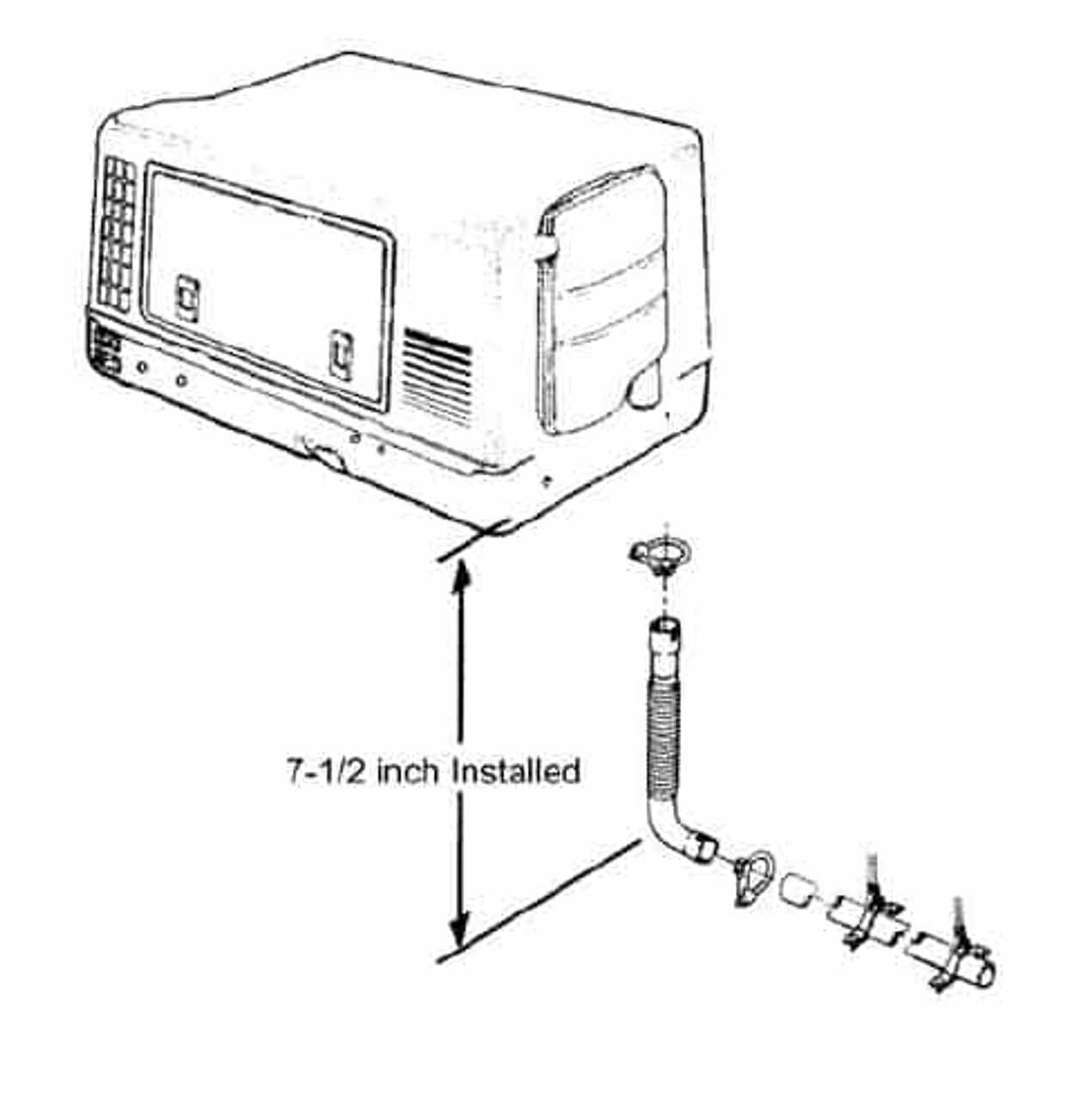

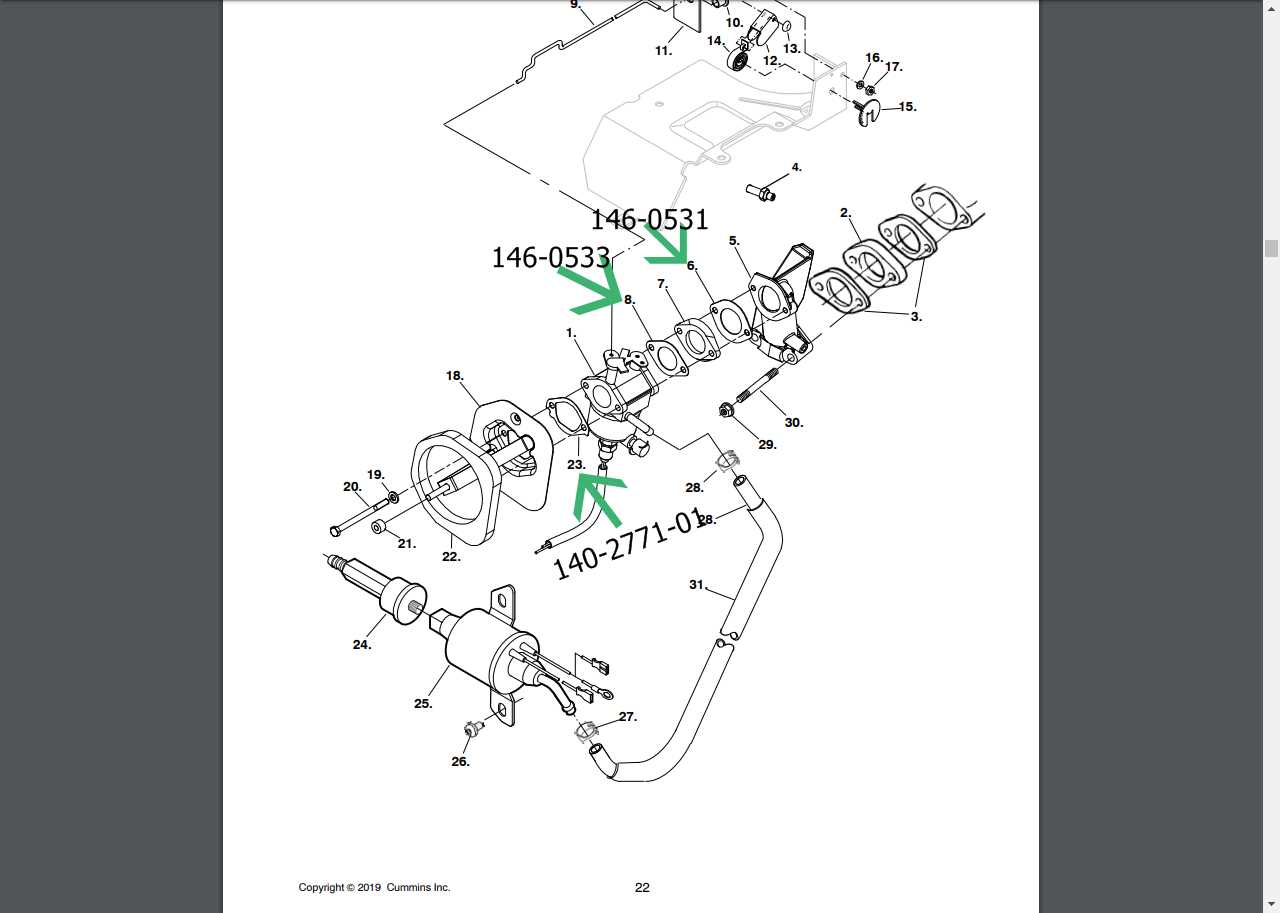

Visual representations of the various elements within a generator provide invaluable assistance for technicians and hobbyists alike. These illustrations serve as a roadmap, guiding users through the intricate design and functionality of the equipment. By recognizing how each part interacts with the others, one can develop a deeper appreciation for the complexity of these systems.

Furthermore, having access to detailed schematics simplifies the process of sourcing replacements and conducting repairs. It empowers users to make informed decisions, whether they are engaging in routine maintenance or addressing specific malfunctions. An organized overview of the generator’s construction promotes confidence and competence in handling technical challenges.

Understanding Onan Microquiet 4000 Generator

This section provides a comprehensive overview of a compact and efficient power-producing device commonly utilized in recreational vehicles and various applications. It is designed to deliver reliable energy in a portable format, catering to users who require a consistent source of electricity while on the go.

The primary features and benefits of this generator can significantly enhance outdoor experiences and emergency situations. Understanding its components and functionality is essential for optimal operation and maintenance. Below are key aspects to consider:

- Power Output: This unit typically offers adequate wattage to support essential appliances and devices, ensuring that users can maintain comfort and convenience in remote settings.

- Noise Levels: One of the standout attributes is its quiet operation, making it suitable for camping and residential use without disturbing the surrounding environment.

- Fuel Efficiency: Designed for economical fuel consumption, it allows for prolonged usage without frequent refueling, thus enhancing user convenience.

- Compact Design: The size of the generator facilitates easy transportation and installation, making it ideal for those with limited space.

To ensure longevity and performance, regular upkeep is vital. Familiarizing oneself with the internal components and their roles can help in troubleshooting and maintenance efforts. Below are critical components to monitor:

- Engine: Responsible for converting fuel into mechanical energy.

- Fuel System: Includes the tank and lines, essential for proper fuel delivery.

- Electrical System: Comprises the alternator and control panel, crucial for managing output.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

By grasping the essential features and components, users can maximize the efficiency and reliability of their portable power source. Proper knowledge empowers individuals to make informed decisions about usage and maintenance, ensuring uninterrupted service in all settings.

Key Components of the Generator

Understanding the essential elements of a power generation unit is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring reliable energy production and overall functionality.

- Engine: This is the primary source of mechanical energy, converting fuel into motion. It is fundamental for initiating the generation process.

- Alternator: Responsible for transforming mechanical energy from the engine into electrical energy. Its efficiency directly affects the output voltage and current quality.

- Fuel System: Comprising tanks, pumps, and filters, this system stores and supplies fuel to the engine, ensuring smooth operation.

- Cooling System: Maintains optimal operating temperatures by dissipating heat generated during the energy conversion process. This includes radiators and coolant lines.

- Exhaust System: Directs harmful gases away from the unit, improving safety and environmental compliance.

- Control Panel: Acts as the command center, allowing users to monitor performance metrics and control operations through various settings and indicators.

- Battery: Provides the necessary power for starting the engine and supporting electronic components, ensuring functionality during initial operation.

By familiarizing yourself with these critical parts, you can enhance your understanding of how the system operates and recognize potential maintenance needs.

Importance of Parts Diagram

Understanding the layout and components of a mechanical system is crucial for effective maintenance and repair. A visual representation of each element offers invaluable insights that enhance both comprehension and efficiency in handling equipment. Such illustrations serve as essential references for technicians and users alike.

Here are several reasons why these visual aids are significant:

- Enhanced Clarity: Visual representations simplify complex assemblies, making it easier to identify individual components and their relationships.

- Efficient Troubleshooting: When issues arise, having a clear visual guide allows for quick identification of potential problem areas, streamlining the diagnostic process.

- Streamlined Repairs: Knowing the exact location and type of each element enables technicians to perform repairs swiftly and accurately.

- Improved Safety: Understanding the layout can help prevent accidents by informing users of hazardous components or assembly points.

- Facilitates Communication: These visuals provide a common reference that enhances collaboration among team members and improves communication with clients.

In conclusion, the significance of these visual guides cannot be overstated. They empower users and technicians to work more effectively and safely, ultimately leading to better performance and longevity of the equipment.

Common Issues with Onan Microquiet

Generators often face a range of common challenges that can affect their performance and reliability. Understanding these issues can help users diagnose problems early, ensuring smoother operation and prolonged lifespan. This section explores frequent complications encountered with these compact power units, providing insights into their potential causes and solutions.

1. Electrical Problems

One of the most prevalent issues involves electrical failures. Users may experience irregular power output or complete shutdowns. Potential causes include:

- Worn or damaged wiring

- Faulty circuit breakers

- Improperly connected terminals

Regular inspection of electrical components can help mitigate these risks.

2. Fuel System Concerns

Another common area of concern pertains to the fuel delivery system. Problems here can lead to performance inconsistencies. Key factors to consider include:

- Clogged fuel lines or filters

- Contaminated fuel

- Faulty fuel pump

Maintaining clean fuel and ensuring proper flow can greatly enhance functionality and reliability.

Locating Replacement Parts Easily

Finding the right components for your equipment can be a daunting task, especially when faced with a myriad of options and technical specifications. However, understanding how to navigate the selection process can streamline your search and ensure you acquire the correct items efficiently.

Begin by identifying the model and specifications of your machinery. This critical step helps narrow down the selection and leads you to the appropriate suppliers. Keep a record of model numbers and relevant details, as these will be invaluable when reaching out to vendors or searching online.

Utilizing online resources can significantly enhance your ability to locate necessary items. Many manufacturers offer comprehensive catalogs or searchable databases on their websites. These platforms often include filtering options that allow you to search by category, size, or function, simplifying the process of pinpointing exactly what you need.

Another effective method is to consult community forums and support groups. Engaging with fellow users can provide insights into where to find specific components, as well as recommendations for trusted suppliers. Additionally, many enthusiasts and experts share their experiences, which can help you avoid common pitfalls.

Local distributors often have a wealth of knowledge and can assist in sourcing components. Establishing a relationship with a nearby retailer may also offer advantages, such as immediate access to stock and personalized service. Don’t hesitate to reach out and inquire about availability or special orders if necessary.

Lastly, keeping an organized inventory of your equipment’s components can save you time and effort in the future. Documenting details about what you have on hand and what you may need to replace can make your next search much more straightforward.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of any equipment. Regular maintenance not only helps to prevent unexpected breakdowns but also enhances efficiency and reliability. By following a few key practices, users can significantly improve the durability of their machines.

First and foremost, establish a routine inspection schedule. Regularly check for signs of wear and tear, leaks, or unusual noises. Addressing minor issues promptly can prevent them from escalating into major problems that may require costly repairs.

Additionally, keeping components clean is vital. Accumulated dirt and debris can lead to overheating and hinder functionality. Use appropriate cleaning agents and methods to maintain cleanliness, paying special attention to air filters and ventilation systems.

Another critical aspect is monitoring fluid levels. Ensure that oil, coolant, and other essential fluids are maintained at the recommended levels. Regularly changing these fluids according to the manufacturer’s guidelines will help to keep the machinery running smoothly.

Finally, always refer to the manufacturer’s manual for specific maintenance recommendations. Adhering to these guidelines can provide valuable insights into the best practices for care and upkeep, tailored to the particular model in use.

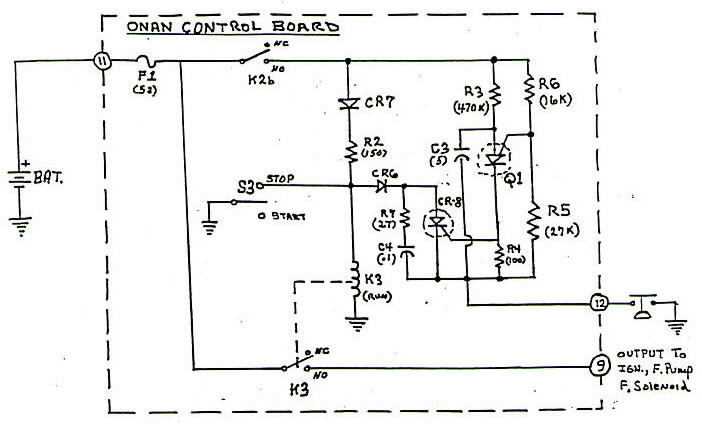

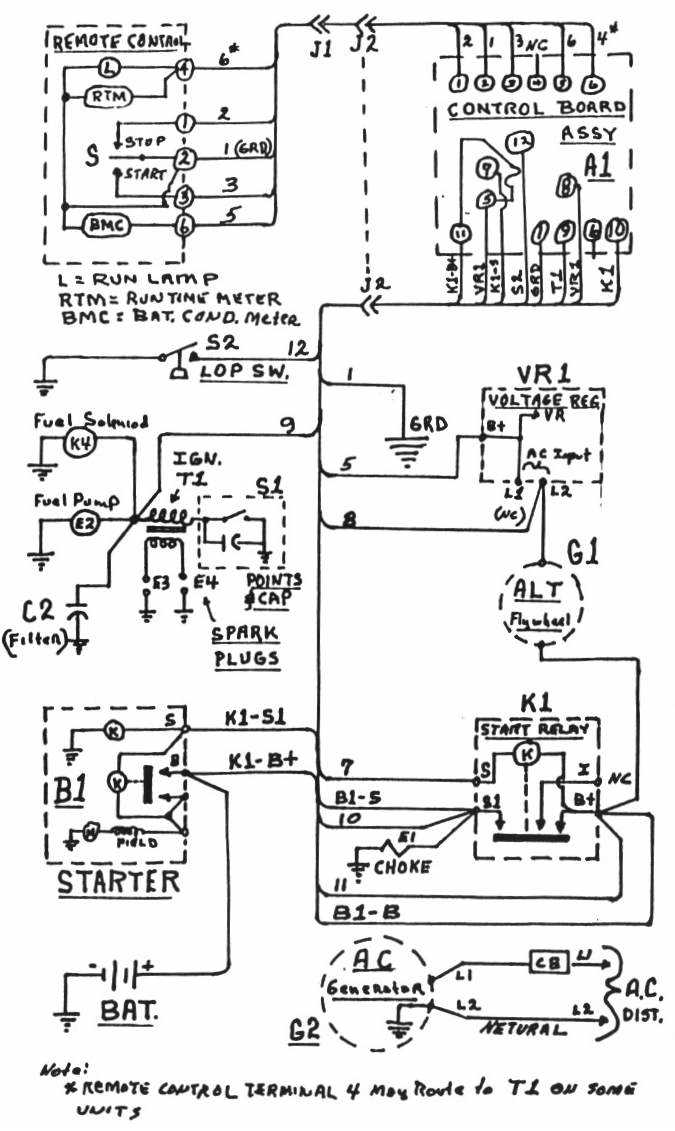

How to Interpret Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide aims to enhance your ability to read and analyze such illustrations, ensuring you can identify individual elements and their relationships within a system.

1. Familiarize Yourself with the Key

Most schematics include a legend or key that explains symbols and notations used throughout the illustration. Take the time to review this section carefully, as it provides crucial insights into the representation of various elements and their functions.

2. Analyze the Layout

Observe the arrangement of the components. The organization often reflects the assembly or flow of operation within the system. Components are typically grouped by function, so recognizing clusters can help you understand how they interact with one another.

3. Identify Individual Elements

Each item in the illustration is usually labeled with a reference number or code. Cross-reference these identifiers with accompanying documentation to gain detailed information about each component’s specifications, including dimensions and materials.

4. Look for Annotations

Annotations can provide additional information regarding installation, maintenance, or troubleshooting. Pay close attention to these notes, as they often highlight important considerations that could affect the performance and longevity of the assembly.

5. Practice with Examples

The best way to improve your interpretation skills is through practice. Work with different schematics, comparing them to actual systems. This hands-on approach will deepen your understanding and enhance your ability to identify and resolve potential issues.

By following these steps, you will develop a more comprehensive understanding of visual representations of components, empowering you to undertake maintenance tasks with confidence and precision.

Tools Required for Repairs

When undertaking maintenance or fixing tasks on compact generators, having the right tools is essential for ensuring efficient and effective repairs. Utilizing appropriate instruments not only streamlines the repair process but also minimizes the risk of damage to components and enhances safety. Below is a list of essential tools and equipment that can assist in carrying out various repair procedures.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for removing and securing screws in the unit.

- Wrenches: Adjustable wrenches and socket sets are necessary for loosening and tightening nuts and bolts.

- Pliers: Needle-nose pliers and standard pliers help grip and manipulate small components and wires.

- Multimeter: This device is vital for measuring electrical parameters and diagnosing issues related to voltage and current.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing over-tightening that could cause damage.

- Wire Strippers: Essential for preparing electrical connections and ensuring proper wiring for repairs.

- Oil Filter Wrench: Useful for removing and replacing oil filters during maintenance.

- Cleaning Supplies: Brushes, rags, and solvents are necessary for keeping parts clean and free of debris.

In addition to these basic tools, having specialized equipment may be beneficial depending on the specific issues encountered. Always ensure to have safety gear, such as gloves and goggles, to protect yourself during the repair process.

Comparing Microquiet 4000 Models

When evaluating different models within a specific generator line, it is essential to recognize the unique features and capabilities that distinguish each variant. This comparison aims to highlight the nuances in performance, efficiency, and overall functionality among the available options, helping users make informed decisions based on their particular needs.

Performance Variability: Different models may exhibit variations in power output and fuel efficiency. Understanding these differences is crucial for users who require specific energy capacities for various applications. For instance, some versions may be better suited for recreational use, while others are tailored for more demanding situations, such as powering larger appliances or equipment.

Design and Features: Beyond performance, the construction and integrated features of each model can significantly influence user experience. Some units may offer advanced sound-dampening technologies, while others prioritize portability or ease of installation. Evaluating these aspects can help users select a model that aligns with their preferences and intended usage scenarios.

Maintenance and Support: Consideration of maintenance requirements and available support services is also vital. Certain models may have more accessible replacement components or provide enhanced customer service options, ensuring longevity and reliability over time. A thorough understanding of these factors can aid in minimizing downtime and ensuring efficient operation.

In conclusion, carefully comparing the various models within this generator series reveals essential distinctions that can impact user satisfaction and operational effectiveness. By considering performance, design, and support, individuals can choose the most appropriate generator to meet their specific requirements.

Identifying OEM vs. Aftermarket Parts

Understanding the distinction between original equipment manufacturer components and those produced by third-party suppliers is crucial for maintaining the integrity and performance of machinery. OEM items are crafted by the same manufacturer that designed the original equipment, ensuring compatibility and reliability. In contrast, aftermarket components are created by independent companies, which may offer alternatives at potentially lower costs but can vary in quality and performance.

OEM components are generally perceived as more trustworthy due to their adherence to specific standards and specifications set by the original manufacturer. This guarantees that each piece is designed to fit seamlessly into the intended machinery, minimizing the risk of malfunctions. Additionally, these items often come with warranties that provide assurance of their longevity and effectiveness.

Aftermarket items, while often more affordable, can present a mixed bag of quality. Some third-party manufacturers produce high-quality alternatives that can rival OEM options, while others may not meet the same standards. It is essential for users to thoroughly research and evaluate the reputation of aftermarket suppliers before making a purchase, as this can significantly affect the overall performance and lifespan of their equipment.

In conclusion, the choice between OEM and aftermarket components hinges on factors such as budget, quality assurance, and specific application needs. Understanding these differences allows users to make informed decisions that will enhance the functionality and durability of their machinery.

Safety Precautions During Repair

Ensuring safety during maintenance and repair activities is paramount to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also safeguard the equipment and surrounding environment. Before commencing any repair tasks, it is essential to follow specific guidelines that minimize risks and promote a secure working atmosphere.

- Always disconnect power sources to avoid electrical shocks.

- Wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Ensure the work area is clean and free of hazards, including tools and debris.

Additionally, consider the following steps to enhance safety:

- Review the manufacturer’s guidelines and manuals for safety recommendations.

- Work in well-ventilated areas, especially when dealing with fuel or chemicals.

- Utilize proper lifting techniques to prevent strain or injury when handling heavy components.

By adhering to these safety measures, you can create a secure environment that facilitates efficient and effective repair processes.

Resources for Further Assistance

When encountering challenges with specific equipment, it is essential to have access to a variety of resources that can provide guidance and support. These resources may include official documentation, community forums, and professional services, each offering unique insights and solutions to enhance your understanding and troubleshooting capabilities.

Official manuals and technical documents often serve as the primary source of information, detailing specifications, installation procedures, and maintenance tips. These documents can usually be found on the manufacturer’s website or through authorized distributors, ensuring that you receive accurate and up-to-date information.

Online forums and discussion groups are invaluable for sharing experiences and solutions with fellow users. Engaging with these communities allows individuals to ask questions, share insights, and learn from others who may have faced similar issues. Additionally, social media platforms and specialized websites can connect you with experts who can offer tailored advice and practical solutions.

If you require more hands-on assistance, consider reaching out to certified technicians or service providers who specialize in the equipment you are working with. Professional services can provide in-depth analysis and repairs, ensuring that your device operates efficiently and safely.

By utilizing a combination of these resources, you can enhance your knowledge and effectively address any issues that may arise with your equipment.