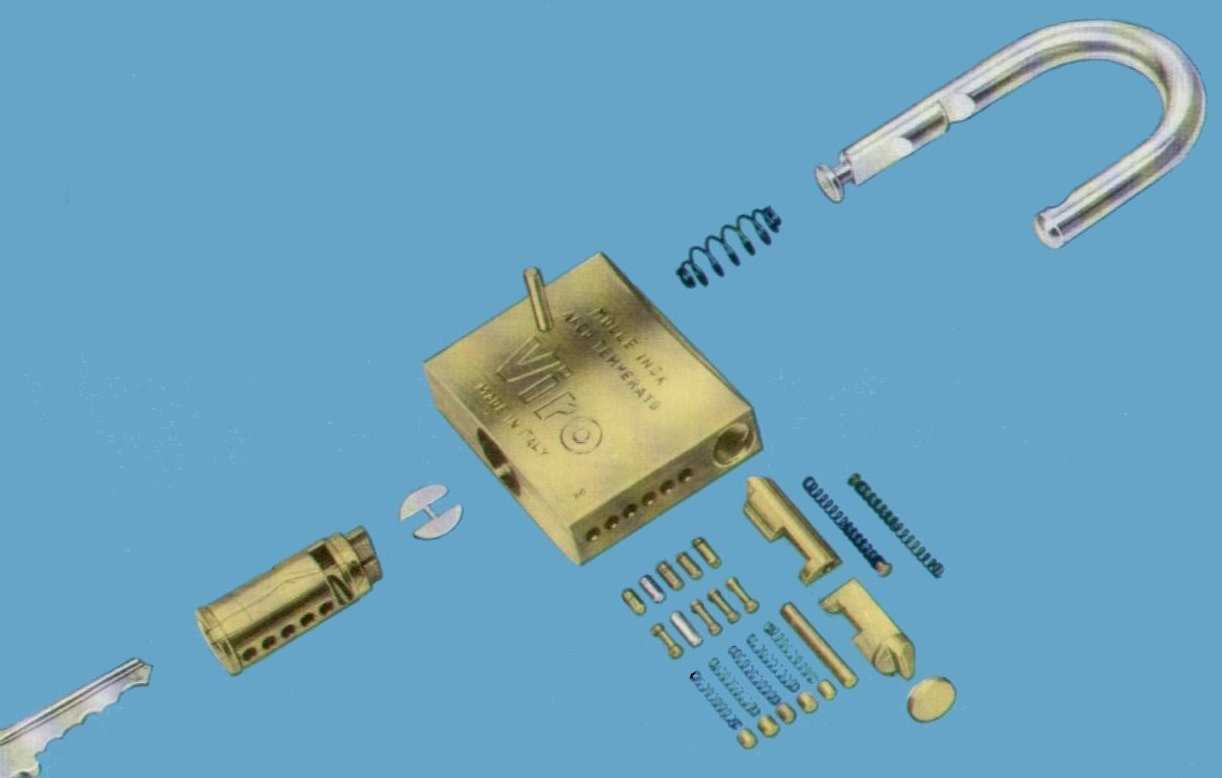

Understanding the internal structure of a reliable locking mechanism provides valuable insights into how it functions to ensure protection. This intricate system is composed of several key components, each playing a vital role in maintaining security and integrity. A thorough look at the design and operation of these elements can help deepen one’s appreciation for the engineering behind everyday security devices.

Each element within this safeguarding tool works in harmony to control access and resist tampering. By exploring the arrangement and purpose of these individual sections, you can gain a better understanding of how they cooperate to form a robust defense. This breakdown helps to reveal the inner workings of a commonly trusted mechanism and illustrates its importance in our daily lives.

Understanding the Internal Mechanism of a Lock

The core of any locking device relies on a well-coordinated system of interacting components. These elements work together to secure the enclosure, allowing only authorized access. By examining how these parts operate in unison, we gain insight into the balance of strength and precision within the device.

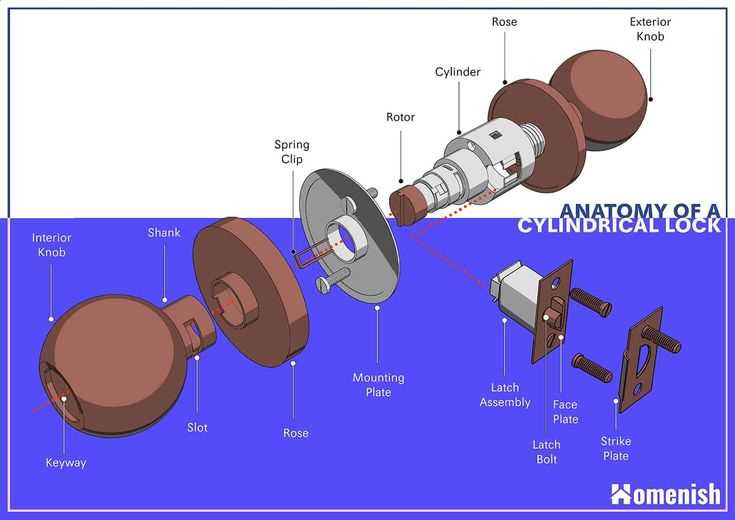

- Shell: The outer casing holds the entire mechanism, providing the necessary structure to contain the inner workings.

- Cylinder: Positioned at the heart of the system, this component rotates when activated, facilitating either the locking or unlocking process.

- Keyway: A precisely shaped pathway through which the proper tool is inserted to engage or disengage the system.

- Tumblers: Small, adjustable pieces that align in a specific sequence to permit movement, ensuring that only the correct key will trigger the unlocking.

- Cam: This small rotating piece connects to the main shaft and serves to translate the key’s movement into action, either locking or unlocking the mechanism.

Each of these components must function in harmony to ensure that the mechanism operates smoothly and

Key Components of Traditional Locking Devices

Traditional locking mechanisms have been refined over time, incorporating various elements that ensure security and functionality. These devices work through a combination of mechanical components, each playing a crucial role in the overall operation. Understanding these core elements reveals how they achieve reliability and protection in various settings.

Internal Structure and Mechanics

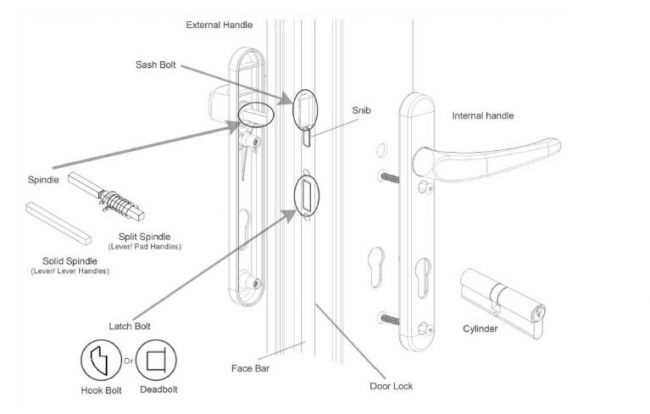

The internal workings typically involve a combination of rotating and sliding elements. These components interact with precision, allowing for smooth operation when engaged or released. The alignment of these internal parts determines how securely the device locks and unlocks.

Outer Shell and Access Mechanism

The outer casing provides the necessary strength and durability, often constructed from materials resistant to tampering. The access mechanism, usually located on the exterior, interfaces with the internal system to activate the locking process, ensuring that only authorized access is granted through a controlled action.

Exploring the Role of the Shackle

The core function of this essential component is tied to security and reliability. It serves as a pivotal element that ensures both closure and resistance to external interference, balancing strength and mobility. When engaged, it acts as a safeguard, playing a critical role in the integrity of the overall mechanism.

Flexibility is a key feature of the shackle, allowing it to operate smoothly while maintaining durability. Its design is crafted to withstand various forms of manipulation, ensuring that only the correct operation will allow release.

Durability is another vital attribute. Constructed from robust materials, this element is designed to resist forceful attempts at access. Its strength lies not only in its structure but also in its ability to endure consistent use while maintaining security.

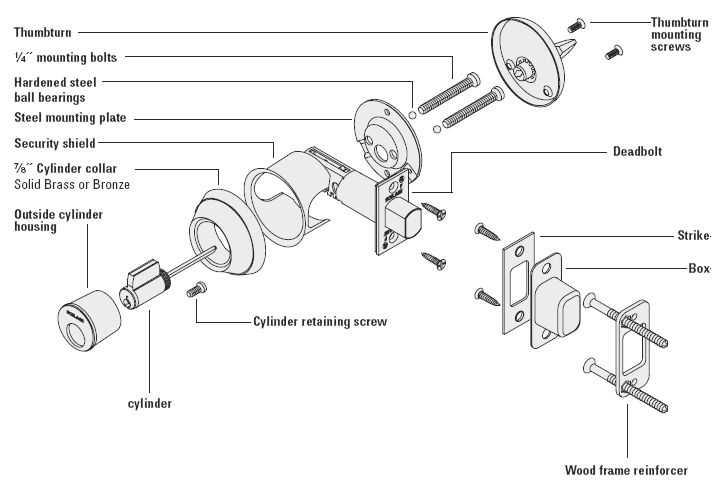

How the Lock Cylinder Functions

The core mechanism is a sophisticated element designed to secure an object by engaging its internal components. Its purpose is to allow or prevent movement based on the correct input being provided. Without the right interaction, the mechanism remains in place, protecting access.

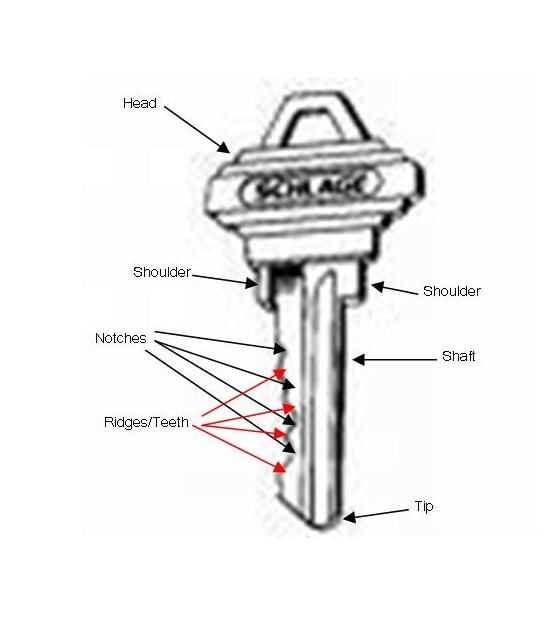

Interaction with Keys

The internal setup is designed to respond to specific sequences. When the correct key is inserted, it aligns the inner structure, enabling the release of the mechanism. Each key is uniquely cut to match the internal configuration, ensuring only authorized access is possible.

Unlocking Process

Once the key is fully engaged, it allows the internal mechanism to rotate, disengaging the lock. This simple yet highly effective process is at the heart of the system’s functionality, combining both security and ease of use.

The Role of Springs in Secure Fastening

Springs are essential components in many fastening mechanisms, ensuring both reliability and durability. Their ability to store and release energy plays a crucial role in maintaining the integrity of various locking devices, contributing to consistent performance under different conditions.

These flexible elements work by applying pressure that holds the mechanism in place until a specific action triggers a release. Whether it’s through compression, tension, or torsion, the precise function of these components ensures the system remains secure.

| Type of Spring | Function in Fastening Mechanisms | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compression Spring | Stores energy when compressed, providing resistance and stability. | |||||||||||||||||||||||

| Tension Spring | Stretches to hold parts together, offering consistent tension over time. | |||||||||||||||||||||||

| Torsion Spring | Tumbler and Pin Systems Explained

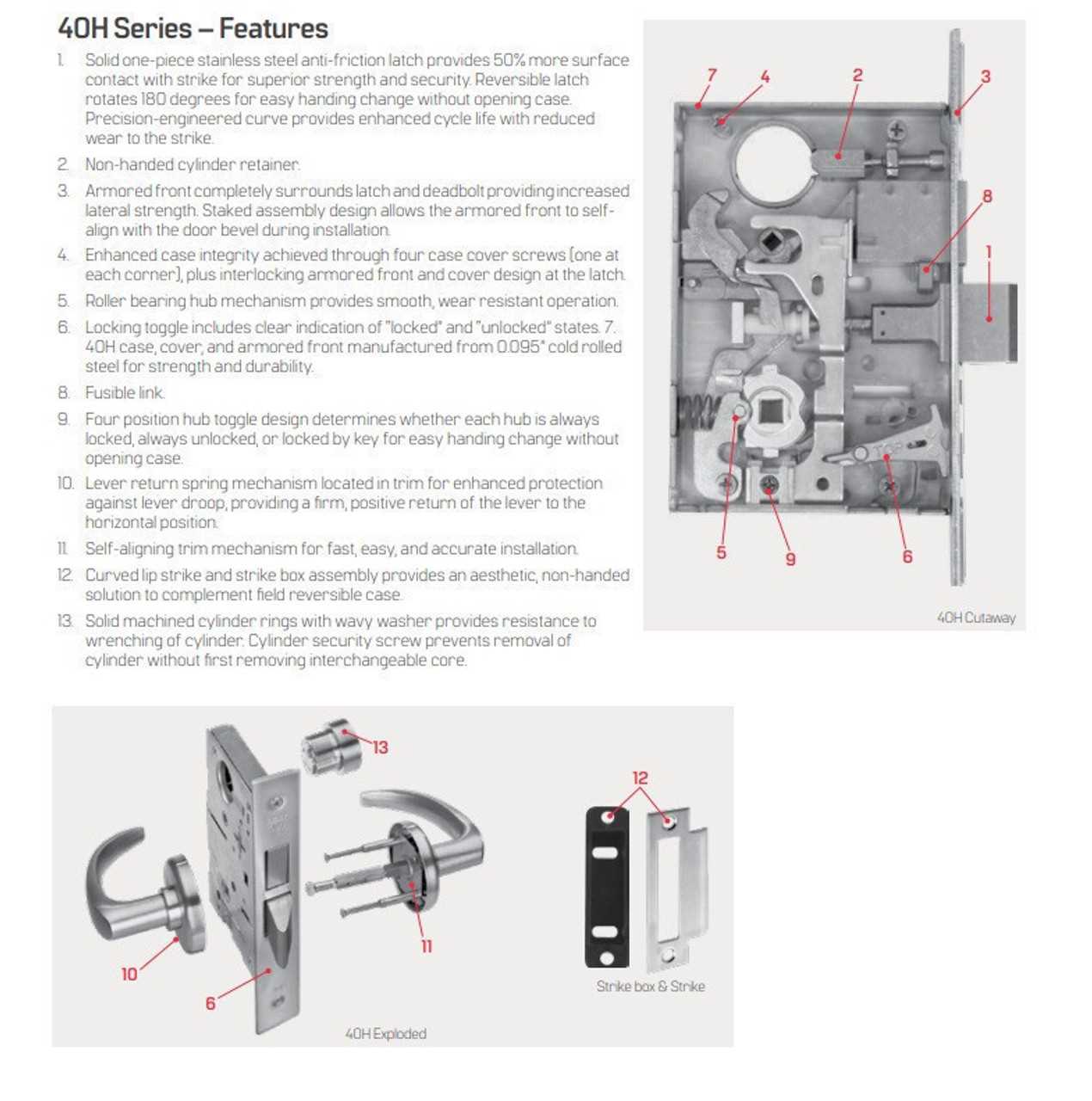

The mechanism used in various locking devices is based on a sophisticated arrangement that provides security and ease of operation. This system relies on a combination of components that work together to ensure that only the correct key can engage the locking mechanism, allowing for secure access while preventing unauthorized entry. At the heart of this mechanism are two essential elements: the tumblers and the pins. These components interact in such a way that the alignment of the tumblers determines whether the lock can be turned. When the appropriate key is inserted, it raises the pins to their correct heights, aligning them with the tumblers and enabling the lock to open.

Understanding this mechanism is crucial for those interested in security technology, as it highlights the importance of precision in design and function. The effectiveness of this locking system hinges on the careful arrangement and interaction of these components, ensuring that only the designated key can facilitate access. Importance of the Housing in Lock SecurityThe outer shell of a locking mechanism plays a crucial role in ensuring its effectiveness and reliability. This component not only provides physical protection but also contributes significantly to the overall durability of the system. A well-constructed exterior can deter tampering and resist various environmental factors, enhancing the integrity of the entire mechanism. Material Considerations

The choice of material for the outer casing is vital in determining the strength and resilience of the locking system. High-quality metals such as stainless steel or hardened alloys offer superior resistance to cutting and drilling attempts. Additionally, corrosion-resistant materials help maintain functionality over time, ensuring the lock remains operational under various conditions. Design FeaturesA thoughtfully designed exterior can improve the overall security of the locking system. Features such as anti-shim technology, which prevents unauthorized access, and reinforced corners, which resist impact, enhance protection. Furthermore, incorporating weatherproofing elements can safeguard the internal mechanisms from moisture and debris, prolonging the lifespan and reliability of the security device. Mechanical Process Behind the Locking ActionThe mechanism that secures access operates through a series of finely tuned components that work together to create a reliable barrier. Understanding how these elements interact reveals the intricacies of the locking mechanism. At the core of the securing system are several critical components, each playing a distinct role in the overall function:

When the appropriate key is inserted or the correct combination is entered, the following steps occur:

In contrast, when an incorrect key or combination is used, the internal components remain misaligned, preventing the shackle from moving and maintaining security. Thus, the synergy of these mechanical elements forms a robust system, ensuring that unauthorized access is effectively thwarted while allowing for ease of use by the rightful owner. How Rotational Motion Unlocks the Mechanism

The process by which a locking device is disengaged relies heavily on the interaction of components designed to respond to circular movement. This fundamental principle allows for the secure retention of objects while providing an effective means of access when needed. Understanding how this motion translates into unlocking mechanisms reveals the ingenuity behind such devices. Components Engaged in the RotationAt the heart of this mechanism lies a rotating element, often manipulated by a key or dial. When turned, this component interfaces with various internal elements that govern the locking mechanism. As rotation occurs, it alters the positioning of these elements, allowing for a transition from a secured to an unsecured state. The Role of Tension and AlignmentThe effectiveness of this unlocking process is further enhanced by the interplay of tension and alignment within the mechanism. As the rotational motion occurs, it ensures that parts shift into precise positions, overcoming any resistance. This seamless transition is essential for achieving the desired outcome of releasing the locking mechanism. Differences in Padlock Designs and UsesVarious locking mechanisms serve distinct purposes and feature unique characteristics tailored to specific security needs. These variations are designed to enhance protection, ease of use, and adaptability to different environments. Understanding these differences is essential for selecting the most suitable locking solution. Types of Locking Mechanisms

Locking devices can be categorized based on their internal mechanisms, which determine their security levels and usability. Some of the common types include:

Application-Based Differences

Different scenarios dictate the choice of locking solutions. Some environments require enhanced durability, while others may prioritize convenience and ease of access. Understanding these applications helps users make informed decisions about their locking options. Common Materials Used in Lock ManufacturingIn the creation of secure locking mechanisms, a variety of materials are utilized to ensure durability, effectiveness, and resistance to tampering. Each material serves a distinct purpose, contributing to the overall functionality and strength of the locking device.

When selecting materials, manufacturers must balance factors such as strength, cost, and intended use. The right combination ensures the locking mechanism performs reliably over time. |