Exploring the intricate structure of mechanical systems can be both fascinating and essential for proper maintenance. The ability to identify individual elements and how they interact ensures smoother operation and a deeper understanding of the overall assembly.

Each mechanism is composed of multiple sections working in harmony. Knowing the positioning of these sections allows for better troubleshooting, enhanced functionality, and more efficient repairs. Mastering these layouts is crucial for anyone involved in assembly, maintenance, or repair of such systems.

Detailed breakdowns provide the necessary insights for precise adjustments, helping users to address potential issues and improve longevity. By learning the layout, you can avoid common pitfalls and ensure the optimal performance of your setup.

Understanding Reel Component Layouts

The organization of mechanical assemblies plays a crucial role in ensuring optimal performance and durability. A clear understanding of how different elements fit together allows for better maintenance, repairs, and upgrades. Properly arranged components contribute to smoother operation and reduced wear over time.

| Component | Function | |||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Frame | Provides structural support and holds all parts in place. | |||||||||||||||||||||||||||||||||||||||||

| Spindle Mechanism | Controls the rotational movement and alignment. | |||||||||||||||||||||||||||||||||||||||||

| Tension Adjustment | Regulates the tightness and flow of the material. | |||||||||||||||||||||||||||||||||||||||||

| Component | Function | |||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Spindle | Supports the rotation of the system, enabling smooth winding and unwinding. | |||||||||||||||||||||||||||||||||

| Guide arm | Directs movement and ensures even distribution during operation. | |||||||||||||||||||||||||||||||||

| Housing | Encloses the mechanism, protecting internal components from external elements. | |||||||||||||||||||||||||||||||||

| Braking system | Controls the tension, preventing excess slack or overrun. |

| Component | Description | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Body | Supports the structure and houses key mechanical elements. | |||||||||||||||||||||||||||

| Central Axis | Facilitates

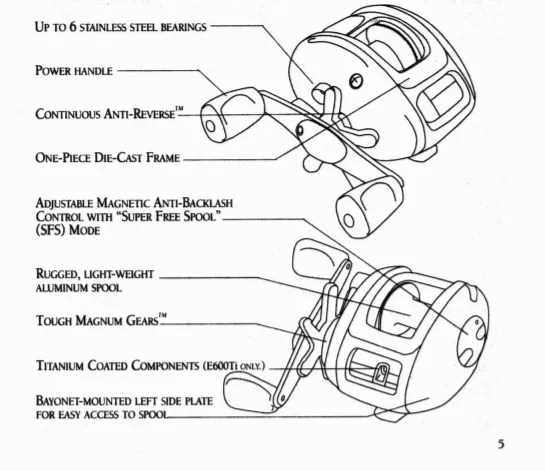

How to Identify Reel ComponentsUnderstanding the various elements of a winding device is essential for ensuring proper maintenance and functionality. Each component plays a specific role in the overall performance, and recognizing these features helps in troubleshooting and repairs.

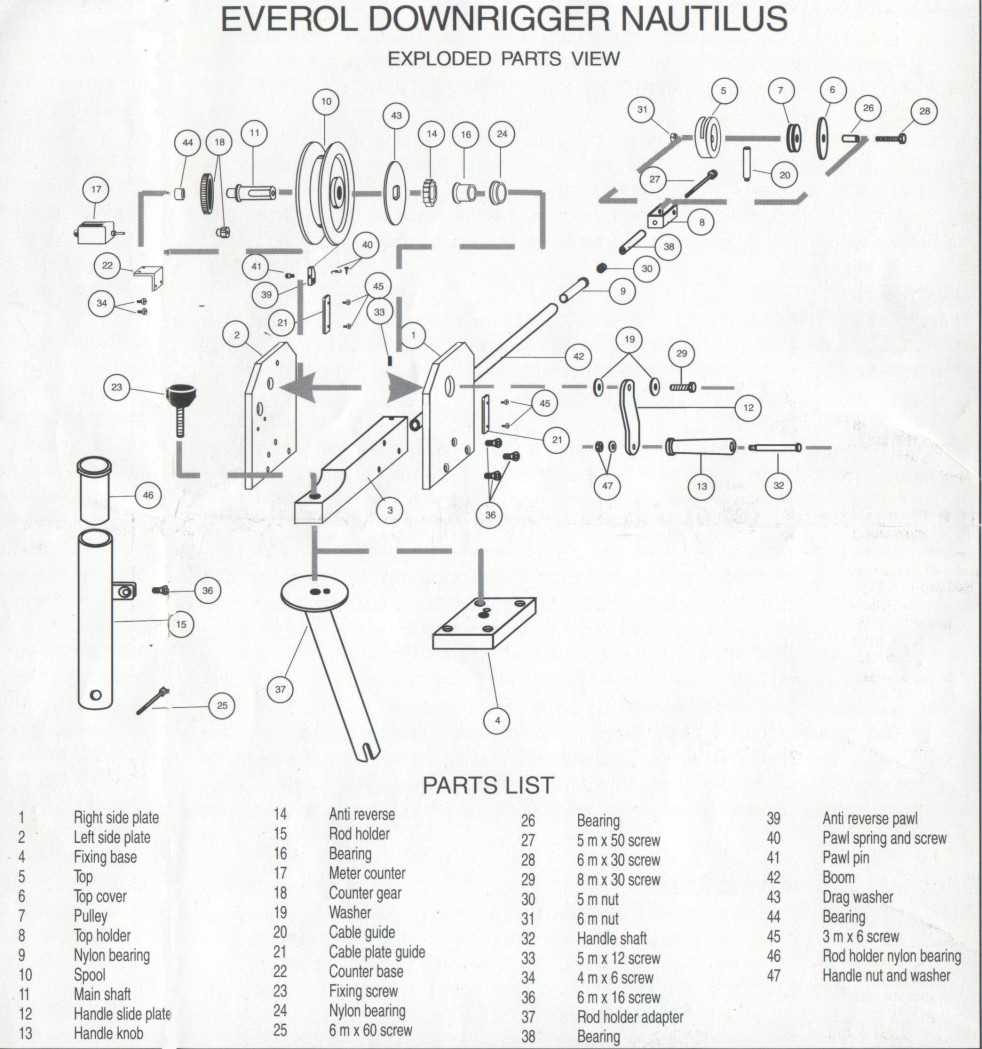

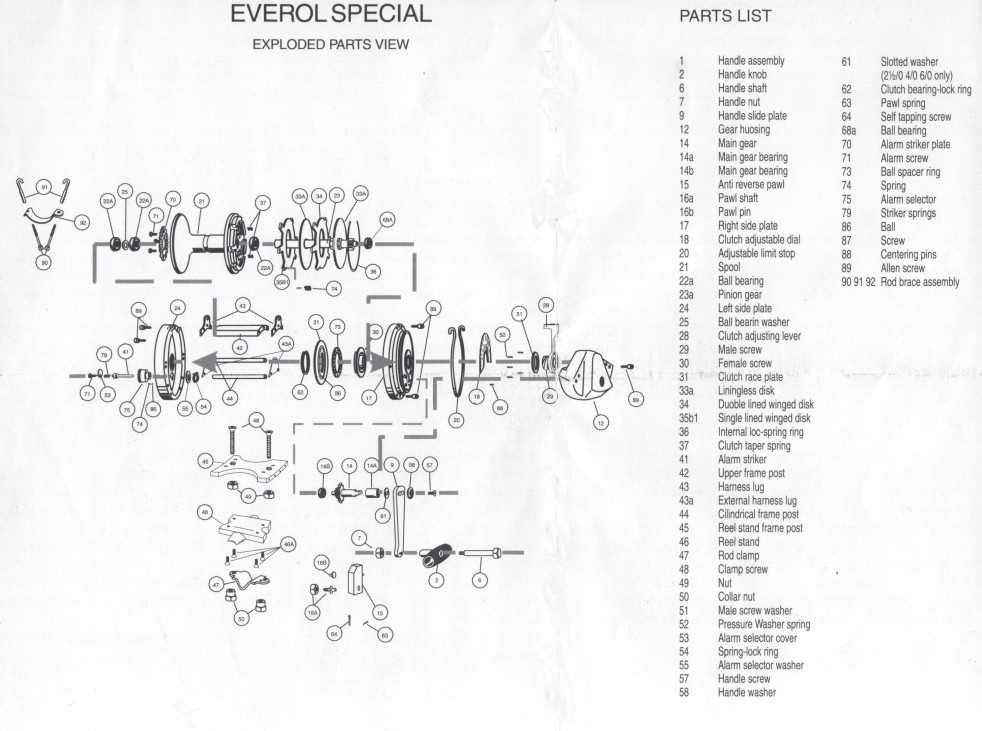

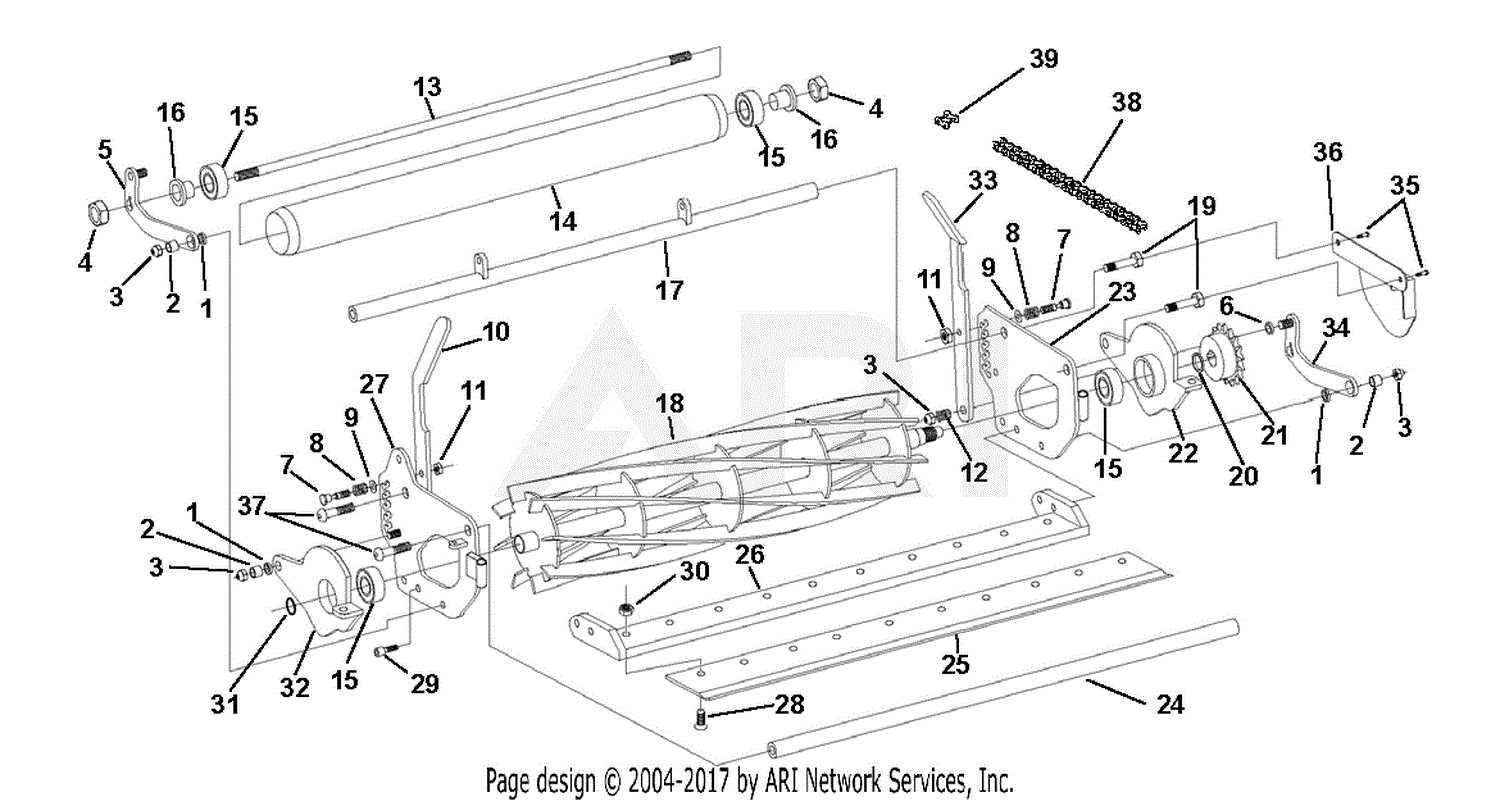

Detailed Breakdown of Reel StructuresThis section aims to provide a comprehensive understanding of the various components that make up these intricate devices. By exploring the essential elements and their functions, we can appreciate the engineering that enables effective performance in various applications. Key Components and Their FunctionsEach structure consists of several critical components, each serving a distinct purpose. The core element is responsible for housing the internal mechanisms, while the exterior framework ensures durability and protection against environmental factors. Additionally, the winding mechanism plays a pivotal role in the storage of materials, enabling smooth operation during use. Interrelationship of ElementsUnderstanding the interconnection between these components is vital for optimal functionality. For instance, the alignment of the winding system with the core significantly affects performance efficiency. Moreover, the materials used in construction can influence both weight and strength, impacting the overall usability of the device. Analyzing Reel Parts for MaintenanceRegular assessment of components is crucial for ensuring optimal performance and longevity of any mechanical system. Understanding the structure and functionality of these elements enables effective upkeep and troubleshooting, ultimately enhancing operational efficiency. This section explores essential strategies for examining and maintaining critical components in various systems. Identifying common wear patterns and potential failure points can greatly improve the maintenance process. The following table outlines key components, their functions, and typical issues that may arise during use:

By regularly inspecting and addressing these critical areas, operators can significantly reduce the risk of failure and extend the lifespan of the system. Visual Guide to Fishing Reel Parts

This section provides a comprehensive overview of the essential components of fishing mechanisms, aiding enthusiasts in understanding their functions and interactions. By familiarizing oneself with these elements, users can enhance their fishing experience and improve maintenance practices. Key Components ExplainedEach component plays a vital role in the overall functionality of the fishing mechanism. The primary elements include the housing, spool, handle, and drag system. Understanding the relationship between these components can help in troubleshooting and optimizing performance. Maintenance Tips for Longevity

Proper care of the individual components is crucial for ensuring durability. Regular cleaning and lubrication of the moving parts prevent corrosion and wear. Users should also inspect the housing for any signs of damage and ensure that the drag system is functioning smoothly for optimal casting and retrieval. Common Failures in Reel ComponentsUnderstanding the typical issues that can arise in these devices is essential for effective maintenance and operation. Components may experience failures due to various factors, including wear and tear, environmental conditions, and improper handling. Identifying common problems can aid in troubleshooting and prolonging the lifespan of the equipment. Frequent Issues Encountered

Signs of Malfunction

Tips for Assembling and Disassembling ReelsProper handling during the assembly and disassembly of mechanisms is crucial for their longevity and optimal performance. This section provides essential advice to ensure a seamless process, minimizing the risk of damage to components while enhancing the user experience. Preparation Before AssemblyBefore starting the process, ensure that you have all necessary tools and components readily available. A clean workspace can significantly reduce the chance of losing small items and help in maintaining organization. Familiarize yourself with each element and its corresponding function to avoid confusion during the assembly. Step-by-Step Disassembly

When taking apart the mechanism, follow a systematic approach. Start by documenting the configuration through photographs or notes. Remove components gently to prevent wear and tear. Store each piece in labeled containers to facilitate easier reassembly later.

Optimizing Reel Performance Through PartsEnhancing the functionality of fishing equipment involves understanding its various components and how they contribute to overall effectiveness. Each element plays a crucial role in ensuring smooth operation, durability, and optimal user experience. By focusing on the specific functions and interactions of these elements, users can achieve improved performance and reliability. Understanding Component InteractionsThe effectiveness of fishing gear hinges on the harmonious interplay of its individual elements. Components such as the spindle, frame, and locking mechanisms must work together seamlessly. Regular maintenance and timely replacements are essential for preserving these interactions, preventing wear and tear, and ensuring that the apparatus operates at peak efficiency. Choosing Quality Materials

Opting for high-quality materials is vital in enhancing the longevity and functionality of fishing equipment. Robust materials resist corrosion, withstand environmental conditions, and reduce the need for frequent replacements. Investing in superior components not only boosts performance but also improves user satisfaction by ensuring reliable and efficient operation during fishing activities. |