The intricate arrangement of essential elements within a system plays a vital role in ensuring optimal functionality and efficiency. A clear visual representation of these components is crucial for anyone looking to comprehend how each piece interacts and contributes to the overall mechanism. By examining the structure, users can identify key functionalities and maintenance needs.

In this section, we will explore various configurations that facilitate seamless operation. A detailed examination reveals how each segment is positioned, providing insights into the purpose and connectivity of each element. Such knowledge is invaluable for troubleshooting and effective management of the entire system.

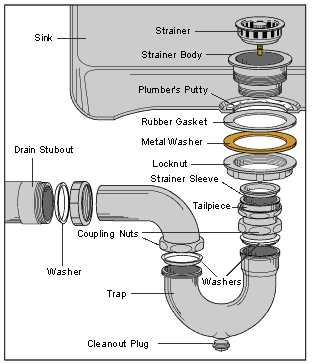

Pat Trap Parts Diagram Overview

This section provides a comprehensive insight into the various components involved in the system, showcasing their arrangement and functionality. Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring optimal performance of the entire setup.

The visual representation serves as a valuable reference for identifying each component’s role and how they interact within the system. By familiarizing oneself with this overview, users can enhance their knowledge and approach repairs with greater confidence.

| Component | Description |

|---|---|

| Body | The main structure that holds everything together. |

| Seal | Ensures a tight fit, preventing leaks. |

| Inlet | Entry point for the fluid or gas. |

| Outlet | Exit point for the processed fluid or gas. |

| Cap | Covers the unit, providing access for maintenance. |

Understanding Pat Trap Components

This section delves into the various elements that make up the mechanism, highlighting their functions and interactions. Familiarity with these components enhances comprehension of the overall system’s efficiency and operation.

| Component | Description |

|---|---|

| Housing | The outer casing that provides protection and structural integrity. |

| Seals | Elements that prevent leakage and maintain pressure within the unit. |

| Filters | Devices that remove unwanted particles from the flow, ensuring optimal performance. |

| Control Valve | A mechanism that regulates the flow and pressure of the system. |

| Connectors | Parts that link different sections, enabling a seamless operation. |

Identifying Key Elements in Diagrams

Understanding the fundamental components depicted in visual representations is essential for effective analysis and application. Each element plays a crucial role in conveying information, enabling users to grasp the overall structure and functionality of the system. Familiarity with these components enhances comprehension and aids in troubleshooting and maintenance tasks.

Main Components to Recognize

- Symbols: These represent various functions or parts within the system, providing a visual shorthand for understanding complex relationships.

- Lines: Connections between symbols indicate relationships, pathways, or flows of information, crucial for interpreting how elements interact.

- Labels: Descriptive text accompanying symbols helps clarify the purpose and characteristics of each element, offering context for the viewer.

Understanding Relationships

Identifying how components interact is vital for an accurate interpretation. Relationships can be categorized into different types:

- Direct connections: Indicate a straightforward relationship between two elements.

- Indirect relationships: Show how components influence each other through intermediary steps.

Recognizing these interactions aids in troubleshooting and enhancing system efficiency.

Functionality of Pat Trap Parts

The various components of a drainage system play a crucial role in maintaining efficient performance and ensuring proper flow management. Understanding the operation of these elements is essential for effective maintenance and troubleshooting.

Key components work together to prevent blockages and allow for the seamless movement of liquids. Each element contributes uniquely to the overall functionality, ensuring that the system operates smoothly under varying conditions.

In summary, familiarity with the functionality of these essential components is vital for anyone involved in the installation, upkeep, or repair of drainage systems. Knowledge of their interactions can help in diagnosing issues and enhancing performance.

Importance of Accurate Diagrams

Clear and precise illustrations are essential for understanding and maintaining complex systems. They provide a visual representation that aids in identifying components, their arrangement, and how they interact with one another. This clarity enhances both the efficiency and effectiveness of various tasks, from installation to troubleshooting.

Benefits of Visual Representations

- Improved Understanding: Visual aids simplify intricate processes, making it easier for users to grasp essential concepts.

- Efficient Problem-Solving: When issues arise, accurate visuals help pinpoint faults quickly, reducing downtime.

- Streamlined Communication: Illustrations foster better collaboration among team members, ensuring everyone is on the same page.

Key Features of Effective Illustrations

- Detail: High-quality visuals include comprehensive details that prevent misinterpretation.

- Clarity: Clear labeling and organization enhance comprehension and usability.

- Accessibility: Easily accessible illustrations ensure that all users can benefit from the information provided.

Common Issues with Pat Trap Parts

Understanding frequent challenges associated with these components is essential for effective maintenance and optimal functionality. Various factors can lead to complications, impacting performance and leading to the need for repairs. Recognizing these common concerns can help users address issues promptly and prevent further complications.

Leakage Problems

One prevalent issue users encounter is leakage. This often occurs due to worn-out seals or improper installation, leading to inefficient operation. Regular inspection and timely replacement of damaged seals can significantly reduce the risk of leaks.

Blockages and Clogs

Another common challenge is the occurrence of blockages. Over time, debris can accumulate, obstructing the flow and reducing efficiency. Implementing a routine cleaning schedule can help maintain clear pathways and ensure smooth functioning.

Maintenance Tips for Pat Trap Systems

Regular upkeep of your system is crucial for optimal performance and longevity. Implementing a consistent maintenance routine can prevent malfunctions and extend the lifespan of the components involved. Below are essential guidelines to ensure your system operates smoothly.

Regular Inspection

Conduct frequent checks to identify wear or damage in the equipment. Look for signs of leaks, corrosion, or unusual noises that may indicate issues. Addressing these concerns promptly can help avoid more significant problems down the line.

Cleaning Procedures

Keeping the system clean is vital for efficiency. Accumulated debris can obstruct flow and reduce functionality. Use appropriate cleaning agents and techniques to remove any build-up without damaging the equipment.

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for leaks and corrosion. |

| Cleaning | Quarterly | Use non-corrosive cleaners. |

| Component Replacement | Annually | Replace worn parts to maintain efficiency. |

Professional Servicing

Consider scheduling professional maintenance to ensure everything is functioning correctly. Experts can identify potential issues that may not be visible during routine inspections and provide solutions to enhance performance.

How to Read Parts Diagrams

Understanding illustrations that display component arrangements is essential for effective assembly and maintenance. These visuals provide critical insights into the positioning and relationships of different elements within a system. By mastering how to interpret these representations, users can simplify their tasks and ensure optimal performance.

Identifying Key Features

Start by familiarizing yourself with the overall layout. Look for legends or notations that explain symbols and designations used in the visual. Each component will typically be labeled clearly, aiding in quick identification. Pay attention to any arrows or lines that indicate connections or relationships between elements, as these can provide context for assembly or troubleshooting.

Utilizing Reference Numbers

Reference numbers play a significant role in understanding these illustrations. Each labeled item often corresponds to a list that details specifications or instructions. Cross-referencing these numbers with the accompanying text will help clarify the function and importance of each element. This step is crucial for accurate repairs and replacements, ensuring that the correct components are utilized.

Repairing Damaged Pat Trap Components

Ensuring the functionality of your equipment involves addressing any wear or damage that may occur over time. Understanding how to effectively restore critical elements is essential for maintaining optimal performance. This section outlines essential steps and considerations for repairing impaired components.

Begin by identifying the specific areas that require attention. Common issues may include:

- Cracks or breaks in structural elements

- Worn or frayed seals and gaskets

- Corrosion on metal surfaces

- Loose or missing fasteners

Once the problems are identified, follow these steps for repair:

- Assess the Damage: Thoroughly examine each component to determine the extent of the impairment.

- Gather Necessary Tools: Collect all required tools and materials, such as adhesives, replacement seals, and cleaning agents.

- Perform Repairs: Depending on the type of damage, apply appropriate techniques, such as:

- Using epoxy for bonding cracked parts

- Replacing worn seals with new ones

- Cleaning and treating corroded surfaces

- Tightening or replacing loose fasteners

Regular maintenance and timely repairs can prolong the lifespan of your equipment, ensuring it operates smoothly for years to come.

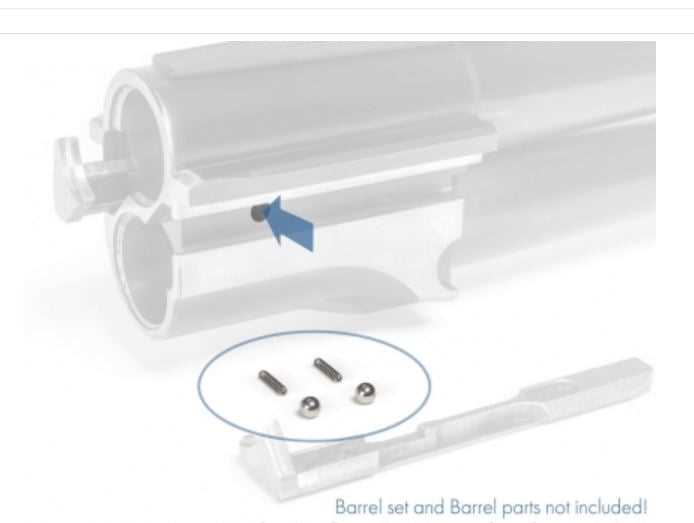

Choosing Quality Replacement Parts

When it comes to maintaining your equipment, selecting high-quality components is essential for ensuring optimal performance and longevity. The right choice can prevent future issues and enhance overall functionality.

Here are some key considerations for making informed decisions:

- Material Quality: Look for durable materials that can withstand wear and tear.

- Compatibility: Ensure that the components match your equipment’s specifications for seamless integration.

- Brand Reputation: Opt for trusted manufacturers known for producing reliable replacements.

- Warranty and Support: Choose products that come with warranties and customer support for peace of mind.

- Reviews and Recommendations: Research customer feedback and seek recommendations to gauge the reliability of a product.

By focusing on these factors, you can make well-informed choices that will ultimately lead to improved performance and satisfaction with your equipment. Quality components not only enhance functionality but also reduce the likelihood of premature failures.

Tools Required for Pat Trap Repairs

When undertaking maintenance or repairs on specific mechanisms, having the right equipment is essential. The correct tools can significantly streamline the process and ensure that tasks are completed efficiently and effectively.

Basic Hand Tools: A set of screwdrivers, wrenches, and pliers are fundamental for loosening and tightening components. These tools are crucial for accessing various areas of the equipment.

Measuring Instruments: Accurate measurements are vital for proper adjustments. Using calipers or tape measures helps ensure that each piece is correctly aligned and fitted.

Cleaning Supplies: Keeping the workspace and parts clean is important. Rags, brushes, and cleaning agents help maintain optimal performance and longevity.

Safety Gear: Protective gloves, goggles, and masks should be used to ensure safety during repairs. This gear protects against potential hazards associated with the maintenance process.

Specialized Equipment: In some cases, specific tools designed for particular tasks may be required. Researching and acquiring these tools in advance can help prevent delays during repairs.

Safety Precautions During Maintenance

Ensuring safety during maintenance activities is essential to prevent accidents and injuries. Proper precautions should be taken to create a secure environment for both the individual performing the work and anyone nearby. Adhering to recommended safety practices not only safeguards health but also enhances the efficiency of maintenance tasks.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial. This may include gloves, safety goggles, and helmets to shield against potential hazards. Wearing suitable clothing can also help minimize risks associated with sharp objects or chemical exposure. Regularly inspecting and maintaining PPE ensures its effectiveness during work.

Work Area Safety

Maintaining a clean and organized workspace contributes significantly to overall safety. Removing unnecessary items and ensuring adequate lighting can help reduce the risk of slips, trips, and falls. It is also advisable to clearly mark hazardous areas and ensure that emergency exits are accessible and free from obstructions.