The functioning of various mechanical systems often hinges on effective methods of energizing motors. These approaches facilitate the efficient operation of equipment across multiple applications, ensuring optimal performance and energy conservation. A deep understanding of these techniques is essential for both technicians and engineers working in the field of mechanical systems.

One such method involves a unique configuration that allows for the gradual engagement of motor components. This arrangement not only enhances the starting process but also helps in managing electrical loads effectively. By implementing this technique, users can achieve smoother transitions and reduce the strain on electrical circuits, thereby extending the lifespan of the machinery involved.

Furthermore, this activation scheme provides flexibility in design, accommodating various installation scenarios. As a result, it has become a preferred choice for many industrial and commercial applications. Understanding this approach can greatly improve troubleshooting skills and enable technicians to optimize system performance in diverse settings.

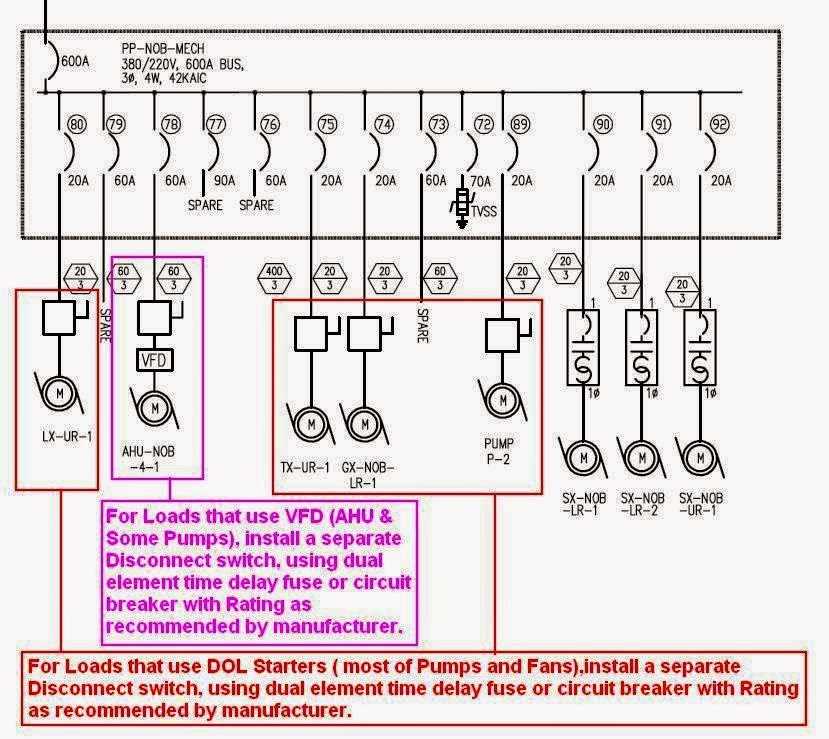

Components of a Wiring Diagram

A schematic representation of electrical connections is essential for understanding how various elements work together in a system. This visual tool enables technicians and engineers to identify the relationships between components, ensuring a smooth operation of the entire assembly. Each element plays a critical role in facilitating the functionality and efficiency of the setup.

Here are the main elements typically found in such representations:

- Symbols: These graphical representations signify various electrical components, such as switches, fuses, and power sources. Each symbol adheres to standardized conventions for easy identification.

- Connections: Lines connecting symbols illustrate the pathways through which electricity flows. Understanding these links is crucial for troubleshooting and circuit design.

- Labels: Annotations provide additional information about the components, such as voltage ratings, current specifications, and part numbers, facilitating a clearer understanding of the system.

- Orientation: The layout often indicates the physical arrangement of components, which can be essential for installation and maintenance tasks.

Familiarity with these elements allows for effective analysis and optimization of electrical systems, leading to improved performance and reliability.

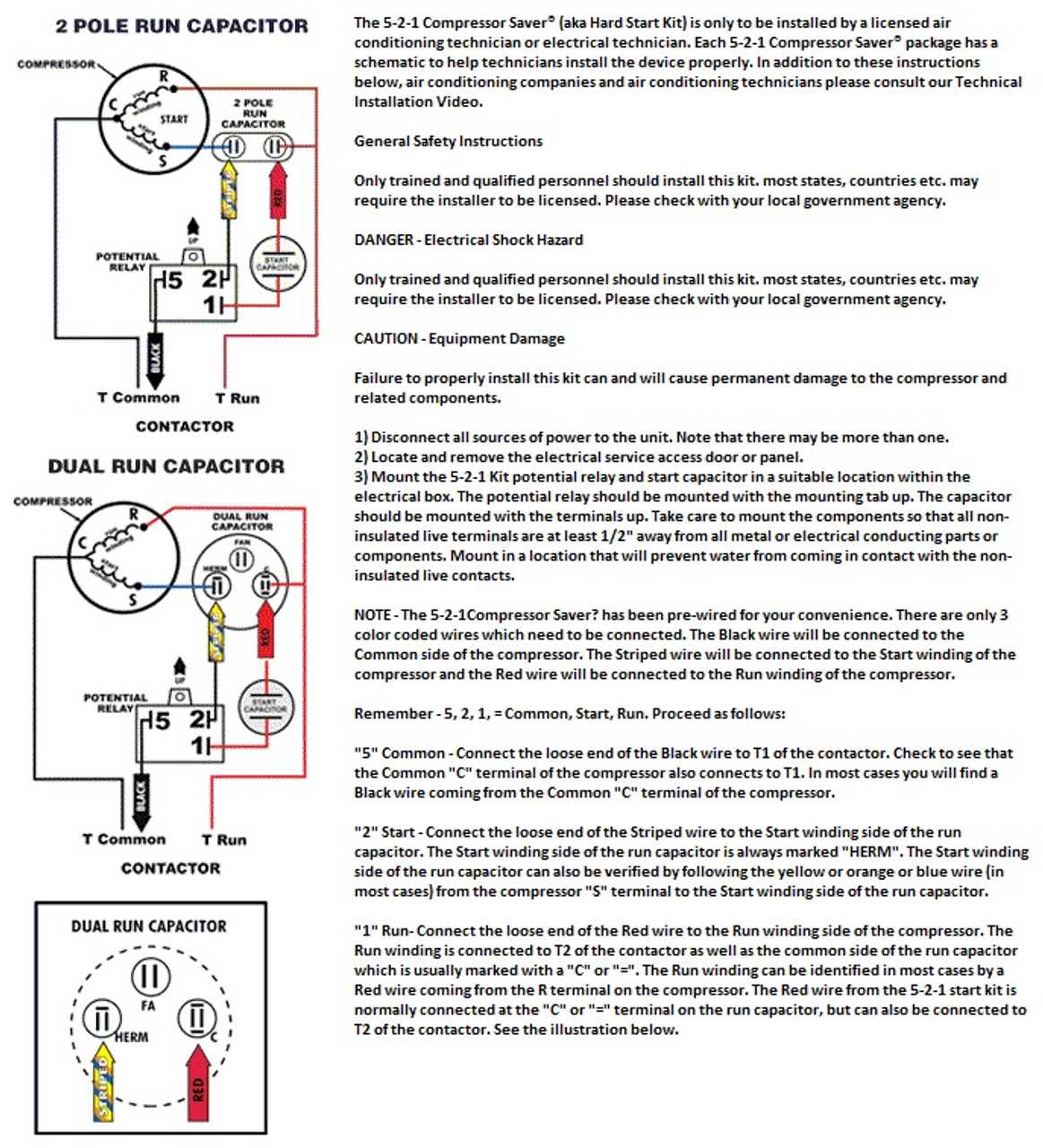

How Part Winding Starts Function

The operation of certain motor systems involves a specialized method that enhances efficiency during the initial phases of activation. This technique is designed to reduce the inrush current, ensuring a smoother engagement of the motor components while providing adequate torque for the task at hand.

Mechanism of Operation

In these systems, the design incorporates multiple coil segments that are activated in a sequence. Initially, only a portion of the coils engages, which allows for a controlled rise in current and minimizes electrical strain. As the motor reaches a predetermined speed, the additional coils are subsequently energized, enabling full performance capacity.

Benefits of This Approach

This method presents several advantages. By limiting the starting current, it decreases the potential for electrical surges that could damage the system. Additionally, it promotes energy savings, extending the lifespan of the motor and associated components. Overall, this approach is highly effective in optimizing performance and enhancing reliability.

Benefits of Part Winding Start Systems

Utilizing systems that initiate operation through segmented engagement offers numerous advantages in electrical applications. These mechanisms are designed to enhance efficiency and improve overall functionality. By employing a method that gradually applies power, users can achieve smoother performance and prolonged equipment lifespan.

Energy Efficiency: One of the primary benefits of this approach is its ability to reduce energy consumption. By minimizing the initial load during startup, the system operates at a lower energy demand, leading to significant savings on utility bills.

Enhanced Durability: Gradual engagement significantly decreases mechanical stress on components. This reduction in stress results in less wear and tear, ultimately extending the lifespan of the machinery and reducing maintenance costs.

Smoother Operation: The controlled application of power facilitates a more stable operation. This smooth transition minimizes vibration and noise, creating a more pleasant working environment.

Overall, adopting segmented engagement systems can lead to substantial improvements in efficiency, reliability, and longevity of electrical applications.

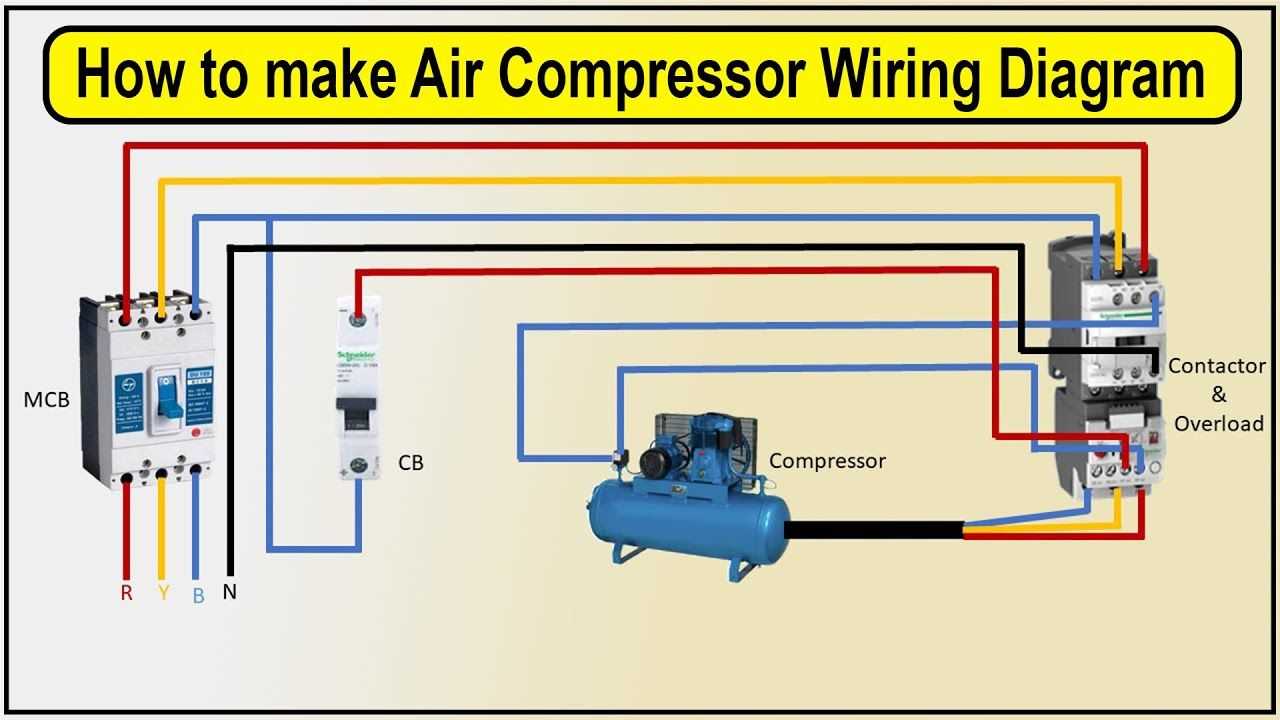

Common Wiring Techniques Explained

When it comes to connecting electrical components, understanding various methodologies is essential for ensuring efficiency and safety. These practices not only facilitate optimal performance but also contribute to the longevity of the systems in which they are implemented. Each method serves a distinct purpose, catering to specific requirements and operational contexts.

Fundamental Approaches to Connections

There are several fundamental approaches to making connections between electrical components. The most common techniques include series and parallel configurations, each offering unique benefits. In a series setup, components are connected end-to-end, allowing the same current to flow through each part, which can be advantageous for applications requiring consistent power distribution. On the other hand, a parallel arrangement enables each component to receive the full voltage, making it suitable for scenarios where individual performance is crucial.

Safety and Efficiency Considerations

When applying these connection techniques, safety and efficiency should remain top priorities. Proper insulation and protective measures help prevent short circuits and electrical hazards. Additionally, using appropriate gauges of conductors ensures that the current capacity aligns with the operational demands. Employing these precautions not only enhances safety but also optimizes the overall performance of the electrical system.

Safety Considerations for Installation

Ensuring a safe setup during the installation of electrical devices is paramount. Proper attention to safety measures can prevent accidents, equipment damage, and personal injury. Adhering to guidelines and best practices not only protects the installer but also enhances the reliability and longevity of the system.

Before beginning the installation process, it is crucial to assess the working environment. Clear the area of any obstacles, ensure adequate ventilation, and keep flammable materials away from the installation site. Additionally, wearing appropriate personal protective equipment (PPE) is essential for safeguarding against potential hazards.

| Safety Measure | Description |

|---|---|

| Power Disconnection | Always disconnect the power supply before starting any installation work to prevent electrical shocks. |

| Grounding | Ensure that all equipment is properly grounded to reduce the risk of electrical surges and faults. |

| Use of Insulated Tools | Utilize insulated tools to minimize the risk of accidental electrical contact during installation. |

| Follow Manufacturer Guidelines | Refer to the manufacturer’s instructions for specific safety protocols and installation procedures. |

| Emergency Preparedness | Have a first aid kit accessible and know the location of emergency shut-off switches in case of accidents. |

Troubleshooting Wiring Issues

Identifying and resolving electrical concerns is crucial for ensuring the efficient operation of various devices. This section focuses on common problems that may arise in the connections of electrical components, offering insights into diagnosing and rectifying these issues. By understanding the basic principles of electrical pathways, users can enhance reliability and performance.

Common Electrical Problems

Several typical issues can affect the functionality of electrical systems. Recognizing these challenges can streamline the troubleshooting process:

- Loose connections that can lead to intermittent operation

- Short circuits resulting from frayed insulation

- Overheating caused by excessive current flow

Diagnostic Steps

Follow these steps to effectively troubleshoot electrical issues:

- Inspect all connections for signs of wear or damage.

- Use a multimeter to test for continuity and voltage.

- Check for correct polarity in the electrical connections.

- Ensure that the circuit is not overloaded.

| Issue | Possible Cause | Solution |

|---|---|---|

| Intermittent operation | Loose connections | Tighten all connections securely |

| Device not powering on | Faulty wiring or damaged components | Replace damaged wires or components |

| Frequent tripping of circuit breaker | Overcurrent condition | Check for overload and redistribute the load |

Best Practices for Wiring Diagrams

Creating clear and effective schematic representations is essential for ensuring the proper functioning of electrical systems. Following established guidelines helps in minimizing errors and improving communication among technicians and engineers. Here are some fundamental approaches to enhance the quality of your schematic representations.

Clarity and Readability

It is crucial to ensure that your diagrams are easy to understand. Use a consistent style for symbols and labels, and maintain a clean layout. Avoid overcrowding by keeping the number of elements manageable, and utilize whitespace effectively to separate different sections.

Standardization

Adhering to standardized symbols and conventions can significantly enhance the comprehension of your schematic illustrations. Familiarity with these standards ensures that anyone reviewing the representation can easily interpret its meaning, regardless of their background.

| Best Practice | Description |

|---|---|

| Use Standard Symbols | Employ universally recognized symbols for components to enhance clarity. |

| Label Clearly | Provide clear and concise labels for each component to avoid confusion. |

| Organize Layout | Arrange components logically to reflect their actual connections in the system. |

| Limit Complexity | Avoid overcrowding the representation; aim for simplicity in design. |

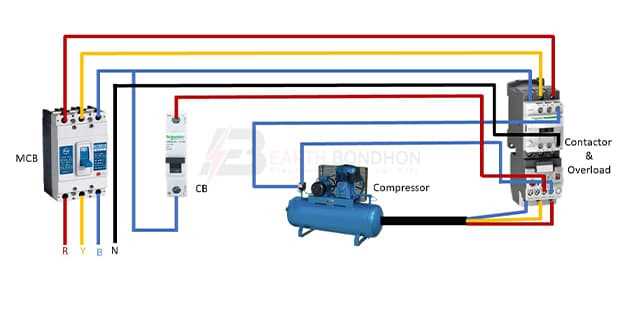

Comparing Different Starting Methods

When selecting an approach for initiating electric motors, various strategies come into play, each with its own benefits and drawbacks. Understanding these options is crucial for optimizing efficiency and performance in electrical systems.

Here are some common methods used for motor initiation:

- Direct-On-Line (DOL): This method applies full voltage directly to the motor, providing high starting torque. However, it can lead to high inrush currents.

- Star-Delta Starting: This technique initially connects the motor in a star configuration to reduce voltage during start-up, then switches to a delta configuration for normal operation. This reduces initial current draw.

- Soft Starters: These devices gradually increase voltage to the motor, minimizing mechanical stress and reducing peak current. They offer better control and smoother operation.

- Variable Frequency Drives (VFDs): VFDs adjust the frequency and voltage supplied to the motor, allowing for precise control over speed and torque, making them versatile for various applications.

Each of these initiation techniques has unique characteristics that make them suitable for different operational contexts. Assessing the requirements of your specific application will aid in selecting the most effective method for optimal results.

Maintenance Tips for Compressors

Regular upkeep is essential for ensuring the longevity and efficiency of mechanical devices used in refrigeration and air conditioning systems. Proper care not only enhances performance but also minimizes the risk of unexpected breakdowns. Implementing a routine maintenance schedule can significantly extend the lifespan of these machines.

Start by routinely checking the lubrication levels, as insufficient oil can lead to wear and tear of critical components. Ensure that the filters are clean and free from obstructions, as dirty filters can hinder airflow and reduce efficiency. Additionally, inspect all electrical connections for signs of wear or damage to prevent potential hazards.

It is also advisable to monitor operating temperatures and pressures regularly. Keeping an eye on these parameters can help detect any irregularities early, allowing for timely interventions. Furthermore, consider cleaning the external surfaces to prevent dust accumulation, which can impact performance. By following these guidelines, you can maintain optimal functionality and reliability.

Applications of Part Winding Compressors

The utilization of specific motor designs plays a crucial role in enhancing the efficiency of various systems. These unique configurations allow for optimized performance across a range of applications, demonstrating their versatility in numerous industrial and commercial settings.

In the field of refrigeration, these specialized motors are widely employed in chillers and cooling units, providing a reliable solution for maintaining temperature control. HVAC systems also benefit significantly, where their ability to start under reduced electrical load minimizes energy consumption while ensuring effective climate regulation.

Moreover, they are integral to processes in manufacturing environments, where controlled operation is vital. By enabling gradual acceleration, these motors reduce mechanical stress on components, promoting longevity and reducing maintenance requirements.

Overall, the implementation of these motor systems proves advantageous in applications that demand energy efficiency and operational reliability, making them a preferred choice in modern engineering solutions.