In any mechanical system, comprehending the individual elements and their organization is crucial for effective maintenance and troubleshooting. This knowledge facilitates a clearer understanding of how each component interacts, ensuring optimal performance and longevity of the entire unit. By gaining insight into the arrangement and functionality of these parts, users can make informed decisions regarding repairs and upgrades.

Visual representations of these elements serve as invaluable tools, offering a roadmap for both novice and experienced technicians alike. They highlight the relationships between various components, illustrating how each fits within the larger structure. Such diagrams not only enhance clarity but also streamline the diagnostic process, enabling quick identification of potential issues.

Whether one is embarking on a DIY repair or seeking professional assistance, familiarity with these layouts empowers individuals to approach maintenance tasks with confidence. This knowledge demystifies the intricacies of mechanical systems, transforming the potentially overwhelming task of repair into a manageable and straightforward endeavor.

This section explores the essential elements found in various heating and cooling units, providing insight into their functions and importance. Understanding these components is crucial for effective maintenance and optimal performance.

- Heat Exchanger: This is a critical part that facilitates the transfer of heat, ensuring efficient operation of the system.

- Burner Assembly: Responsible for generating heat, this component plays a vital role in the overall heating process.

- Thermostat: This device helps regulate the temperature by signaling the system when to activate or deactivate.

- Compressor: In cooling units, the compressor is essential for circulating refrigerant, enabling effective temperature control.

- Expansion Valve: This component controls the flow of refrigerant, ensuring the correct pressure and temperature for optimal cooling performance.

In addition to these key elements, other components such as the fan, filters, and safety devices contribute significantly to the unit’s functionality and reliability.

- Fan: This component helps circulate air throughout the system, improving efficiency and comfort.

- Filters: Essential for maintaining air quality, these components capture dust and debris, protecting the system from damage.

- Safety Devices: These include features like pressure relief valves and high-temperature sensors, ensuring safe operation and preventing potential hazards.

By familiarizing oneself with these components, users can better appreciate the technology behind their heating and cooling systems and enhance their maintenance practices.

Importance of Parts Identification

Understanding the components of a system is crucial for effective maintenance and repair. Identifying each element helps in ensuring optimal performance and longevity of the equipment. A clear grasp of the individual elements allows users to diagnose issues accurately and implement the necessary solutions promptly.

Benefits of Component Recognition

- Improved Efficiency: Knowing each part’s function aids in quick troubleshooting and reduces downtime.

- Cost-Effective Maintenance: Proper identification allows for targeted repairs, minimizing unnecessary expenses.

- Enhanced Safety: Understanding the components ensures that users can operate the equipment safely, reducing the risk of accidents.

- Informed Decision-Making: Users can make better choices regarding upgrades or replacements when they understand the role of each component.

Strategies for Effective Identification

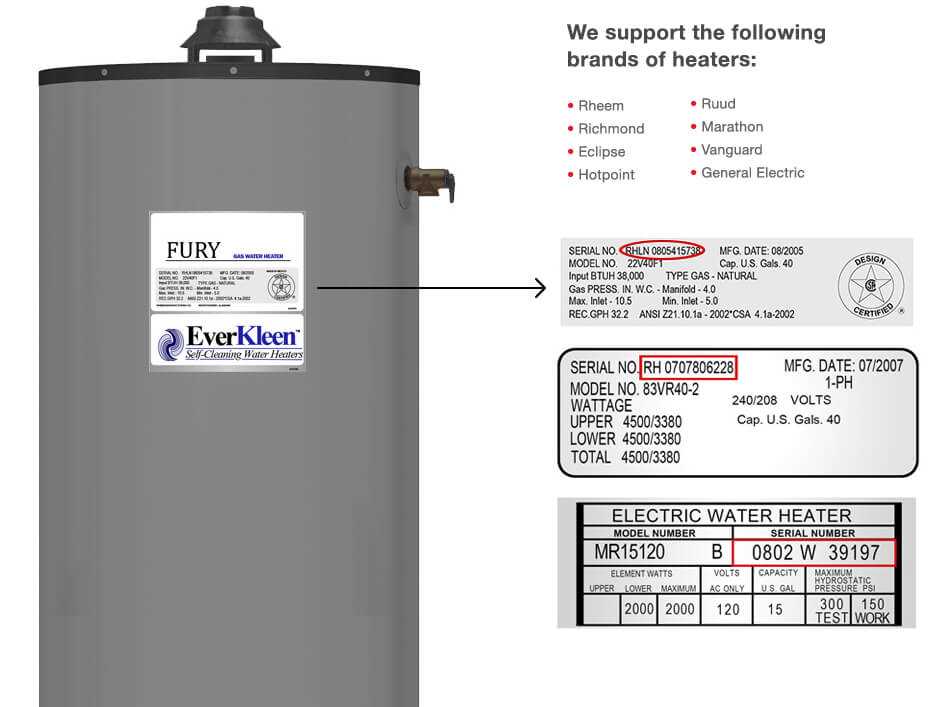

- Utilize visual aids, such as schematics or illustrations, to enhance comprehension.

- Keep a detailed inventory of components, including their specifications and functions.

- Regularly consult manuals or guides to stay updated on component information.

- Engage in training sessions to familiarize staff with the equipment’s elements.

Common Issues and Solutions

In any system, certain challenges may arise that require attention and effective resolution. Identifying these common problems can significantly enhance the overall performance and longevity of the unit. Below are some prevalent issues and their corresponding solutions that can help restore optimal functionality.

Frequent Performance Interruptions

One of the most common complaints is unexpected disruptions in operation. This may result from various factors, including insufficient power supply or blockage in the ventilation system. To address this, ensure that all connections are secure and free from debris. Regular maintenance checks can also prevent buildup that may impede performance.

Inconsistent Temperature Control

Another issue that users often face is fluctuating temperature settings. This can lead to discomfort and inefficiency. To resolve this, inspect the thermostat for any faults and ensure it is calibrated correctly. Additionally, examining the sensors and adjusting their placement may improve accuracy in maintaining desired temperatures.

How to Read the Diagram

Understanding a visual representation of components is crucial for effective troubleshooting and maintenance. This section will guide you through the process of interpreting the layout, ensuring you can easily identify and locate the various elements involved in the system.

Familiarize Yourself with Symbols

Start by getting acquainted with the various symbols used in the representation. Each symbol corresponds to a specific element, such as valves, connectors, or electrical components. Recognizing these symbols will enhance your ability to navigate the illustration efficiently.

Follow the Flow of Operations

Next, pay attention to the flow of operations depicted in the layout. Arrows and lines often indicate the direction of flow or connections between elements. By following these paths, you can better understand how the system functions and how each component interacts with the others.

Maintenance Tips for Longevity

Proper care and upkeep are essential to ensuring the long-term efficiency and reliability of any system. By following regular maintenance practices, you can significantly extend the lifespan of your equipment, while also preventing potential breakdowns and costly repairs. Establishing a routine for inspections and minor adjustments can make a substantial difference in overall performance.

Regular Cleaning – Accumulated dirt and debris can hinder functionality over time. Make sure to clean the system periodically to avoid clogs or other blockages that could reduce efficiency.

Monitor Performance – Pay attention to any unusual noises, changes in operation, or a decline in performance. These could be early indicators of issues that need to be addressed before they escalate.

Check for Leaks – Even small leaks can lead to larger problems if left untreated. Inspect all connections and joints regularly to catch any signs of moisture or corrosion.

Replace Worn Components – Regularly check for wear and tear

Replacement Parts and Their Uses

When dealing with the maintenance of any system, it is essential to understand the role of various components and their functions within the overall mechanism. Ensuring that each item operates efficiently is crucial for the longevity and performance of the equipment.

In cases where wear and tear occur, substituting worn elements becomes necessary to maintain optimal functioning. Each element in the system has a specific function, and when replaced correctly, it can restore or even improve performance. Identifying and installing the right components ensures the system continues running smoothly and efficiently.

Examples of Critical Components: Filters, valves, and connectors are commonly replaced to ensure proper airflow, temperature regulation, and safety mechanisms. These elements must fit perfectly to avoid operational issues.

Choosing the appropriate substitutes

Tools Needed for Repairs

Proper equipment is essential for efficient maintenance and repair work. Having the right tools on hand not only ensures safety but also makes the process smoother and faster. Below, we outline the key instruments that are typically required to handle various repair tasks.

Basic Hand Tools

- Screwdrivers: A set of both flathead and Phillips screwdrivers will cover most needs.

- Wrenches: Adjustable wrenches are versatile for loosening and tightening fasteners of different sizes.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, twisting, or cutting wire.

- Hammer: Essential for driving nails or breaking loose tight components.

Specialized Equipment

- Multimeter: Crucial for checking electrical connections and diagnosing potential issues.

- Pipe Wrench: Ideal for gripping and turning pipes during plumbing-related repairs.

- Allen Wrench Set: These are often necessary for loosening or tightening specific bo

Where to Find Authentic Parts

Locating genuine components for your equipment is essential to ensure long-lasting performance and reliability. Whether you’re handling repairs or routine maintenance, using original items from trusted sources guarantees that the functionality and safety of your system are maintained. It’s important to rely on authorized suppliers who specialize in delivering certified replacements.

You can explore dedicated stores or certified retailers that stock items specifically designed for your model. Additionally, many online platforms offer official replacements, often providing detailed descriptions to help you match the correct pieces to your setup. Checking the manufacturer’s website is another effective way to ensure you’re getting certified replacements directly from the source.

Be cautious when purchasing from third-party vendors. While some may offer lower prices, uncertified components can compromise the integrity of your system. Prioritize quality and certification to avoid potential issues down the line.

Visual Aids and References

Clear visual resources provide an excellent way to better understand the structure and function of various components. By offering an easy-to-follow guide, these tools assist in identifying and locating specific elements, making the process more efficient and less prone to errors.

- Illustrated guides offer a comprehensive look at the overall structure.

- Step-by-step visual instructions help with installation and maintenance.

- Annotated images highlight important connections and functional areas.

- Color-coded diagrams enhance the clarity of complex systems.

These references simplify technical processes and support users by providing a clear roadmap for successful outcomes.

Expert Recommendations for Users

Professionals in the industry often advise paying close attention to regular maintenance and timely checks of your equipment to ensure smooth operation. By understanding how different components interact, users can prevent issues before they escalate.

First and foremost, it is crucial to schedule routine inspections. These inspections allow users to spot wear and tear that may not be immediately noticeable during daily use. Addressing these small issues early on will significantly extend the life of your system.

Another key point is keeping your equipment clean. Accumulated debris can obstruct the function of critical elements, leading to inefficiencies. Regular cleaning helps avoid the buildup of materials that could impact performance over time.

Lastly, always follow the recommended guidelines for adjustments and repairs. Attempting to fix problems without the proper knowledge can lead to further complications. It is often beneficial to consult a professional if a problem seems beyond your expertise

Frequently Asked Questions

In this section, we address common inquiries that arise when working with different components and systems. We aim to provide clear answers that will help resolve frequent issues and enhance understanding of the subject.

What should I do if my system isn’t functioning properly?

If you encounter issues with your system’s performance, the first step is to verify if all connections are secure and if the equipment has been correctly maintained. Checking for visible signs of wear or blockages may also help identify the problem.

How can I ensure optimal system efficiency?

Regular inspections and cleaning are crucial to maintaining efficiency. Ensuring that all parts are free from dust and debris, as well as following recommended service schedules, will extend the lifespan of your equipment.

Why is my system making unusual noises?

Unusual sounds may indicate loose components or a need for cleaning. It’s important to address these sounds quickly to prevent further damage. If cleaning does not resolve the issue, consulting a technician may be necessary.