In the world of construction and woodworking, the efficiency of any tool greatly relies on its individual elements. Each component plays a vital role in ensuring seamless operation and achieving the desired results. Familiarity with these elements enhances not only maintenance but also overall functionality.

Exploring the anatomy of a fastening device reveals the intricate design that supports its power and precision. From the housing to the mechanism that drives the fasteners, every part is meticulously engineered to withstand rigorous use. This knowledge empowers users to troubleshoot and optimize their equipment effectively.

By dive into the specifics, one can uncover the ultimate potential of their tools. Understanding how each segment interacts and contributes to the whole system enables better decision-making regarding repairs and upgrades, ensuring longevity and reliability in various applications.

Understanding Paslode Nailer Components

Grasping the essential elements of fastening tools is crucial for effective operation and maintenance. Each component plays a specific role, contributing to the overall functionality and efficiency of the device. Familiarity with these parts enhances performance and extends the tool’s lifespan.

Key Components

- Power Source: Provides the energy required for operation.

- Housing: The outer shell that protects internal mechanisms.

- Trigger Mechanism: Initiates the fastening action.

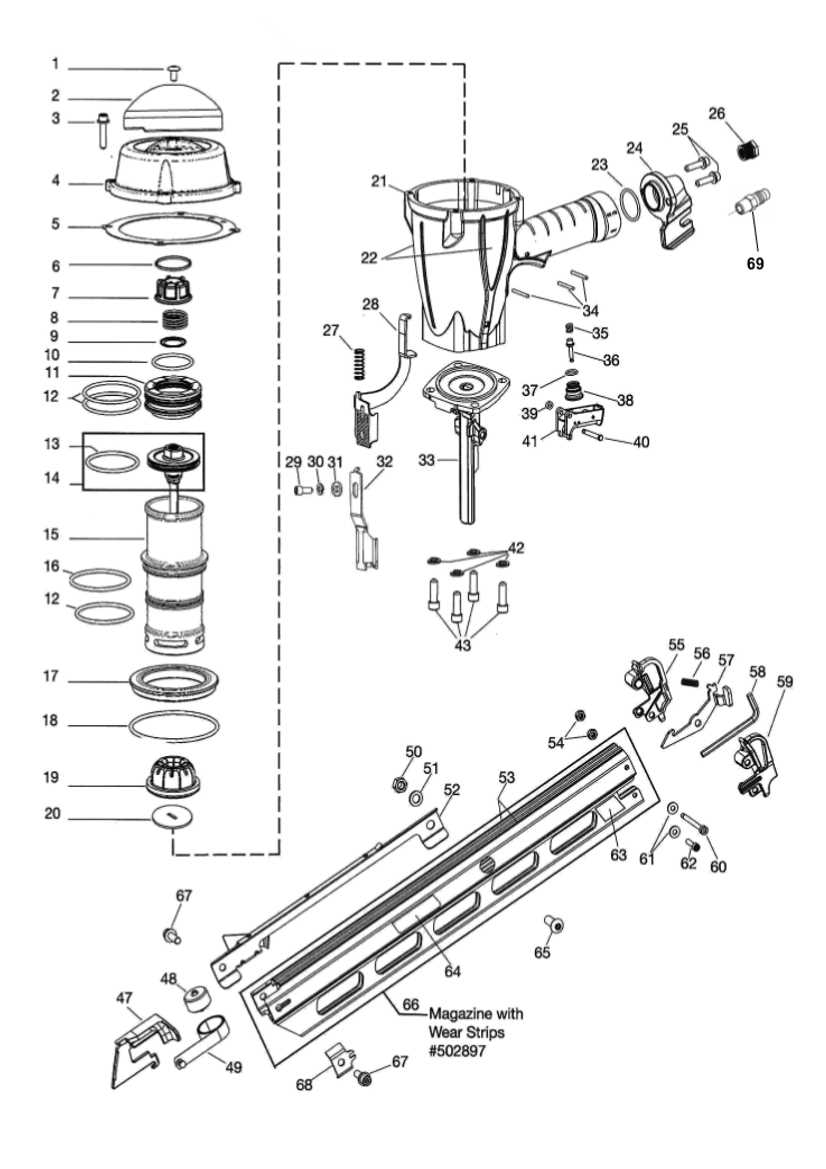

- Magazine: Holds fasteners in place for quick access.

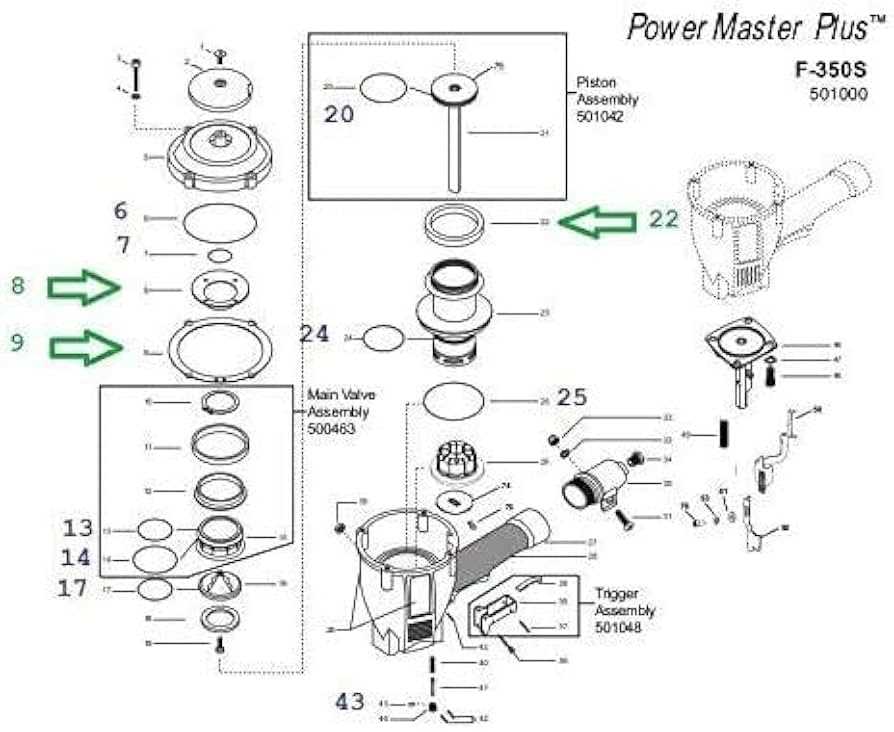

- Piston Assembly: Drives the fastener into the material.

Maintenance Tips

- Regularly inspect and clean components to ensure optimal performance.

- Replace worn parts promptly to avoid tool malfunction.

- Lubricate moving elements as needed to reduce friction.

Key Parts of a Paslode Nailer

Understanding the essential components of a fastening tool can enhance its performance and maintenance. Each element plays a crucial role in ensuring effective operation and durability. Familiarity with these key features empowers users to troubleshoot and optimize their equipment.

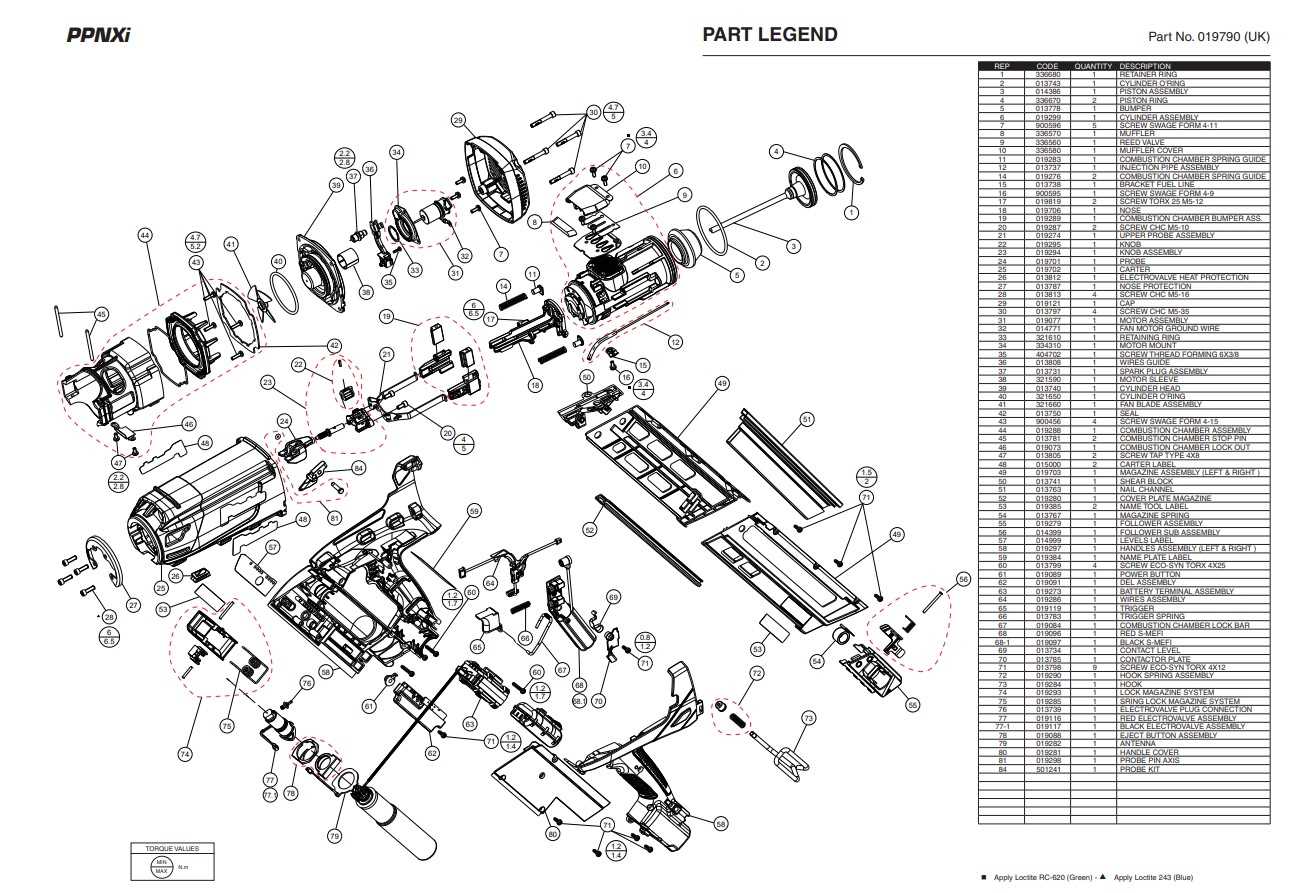

Motor: This is the powerhouse of the device, driving the mechanism that propels the fasteners. A well-functioning motor is vital for consistent operation.

Magazine: The loading section holds the fasteners in place. Its design allows for easy reloading, which minimizes downtime during projects.

Trigger: This control mechanism initiates the driving action. A responsive trigger ensures precise placement and reduces the risk of misfires.

Contact Arm: This part is essential for safety, as it engages the tool only when pressed against the surface. Proper function prevents accidental discharges.

Piston: The component that delivers the final force, driving the fastener into the material. A well-maintained piston ensures efficiency and minimizes wear.

Housing: The outer shell provides protection and stability for internal components. Its design can affect overall handling and ergonomics.

How to Read a Parts Diagram

Understanding an assembly representation is essential for effective maintenance and repair tasks. These visuals provide a detailed layout of components, allowing users to identify and locate each piece quickly. Familiarity with the format and symbols used can significantly enhance your efficiency when working on mechanical devices.

To interpret these visuals accurately, follow these steps:

| Step | Description |

|---|---|

| 1 | Start by examining the overall layout to get a sense of the configuration and how components interact. |

| 2 | Identify the symbols and labels that correspond to each component, as these indicate specific parts and functions. |

| 3 | Check for any notes or legends that may explain additional details, such as part numbers or installation tips. |

| 4 | Use the information gathered to compare against your device, ensuring all necessary components are accounted for. |

By mastering this skill, you will be better equipped to tackle repairs and ensure optimal functionality.

Common Issues with Nailer Components

Tools that drive fasteners are essential in various construction and woodworking projects. However, like any mechanical device, they can experience malfunctions that hinder performance. Understanding typical problems related to their components can help users maintain efficiency and extend the tool’s lifespan.

Jamming is one of the most frequent issues encountered. This occurs when fasteners fail to feed correctly, leading to frustration and delays. Common causes include improper loading of the fasteners, debris buildup, or worn-out feeding mechanisms.

Misfiring is another prevalent concern. This can manifest as the tool failing to discharge a fastener or firing multiple times in quick succession. Such problems often stem from issues with the trigger mechanism, air pressure inconsistencies, or faulty safety features.

Inconsistent performance can arise from air leaks or insufficient lubrication. When the internal components are not properly maintained, users may notice irregularities in power and speed, which can affect the quality of the work.

Finally, overheating can lead to premature wear or damage. This often happens when the tool is used continuously without breaks, or if the air supply is inadequate. Monitoring usage and ensuring proper cooling can help mitigate this risk.

Maintenance Tips for Paslode Nailers

Regular upkeep is essential for ensuring optimal performance and longevity of your fastening tools. By following a few simple practices, you can keep your equipment running smoothly and avoid costly repairs.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Clean the tool | After each use | Remove debris and dust to prevent jams and ensure smooth operation. |

| Check the o-rings | Monthly | Inspect and replace any worn or damaged o-rings to maintain air pressure. |

| Lubricate moving parts | Weekly | Use appropriate oil to keep mechanisms functioning efficiently. |

| Inspect the battery | Before major jobs | Ensure the power source is charged and free from corrosion. |

| Test firing | Before use | Conduct a test run to verify that the tool is operating correctly. |

Identifying Wear and Tear in Parts

Recognizing the signs of deterioration in components is crucial for maintaining optimal performance and safety in tools. Regular inspection can help users spot issues early, preventing more significant problems down the line.

Common Signs of Damage

Look for visible cracks, deformation, or excessive wear on surfaces that undergo regular friction. Additionally, listen for unusual sounds during operation, which may indicate malfunctioning elements.

Maintaining Component Integrity

Establish a routine maintenance schedule to clean and lubricate moving parts. This proactive approach can significantly extend the lifespan of your equipment and ensure efficient functionality.

Tools Needed for Nailer Repair

To effectively restore and maintain your fastening device, having the right equipment is crucial. This section outlines essential instruments that will enable you to tackle repairs efficiently and safely.

Essential Equipment

Gathering the appropriate tools ensures a smooth repair process. Here are the primary items you’ll need:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws. |

| Wrenches | To adjust and secure various components. |

| Pliers | Useful for gripping and bending parts. |

| Cleaning Supplies | For removing debris and maintaining functionality. |

| Replacement Components | To substitute worn or damaged elements. |

Safety Gear

Always prioritize safety during repairs. Wearing protective eyewear and gloves can help prevent injuries and ensure a secure working environment.

Upgrading Your Paslode Nailer Parts

Enhancing your tool’s components can significantly improve its performance and longevity. Upgrades can lead to better efficiency, increased accuracy, and a smoother operation overall. Understanding which elements to focus on is crucial for achieving the ultimate results.

First, consider replacing worn-out or outdated components. Regularly inspecting and refreshing these parts can prevent potential issues and ensure optimal functionality. For instance, new fasteners or drives can drastically change the tool’s efficiency.

Additionally, exploring advanced accessories may also enhance your experience. Innovative attachments or specialized kits can provide greater versatility, allowing you to tackle various projects with ease. Investing in quality upgrades not only improves the tool but can also elevate your overall craftsmanship.

Ultimately, making thoughtful upgrades to your equipment is an essential step toward achieving superior performance and reliability in your projects.

Comparison of Different Paslode Models

This section explores the various models available in the market, highlighting their unique features, performance, and suitability for different applications. By understanding these distinctions, users can make informed decisions based on their specific needs and preferences.

Key Features

| Model | Weight | Power Source | Capacity |

|---|---|---|---|

| Model A | 4.5 lbs | Gas & Battery | 1100 shots |

| Model B | 5.0 lbs | Electric | 500 shots |

| Model C | 4.2 lbs | Gas | 1000 shots |

Application Suitability

Different models cater to varying tasks, from lightweight framing to heavy-duty construction. Understanding the strengths of each version allows users to select the ultimate tool for their specific job requirements.

Safety Precautions When Repairing Nailers

Ensuring safety during repairs is crucial to prevent accidents and injuries. Adhering to specific guidelines not only protects the individual performing the task but also extends the lifespan of the equipment being serviced. Here are essential precautions to follow.

Preparation Steps

- Disconnect the power source before starting any repairs.

- Wear appropriate personal protective equipment (PPE), such as goggles and gloves.

- Work in a well-ventilated area to avoid inhaling fumes or dust.

Repair Process Guidelines

- Inspect tools for damage and ensure they are in good working condition.

- Keep your workspace organized to minimize hazards.

- Use the correct tools for the job to prevent mishaps.

- Consult the manufacturer’s guidelines for specific instructions and safety information.

Where to Buy Replacement Parts

Finding suitable components for your tools can significantly enhance their performance and longevity. This section highlights various sources where you can obtain the necessary items to keep your equipment in top condition.

Online Retailers

- Major e-commerce websites often have a wide range of options.

- Specialized tool supply sites may offer detailed listings and specific brands.

- Marketplaces can provide new and refurbished choices at varying prices.

Local Stores

- Home improvement centers usually stock common components.

- Specialty tool shops can provide expert advice and specialized items.

- Repair service centers might have parts available for direct purchase.

By exploring these options, you can easily locate the components you need to ensure your tools operate efficiently.