The effective operation of a pneumatic device relies on its various components working in harmony. Familiarity with these elements can significantly enhance the user’s experience and ensure proper maintenance. Each piece plays a crucial role, contributing to the overall functionality of the machine.

Identifying the specific elements within this tool provides valuable insights into its performance. By exploring the arrangement and function of these components, users can troubleshoot issues more effectively and perform necessary repairs. A comprehensive understanding allows for better decision-making regarding maintenance and upgrades.

As users engage with this equipment, recognizing the significance of each part becomes essential. This knowledge empowers individuals to maximize efficiency and extend the lifespan of the tool, ultimately leading to improved outcomes in their projects. Embracing this understanding fosters confidence and proficiency in using the equipment.

This section aims to provide an organized framework for understanding the components and mechanisms of a specific type of fastening tool. A well-structured overview can enhance knowledge and proficiency in using this equipment effectively.

- Introduction to the Tool

Discuss the functionality and significance of the tool in construction and carpentry.

- Key Components

- Trigger mechanism

Explain how the trigger operates and its importance in the fastening process.

- Magazine assembly

Describe the role of the magazine in holding and feeding fasteners.

- Piston assembly

Detail how the piston generates the driving force for the fasteners.

- Housing and body

Highlight the significance of the outer casing and its ergonomic design.

- Trigger mechanism

- Maintenance Tips

Provide guidelines for keeping the tool in optimal condition, including cleaning and lubrication.

- Common Issues and Solutions

Outline frequent problems users may encounter and troubleshooting tips.

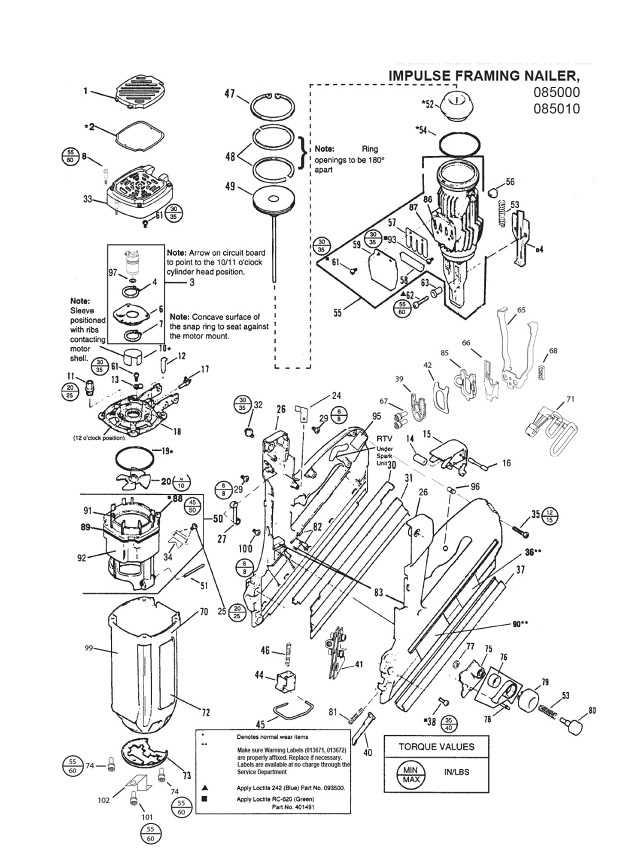

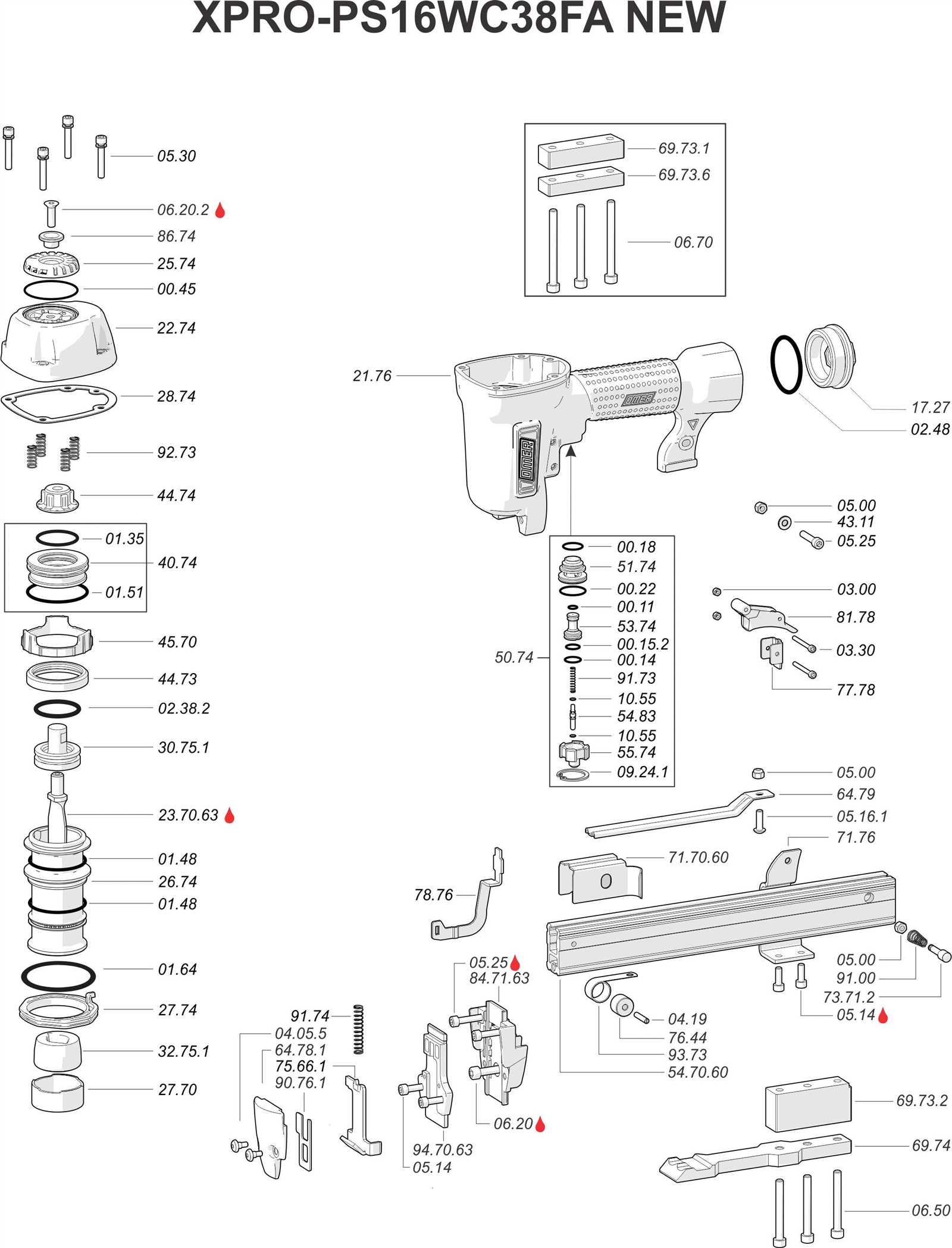

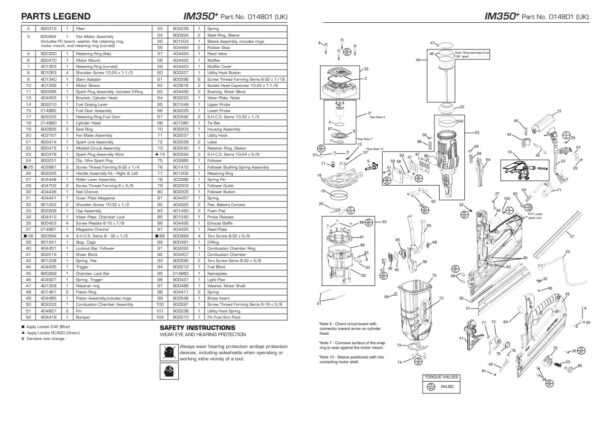

Components of the Framing Nailer

The functionality of a construction tool relies heavily on its essential elements. Understanding the key components enhances the user’s ability to operate the device effectively and maintain it properly. Each element plays a significant role in ensuring optimal performance, safety, and durability.

Main Elements

Among the primary features are the motor assembly, which powers the tool, and the trigger mechanism, which initiates its operation. These components work in unison to deliver precision and efficiency, making the tool invaluable in various construction tasks.

Additional Features

Other vital aspects include the magazine, which holds the fasteners, and the exhaust port that releases air. Understanding these elements contributes to a comprehensive grasp of the tool’s operation, enabling users to perform maintenance and troubleshooting effectively.

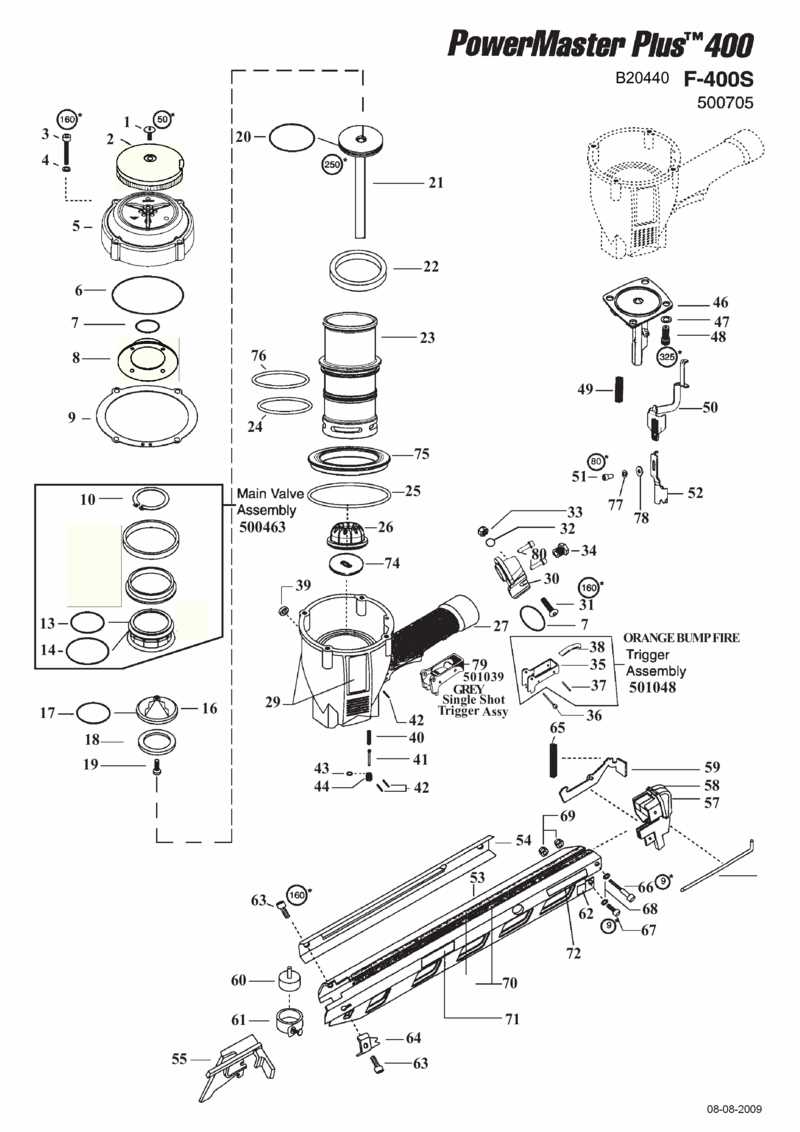

Exploring the Parts Diagram

This section delves into the various components of a specific tool, providing a comprehensive overview of its structure. Understanding the arrangement and function of each element can significantly enhance the user’s experience and maintenance of the device. A clear representation of the assembly is essential for troubleshooting and effective operation.

Key Components Overview

Identifying the essential features of the tool allows users to familiarize themselves with its functionality. Each component plays a crucial role in the overall performance, ensuring optimal results during use. Below is a table summarizing the key elements and their functions:

| Component | Function |

|---|---|

| Housing | Encases and protects internal parts |

| Trigger | Initiates the action of the device |

| Piston | Drives the fastener into the material |

| Fuel Cell | Provides power for operation |

Understanding the Assembly

Comprehending how these elements interconnect enhances the user’s ability to perform maintenance and repairs. Familiarity with the layout facilitates quicker identification of any issues that may arise, ultimately leading to improved efficiency and longevity of the tool.

Function of Each Component

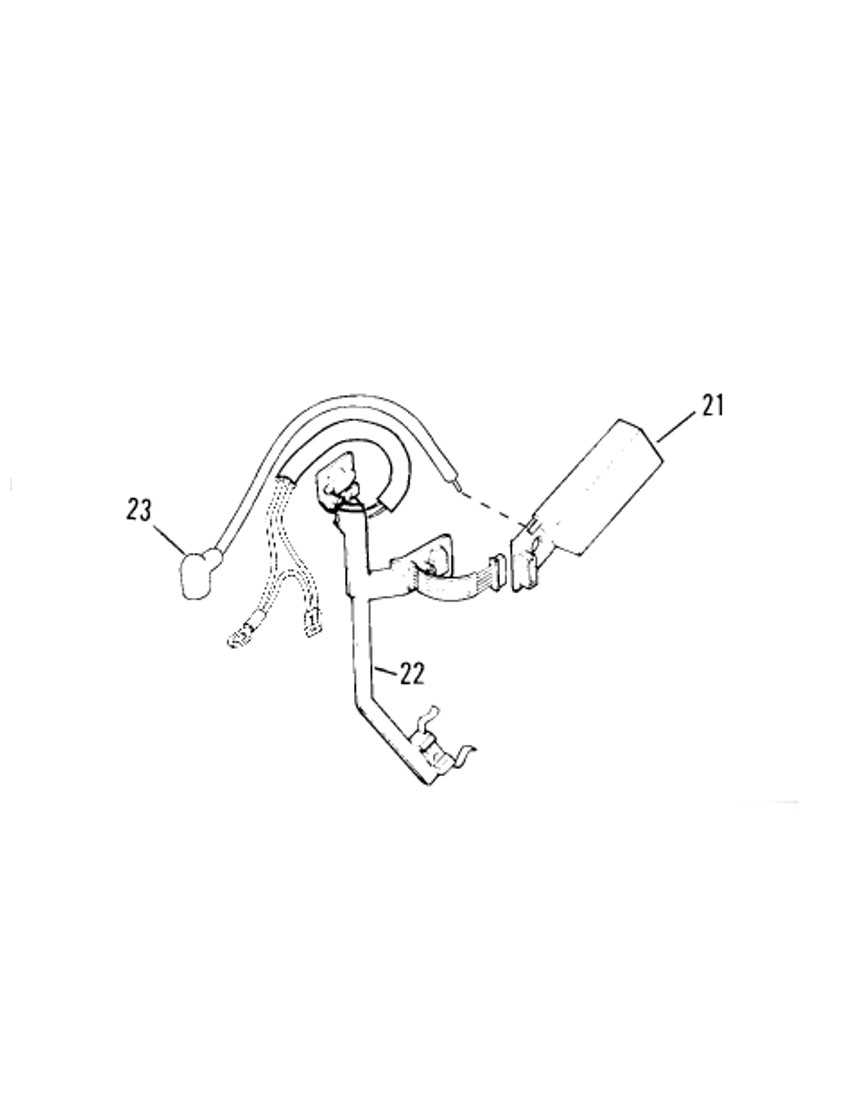

The effectiveness of a nail-driven tool relies heavily on the precise roles played by its various elements. Each component works in harmony to ensure that the tool operates efficiently, delivering powerful performance while enhancing user control and safety. Understanding the functions of these elements is essential for proper maintenance and optimal usage.

Power Source

The power source is crucial as it generates the energy needed to drive nails into various materials. This component ensures consistent performance by providing the necessary force, enabling the tool to function efficiently across different tasks.

Guide Mechanism

The guide mechanism plays a pivotal role in directing the nails accurately during operation. It helps maintain alignment and stability, which is essential for achieving precise placement. This component significantly contributes to the overall effectiveness and accuracy of the tool.

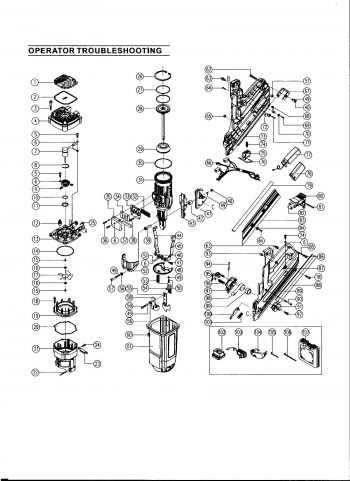

Common Issues with Nailers

Nailers are essential tools in construction and woodworking, but they can encounter several common challenges that hinder their performance. Understanding these issues can help users troubleshoot effectively and maintain optimal functionality.

Frequent Misfires

One of the most typical problems is the occurrence of misfires. This can be attributed to factors such as insufficient pressure, improper loading of fasteners, or even dirt obstructing the firing mechanism. Regular maintenance and ensuring the correct settings can significantly reduce this issue.

Jamming Mechanisms

Another prevalent concern is jamming. When the device fails to discharge fasteners smoothly, it often leads to frustrating delays. Common causes include the use of incompatible fasteners, debris buildup, or mechanical wear. Clearing jams promptly and using the right supplies can help mitigate this problem.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. By implementing a consistent maintenance routine, you can enhance performance, reduce wear and tear, and prolong the life of your tools. Here are some essential practices to keep in mind.

Firstly, always keep the device clean and free from debris. Accumulated dust and particles can impede functionality and lead to malfunctions. Regularly inspect and clean all components to prevent buildup that could affect performance.

Additionally, lubricating moving parts is crucial. Using the appropriate lubricant will minimize friction and ensure smooth operation. Refer to the manufacturer’s guidelines for specific recommendations on the best products to use.

Furthermore, check for any signs of damage or wear regularly. Early detection of issues can save you from costly repairs or replacements in the future. Replace any worn-out components immediately to maintain optimal functionality.

Lastly, store your tools properly when not in use. Keeping them in a dry and secure location will protect them from environmental factors that can cause deterioration. Implementing these maintenance tips will significantly contribute to the longevity of your equipment.

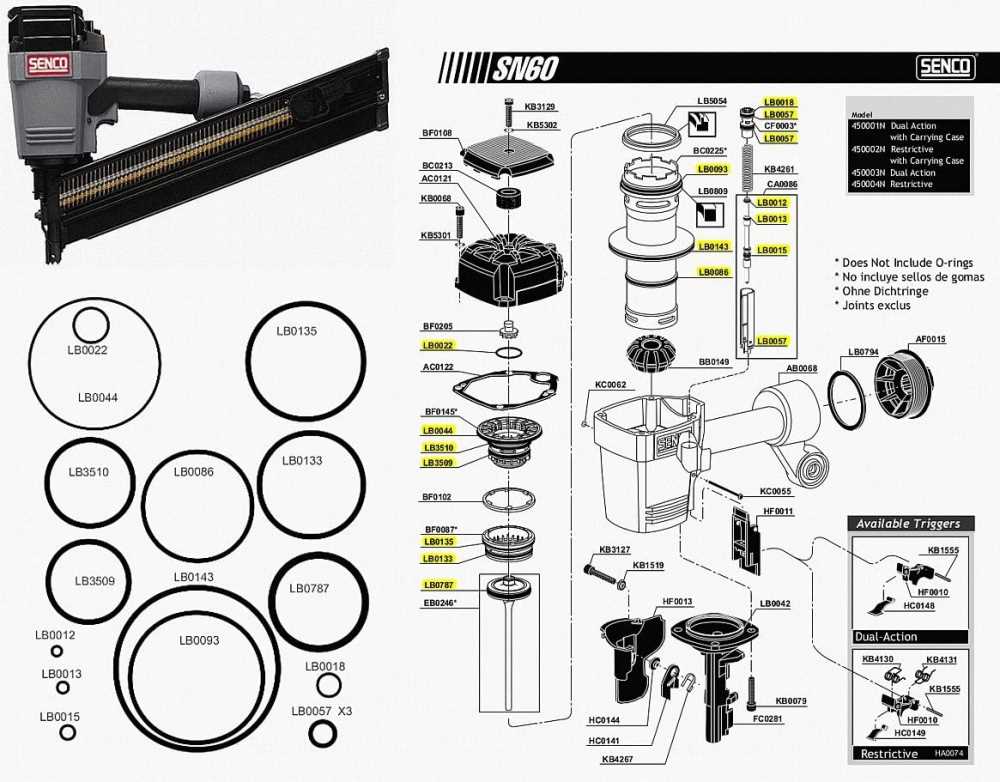

How to Replace Worn Parts

Maintaining the functionality of your tool is essential for achieving optimal performance. Over time, certain components may experience wear and tear, leading to decreased efficiency and effectiveness. Understanding how to identify and replace these worn elements can significantly extend the lifespan of your equipment and ensure reliable operation.

Identifying Worn Components

Before proceeding with the replacement process, it is crucial to recognize which components need attention. Common signs of wear include irregular operation, increased noise, and visible damage to the items. Regularly inspecting your tool can help you catch issues early, preventing further complications.

Replacement Process

Once you have identified the components requiring replacement, follow these general steps to carry out the procedure:

- Gather necessary tools: Ensure you have all required tools and replacement elements ready before starting.

- Disassemble the tool: Carefully take apart the tool according to the manufacturer’s guidelines, noting the order of disassembly.

- Remove worn components: Take out the damaged elements with caution to avoid causing additional harm.

- Install new parts: Place the new components into their designated positions, ensuring a secure fit.

- Reassemble the tool: Put the tool back together following the steps you noted during disassembly.

- Test functionality: After reassembly, run a test to verify that the tool operates smoothly.

By following these steps, you can effectively replace worn components and keep your tool in top condition.

Safety Features of Paslode Nailers

The importance of safety mechanisms in power tools cannot be overstated. These features are designed to protect users from potential accidents and ensure a secure operating environment. Understanding the safety attributes of these devices enhances user confidence and promotes responsible usage.

First and foremost, modern devices are equipped with triggers that prevent accidental firing. This ensures that the tool only activates when intentionally engaged, significantly reducing the risk of unintended discharge. Additionally, many models incorporate a safety tip that must be pressed against the work surface before the tool can operate, adding an extra layer of security.

Another essential feature is the depth adjustment mechanism, allowing users to set the appropriate penetration level for various materials. This not only improves the quality of the work but also minimizes the chances of damage or injury from improper nail placement. Furthermore, protective casing surrounds critical components, shielding users from debris and accidental contact.

Finally, comprehensive user manuals provide essential safety guidelines, educating operators on the correct handling and maintenance of these tools. By adhering to these recommendations, users can maximize safety and efficiency while using their devices.

Choosing the Right Fasteners

Selecting the appropriate fasteners is crucial for ensuring the stability and longevity of your construction projects. The right choice not only affects the structural integrity but also impacts the overall appearance and performance of the finished work. Understanding the different types available and their specific uses can help you make informed decisions that lead to successful outcomes.

Types of Fasteners

There are various types of fastening solutions available, each designed for specific applications. Common options include nails, screws, and staples. Nails are often used for framing and decking, providing quick assembly. Screws, on the other hand, offer superior holding power and are ideal for securing materials together more permanently. Staples are typically employed for lighter materials, such as sheathing or insulation.

Material Considerations

When choosing fastening elements, it is essential to consider the material they will be used with. Galvanized options are recommended for outdoor projects due to their resistance to rust and corrosion, while stainless steel is an excellent choice for high-moisture environments. Ensuring compatibility between the fastener and the material can enhance durability and performance over time.

Comparing Different Paslode Models

This section provides a comprehensive overview of various models within a specific brand of pneumatic tools, highlighting their unique features and specifications. Understanding the differences among these devices can aid users in selecting the most suitable option for their specific needs, whether for professional construction projects or DIY tasks.

Key Features to Consider

When evaluating different models, it is crucial to consider several factors. Performance capabilities, such as firing speed and power, play a significant role in determining efficiency during use. Additionally, ergonomics should not be overlooked, as a comfortable design can greatly enhance the user experience, especially during extended work sessions.

Model Variations

Each model presents a unique set of specifications that cater to different applications. Some may offer advanced features such as adjustable depth settings and improved battery life, while others might prioritize lightweight construction for easier handling. By comparing these variations, users can make informed decisions that align with their project requirements.

Benefits of Using Impulse Technology

The integration of advanced technology in construction tools has revolutionized the industry. One significant innovation is the adoption of a unique energy-efficient mechanism that enhances performance and usability. This system not only improves speed and efficiency but also reduces operational costs, making it a valuable choice for professionals.

- Increased Efficiency: Tools utilizing this technology can operate faster, allowing users to complete tasks in less time.

- Reduced Energy Consumption: These devices consume less energy compared to traditional models, contributing to lower electricity bills.

- Enhanced Precision: The innovative design ensures accurate placements, resulting in a cleaner and more professional finish.

- Improved Safety: Modern features help minimize the risk of accidents, providing a safer working environment.

- Low Maintenance: Fewer moving parts lead to less wear and tear, resulting in lower maintenance costs and longer tool life.

In conclusion, the advantages offered by this technology significantly contribute to increased productivity and effectiveness in various applications. As more professionals recognize these benefits, its popularity continues to rise.

FAQs About Paslode Framing Nailers

This section addresses common inquiries regarding the functionality, maintenance, and usage of popular fastening tools. Understanding these aspects can enhance user experience and ensure optimal performance.

Common Questions

- What is the ideal pressure for operation?

- How often should I perform maintenance on my tool?

- Can I use different types of fasteners?

Troubleshooting Tips

- If the tool jams, first disconnect it from power and remove any stuck fasteners.

- Ensure that the correct type of fasteners is loaded properly.

- Check for any obstructions in the firing mechanism.

For further assistance, consult the manufacturer’s guidelines or seek advice from experienced users.