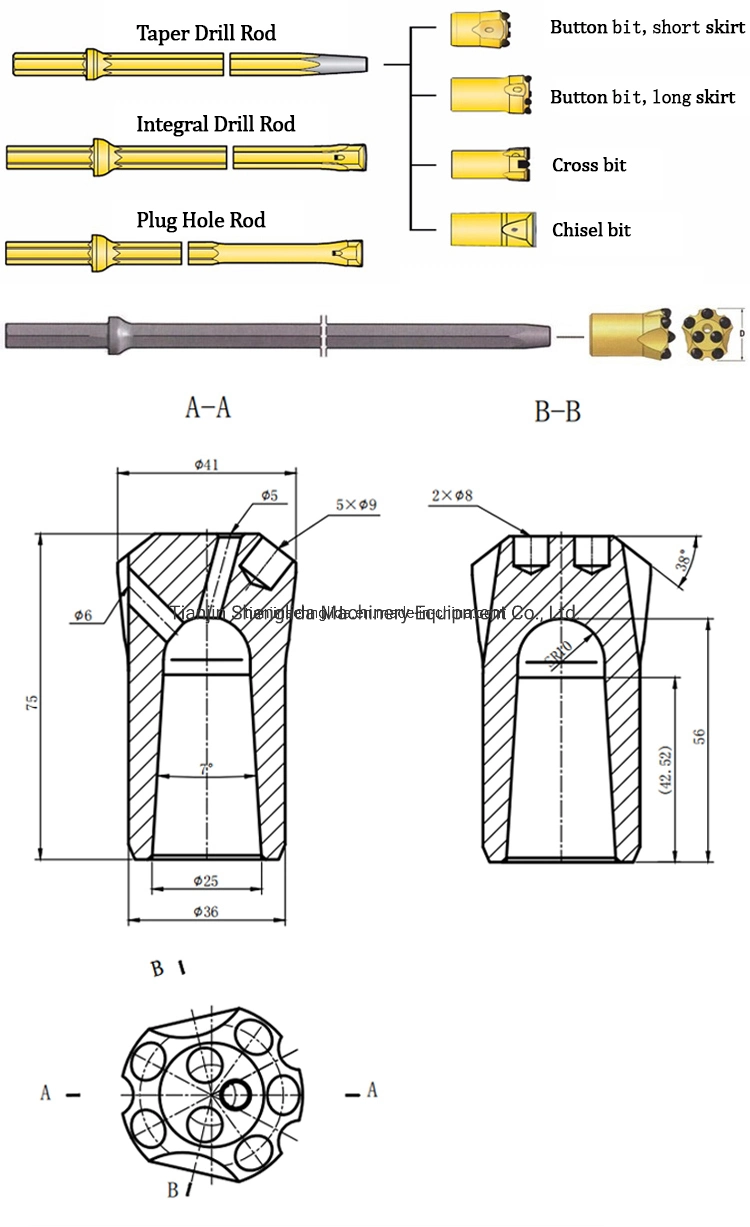

When working with cutting tools, it is essential to have a clear comprehension of how they are built and function. These tools are designed with precision to ensure optimal performance for various materials. Each section plays a crucial role in ensuring that the tool achieves the desired outcome efficiently and safely.

In this guide, we will explore the different components of these tools that contribute to their overall effectiveness. By breaking down each segment, we can gain insight into how they interact during use. Whether for professional tasks or DIY projects, understanding the makeup of these tools can significantly enhance the quality of your work.

The structure is more than just a simple configuration; each element is meticulously crafted to serve a specific purpose. From cutting edges to the core, every detail influences the tool’s ability to cut, bore, or shape materials with precision. Let’s delve into how these elements come together to create an efficient and reliable tool.

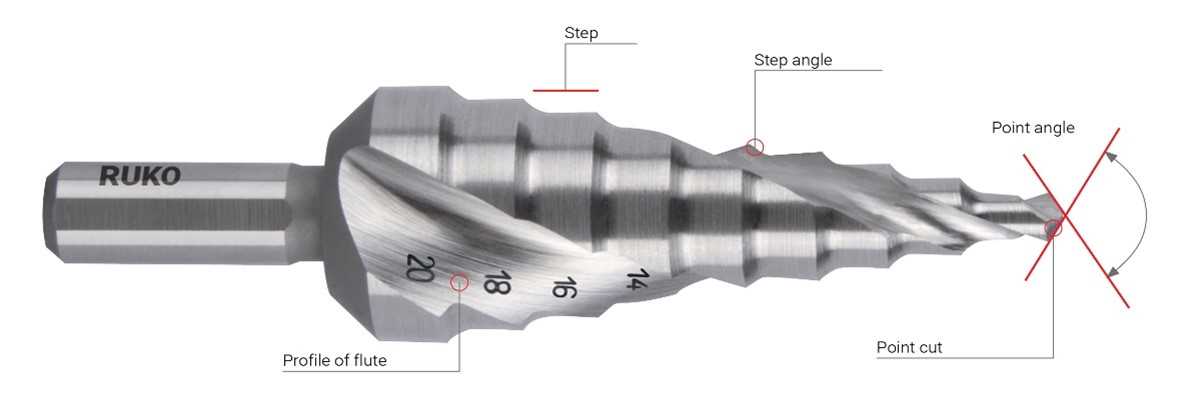

Understanding the Components of a Drill Bit

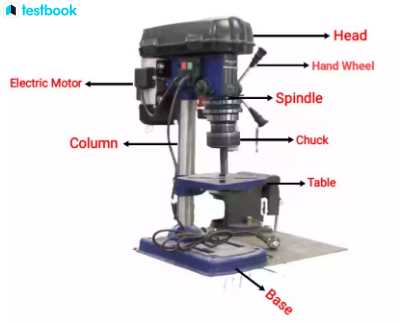

To achieve efficient and precise performance, it is crucial to grasp the design elements of this essential tool. Each section is crafted to fulfill a unique role, ensuring optimal functionality for various tasks. Whether creating openings in wood, metal, or other materials, knowing how each segment works together allows for better control and effectiveness.

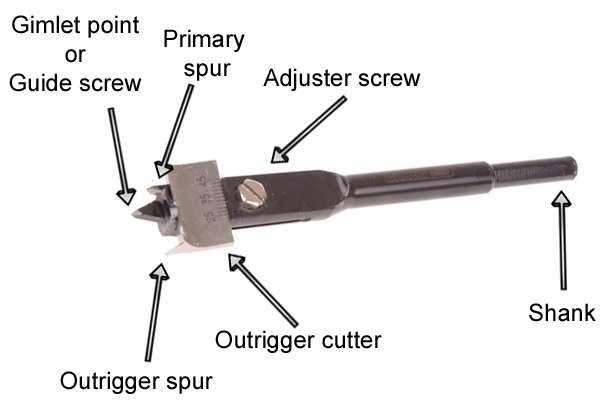

The tip is responsible for initiating the process, ensuring an accurate start. Following that, the cutting edges are designed to handle the material removal, allowing smooth penetration. Finally, the shank connects to the equipment, providing the necessary stability and power transfer. Each of these elements contributes to overall efficiency, making it important to understand their functions in detail.

Anatomy of a Drilling Tool

Understanding the structure of a precision tool used for cutting into materials is crucial for effective usage. Each component plays a vital role in ensuring stability, accuracy, and longevity. Knowing how the various segments interact with each other can significantly improve performance during tasks involving material removal.

Main Sections Overview

The design of the tool includes multiple segments, each tailored to specific purposes such as guiding, cutting, or clearing debris. The arrangement and functionality of these elements determine the tool’s efficiency and durability. Key segments also influence how well the tool handles various materials, from soft woods to tough metals.

Segment Breakdown

| Component | Function | ||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tip | Initial point of contact; directs cutting action. | ||||||||||||||||||||||||||||||||||||||||

| Body |

| Benefit | Description |

|---|---|

| Precision | Enables accurate placement and reduces wandering during operation. |

| Reduced Splintering | Minimizes damage to the surface of the material, resulting in cleaner edges. |

| Efficiency | Facilitates quicker penetration through wood, saving time during tasks. |

Conclusion

Incorporating a spur tip into woodworking tools is essential for those seeking to achieve high-quality results. Its design not only enhances performance but also ensures that projects are completed with precision and finesse.

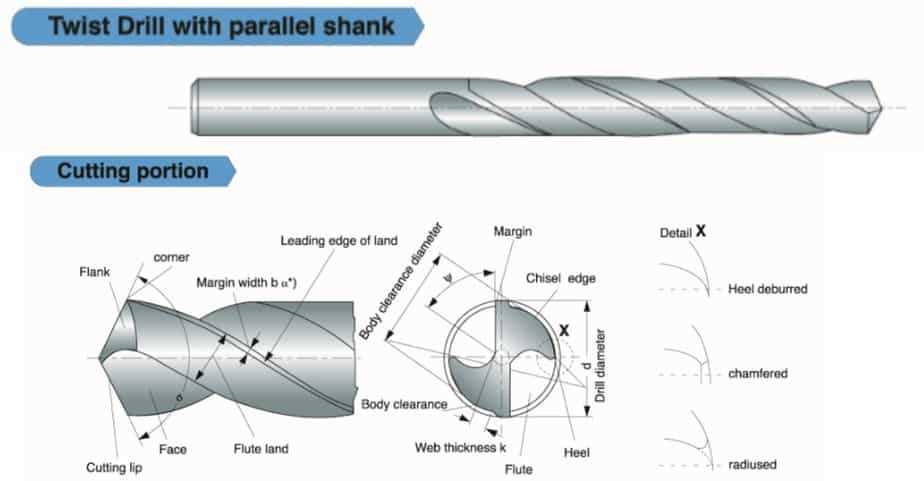

Twist Design and Its Effect on Speed

The configuration of a tool’s helical grooves plays a crucial role in determining its operational efficiency. These spiraled features influence how quickly and effectively the instrument can penetrate various materials. By understanding the mechanics behind this design, one can optimize performance and adapt to different tasks more efficiently.

Influence on Cutting Action

The spiral structure enhances the cutting action by allowing debris to be removed from the workpiece more efficiently. As the tool rotates, the twist angle helps guide waste away from the contact area, reducing friction and heat buildup. This design not only facilitates a smoother operation but also contributes to prolonged durability.

Impact on Rotation Speed

A well-designed helical arrangement can significantly increase the rotation speed, allowing for faster completion of tasks. The specific angle of the twist is essential; a steeper angle may lead to higher speeds but can also create challenges in maintaining stability. Balancing these factors ensures optimal performance while minimizing wear on the tool.

Body Taper: Controlling Friction and Heat

The design of a tool’s body taper plays a crucial role in its overall performance and efficiency. This aspect influences the interaction between the tool and the material being worked on, impacting both friction levels and heat generation during operation. Understanding the significance of this feature can lead to enhanced productivity and prolonged tool life.

A well-crafted taper allows for optimal penetration and minimizes resistance as the tool engages with various materials. By reducing friction, it decreases the amount of heat produced, which can otherwise lead to tool wear and damage. The right angle and dimensions are essential for ensuring that the cutting action remains efficient and effective, providing a smoother experience for the operator.

In addition to performance, the body taper’s characteristics contribute to the heat dissipation during usage. Proper design helps in transferring heat away from the cutting edge, thereby preventing overheating. This balance between friction and thermal management is vital for maintaining the integrity of the tool and ensuring consistent results throughout its lifespan.

Overall, the taper of a tool is not merely a geometric feature; it is a key determinant of efficiency, longevity, and operational safety. Attention to this detail can lead to significant improvements in the effectiveness of various cutting applications.

Web Thickness and Its Impact on Strength

The thickness of the web in cutting tools plays a crucial role in determining their overall durability and performance. Variations in this dimension can significantly influence how well the tool withstands stresses encountered during operation. Understanding the relationship between web thickness and strength is essential for optimizing tool design and enhancing effectiveness in various applications.

Importance of Thickness

A thicker web generally provides greater strength, allowing the tool to endure higher levels of pressure and torque. This added robustness helps in minimizing deformation and wear, leading to a longer lifespan. However, excessive thickness can lead to increased weight and reduced precision, which may hinder performance in specific tasks.

Balancing Act

Finding the right balance between web thickness and other dimensions is vital. Manufacturers often employ advanced materials and engineering techniques to achieve optimal strength while maintaining the necessary agility. Research in this area continues to evolve, offering insights that enhance the design of cutting instruments for improved functionality.

Coatings and Their Influence on Durability

Coatings play a crucial role in enhancing the longevity and performance of cutting tools. These protective layers serve to improve resistance against wear, corrosion, and thermal degradation, thus extending the service life of the tools. By selecting the appropriate coating, manufacturers can tailor the properties of the tools to meet specific application requirements.

Different types of coatings are applied to enhance the functionality of the tools, and their effectiveness can significantly vary. Understanding the characteristics of these coatings helps in optimizing the performance of the tools across various materials and operating conditions.

| Coating Type | Benefits | Applications |

|---|---|---|

| TiN (Titanium Nitride) | Increased hardness, reduced friction | General machining, woodwork |

| TiAlN (Titanium Aluminum Nitride) | High thermal resistance, excellent wear resistance | High-speed machining, metalworking |

| CrN (Chromium Nitride) | Good adhesion, corrosion resistance | Tooling for non-ferrous materials |

| Diamond Coating | Extreme hardness, superior wear resistance | Machining of composites, ceramics |

Choosing the right coating not only affects the durability but also influences the efficiency and quality of the finished product. As technology advances, new coatings are developed to meet the growing demands of various industries, ensuring that tools remain reliable and efficient in challenging environments.

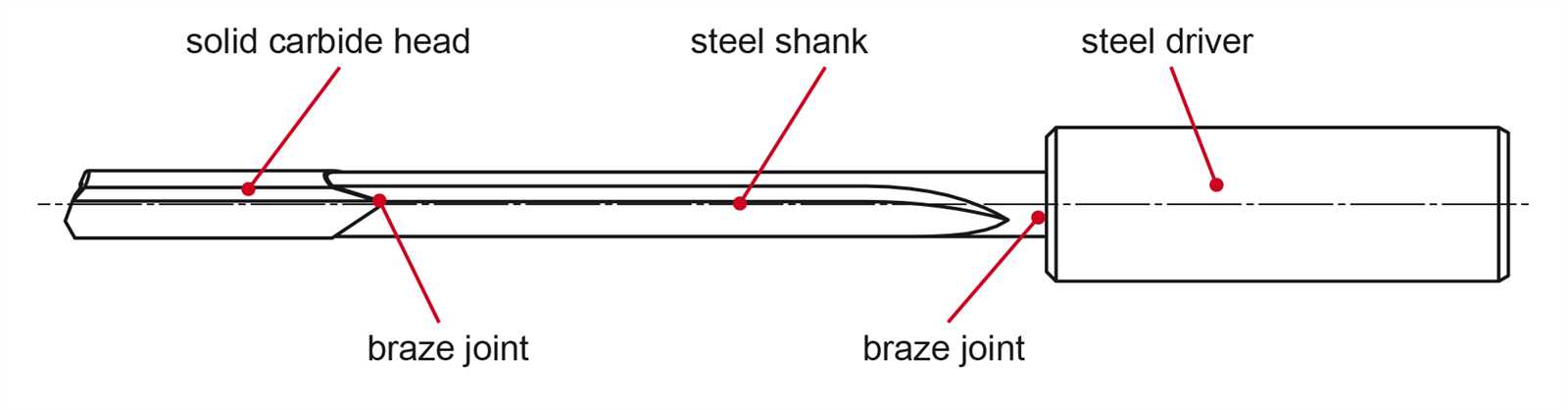

Common Drill Bit Materials and Their Applications

Choosing the right material for a cutting tool is crucial, as it significantly influences performance, durability, and suitability for specific tasks. Various materials are employed in the manufacturing of these tools, each offering distinct advantages and disadvantages based on the intended use. Understanding these materials helps users select the most appropriate tool for their projects, ensuring efficiency and effectiveness in various applications.

Overview of Material Types

Several materials are commonly utilized in the production of cutting tools, ranging from basic steel to advanced composites. The choice of material often depends on the type of material being worked on, the desired finish, and the operating conditions. Below is a table summarizing the most common materials, their characteristics, and typical uses:

| Material | Characteristics | Typical Applications |

|---|---|---|

| High-Speed Steel (HSS) | Good toughness, wear resistance, and heat resistance | Woodworking, metalworking, and general-purpose tasks |

| Cobalt Steel | Increased hardness and heat resistance compared to HSS | Drilling tough materials such as stainless steel and alloyed metals |

| Carbide | Extremely hard, excellent wear resistance, and suitable for high-speed applications | Machining hard metals and abrasive materials |

| Diamond | Superior hardness and longevity, ideal for precision work | Cutting ceramics, glass, and other hard surfaces |

| High-Carbon Steel | High hardness but lower toughness, prone to brittleness | Basic applications, especially in softer materials |

Choosing the Right Material

Selecting the appropriate material for a cutting tool depends on several factors, including the nature of the workpiece, required precision, and operating environment. By understanding the unique properties of each material, users can make informed decisions, ensuring optimal performance and longevity of their tools.