In the realm of automotive engineering, comprehending the intricacies of sound attenuation mechanisms is crucial for optimal vehicle performance. These systems play a vital role in managing engine noise while enhancing efficiency. By exploring their various elements, one can gain valuable insights into how they function and contribute to the overall driving experience.

Each element within these noise-reducing assemblies serves a distinct purpose, collectively working to minimize unwanted sounds emitted from the engine. From the entry point of exhaust gases to their eventual exit, understanding the flow and interaction of these components can reveal the underlying principles of acoustic control. This knowledge is essential for anyone looking to maintain or modify their vehicle effectively.

Through a detailed examination, enthusiasts and professionals alike can appreciate the engineering marvel behind these sound-modulating systems. By identifying the key features and their interactions, one can better grasp how these mechanisms influence performance and sound quality, making it an essential topic for those invested in automotive technology.

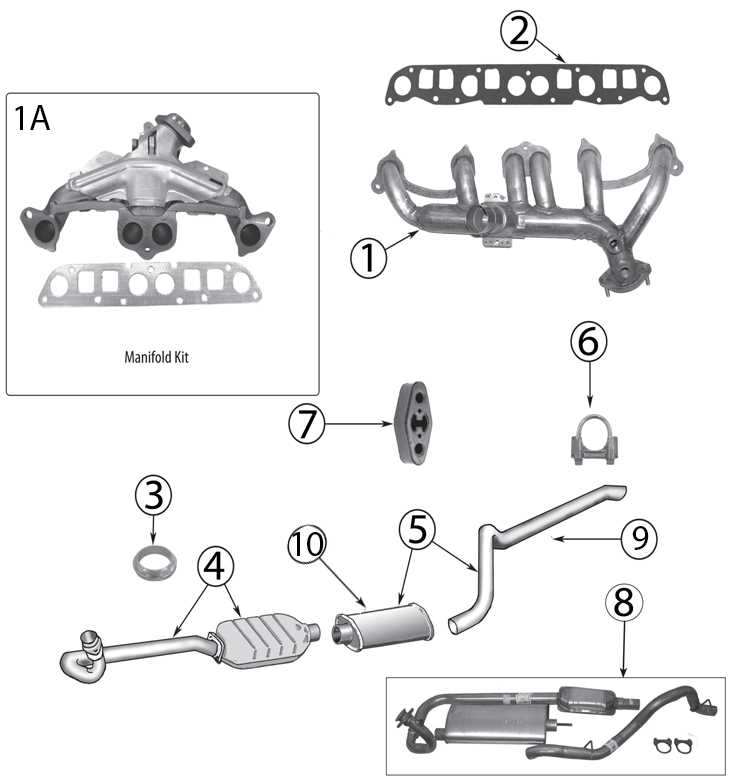

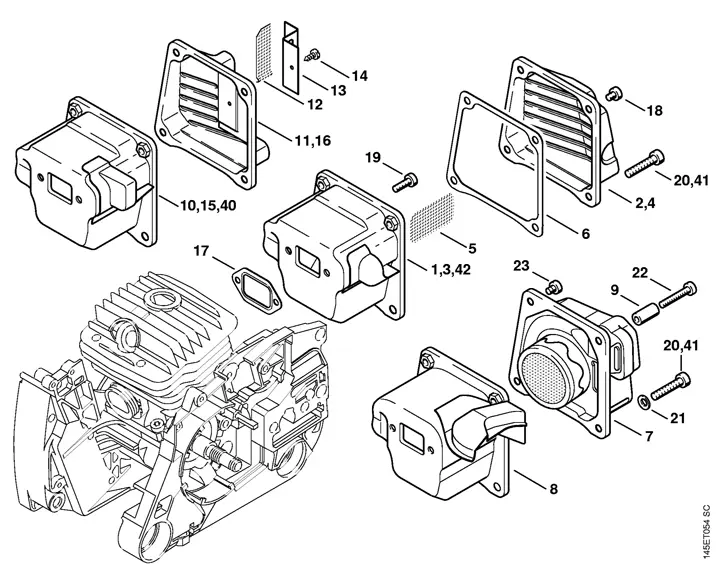

Understanding Muffler Components

The elements of an exhaust system play a crucial role in vehicle performance and noise reduction. Each component contributes to the overall efficiency, ensuring optimal operation and a smoother driving experience. Familiarity with these essential features aids in maintenance and troubleshooting, enhancing longevity and functionality.

Key elements involved in this system include:

- Shell: The outer casing that houses internal components, providing structural integrity.

- Inner Chamber: A space designed to allow gases to flow while minimizing noise.

- Baffles: Internal barriers that redirect and disperse sound waves, contributing to noise attenuation.

- Resonators: Additional structures that help fine-tune sound frequencies for a more pleasant auditory experience.

- Pipes: Pathways through which exhaust gases travel, connecting various components within the system.

Understanding these elements enables better insight into how they interact, leading to improved performance and efficiency of the entire exhaust mechanism.

Functionality of a Muffler System

The primary purpose of an exhaust silencer system is to manage and reduce the noise produced by an internal combustion engine. By employing various techniques and components, this system effectively minimizes sound waves while ensuring optimal performance and efficiency. Understanding the mechanics behind this assembly reveals its significance in maintaining a pleasant driving experience.

Noise Reduction Mechanisms

To achieve effective sound dampening, the assembly utilizes multiple strategies. The primary methods include expansion chambers and sound-absorbing materials. Expansion chambers work by allowing exhaust gases to expand and cool before exiting, which diminishes the intensity of sound waves. Additionally, the use of absorbent materials helps in further reducing noise levels by converting sound energy into thermal energy.

Impact on Performance

While sound reduction is crucial, the assembly also plays a vital role in maintaining engine performance. A well-designed system ensures proper exhaust flow, which is essential for efficient engine operation. Any restrictions can lead to back pressure, negatively impacting performance and fuel efficiency. Thus, balancing sound control with optimal flow dynamics is key to the overall functionality of this system.

| Function | Description |

|---|---|

| Noise Control | Reduces engine noise through various mechanisms. |

| Gas Expansion | Allows gases to expand, lowering sound intensity. |

| Flow Optimization | Maintains optimal exhaust flow for better performance. |

| Heat Dissipation | Helps in cooling exhaust gases, improving efficiency. |

Common Types of Mufflers Explained

When it comes to automotive sound management, various designs play crucial roles in enhancing performance while minimizing noise. Understanding these variations can help in making informed choices for different vehicle needs.

Chambered Designs are popular for those seeking a deep, aggressive sound. These systems utilize internal chambers to create sound waves that cancel out unwanted noise, resulting in a distinctive tone that many enthusiasts prefer.

Glass Pack Variants offer a different approach by using a perforated tube surrounded by fiberglass packing. This construction provides a louder, more pronounced exhaust note, appealing to drivers looking for a sportier sound.

Turbo Types are engineered for a quieter operation while maintaining efficient exhaust flow. They typically feature multiple chambers and sound-deadening materials, making them ideal for those who prioritize comfort over volume.

Resonators serve as additional components that fine-tune the sound profile of the exhaust system. While they are not always standalone units, they significantly impact the overall auditory experience of the vehicle.

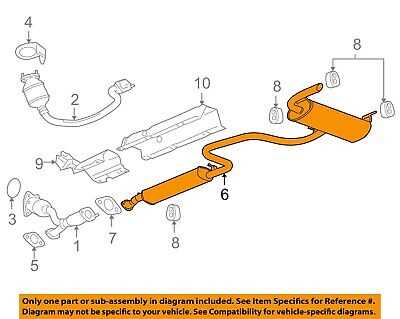

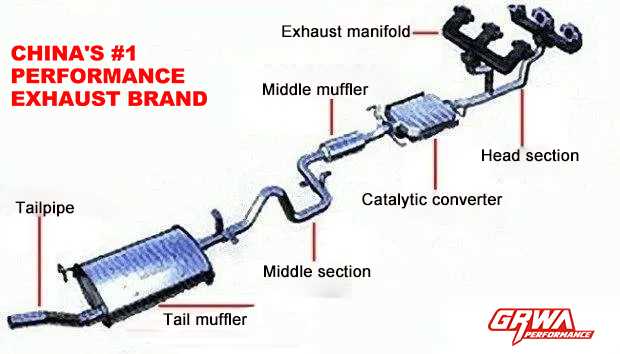

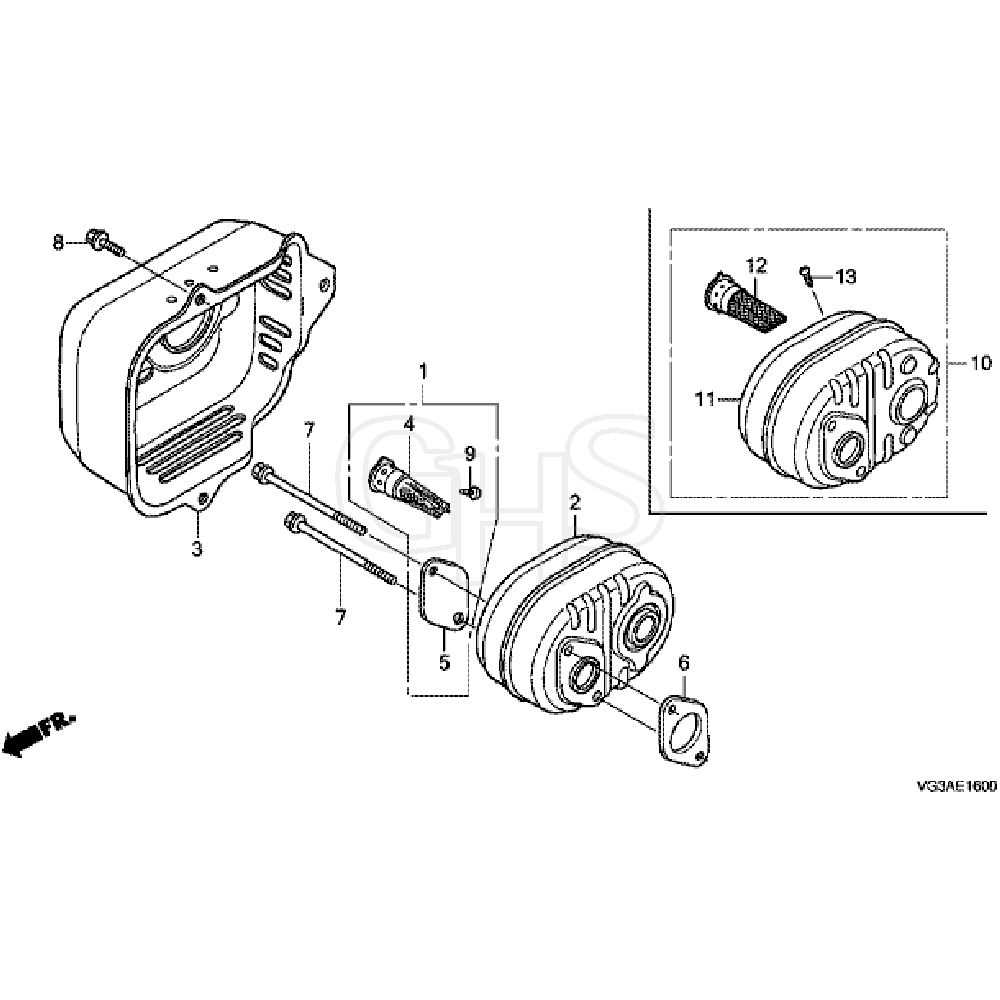

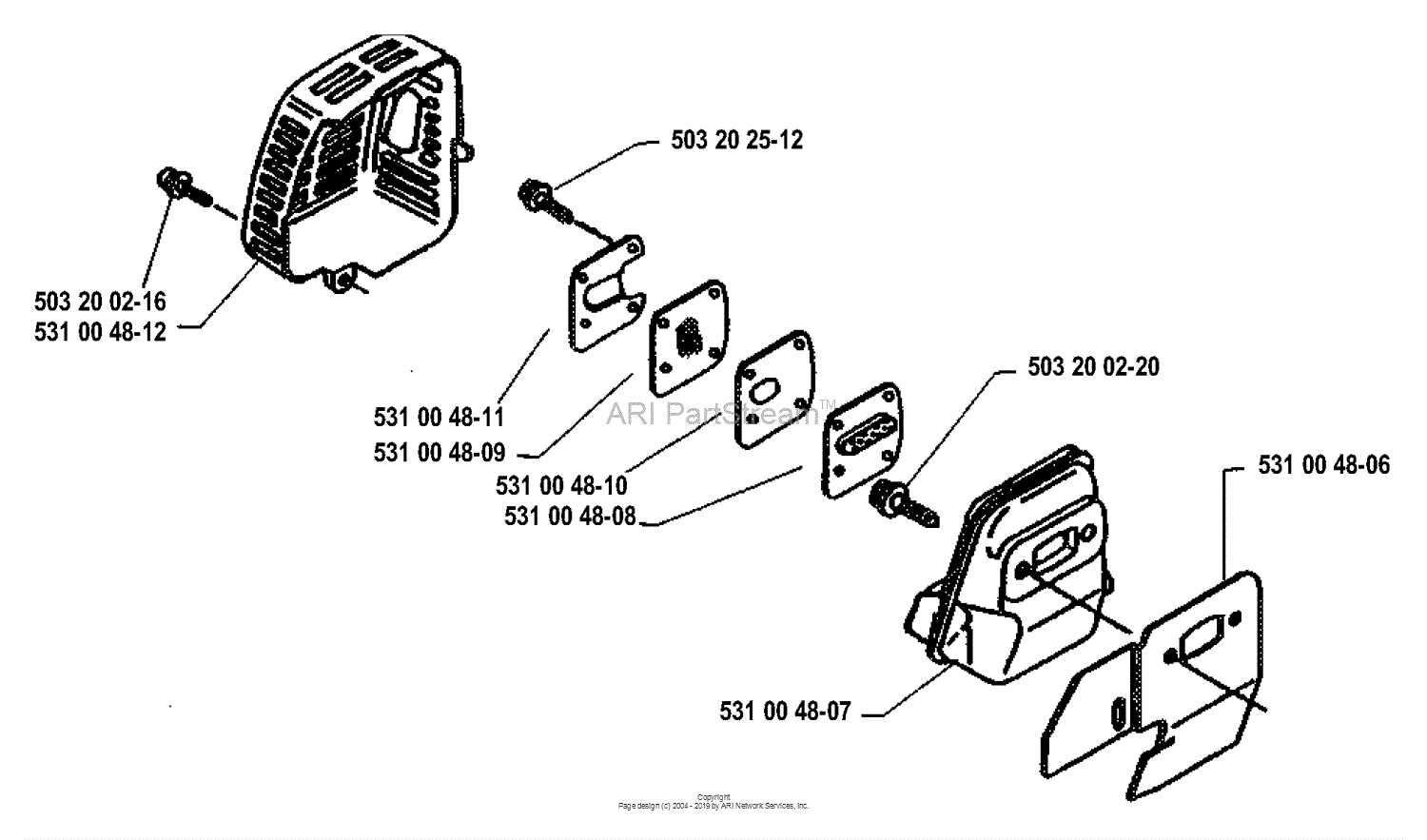

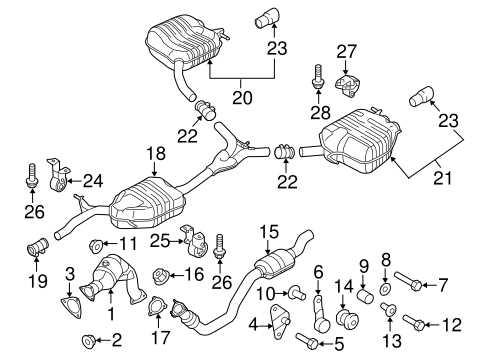

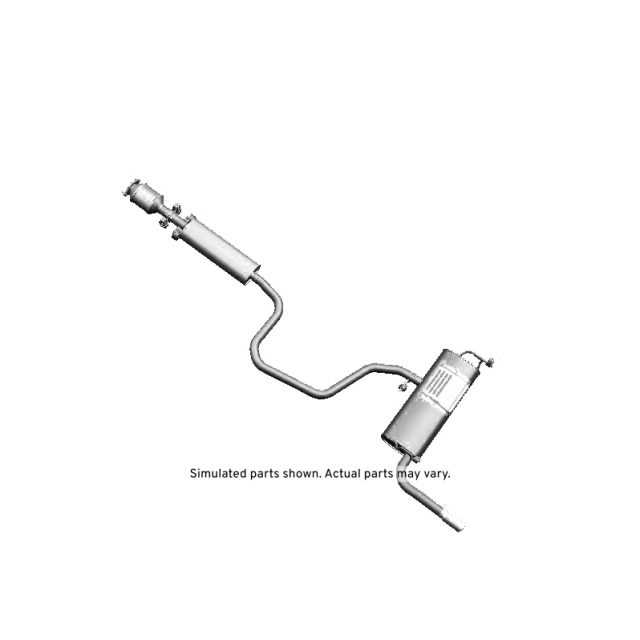

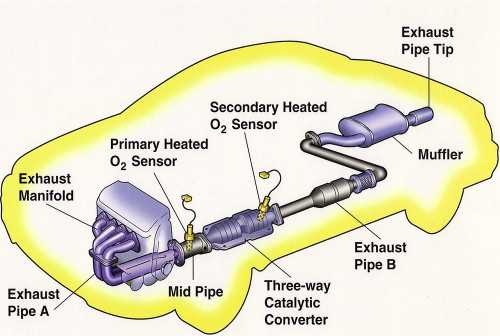

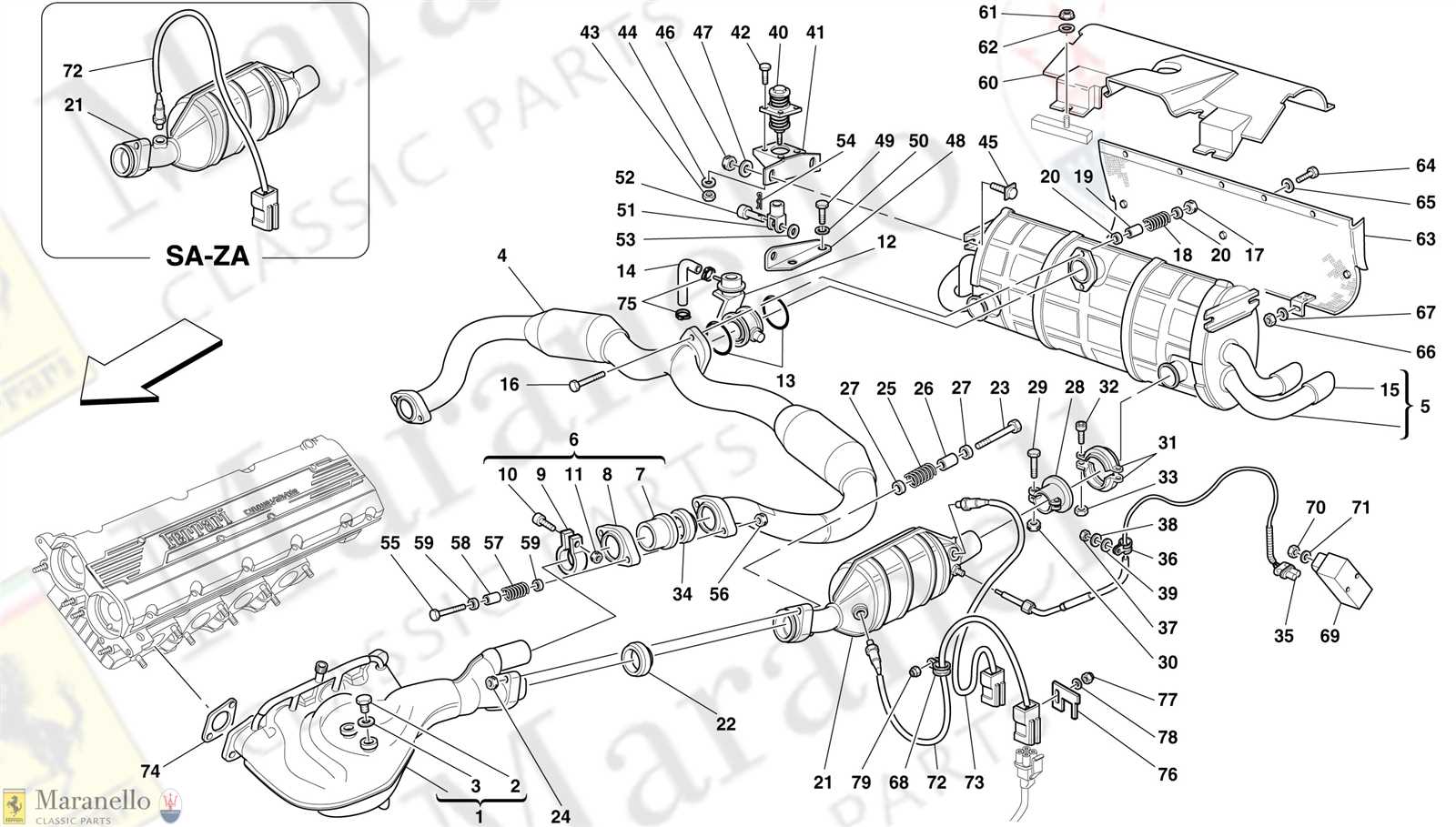

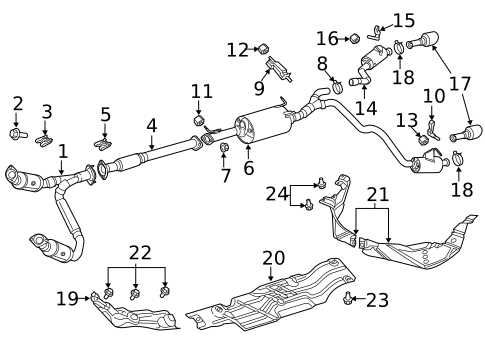

Visual Representation of Muffler Parts

This section focuses on the graphical depiction of essential components within an exhaust system. Understanding these elements is crucial for grasping how sound reduction and emission control are achieved. Through a well-crafted illustration, one can appreciate the intricate relationships and functions of each individual piece.

Key Elements Illustrated

- Inlet: The entry point for exhaust gases from the engine.

- Resonator: A chamber designed to enhance sound quality by reducing certain frequencies.

- Silencer: The main element responsible for minimizing noise levels, ensuring a quieter operation.

- Outlet: The exit point for treated gases before they are released into the atmosphere.

Importance of Visual Understanding

Comprehending the layout and function of these components provides insight into the overall efficiency of the system. A visual guide serves not only as an educational tool but also as a practical reference for maintenance and troubleshooting. Recognizing the significance of each element fosters a deeper appreciation for automotive engineering.

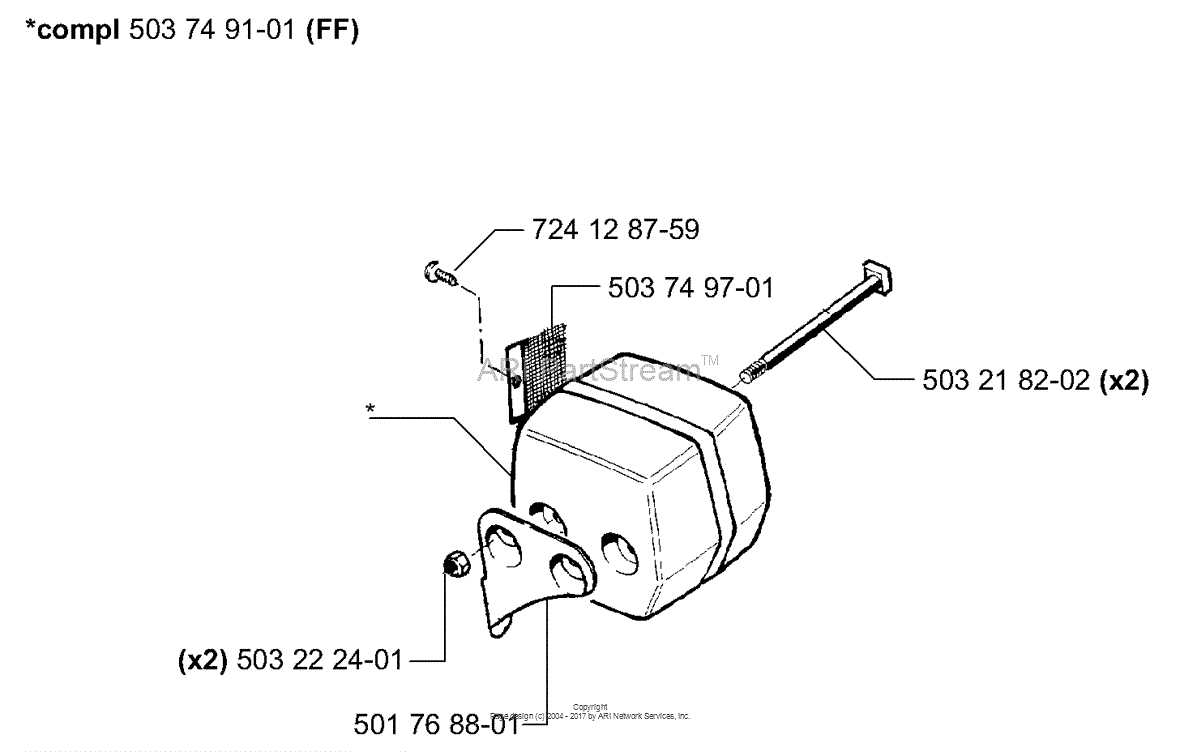

Key Elements of Exhaust Silencers

Exhaust silencers play a crucial role in regulating sound and managing emissions in various vehicles and machinery. Understanding their essential components can provide insight into their functionality and importance in maintaining compliance with environmental regulations while ensuring a pleasant auditory experience.

Main Components

- Sound Absorbers: These elements are designed to minimize noise by dissipating sound waves through various materials.

- Resonators: These are specialized sections that work to eliminate specific sound frequencies, enhancing the overall sound quality.

- Flow Control Devices: These mechanisms manage the flow of exhaust gases, ensuring optimal performance and reducing back pressure.

- Inlet and Outlet Pipes: These channels connect the silencer to the exhaust system, facilitating the efficient passage of gases.

Functionality and Benefits

- Noise Reduction: One of the primary functions is to significantly lower the sound produced by the engine.

- Emissions Control: They help to limit harmful pollutants from entering the atmosphere, contributing to environmental protection.

- Performance Enhancement: By optimizing exhaust flow, they can improve engine efficiency and power output.

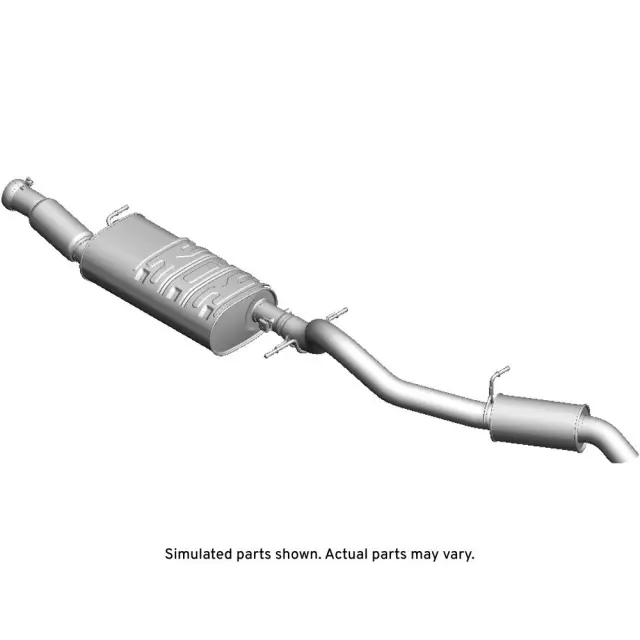

Impact of Muffler Design on Performance

The configuration of exhaust systems significantly influences the overall performance of vehicles. Various factors, such as the shape, materials, and internal structures, play crucial roles in how effectively these systems manage sound and emissions while optimizing engine output.

Key Factors in Design

- Shape: The external contours can affect airflow dynamics, which in turn influences backpressure and engine efficiency.

- Material: Different substances can alter weight, durability, and thermal resistance, affecting both performance and longevity.

- Internal Layout: The arrangement of baffles and chambers directly impacts sound attenuation and exhaust flow.

Performance Benefits

- Improved Engine Efficiency: A well-engineered system can reduce backpressure, allowing for better exhaust flow and enhancing engine performance.

- Sound Control: Effective design can minimize noise pollution, ensuring compliance with regulations while providing a pleasant auditory experience.

- Emissions Reduction: Strategic design features can help in meeting environmental standards by optimizing the removal of harmful gases.

In conclusion, the design of exhaust components is integral to maximizing vehicle performance. By carefully considering factors such as shape, material, and internal arrangement, manufacturers can create systems that not only enhance engine output but also provide a better overall driving experience.

Materials Used in Muffler Construction

The construction of exhaust systems involves a selection of diverse materials, each chosen for its specific properties that enhance performance and durability. Understanding these materials is essential for appreciating how they contribute to overall functionality and efficiency.

Commonly Used Materials

Several materials are prevalent in the fabrication of exhaust components. These options are often evaluated based on factors such as corrosion resistance, thermal stability, and weight. The most widely used substances include:

| Material | Properties | Advantages |

|---|---|---|

| Stainless Steel | Corrosion-resistant, high-temperature tolerance | Long lifespan, aesthetic appeal |

| Aluminized Steel | Moderate corrosion resistance, lightweight | Cost-effective, good performance |

| Carbon Steel | Strong, affordable | Easy to work with, good for custom designs |

| Composite Materials | Lightweight, variable thermal properties | Advanced sound dampening, innovative design flexibility |

Importance of Material Selection

The choice of material significantly affects not only the performance but also the overall lifespan of exhaust systems. By carefully selecting appropriate substances, manufacturers can optimize the functionality, ensuring that these systems meet the demanding conditions they face during operation.

How Mufflers Reduce Engine Noise

Vehicle exhaust systems are designed to manage sound produced by the engine during operation. By implementing various components, these systems effectively minimize the auditory output, creating a more pleasant driving experience. The primary objective is to dampen noise levels while allowing exhaust gases to exit efficiently.

One of the key mechanisms at play involves the use of specific structures that disrupt sound waves. These structures are strategically positioned within the system to reflect and absorb sound, converting it into less intrusive forms. The process includes a combination of resonance and absorption, enabling the reduction of high-frequency sounds that can be particularly bothersome.

Additionally, the incorporation of baffles plays a significant role. These barriers redirect the flow of gases, creating turbulence that interrupts sound waves. By breaking up the intensity of noise before it exits the system, the overall volume is significantly lowered. This engineering approach not only enhances comfort for occupants but also contributes to compliance with regulatory noise standards.

In summary, the thoughtful arrangement and design of exhaust system components effectively diminish engine-generated sounds. Through reflection, absorption, and redirection, these systems achieve a harmonious balance, ensuring a quieter ride without compromising performance.

Muffler Maintenance Tips for Longevity

Regular upkeep of your vehicle’s exhaust system is essential for ensuring optimal performance and extending its lifespan. By following a few simple guidelines, you can help prevent costly repairs and maintain efficiency.

Routine Inspections

- Check for rust or corrosion, especially in areas exposed to moisture.

- Look for signs of leaks, such as unusual noises or vibrations during operation.

- Inspect mounting points to ensure everything is secure and free of damage.

Proper Cleaning

- Remove dirt and debris from the exterior regularly to prevent buildup.

- Use appropriate cleaning solutions to avoid damaging protective coatings.

- Consider professional cleaning services if significant deposits are present.

By adhering to these maintenance tips, you can enhance the longevity of your vehicle’s exhaust components and ensure they function efficiently for years to come.

Signs of Muffler Wear and Tear

Recognizing the signs of deterioration in exhaust systems is essential for maintaining optimal vehicle performance. Over time, these components can exhibit various symptoms indicating they are not functioning as intended, which can lead to further complications if left unaddressed.

Common Indicators of Damage

- Unusual Noise: A significant increase in noise levels, such as hissing or rattling, can indicate a problem within the system.

- Vibration: Excessive shaking or vibrations felt in the vehicle’s cabin may suggest loose or broken components.

- Rust and Corrosion: Visible signs of rust or corrosion on the exterior of the system can point to wear and potential failure.

Performance-Related Symptoms

- Decreased Fuel Efficiency: A noticeable drop in fuel efficiency can be a result of poor exhaust flow, indicating possible issues.

- Emissions Problems: An increase in exhaust emissions may signal that the system is not effectively filtering harmful gases.

- Check Engine Light: The illumination of the check engine light can often be related to issues within the exhaust mechanism.

Upgrading Your Muffler for Efficiency

Enhancing the exhaust system of your vehicle can lead to significant improvements in overall performance and fuel economy. A well-designed component can reduce back pressure, allowing the engine to operate more efficiently. By choosing a higher-quality replacement or modifying the existing setup, you can achieve better airflow, which ultimately translates into improved horsepower and torque.

Choosing the Right Replacement

Selecting the ideal alternative involves considering materials, design, and compatibility with your vehicle’s make and model. Options range from stainless steel to aluminized steel, each offering different levels of durability and resistance to corrosion. It’s essential to evaluate the design features, such as straight-through configurations, which can facilitate optimal exhaust flow.

Installation Considerations

Proper installation is crucial for maximizing the benefits of the upgrade. Ensure that the new component is securely fitted and sealed to prevent leaks, which can diminish efficiency. Consulting with a professional can help achieve the best results, ensuring that the new setup works harmoniously with the engine and exhaust system.