The process of maintaining clean and clear water in outdoor installations requires specific mechanisms that work together efficiently. These systems are essential for ensuring the consistent movement and purification of the liquid. By breaking down the individual elements, it’s possible to get a clearer view of how everything functions together to keep water in pristine condition.

Key components within these systems serve unique purposes, each contributing to the overall effectiveness of the setup. Some of these parts are responsible for moving the liquid, while others work to remove unwanted debris. Understanding these elements helps with troubleshooting and maintenance, ensuring that everything runs smoothly.

Knowing the role of each component is also crucial for proper upkeep. Regular checks and replacements of certain elements can significantly extend the lifespan of the system, ensuring long-term reliability. This guide will explore the various pieces involved and explain their roles in the overall function of the system.

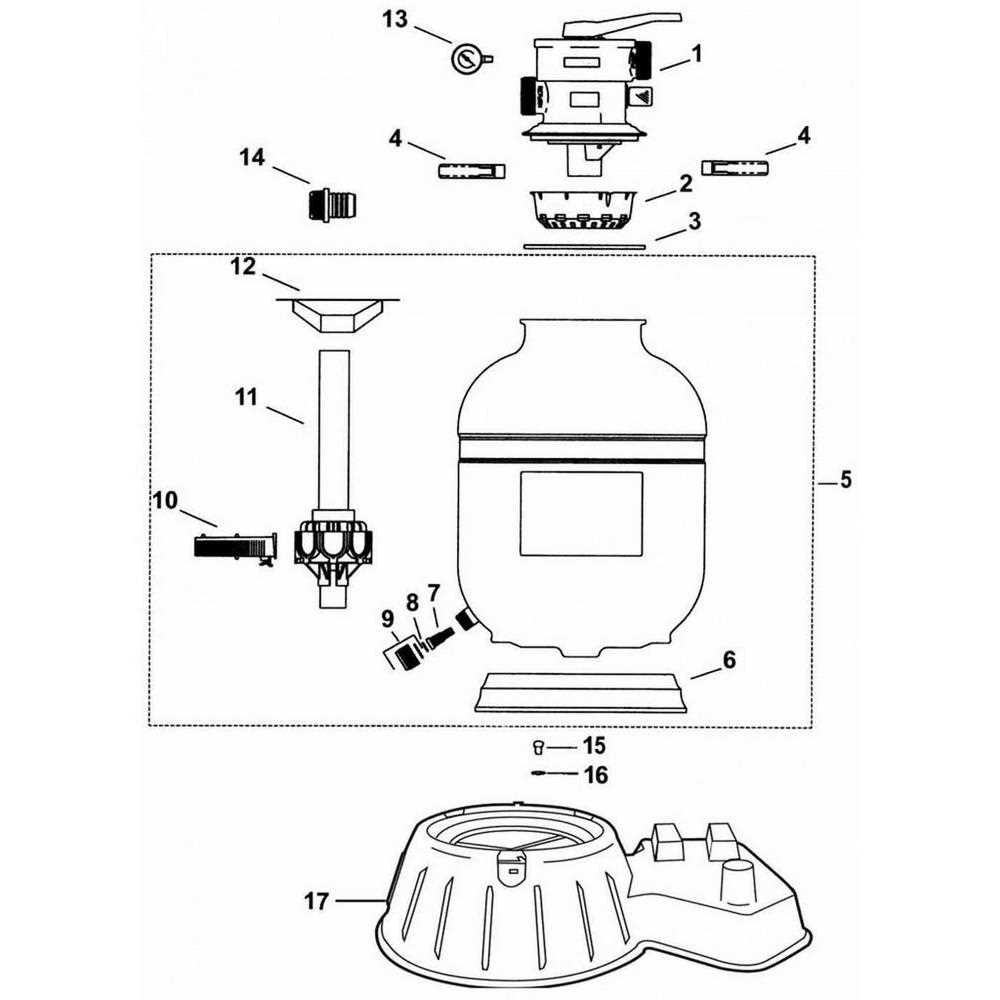

The mechanism described here is composed of several critical components that work together to ensure efficient performance in various systems. Each element has a specific role in maintaining the cleanliness and circulation of fluids, contributing to the overall functionality of the setup.

| Component | Description |

|---|---|

| Valve | This controls the direction and flow, allowing the user to adjust how and where the fluid moves within the system. |

| Tank | The primary container where the process occurs, designed to hold and manage materials while they are being processed. |

| Laterals | These small tubular sections at the bottom of the structure help in distributing and collecting fluids, ensuring even movement. |

| Pressure Gauge | This monitoring device provides real-time data on the pressure levels, essential for maintaining safe operation. |

Function of Sand Filter Valves

The valves in a water filtration system play a crucial role in controlling the direction and flow of water through various stages of the cleaning process. These components manage the distribution, ensuring that the system operates efficiently and effectively, whether it’s performing regular maintenance or running during standard operation.

| Valve Type | Main Function |

|---|---|

| Backwash Valve | Reverses the flow to clean out debris. |

| Recirculate Valve | Bypasses filtration to circulate water. |

| Rinse Valve | Clears out any residual particles post-backwash. |

| Waste Valve | Directs the water out of the system during cleaning. |

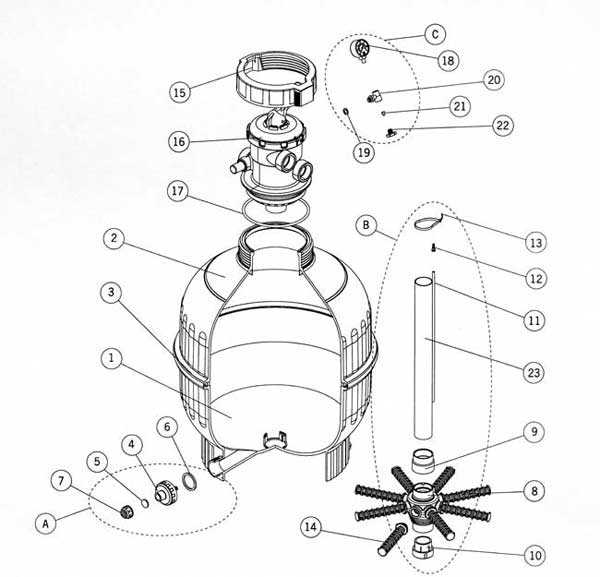

Importance of the Sand Tank

The main reservoir plays a crucial role in the overall efficiency of the water purification system. It acts as a key component that ensures the removal of unwanted debris, keeping the entire setup functioning smoothly. This section is vital for maintaining clarity and quality in the system’s performance.

How the Main Reservoir Functions

The container works by trapping impurities as the liquid flows through, allowing cleaner water to pass on. Its design is simple yet effective, making it an essential part of the system’s filtration process.

Maintenance and Care

Proper upkeep of this unit is essential to avoid blockages and maintain its performance. Regular cleaning and timely replacements contribute to its longevity and ensure that the system continues to operate effectively.

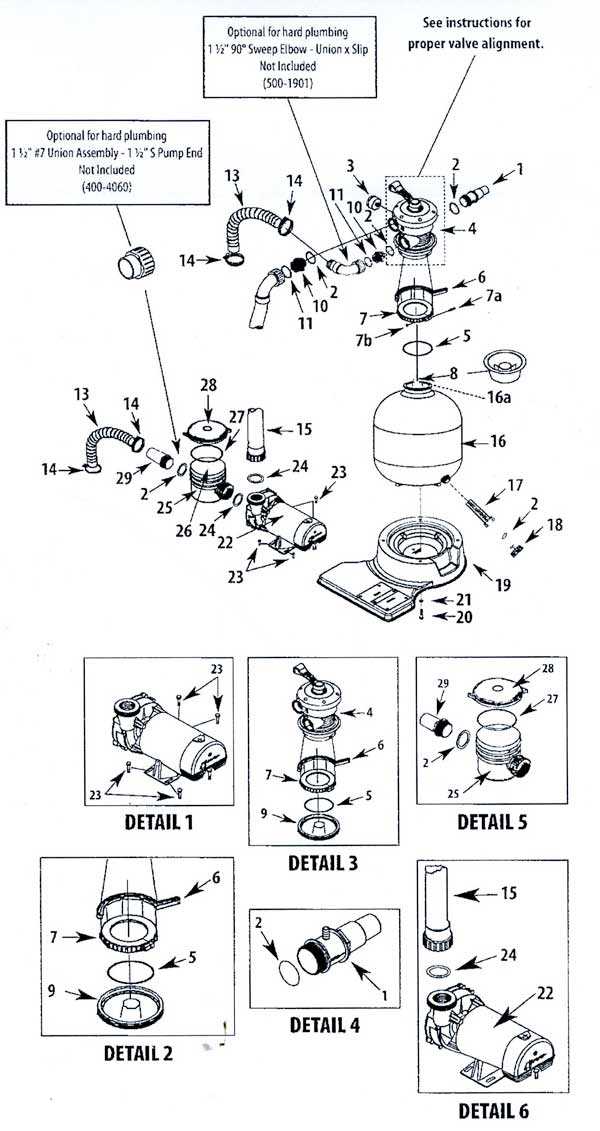

Role of the Pump in Circulation

The pump is essential for maintaining the movement of water within a closed system. It ensures that liquid consistently flows through all necessary components, promoting efficient operation and even distribution of chemicals or other elements present in the water. The continuous flow also prevents stagnation and maintains clarity.

Ensuring Proper Flow

A key function of the pump is to generate sufficient pressure to drive water through various channels and back into the system. This consistent flow rate is crucial for optimizing the overall performance of the system and ensuring that all areas receive adequate circulation.

Preventing Blockages

By keeping water in constant motion, the pump minimizes the risk of blockages that could hinder the system’s efficiency. Regular circulation helps prevent debris buildup and keeps all mechanical parts working smoothly without interruptions.

Filter Media: Sand Types Explained

The choice of filtration material plays a significant role in maintaining clean water in various systems. Different varieties of granular materials are commonly used in filtration setups, each with distinct characteristics that contribute to the overall effectiveness of the system. Understanding the differences can help improve the clarity and quality of water in the long run.

Silica-Based Granules

One of the most common types of filtration media is composed of silica-based granules. These are highly effective due to their natural structure, which allows for the capture of fine particles. The granular texture aids in trapping debris while ensuring water flows through with ease.

Alternative Options

In addition to silica-based varieties, alternative materials such as zeolite and glass granules are also popular. These materials offer unique advantages, such as enhanced durability and the ability to filter smaller particles. Choosing the right material depends on specific needs and the desired level of filtration.

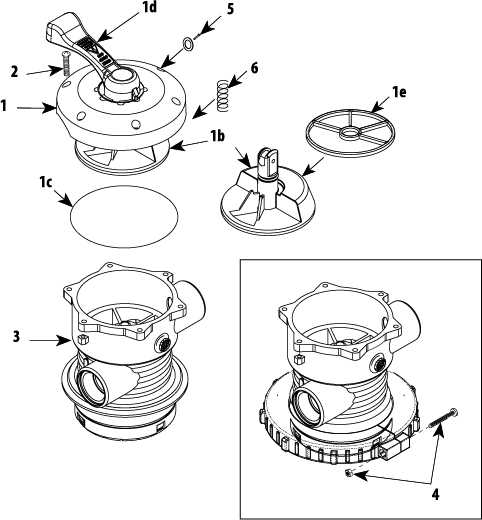

Understanding Multiport Valves

Multiport valves play a crucial role in directing the flow of water within various systems. They offer multiple functions, allowing users to manage different operations efficiently. By understanding how these valves work, one can better control water movement and optimize the performance of the system.

Key Functions of a Multiport Valve

- Backwash: Helps to clean internal components by reversing water flow.

- Rinse: Ensures that the system is cleared after cleaning operations.

- Circulate: Allows water to bypass certain elements while maintaining circulation.

- Waste: Diverts water out of the system to remove unwanted debris.

Maintaining a Multiport Valve

Regular maintenance ensures that the multiport valve remains in optimal condition. It’s essential to check for leaks, lubricate seals, and clean any debris to avoid malfunctions. Proper care can extend the life of the valve and improve the efficiency of the entire setup.

Maintaining the Pressure Gauge

Ensuring the accuracy of the pressure gauge is essential for the proper functioning of the system. Regular maintenance can help detect issues early and prevent potential damage to the equipment. It is important to monitor the gauge closely and address any irregularities promptly.

- Regularly check the gauge for any visible signs of wear or damage.

- Ensure the connections are secure and free from leaks.

- Clean the gauge face to ensure readings are easily visible.

- If the gauge consistently shows incorrect readings, consider recalibrating or replacing it.

Proper care and attention to this component will ensure the system continues to operate efficiently and effectively.

Cleaning and Backwashing Procedures

Maintaining optimal performance of your water circulation system is essential for ensuring clarity and hygiene. Regular cleaning and backwashing are vital steps to remove accumulated debris and contaminants, helping to enhance the overall efficiency of the equipment.

Importance of Regular Maintenance

Consistent upkeep not only prolongs the lifespan of the system but also ensures that the water remains free of impurities. By adhering to a systematic maintenance routine, you can significantly improve the effectiveness of the operation.

Step-by-Step Backwashing Process

Begin by shutting off the system to prevent any mishaps. Next, switch the operation mode to backwash, allowing the water to flow in the reverse direction. This process dislodges trapped particles and pushes them out of the system. After a few minutes, revert the setting to the normal operation mode and allow fresh water to flow through, ensuring all remnants are washed away. Finally, check the pressure gauge and repeat the procedure as necessary.

Common Issues with Sand Filters

Maintaining an efficient water circulation system is crucial for any recreational area. However, various challenges may arise that can hinder performance. Understanding these common issues is essential for effective troubleshooting and ensuring optimal functionality.

Clogging and Debris Buildup

One prevalent problem is the accumulation of debris within the system. Over time, particles can obstruct flow, leading to reduced efficiency. Regular maintenance is necessary to prevent this issue from becoming severe.

Pressure Imbalance

Another frequent concern involves pressure variations within the setup. A significant drop or spike in pressure can indicate underlying problems, such as leaks or malfunctions in specific components. Monitoring pressure gauges is vital for timely intervention.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Clogging | Debris buildup, inadequate maintenance | Regular cleaning, backwashing |

| Pressure imbalance | Leaks, component malfunctions | Inspecting for leaks, replacing faulty parts |

Replacement Parts for Sand Filters

Maintaining an effective circulation system is essential for the longevity and efficiency of water management systems. Various components may require periodic replacement to ensure optimal performance. This section outlines essential components that might need attention or substitution over time.

Common Components

- Valves – These mechanisms control the flow and direction of water, vital for system operation.

- Hoses – Flexible conduits that transport water between different elements.

- O-rings – Seals that prevent leaks, ensuring a tight fit between components.

- Clamps – Fasteners used to secure hoses and other connections in place.

- Strainers – Devices that capture debris and prevent it from entering the system.

Choosing the Right Replacements

When selecting new components, consider compatibility with existing systems. Quality and durability are crucial factors, as inferior parts may lead to further issues or inefficiencies. It’s advisable to consult with professionals or trusted suppliers to find suitable options.