The intricate design of aerial descent systems plays a crucial role in ensuring safety and efficiency during airborne activities. Each element within this system is engineered to perform specific functions that contribute to a seamless experience. A thorough exploration of these individual elements can enhance our understanding of how they interact and operate collectively.

From the initial release mechanism to the final landing sequence, each section serves a vital purpose. Recognizing the significance of these components allows enthusiasts and professionals alike to appreciate the engineering prowess involved. An informed perspective can lead to improved maintenance practices and heightened awareness of safety protocols.

In this discussion, we will delve into the various segments that constitute these systems, examining their roles and interconnections. By dissecting the assembly, we aim to illuminate the complexity and elegance inherent in the design, fostering a deeper appreciation for the art of aerial navigation.

Understanding Parachute Components

Exploring the essential elements that contribute to the functionality of aerial descent mechanisms is crucial for both enthusiasts and professionals. Each component plays a vital role in ensuring safety and efficiency during descent, making it important to comprehend how they work together.

Key Elements

- Canopy: The large fabric section that creates drag and slows down descent.

- Lines: Cords that connect the canopy to the harness, responsible for transmitting loads.

- Harness: The system that secures the individual, distributing forces during descent.

- Deployment Bag: A container that houses the canopy before it is released.

- Container: The overall assembly that holds the deployment bag and other components.

Functional Importance

- The canopy must be designed for optimal airflow to ensure effective lift and stability.

- Lines need to be durable and well-organized to prevent tangles and ensure smooth deployment.

- A properly fitted harness enhances comfort and safety during the entire experience.

- The deployment bag should facilitate a smooth release of the canopy to minimize risks during opening.

- Each element’s design contributes to the overall performance and reliability of the system.

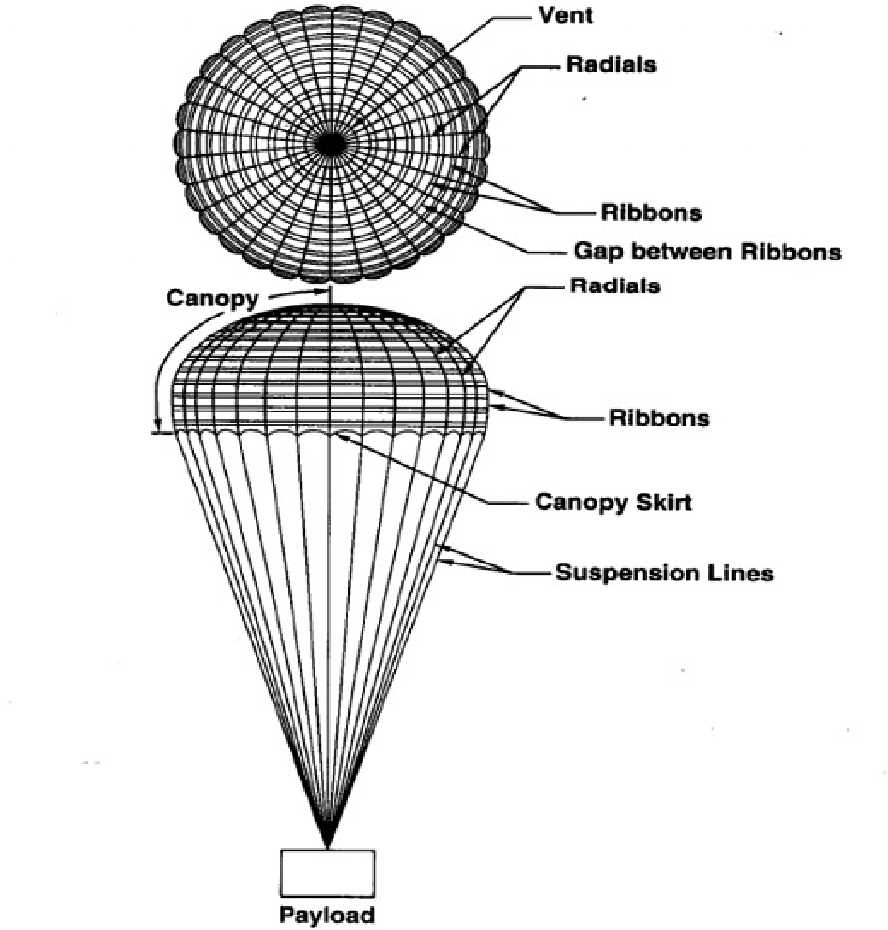

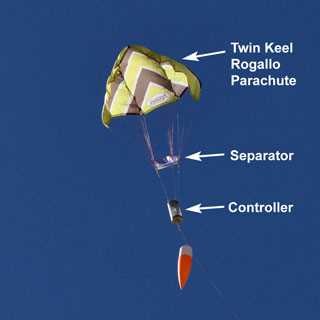

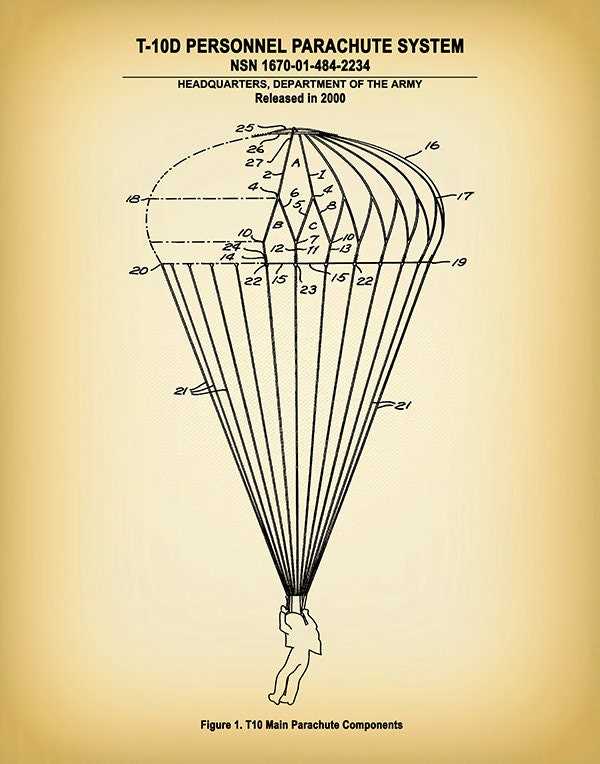

Types of Parachute Designs

Various designs of aerial descent devices have evolved to meet the needs of different applications, each offering unique features and benefits. Understanding these variations can help users choose the most suitable option for their specific requirements, whether for recreational use, military operations, or emergency situations.

Common Designs

- Round Canopy: A traditional design characterized by a circular shape, providing stable descent and ease of deployment.

- Ram-Air: A modern option featuring two layers of fabric, allowing for better control and maneuverability during descent.

- Square Canopy: Known for its rectangular shape, this type offers a more horizontal descent profile and improved glide capability.

Specialized Variants

- Wingsuit: Designed for extreme sports, combining a suit and canopy to enable flight-like maneuvers.

- Stealth Canopy: Used in military applications, crafted to minimize visibility and noise during deployment.

- Multi-Canopy Systems: Incorporating multiple canopies for increased stability and safety, often used in tandem jumps.

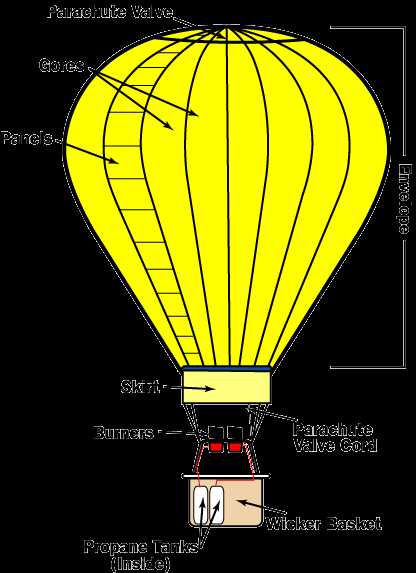

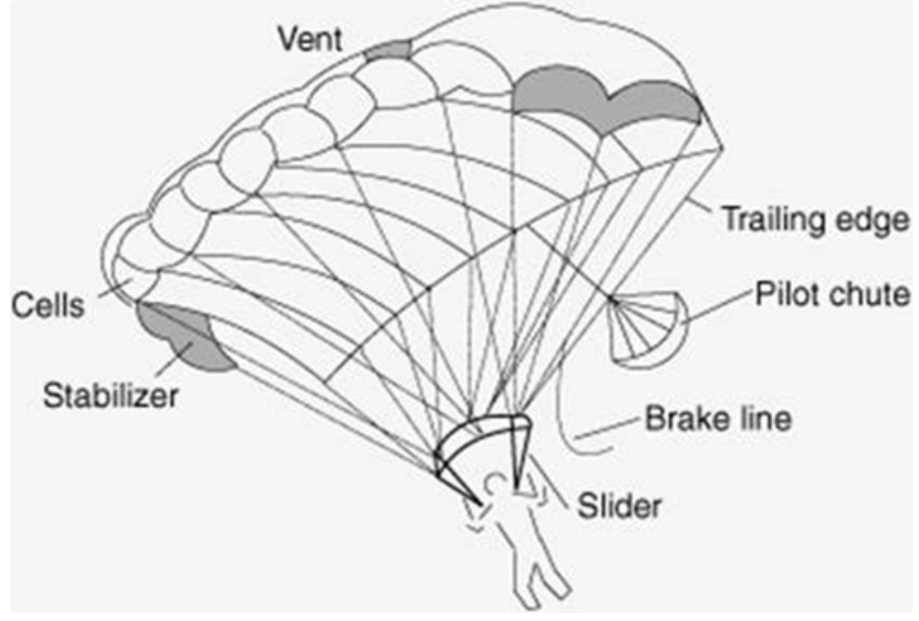

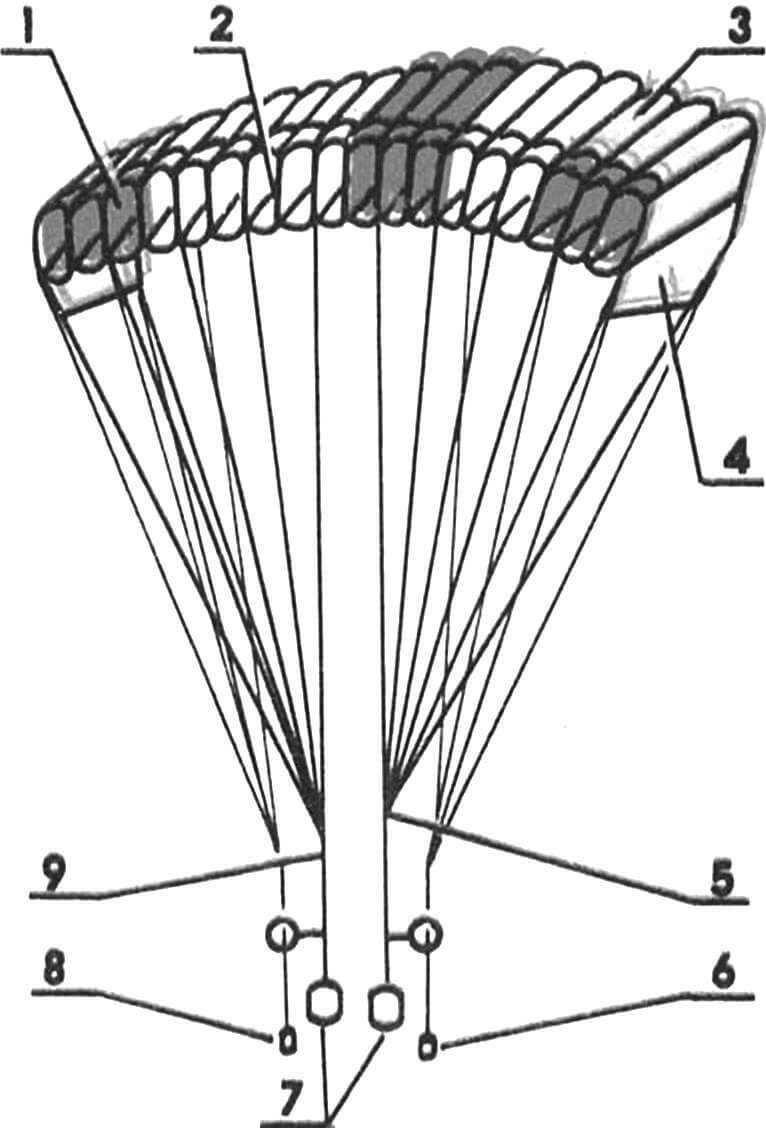

Key Parts of a Parachute

The functioning of a descent device relies on various essential components that work harmoniously to ensure safety and efficiency during free fall. Understanding these critical elements provides insight into the design and operation of the equipment used for aerial landings.

The canopy is the fabric structure that creates drag, slowing descent by capturing air. It plays a vital role in stability and maneuverability. The suspension lines connect the canopy to the harness, distributing the load evenly and allowing for controlled descent.

The harness secures the user, ensuring safety and comfort throughout the jump. It is designed to withstand significant forces and allows for easy attachment and detachment. The deployment system is crucial for the reliable release of the canopy, often using a pilot chute to initiate inflation.

Functionality of Each Component

Understanding the roles of individual elements is crucial for grasping the overall efficiency and safety of aerial descent systems. Each segment contributes uniquely to the successful deployment and stabilization of the device during descent.

- Canopy: Acts as the primary surface that creates lift, slowing the descent.

- Suspension Lines: Connect the canopy to the harness, distributing weight evenly.

- Harness: Ensures secure attachment of the user to the system, providing comfort and safety.

- Deployment Bag: Houses the canopy and controls the opening sequence during descent.

- Release Mechanism: Allows for the quick detachment of the canopy when necessary.

Each element is meticulously designed to enhance the ultimate performance of the entire system, ensuring reliable operation and user safety.

Materials Used in Parachute Construction

The choice of materials is crucial for the functionality and safety of aerial devices. Various elements are combined to ensure durability, lightweight properties, and reliability during descent.

Common Materials

- Nylon: Known for its strength and resistance to abrasion, nylon is a popular choice for canopies.

- Polyester: Offers UV resistance and maintains structural integrity in varying conditions.

- Ripstop fabric: This woven material prevents tearing and adds to overall durability.

Additional Components

- Lines: Typically made from strong, lightweight cords that ensure reliable descent.

- Webbing: Used for harnesses, webbing provides essential support and security.

- Hardware: Metal or plastic components, such as buckles and rings, enhance functionality and safety.

Safety Features of Parachute Systems

Ensuring the well-being of individuals during aerial descents involves a variety of crucial mechanisms designed to enhance reliability and minimize risks. These systems incorporate innovative technologies and practices that contribute to the safety of users, allowing them to trust in the equipment’s performance under varying conditions.

Key Safety Mechanisms

- Automatic Activation Device (AAD): This device automatically deploys the canopy if the user has not done so at a predetermined altitude, preventing potential accidents.

- Riser Releases: Quick-release mechanisms on the risers allow for rapid disconnection in emergency scenarios, enhancing the safety of the descent.

- Reserve Canopy: A secondary canopy provides a backup option in case of main system failure, ensuring a reliable alternative.

Regular Maintenance and Inspections

Routine checks and servicing of the equipment are essential to uphold safety standards. Key practices include:

- Performing visual inspections for wear and tear.

- Testing all release mechanisms to ensure functionality.

- Following manufacturer guidelines for maintenance schedules.

By integrating advanced safety features and adhering to stringent maintenance protocols, these systems significantly reduce the likelihood of accidents, instilling confidence in users as they embark on their airborne adventures.

Maintenance Tips for Parachute Gear

Ensuring the longevity and reliability of your aerial equipment requires regular care and attention. Proper upkeep not only enhances performance but also ensures safety during usage. Following a few essential guidelines can help you maintain your gear in optimal condition.

Regular Inspections

Conduct thorough checks before and after each use. Look for signs of wear, fraying, or any irregularities that might compromise functionality. Pay particular attention to stitching and fabric integrity, as these are critical for safe deployments.

Proper Storage

Store your gear in a cool, dry place away from direct sunlight. Avoid damp environments to prevent mold and degradation. Use breathable bags and avoid overpacking to maintain the shape and quality of the materials.

Common Issues and Troubleshooting

Understanding potential problems and their solutions is crucial for maintaining optimal performance in aerial gear. By identifying common challenges, users can ensure safety and reliability during use. This section provides insights into frequent malfunctions and effective troubleshooting methods.

| Issue | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Inadequate Deployment | Obstructions, improper packing | Check for entanglements and repack carefully |

| Unstable Descent | Uneven weight distribution, wind interference | Reassess load distribution and choose optimal weather |

| Material Wear | Excessive usage, exposure to elements | Inspect for tears or fraying and replace worn items |

| Failure to Open | Faulty mechanism, improper setup | Test the mechanism and ensure correct assembly |

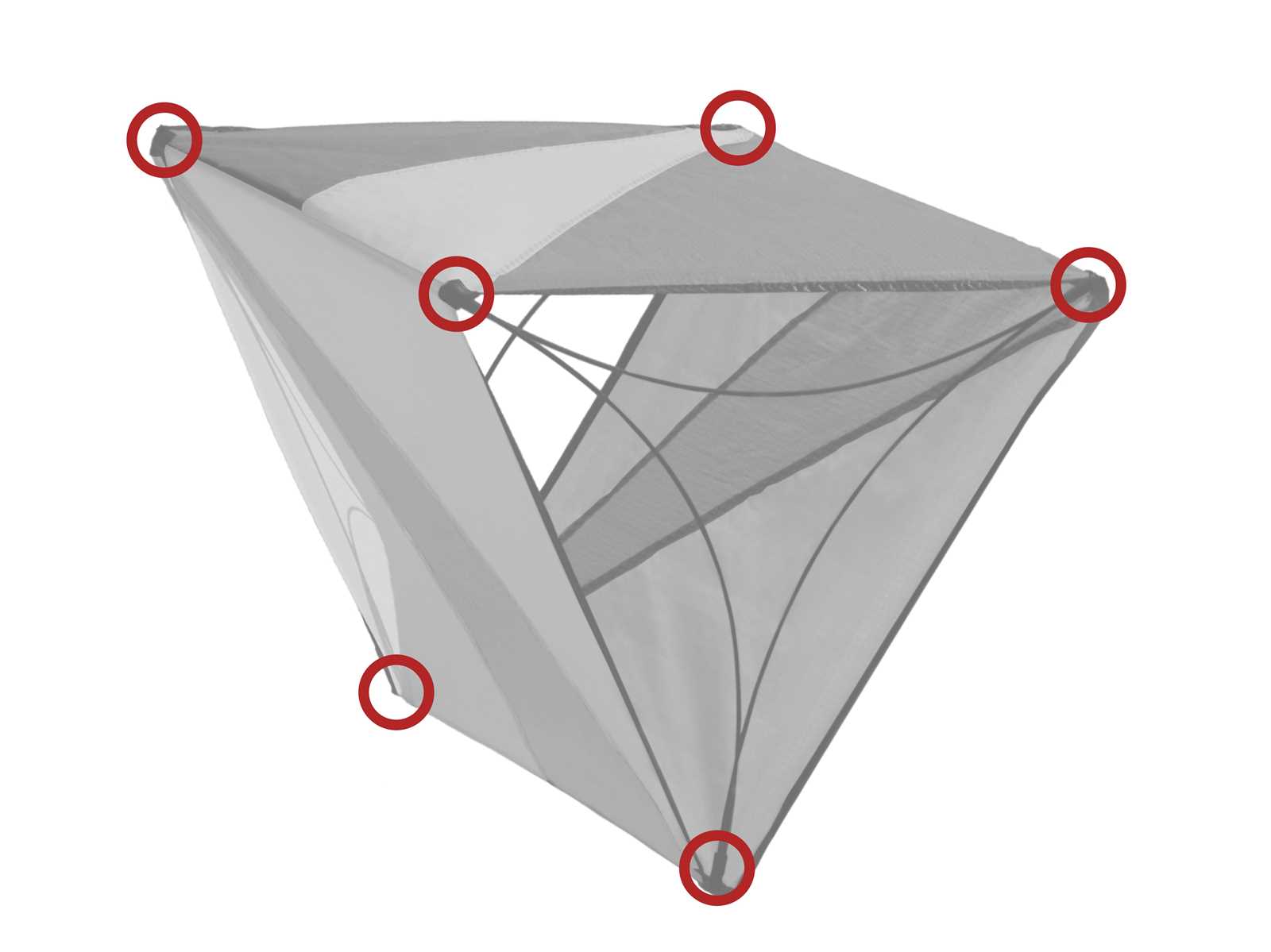

Innovations in Parachute Technology

The advancement of aerial descent systems has significantly transformed how individuals engage with airborne activities. Recent developments focus on enhancing safety, performance, and user experience, reflecting the industry’s commitment to innovation.

Among the most notable breakthroughs are:

- Smart Deployment Systems: Modern mechanisms utilize sensors and algorithms to determine optimal opening times, reducing the risk of malfunction.

- Lightweight Materials: The introduction of advanced fabrics and composites has led to a decrease in weight while maintaining durability and strength.

- Stability Enhancements: New designs incorporate features that improve stability during descent, minimizing drift and ensuring a controlled landing.

Furthermore, advancements in aerodynamics have played a crucial role in enhancing the efficiency of descent. Innovations include:

- Variable Geometry: Designs that can adapt their shape during flight to optimize performance under varying conditions.

- Active Control Surfaces: Systems that adjust in real time to manage descent trajectory and speed.

These cutting-edge developments not only boost safety but also open new possibilities for recreational and professional applications. The future of aerial descent systems promises continued evolution, driven by ongoing research and technological integration.

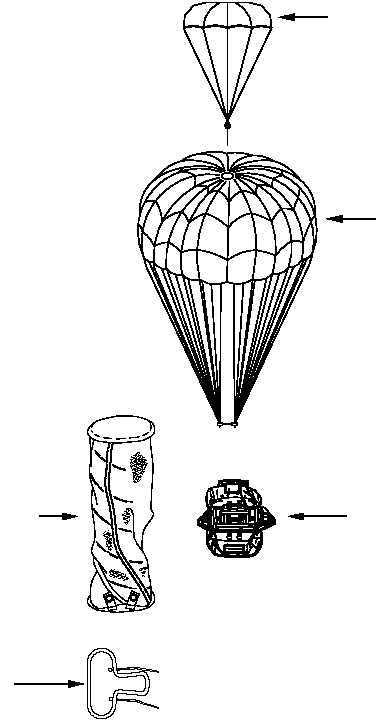

Parachute Deployment Mechanisms Explained

This section delves into the intricate systems that facilitate the effective release and expansion of aerial descent devices. Understanding these mechanisms is crucial for ensuring a safe and reliable descent during various activities, such as skydiving and aerial operations.

Key Components of Deployment Systems

- Activation Device: Triggers the opening sequence.

- Deployment Bag: Houses the canopy until release.

- Bridle: Connects the bag to the main canopy.

- Release Mechanism: Ensures smooth extraction of the canopy.

Types of Deployment Mechanisms

- Static Line Deployment: Utilizes a cord attached to an aircraft, automatically opening the canopy.

- Manual Deployment: Requires the user to pull a cord to release the canopy.

- Automatic Activation Device (AAD): Engages if the user fails to deploy at a specific altitude.

Each of these systems plays a vital role in the overall functionality and safety of descent operations, ensuring a smooth transition from free fall to canopy flight.

Parachute Packing Techniques

Properly preparing a canopy is essential for ensuring a safe and effective descent. Mastering various techniques can significantly influence the performance and reliability of the equipment during use. Understanding the intricacies of the process is key for both novice and experienced enthusiasts.

Methodical Approach: Begin by laying out the canopy in a clean, flat area. This step prevents tangles and ensures that all components are in optimal condition. A systematic method aids in identifying any wear or damage that might compromise safety.

Layering: Employing a consistent layering technique is crucial. Start with the deployment bag, followed by folding the canopy in an organized manner. Ensuring uniformity in folds can enhance the flow of air during inflation, leading to a smoother opening.

Rolling vs. Folding: Some prefer rolling the fabric, while others advocate for folding. Each method has its benefits, but the choice should align with personal comfort and experience. Rolling can reduce bulk, while folding may allow for easier inspection of the material.

Final Checks: Once packed, perform a thorough inspection. Verify that all lines are free of twists and that the deployment mechanism functions correctly. This final step is vital for ensuring that the descent will proceed as planned, free of unexpected complications.

By refining these techniques, users can enhance their confidence and safety, ensuring that each descent is both enjoyable and secure.

History of Parachute Development

The evolution of aerial descent devices showcases humanity’s relentless quest for safer landings from heights. From early concepts rooted in imagination to the sophisticated systems used today, this journey reflects significant technological advancements and a deeper understanding of aerodynamics.

In ancient times, visionaries like Leonardo da Vinci imagined contraptions that could slow a fall. However, it wasn’t until the 18th century that practical designs began to emerge, driven by experimentation and a desire to defy gravity. The first successful descent using a canopy system occurred in 1797, marking a pivotal moment in this ongoing story.

The 20th century saw rapid developments, particularly during wartime, when these devices became essential for military operations. Innovations in materials and design transformed functionality, leading to increased safety and reliability. As the decades progressed, recreational use also gained popularity, broadening the appeal and application of these life-saving tools.

Today, advanced technologies continue to refine and enhance these descent mechanisms, ensuring they meet the demands of both thrill-seekers and professionals alike. This dynamic history not only highlights human ingenuity but also our enduring fascination with the skies.

Future Trends in Parachute Design

The advancement of aerial safety equipment is on the verge of a significant transformation, driven by technological innovations and evolving user needs. As materials science progresses and design methodologies become more sophisticated, the focus is shifting towards enhancing performance, safety, and usability in challenging environments.

Innovative Materials

New materials are set to redefine how aerial devices are constructed. Key trends include:

- Ultra-lightweight fabrics: Using advanced composites that reduce weight while maintaining strength.

- Smart textiles: Integrating sensors that provide real-time data on altitude, speed, and environmental conditions.

- Self-repairing materials: Developing fabrics that can mend themselves upon damage, increasing durability.

Enhanced Deployment Mechanisms

As technology evolves, so do the mechanisms that control how these devices are deployed. Future developments may include:

- Automated opening systems: Utilizing robotics to ensure optimal deployment timing, reducing human error.

- Adaptive configurations: Creating designs that adjust their shape in response to changing wind conditions, optimizing stability and control.

- Integrated navigation systems: Implementing GPS and advanced tracking to guide descent and landing with precision.

These trends highlight a future where aerial safety equipment not only prioritizes user safety but also embraces cutting-edge technology, making every descent a controlled and informed experience.