When it comes to the efficient handling and movement of heavy loads, a specific type of equipment plays a crucial role in various industries. This essential device simplifies the process of transporting goods, enhancing productivity and safety within a workspace. Familiarity with its structure is key to ensuring optimal performance and maintenance.

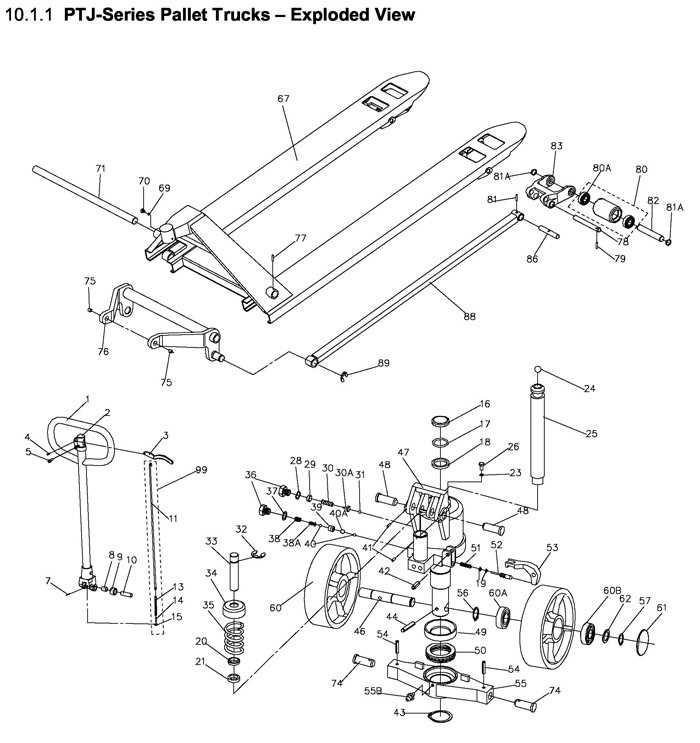

A comprehensive exploration of the various elements that constitute this equipment reveals the intricate design and functionality inherent in each component. Recognizing how these elements work together not only aids in effective operation but also assists in troubleshooting and repairs. With a clear visual representation, users can easily identify and understand the significance of each section, promoting a smoother workflow.

Furthermore, understanding the individual components empowers operators to maintain their equipment better, thereby extending its lifespan. This knowledge fosters confidence in handling the tool, ensuring that users are well-equipped to manage any challenges that may arise during operation. Overall, a deeper insight into the structure of this transport device is invaluable for enhancing efficiency and reliability in everyday tasks.

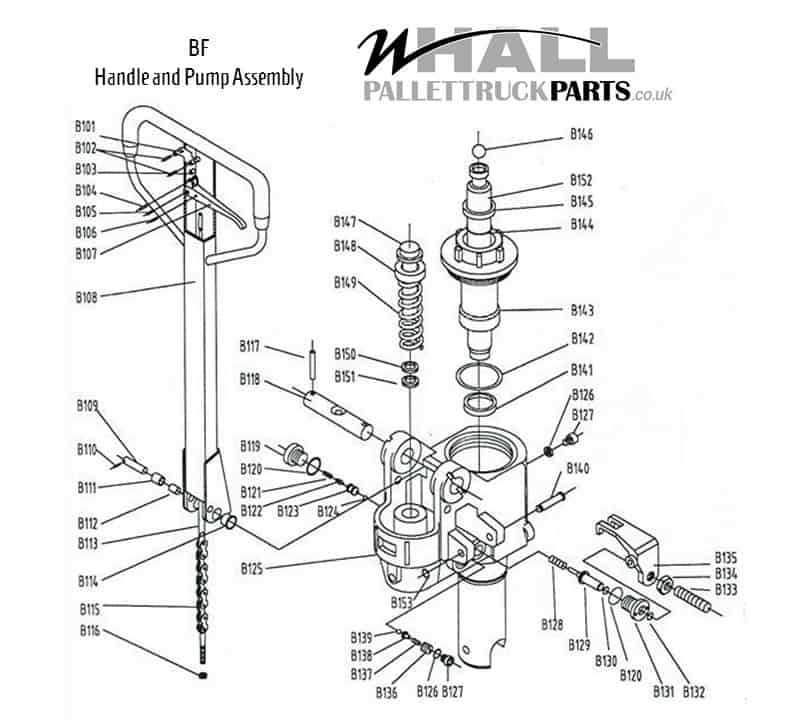

The hydraulic system is a crucial component that enables efficient movement and control in various equipment. This mechanism relies on the principles of fluid dynamics to facilitate lifting and lowering heavy loads with ease. Understanding its functionality can enhance both safety and efficiency during operation.

Key Components of the Hydraulic System

The primary elements that constitute the hydraulic mechanism include:

- Hydraulic Pump: Converts mechanical energy into hydraulic energy, creating fluid flow.

- Hydraulic Cylinder: Transforms hydraulic energy back into mechanical energy to produce motion.

- Fluid Reservoir: Stores hydraulic fluid, ensuring the system has an adequate supply for operation.

- Valves: Control the flow and direction of the hydraulic fluid within the system.

How the System Functions

The operation of the hydraulic mechanism involves several key steps:

- The pump draws hydraulic fluid from the reservoir and pressurizes it.

- The pressurized fluid is directed through valves to the hydraulic cylinder.

- The cylinder extends or retracts, depending on the fluid’s direction, enabling movement.

- The fluid then returns to the reservoir, completing the cycle.

Understanding these components and their interactions can significantly improve the effective use of machinery equipped with hydraulic systems.

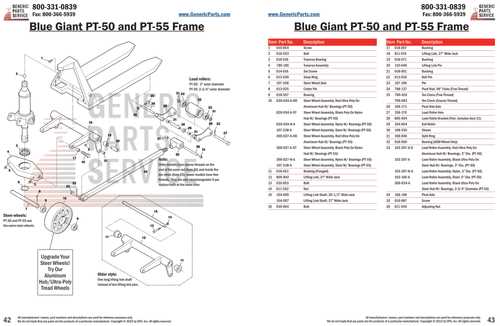

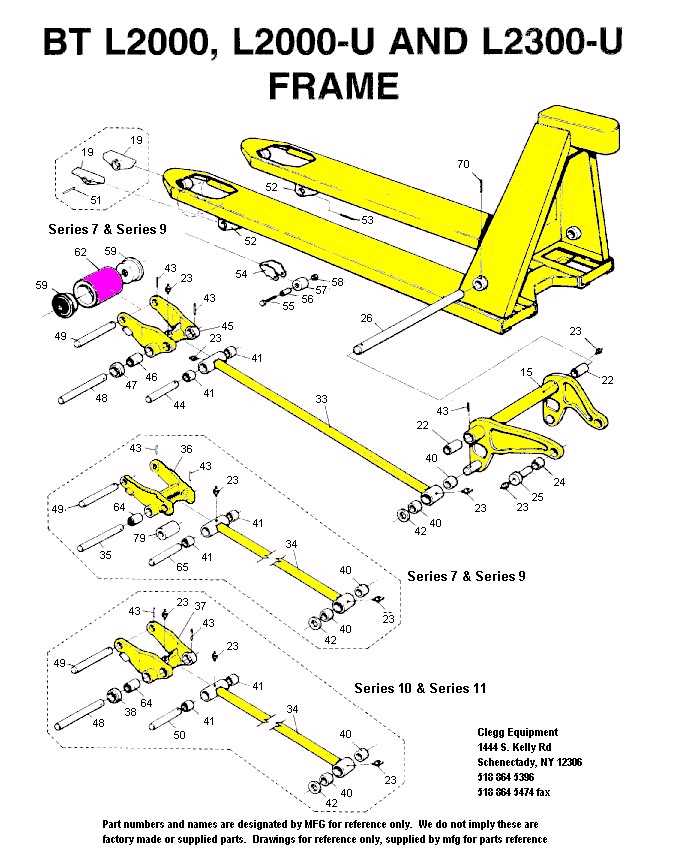

Frame and Structure Details

The framework and structural components of a lifting device play a crucial role in its overall functionality and durability. This section explores the essential elements that contribute to the strength and stability of the equipment.

Primarily, the chassis serves as the foundational element, providing a robust base that supports the entire assembly. It is designed to withstand substantial loads while ensuring smooth maneuverability. The materials used in constructing the chassis often include high-quality steel, which offers excellent resilience against wear and tear.

Additionally, the support beams are integral to maintaining the device’s structural integrity. These components are strategically placed to evenly distribute weight and enhance stability during operation. Proper alignment and secure fastening of these beams are vital for safe functionality.

Finally, the forks, which extend from the chassis, are crafted to facilitate the lifting and lowering of goods. Their design ensures optimal balance and control, allowing for precise handling of various loads. Understanding these structural details is essential for ensuring the effective operation and longevity of the equipment.

Wheels and Movement Mechanism

The efficient operation of any transport device relies heavily on the functionality of its rolling components and the systems that facilitate movement. Understanding these elements is crucial for optimal performance and maintenance.

Types of Wheels

There are several varieties of rolling elements designed for different surfaces and loads. The selection of wheels impacts the overall maneuverability and stability of the equipment.

| Wheel Type | Material | Load Capacity |

|---|---|---|

| Polyurethane | Flexible and durable | High |

| Nylon | Lightweight and resistant | Medium |

| Rubber | Shock-absorbing | Medium to high |

Movement Mechanism

The system responsible for movement encompasses various components that interact to enable smooth transitions. Key features include the steering and hydraulic systems, which work together to provide control and ease of handling.

| Component | Function |

|---|---|

| Steering Wheel | Facilitates direction control |

| Hydraulic Pump | Enables lifting and lowering |

| Linkage System | Connects wheels to the frame |

Control Handle Functions Explained

The control mechanism plays a crucial role in the operation of lifting devices, enabling the user to manage various functions effectively. Understanding how these controls work enhances the efficiency of handling loads, ensuring smooth navigation and maneuverability in tight spaces.

Functionality Overview

The primary functions of the control handle include lifting, lowering, and steering. By engaging different components, the operator can adjust the height of the load with precision while maintaining stability during movement. This intuitive design allows for easy handling, even in complex environments.

Operational Insights

In addition to basic lifting and lowering, some control mechanisms offer advanced features such as speed adjustment and braking systems. These enhancements provide greater control over the device, allowing the user to adapt to various operational demands seamlessly. Familiarity with these functionalities is essential for maximizing productivity and safety.

Fork Assembly and Specifications

This section outlines the structure and characteristics of the lifting component essential for transporting heavy loads. Understanding the configuration and requirements of this element is crucial for ensuring optimal performance and safety during operation.

Structure Overview

The assembly consists of several key elements that work in unison to provide stability and strength. Each component is designed to withstand significant pressure and facilitate efficient movement of goods.

Key Specifications

| Specification | Details |

|---|---|

| Length | Standard length varies from 48 to 72 inches. |

| Width | Typical width ranges from 20 to 27 inches. |

| Weight Capacity | Can handle loads up to 5000 pounds. |

| Material | Commonly made from high-strength steel for durability. |

Braking System Insights

The braking mechanism plays a crucial role in ensuring safety and control in various transport equipment. Understanding its components and functionality is essential for optimal performance and maintenance.

This system typically consists of several key elements that work together to facilitate smooth and effective stopping. Regular inspection and proper adjustments can enhance the overall efficiency and reliability of the equipment.

| Component | Description |

|---|---|

| Brake Lever | Used to engage and disengage the braking mechanism. |

| Brake Pad | Friction material that slows down or stops the wheels. |

| Actuator | Transmits force from the lever to the braking system. |

| Spring | Provides tension to ensure the brake engages properly. |

Understanding these components can help operators maintain their equipment effectively, thereby enhancing safety and prolonging service life.

Maintenance of Pallet Jack Parts

Proper upkeep of equipment components is essential for ensuring optimal performance and longevity. Regular maintenance routines help to identify wear and tear, preventing unexpected breakdowns and costly repairs. By paying attention to each segment of the machinery, operators can maintain efficiency and enhance the overall safety of operations.

Routine Inspections

Conducting frequent evaluations is crucial in spotting potential issues before they escalate. Check for signs of damage or deterioration, particularly on wheels, handles, and hydraulic systems. Ensure that all moving elements are free of obstructions and function smoothly. Addressing minor concerns promptly can prevent major malfunctions.

Lubrication and Cleaning

Keeping components well-lubricated is vital for reducing friction and wear. Apply appropriate lubricants to moving parts to enhance their operation. Additionally, regular cleaning of the equipment helps to eliminate dirt and debris that can hinder performance. A clean machine not only looks better but also operates more efficiently, extending its lifespan.

Identifying Wear and Tear

Recognizing signs of degradation is crucial for maintaining the functionality and safety of handling equipment. Regular inspections can help identify components that may require attention or replacement, ensuring optimal performance and reducing the risk of accidents.

When assessing for deterioration, look for visible indicators such as unusual noises, uneven movement, or resistance during operation. These symptoms may suggest that certain elements are not functioning as intended and need to be examined further.

| Component | Common Signs of Wear | Recommended Action |

|---|---|---|

| Wheels | Flat spots, cracks, or excessive noise | Replace if damage is severe |

| Forks | Deformation, cracks, or uneven wear | Inspect regularly; replace if necessary |

| Hydraulic System | Leaks, slow operation, or inconsistent lifting | Check for leaks and pressure issues; repair or replace |

| Handle | Excessive play or difficulty in operation | Lubricate or replace if worn |

By monitoring these aspects, operators can ensure that their equipment remains in good condition, enhancing both efficiency and safety in their operations.

Replacement Parts and Accessories

Ensuring optimal performance and longevity of your lifting equipment requires access to quality components and add-ons. This section highlights essential replacements and supplementary items that can enhance the functionality and reliability of your device.

When considering replacements, it’s crucial to identify the specific elements that may require attention. Commonly needed components include:

- Wheels and casters for improved mobility

- Hydraulic pumps for effective lifting mechanisms

- Handles and grips for user comfort and control

- Fork extensions to accommodate larger loads

- Safety features such as brakes and reflectors

Additionally, various accessories can provide extra support and versatility:

- Protective covers to shield against dust and debris

- Maintenance kits to ensure smooth operation

- Load stabilizers for secure handling

- Battery-powered options for enhanced efficiency

By investing in high-quality replacements and accessories, users can maximize the utility and lifespan of their equipment, ensuring it operates effectively for years to come.