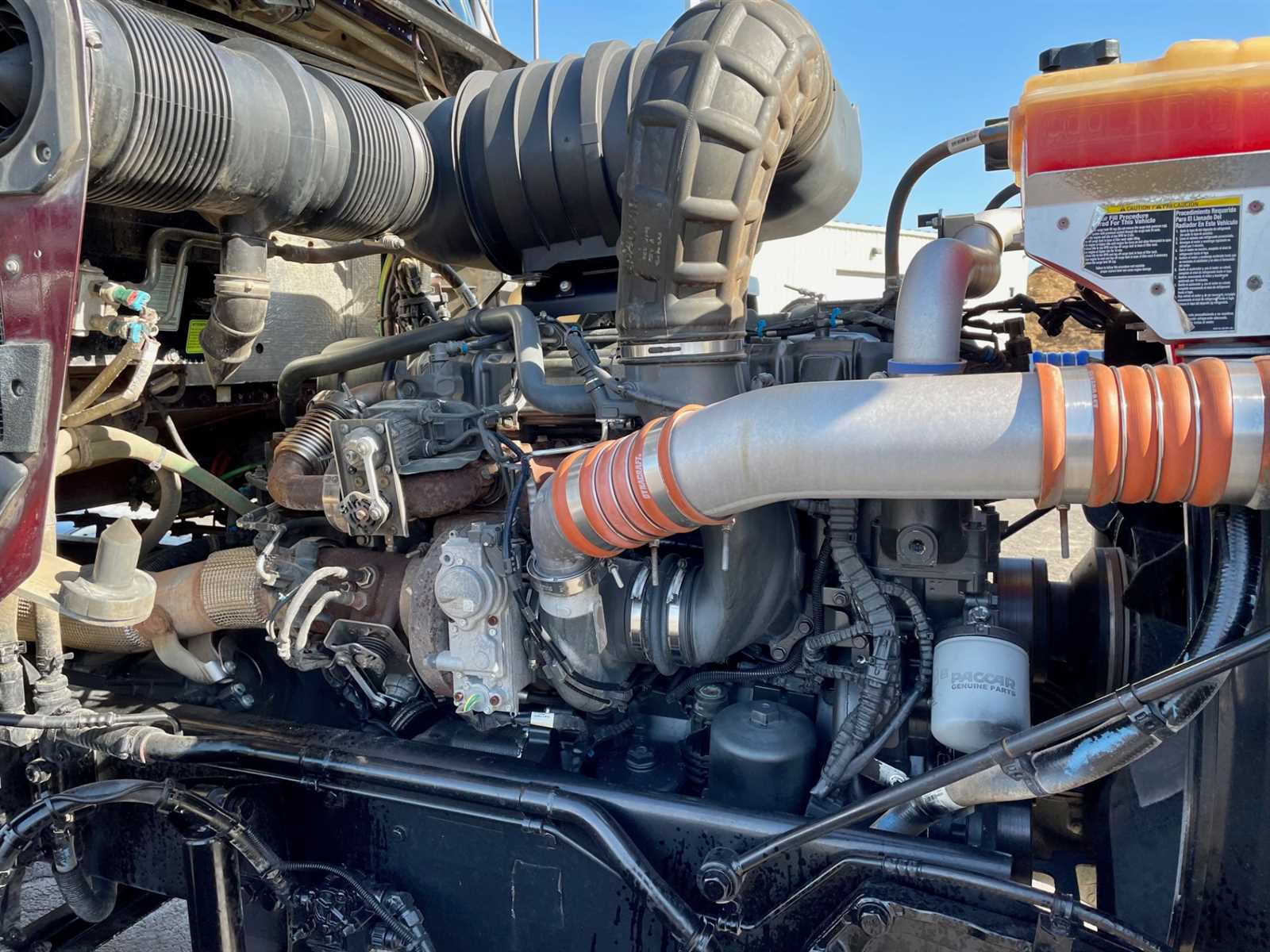

The intricacies of modern machinery demand a comprehensive grasp of their constituent elements. For those working with heavy-duty engines, having a clear view of how each piece interrelates can significantly enhance maintenance and repair efforts.

In this exploration, we will delve into the essential components that make up a specific model of heavy-duty engine. Understanding this layout not only aids in troubleshooting but also contributes to optimizing performance and longevity.

By examining a detailed illustration of engine elements, enthusiasts and professionals alike can identify key parts, facilitating informed decision-making during repairs or upgrades. Mastering these visual guides is the ultimate step toward effective engine management.

Overview of the Engine Series

This section provides an insight into a robust line of heavy-duty engines renowned for their performance and reliability in various commercial applications. These power units are designed to deliver exceptional torque and efficiency, making them a popular choice among fleet operators.

Key Features

- High efficiency and fuel economy

- Advanced emission control technology

- Durability for long-term usage

Applications

- Long-haul transportation

- Construction vehicles

- Heavy-duty trucks

Key Components of MX-13 Engine

The performance and reliability of a modern heavy-duty engine rely on several crucial elements working in harmony. Understanding these components is essential for maintenance, troubleshooting, and optimization. Each part plays a specific role in ensuring the engine operates efficiently, providing the necessary power and torque for demanding applications.

| Component | Description |

|---|---|

| Cylinder Head | Contains the combustion chambers and houses the intake and exhaust valves. |

| Fuel Injector | Delivers precise amounts of fuel into the combustion chamber for efficient burning. |

| Turbocharger | Increases engine efficiency and power output by forcing extra air into the combustion chamber. |

| Crankshaft | Converts linear motion from the pistons into rotational motion to drive the vehicle. |

| Oil Pump | Circulates oil throughout the engine for lubrication and cooling, ensuring smooth operation. |

| Exhaust Manifold | Collects exhaust gases from the cylinders and directs them into the exhaust system. |

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for efficient maintenance and repairs. Visual representations of components serve as crucial tools, enabling technicians to identify and locate essential elements quickly. Such resources enhance the overall effectiveness of service operations, ensuring optimal performance and longevity of equipment.

Facilitating Maintenance

Clear illustrations aid in troubleshooting and streamline the repair process. Technicians can pinpoint issues more efficiently, minimizing downtime and enhancing productivity.

Improving Communication

Visual aids foster better communication among team members. When everyone can reference the same detailed visuals, discussions about repairs and upgrades become more precise and informed.

| Benefit | Description |

|---|---|

| Efficiency | Reduces time spent identifying components. |

| Accuracy | Ensures correct parts are used in repairs. |

| Training | Serves as a valuable resource for new technicians. |

Common Issues and Solutions

When it comes to heavy-duty engines, various challenges can arise over time due to wear and tear, environmental factors, or maintenance oversights. Identifying these problems early on and knowing how to address them can save time and money in the long run. Below, we explore some frequent complications along with their effective remedies.

| Issue | Description | Solution |

|---|---|---|

| Oil Leaks | Excessive oil leakage can lead to decreased performance and increased emissions. | Inspect seals and gaskets for damage; replace as necessary and ensure proper torque specifications. |

| Overheating | Engine overheating can result from insufficient coolant levels or blocked passages. | Check coolant levels regularly and clean or replace the radiator as needed to maintain proper flow. |

| Poor Fuel Efficiency | Decreased fuel economy may indicate problems with fuel injectors or air intake. | Perform routine checks on injectors and air filters; clean or replace components as required. |

| Strange Noises | Unusual sounds during operation can signal mechanical issues. | Conduct a thorough inspection of belts, pulleys, and bearings to identify and rectify the source of the noise. |

Finding OEM vs. Aftermarket Parts

When it comes to sourcing components for heavy machinery, understanding the differences between original equipment manufacturer and alternative options is crucial. Each category presents unique benefits and considerations that can impact performance and reliability.

OEM components are crafted by the original manufacturer, ensuring a precise fit and compatibility with your machinery. They often come with warranties and are backed by the manufacturer’s reputation for quality. However, they can be more expensive compared to their alternatives.

On the other hand, aftermarket alternatives can offer significant cost savings and a variety of choices. While many of these parts are designed to meet or exceed industry standards, quality can vary widely. It’s essential to conduct thorough research and choose reputable suppliers to ensure you are receiving a reliable product.

Ultimately, the decision between these options should consider factors such as budget, intended use, and long-term performance goals. Delving into reviews and manufacturer credentials can guide you towards making an informed choice that aligns with your operational needs.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visuals offer a detailed view of components, helping users identify and locate each piece within a complex assembly. By familiarizing yourself with the layout and symbols used, you can streamline your work and ensure accuracy in part selection.

Start by examining the overall layout to get a sense of the arrangement. Identify the key sections and how they relate to one another. Next, look for reference numbers or codes that correspond to a list of items, usually found alongside the illustration. This will provide clarity on the specifics of each element depicted.

Pay attention to color coding and annotations, which often indicate different materials or specifications. Understanding these nuances can greatly enhance your ability to interpret the illustration effectively. With practice, you will be able to navigate these visuals with ease, leading to more informed decisions during repairs and upgrades.

Maintenance Tips for MX-13

Regular upkeep is essential for ensuring optimal performance and longevity of heavy-duty engines. Implementing a structured maintenance routine can prevent costly repairs and enhance reliability on the road. Below are key strategies to maintain your engine effectively.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 15,000 miles | Replace engine oil and filter to maintain lubrication and prevent wear. |

| Air Filter Inspection | Every 10,000 miles | Check and replace as needed to ensure proper airflow and engine efficiency. |

| Coolant Level Check | Monthly | Inspect coolant levels to prevent overheating and ensure optimal engine temperature. |

| Fuel System Cleaning | Every 20,000 miles | Clean injectors and fuel lines to enhance performance and fuel efficiency. |

| Belt and Hose Inspection | Every 6 months | Check for wear and tear to prevent breakdowns and maintain system integrity. |

Installation Process for Key Parts

The installation of essential components is crucial for ensuring optimal performance and longevity of any machinery. A systematic approach is required to achieve a seamless integration, minimizing the risk of future issues. This section outlines the fundamental steps necessary for proper installation, emphasizing precision and attention to detail.

Step 1: Preparation – Before commencing the installation, gather all necessary tools and components. Ensure that the workspace is clean and well-organized. Reviewing the installation guide can provide valuable insights into specific requirements for each component.

Step 2: Removal of Old Components – Carefully detach any existing parts that need to be replaced. This may involve unscrewing bolts or disconnecting electrical connections. It is important to keep track of all hardware for reinstallation or future reference.

Step 3: Alignment and Placement – Position the new component accurately, ensuring that it aligns correctly with adjacent parts. Proper alignment is vital for the functionality of the entire system. Utilize any alignment tools as needed.

Step 4: Fastening – Securely attach the component using the appropriate fasteners. Be cautious not to overtighten, as this can lead to damage. Following the torque specifications provided in the manual will ensure a snug fit without compromising integrity.

Step 5: Testing – Once the installation is complete, conduct a thorough check to ensure everything is functioning correctly. This may involve running the machinery and monitoring for any irregularities. Addressing issues at this stage can prevent complications later on.

By following these steps meticulously, you can achieve a successful installation that enhances the performance and reliability of your equipment.

Understanding Engine Performance Metrics

Engine performance metrics are essential for assessing the efficiency and effectiveness of a power unit. These measurements provide insights into how well an engine operates under various conditions, influencing everything from fuel consumption to overall output. By analyzing these factors, one can identify strengths and weaknesses, ultimately leading to improved performance and longevity.

Key metrics often include horsepower, torque, and thermal efficiency. Horsepower represents the engine’s ability to perform work, while torque measures the rotational force generated. Thermal efficiency, on the other hand, indicates how well the engine converts fuel energy into mechanical power, highlighting potential areas for enhancement.

Understanding these metrics allows for deeper insights into engine functionality, enabling operators to make informed decisions regarding maintenance and modifications. Ultimately, this knowledge can lead to enhanced performance and reduced operational costs.

Resources for Parts Acquisition

When it comes to sourcing components for heavy-duty vehicles, a strategic approach can ensure quality and efficiency. Various resources are available to facilitate the acquisition process, making it easier to find the right elements for your needs.

Online Marketplaces

- eBay: A wide range of sellers offering new and used items.

- Amazon: Reliable shipping and customer service for various components.

- Alibaba: Access to manufacturers and bulk purchasing options.

Specialized Retailers

- Local dealerships: Expert advice and OEM products.

- Aftermarket suppliers: Competitive pricing and diverse selections.

- Online specialty shops: Focused inventory catering to specific vehicle models.

Latest Updates in MX-13 Technology

The advancement of heavy-duty engines continues to evolve, focusing on enhancing performance, efficiency, and sustainability. Recent innovations in this technology have introduced features that not only improve fuel economy but also reduce emissions, catering to modern environmental standards. This section highlights the most significant updates that are reshaping the landscape of high-performance diesel engines.

Enhanced Fuel Efficiency

Recent developments have led to remarkable improvements in fuel efficiency. Advanced fuel injection systems now allow for more precise delivery, optimizing combustion processes. This results in a notable decrease in fuel consumption while maintaining power output. The integration of electronic control units enables real-time adjustments, ensuring that the engine operates at peak efficiency under varying loads and conditions.

Emissions Reduction Technologies

With growing concerns over environmental impact, manufacturers have implemented cutting-edge emissions control technologies. The use of selective catalytic reduction (SCR) systems and advanced exhaust gas recirculation (EGR) has proven effective in minimizing harmful emissions. These systems not only comply with stringent regulations but also enhance overall engine performance, leading to a cleaner and more sustainable operation.

Comparative Analysis with Competitor Engines

This section explores the differences and similarities between various heavy-duty powertrains in the market. By examining their design, performance, and reliability, we aim to provide insights that can assist in making informed decisions for fleet management and maintenance strategies.

Performance Metrics

When evaluating different engines, performance metrics such as horsepower, torque, and fuel efficiency play crucial roles. These elements directly influence operational costs and overall vehicle performance. Below is a comparative table showcasing key specifications of selected models:

| Engine Model | Horsepower | Torque (lb-ft) | Fuel Efficiency (mpg) |

|---|---|---|---|

| Model A | 500 | 1850 | 7.5 |

| Model B | 550 | 1950 | 8.0 |

| Model C | 480 | 1700 | 7.2 |

Reliability and Maintenance

Reliability is another critical factor, often assessed through user feedback and service history. Maintenance intervals and ease of access to components can greatly influence downtime and repair costs. Understanding these aspects can help fleet operators choose engines that not only perform well but also offer long-term value and dependability.