Understanding the internal and external structure of mechanical systems is essential for proper maintenance and upgrades. Every detail in the assembly contributes to the overall performance, making it crucial to be familiar with how these elements fit together. This knowledge helps users identify and address issues efficiently.

Each section of the machine consists of interconnected components that work in harmony. From the engine block to the suspension, every piece has its role. By exploring these configurations, owners can ensure their machine operates at its peak performance.

Knowing how the various elements align within the system offers valuable insights into potential improvements or repairs. This guide will help navigate through the setup, providing clarity on the structure without overwhelming technical details.

Comprehensive Guide to Raptor 660 Components

The intricate structure of an all-terrain vehicle is built from various essential mechanisms, each playing a vital role in ensuring optimal performance. Understanding these elements provides a deeper insight into how the entire machine operates, highlighting key areas for maintenance and upgrades.

Engine Assembly: The core of any off-road machine, the engine combines power and efficiency. Regular inspection and proper care of this unit are critical for long-term reliability. It’s important to stay aware of potential wear or damage in order to avoid costly repairs.

Transmission System: Responsible for the smooth transfer of power, the transmission is designed to handle the stresses of varying terrains. Keeping this component in peak condition ensures seamless gear shifts and improved overall vehicle responsiveness.

Suspension Components: These elements help absorb the impact of uneven surfaces, providing a smoother ride and reducing stress on the frame. Ensuring these parts are in good condition enhances both comfort and vehicle handling during off-road adventures.

Braking System: A well-maintained braking system is essential for rider safety. Routine checks of brake pads and fluid levels will prevent any unexpected failures, offering peace of mind while navigating challenging routes.

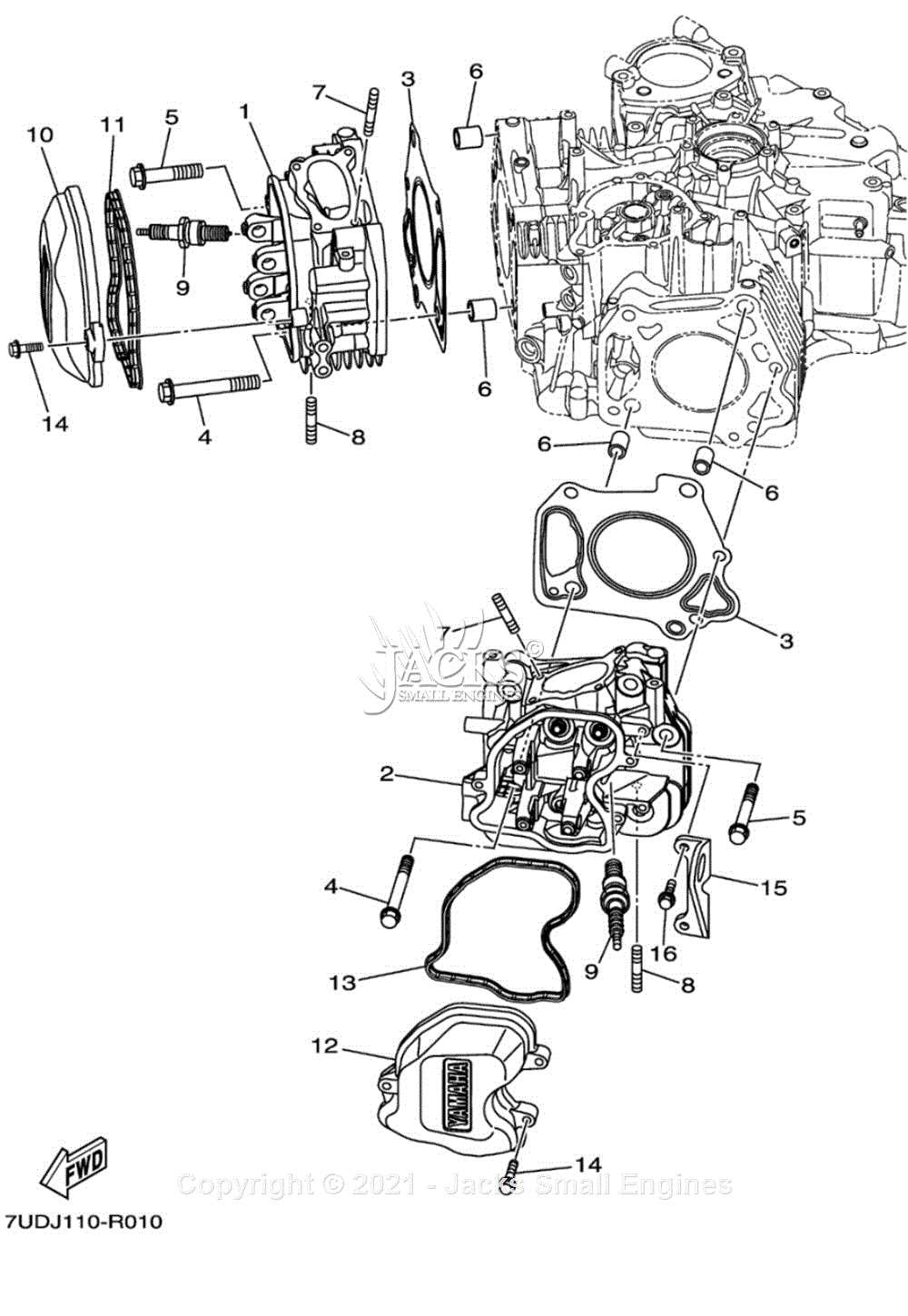

Engine Layout and Key Components

The engine layout is essential for understanding the overall performance and efficiency of a vehicle’s powertrain. By familiarizing yourself with the structure and crucial elements, you can gain a deeper appreciation of how each part functions in harmony to deliver power and reliability.

Main Sections of the Engine

- Cylinder Block: This is the core of the engine, housing the cylinders where fuel combustion occurs.

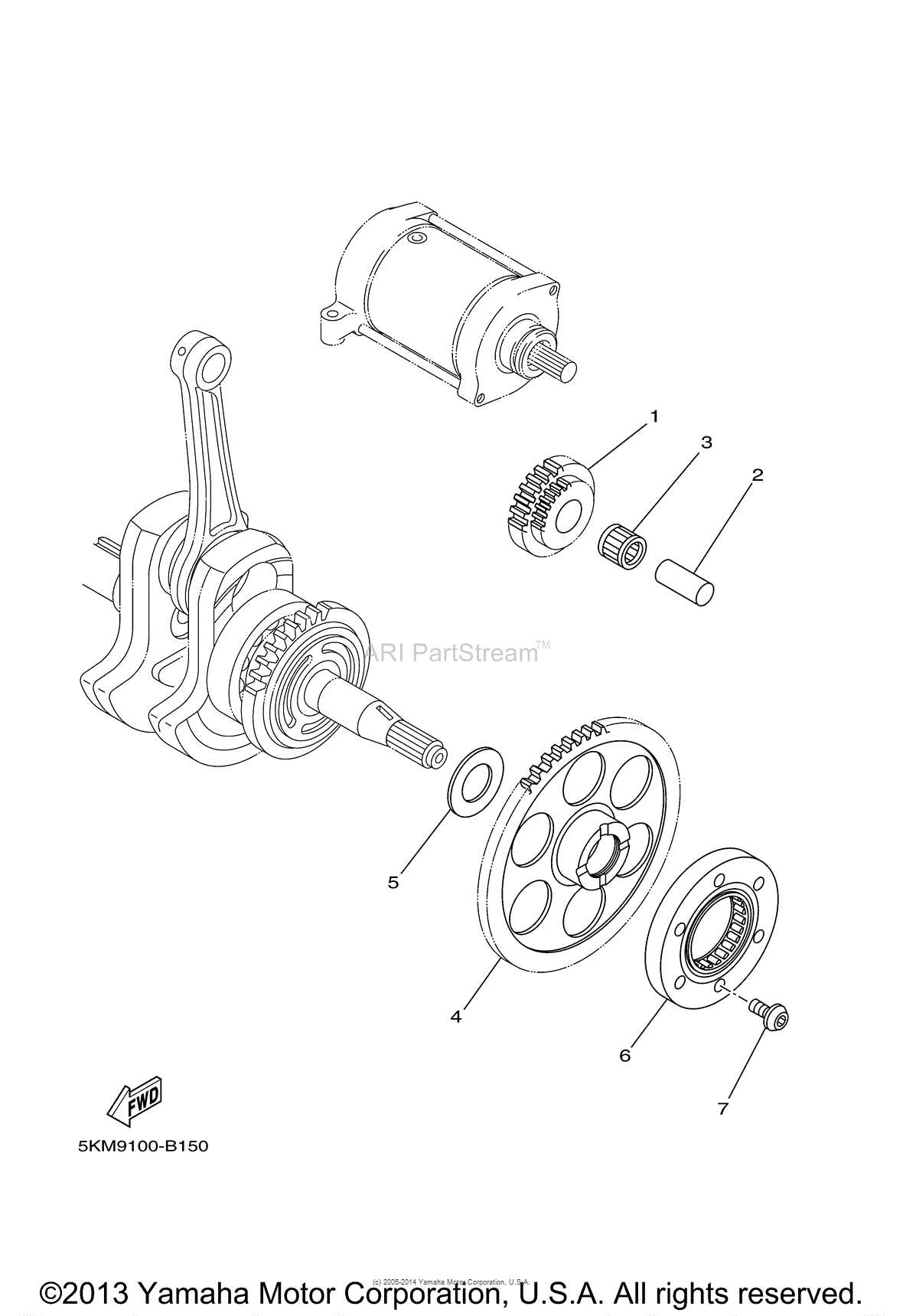

- Crankshaft: Located at the bottom of the block, it converts the linear motion of the pistons into rotational movement, driving the vehicle forward.

- Camshaft: Responsible for controlling the timing of the intake and exhaust valves, ensuring proper airflow into and out of the cylinders.

Additional Important Components

- Pistons: These move within the cylinders, compressing the air-fuel mixture before ignition and generating power.

- Valves: These regulate the flow of air and fuel into the cylinders and allow exhaust gases to exit.

- Connecting Rods: These link the pistons to the crankshaft, transferring the energy generated by combustion.

- Flywheel:

Exploring the Frame Structure

The core design of the frame serves as the foundation for the vehicle’s overall strength and durability. Built with precision, it supports the essential components that ensure balance and performance during operation. The framework is constructed to provide stability, absorbing impact while maintaining control, particularly on challenging terrains.

Below is a detailed table summarizing the key aspects of the framework’s construction:

Component Function Main Frame Supports the engine and distributes weight evenly. Subframe Provides additional support for the rear suspension and rider’s seat. Swingarm Holds the rear wheel and allows for suspension movement. Crossmembers Enhances structural rigidity and reduces flexing during use. Brake System Parts Overview

The brake system plays a critical role in ensuring safe and reliable stopping power in any off-road vehicle. Understanding the components involved in this system helps in maintaining efficiency and ensuring proper functionality during intense use. This section provides an overview of the essential elements that contribute to effective braking.

Main Components of the Brake Setup

The braking setup includes several key components that work together to provide control. The brake calipers are responsible for applying pressure to the rotors, while rotors themselves are designed to dissipate heat and provide the surface for friction. Additionally, brake pads play a crucial role by pressing against the rotors to slow down the vehicle.

Hydraulic System Functionality

The hydraulic aspect of the braking system ensures that pressure is transmitted efficiently from the brake lever or pedal to the calipers. Fluid in the system amplifies the force applied, making sure the brakes engage with minimal effort. Proper maintenance of the hydraulic lines and fluid levels is essential for optimal performance.

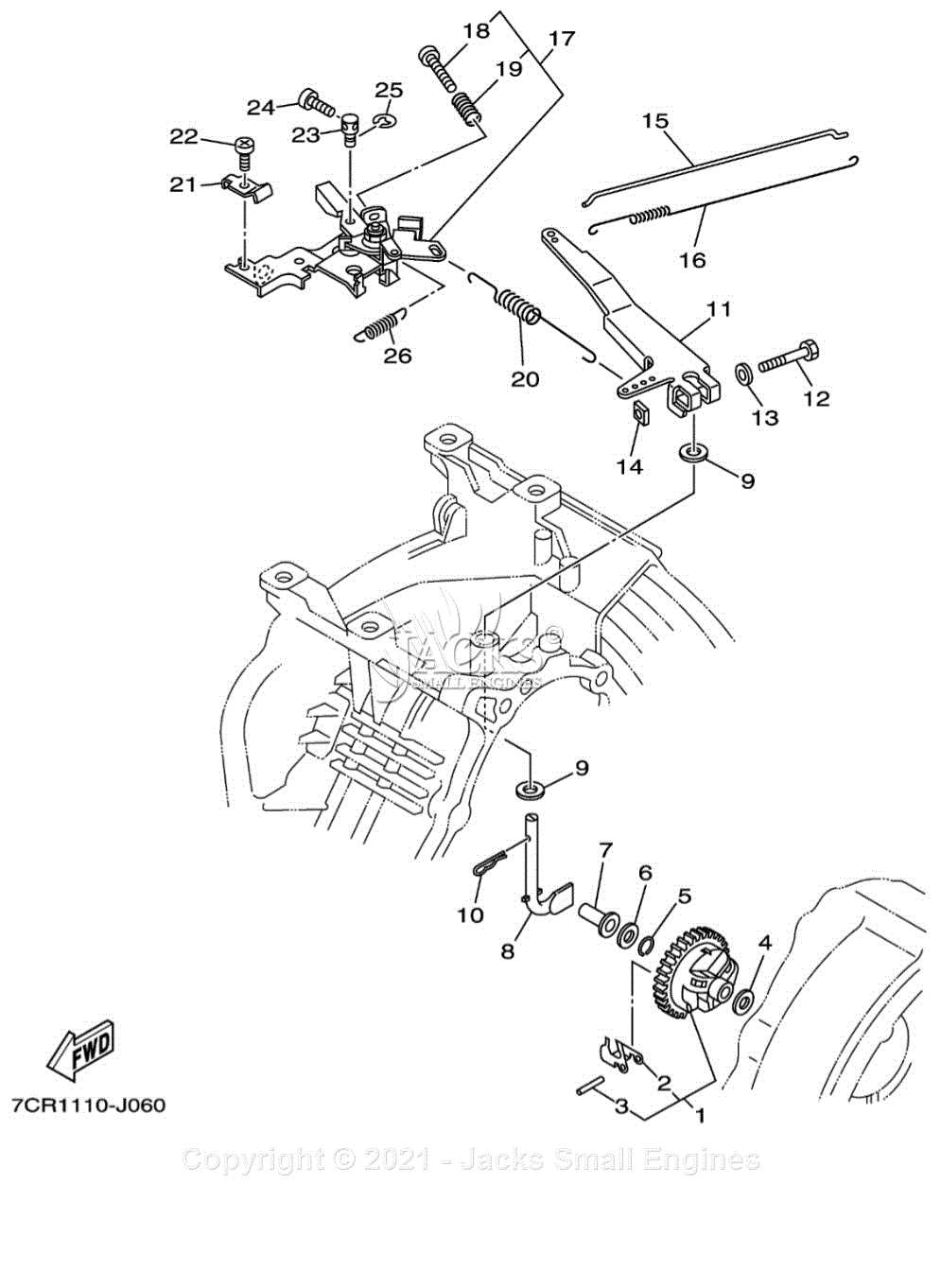

Transmission and Clutch Mechanism Breakdown

The transmission and clutch system play a crucial role in managing the power flow between the engine and the wheels. This section provides an in-depth look into how these components work together to ensure smooth power delivery and control over the vehicle’s movement.

Function of the Transmission

The transmission serves as the intermediary between the engine’s power output and the drive system. It allows the rider to control speed and torque through gear changes, adapting to different terrain or riding conditions. Without a functional transmission, managing engine power efficiently would be impossible.

Clutch Operation

The clutch mechanism allows for the disengagement of power from the engine when shifting gears. This ensures smooth transitions between different speeds. By engaging and disengaging the clutch, the rider maintains full control over the power delivery to the drivetrain.

Suspension System and Shock Absorbers

The suspension system plays a critical role in ensuring a smooth and controlled ride, absorbing impacts and reducing the effects of rough terrain. It consists of several components working together to maintain stability and comfort, allowing the vehicle to handle various types of obstacles and terrains with ease. Proper suspension performance is essential for both safety and overall riding experience.

Key Components of the Suspension

The primary elements of the suspension system include springs, shock absorbers, and control arms. These components work in harmony to control the movement of the vehicle’s wheels, reducing the impact of bumps and enhancing traction. Shock absorbers, in particular, are designed to dampen vibrations and limit the oscillation of the springs, ensuring the ride remains stable and smooth.

Importance of Quality Shock Absorbers

Shock absorbers are vital in managing the forces transmitted from the road to the chassis. They improve both the comfort and safety of the vehicle by controlling the rebound and compression of the springs. High-quality shock absorbers are essential for maintaining optimal control, especially in demanding conditions such as uneven surfaces or high-speed riding.

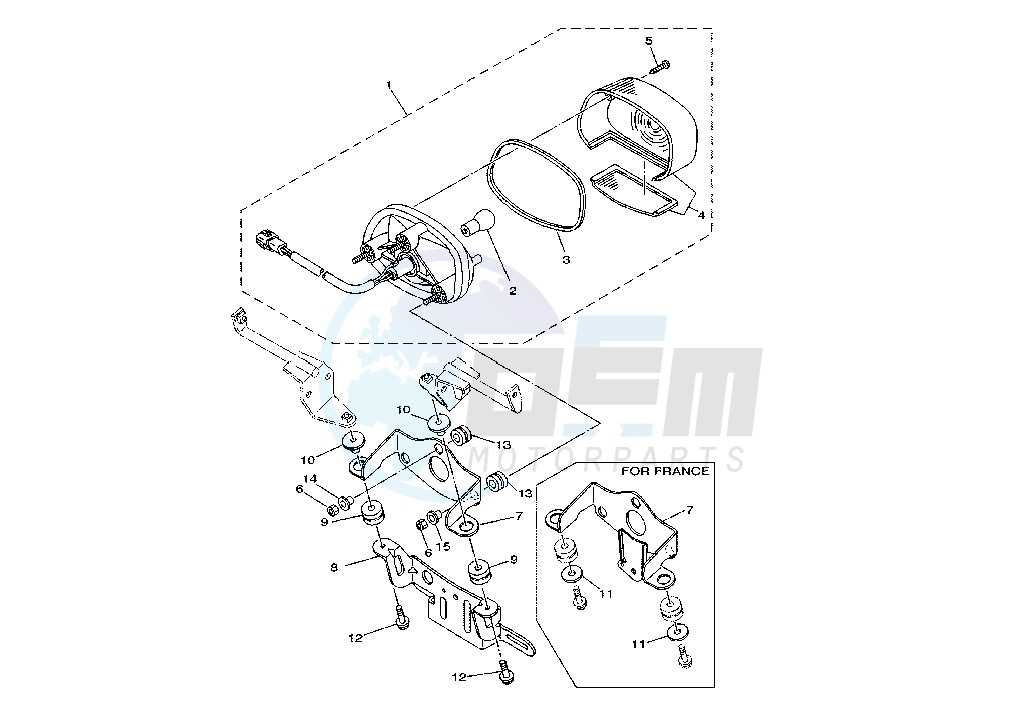

Electrical System and Wiring Overview

The electrical layout of an all-terrain vehicle is crucial for ensuring all components function properly. A well-designed network of wires and connectors ensures smooth operation of lights, sensors, and other electronic systems. Understanding how electricity flows through the vehicle’s components can help with troubleshooting and upgrades.

Key components include the battery, ignition system, wiring harness, and fuses. Each element plays a role in transmitting power to various parts, allowing for efficient communication between them. The entire system is interconnected to maintain power delivery and safety features.

For maintenance and repair, a thorough knowledge of the electrical routing can simplify the process of identifying faults. Knowing the flow of electricity helps in diagnosing issues with components such as the starter motor, lighting, and other accessories.

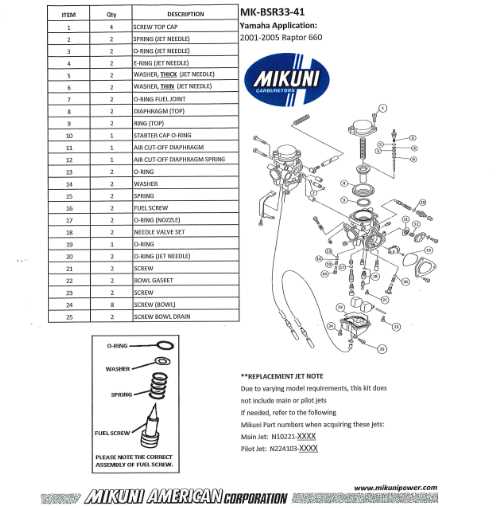

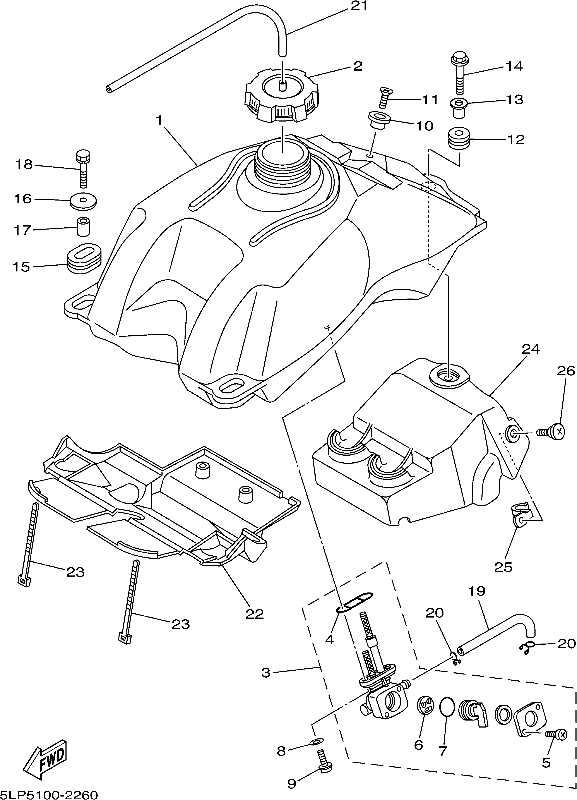

Fuel System Components and Assembly

The fuel system is crucial for the efficient operation of the vehicle, ensuring the engine receives the right mixture of air and fuel for optimal performance. Each element within this system plays a specific role in controlling fuel flow, maintaining pressure, and regulating air-fuel ratios. Proper assembly and maintenance are essential to avoid performance issues and ensure longevity.

Fuel Delivery Mechanism

This section covers the components responsible for transporting fuel from the tank to the engine. Key elements include the fuel pump, fuel filter, and the fuel injectors. The pump moves fuel through the system, the filter ensures clean fuel reaches the injectors, and the injectors spray the precise amount of fuel needed for combustion.

Air-Fuel Management

The air-fuel management system regulates the mixture of air and fuel that enters the engine. The throttle body controls airflow, while sensors monitor air quality and fuel volume to ensure a balanced mixture. Proper synchronization between these components is vital for efficient combustion and smooth engine operation.

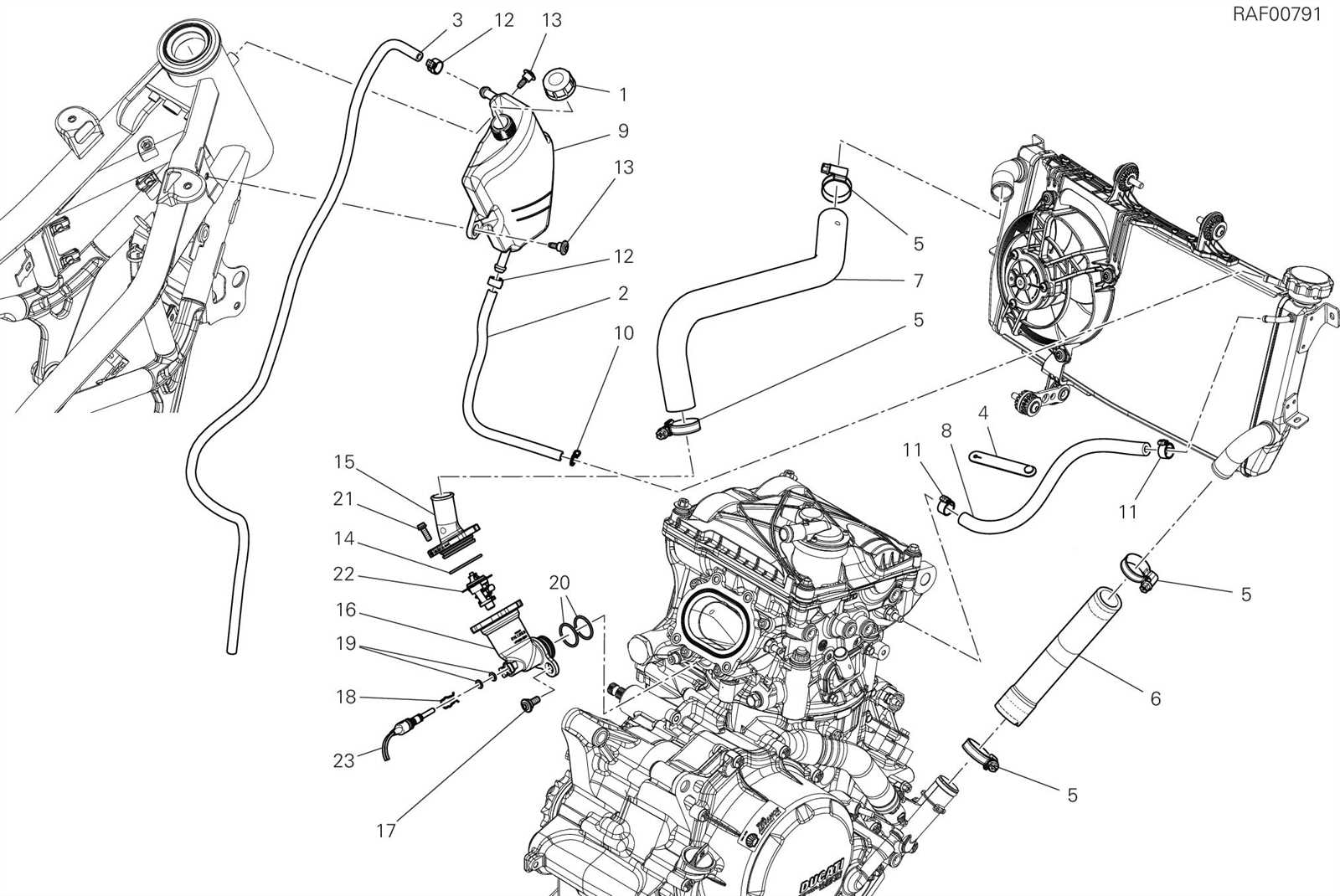

Cooling System Components and Layout

The cooling mechanism plays a crucial role in maintaining optimal engine temperatures. It ensures that the engine operates efficiently by dissipating excess heat, preventing overheating and enhancing performance. A well-organized system guarantees consistent operation, even under high-stress conditions.

The cooling assembly is composed of various elements that work in tandem to regulate the engine temperature. These include the radiator, hoses, water pump, and fans. The layout of these components is designed to promote optimal airflow and fluid circulation, which effectively draws heat away from the engine.

Component Function Radiator Transfers heat from the coolant to the air. Water Pump Circulates coolant through the engine and radiator. Thermostat Regulates the temperature of the coolant by controlling flow. Coolant Hoses Carry coolant between components in the cooling system. Fan Assists in drawing air through the radiator to aid cooling. Exhaust System and Pipe Placement

The exhaust system plays a crucial role in optimizing engine performance by facilitating the efficient flow of gases. Proper placement of the exhaust components ensures not only effective gas expulsion but also contributes to enhanced power output and sound quality. Understanding how each component interacts within the setup can greatly influence the overall functionality of the vehicle.

Key Components of the Exhaust Setup

The system consists of various elements that must be carefully aligned for optimal operation. These include the exhaust manifold, header, muffler, and pipe routing. Each part needs to be strategically placed to reduce backpressure and ensure smooth exhaust gas expulsion.

Pipe Routing and Placement Considerations

When it comes to pipe placement, careful attention is required to avoid obstructing other components. The pipes should be positioned to ensure minimal resistance while maintaining structural integrity. Incorrect placement can lead to inefficiencies, such as reduced engine power or increased noise levels.

Component Purpose Placement Considerations Exhaust Manifold Collects exhaust gases from engine cylinders Should be close to the engine for efficient gas flow Header Helps direct gases into the exhaust pipe Positioned to minimize bends for optimal flow Muffler Reduces noise produced by the exhaust gases Placed towards the rear for better sound management Exhaust Pipe Directs gases from the manifold to the muffler Should be routed in a way that reduces resistance Handlebars and Control System Parts

The handlebar and control system is essential for the rider’s ability to steer and operate the vehicle effectively. It comprises various components that allow smooth handling and responsive control over different functions. These elements are designed to offer both comfort and precision, ensuring optimal performance and safety during rides.

Handlebar Components

The handlebars themselves are the central interface between the rider and the machine. They include grips, bar ends, and mounting brackets, which provide stability and a comfortable hold. Additionally, the handlebar risers and clamps contribute to adjusting the riding posture and ensuring the proper alignment of the controls.

Control Mechanisms

The control mechanisms encompass the throttle, brake levers, and clutch controls, each designed for effortless manipulation. The throttle handle allows the rider to regulate speed, while the brake and clutch levers ensure smooth deceleration and gear shifting. Together, these controls facilitate seamless operation of the vehicle in various riding conditions.

Wheel Assembly and Tire Information

The wheel setup and tire selection are crucial elements for ensuring optimal performance and handling. Understanding how these components interact with the vehicle frame and suspension system is essential for both durability and safety. Proper maintenance and the right specifications can significantly enhance ride quality and control on various terrains.

Component Details Wheel Rim Made from durable materials, typically aluminum or steel, designed to withstand impacts and pressure from rough surfaces. Tire Type Available in various patterns such as knobby or smooth, each suited for different riding conditions like off-road or track environments. Tire Pressure Maintaining the correct air pressure is vital for optimal traction, handling, and longevity of both tires and rims. Hub Connects the wheel to the axle, enabling smooth rotation and transfer of power to the ground. Bearings Facilitate the rotation of the wheel while reducing friction and wear over time.