Maintaining and troubleshooting your machinery requires a clear understanding of its essential elements. A well-structured illustration can serve as a valuable guide, highlighting the various components and their functions. This resource provides a comprehensive view of the assembly, aiding users in identifying parts quickly and efficiently.

Each element plays a crucial role in the overall performance of the equipment. Familiarizing yourself with these components can significantly enhance your ability to perform maintenance tasks and resolve issues. This knowledge empowers users to operate their machinery with confidence and ensures longevity.

Utilizing a detailed representation of the assembly allows for easier navigation through the intricate design of the device. Whether you are conducting routine checks or addressing specific concerns, having access to such a reference will facilitate smoother operations and promote effective troubleshooting.

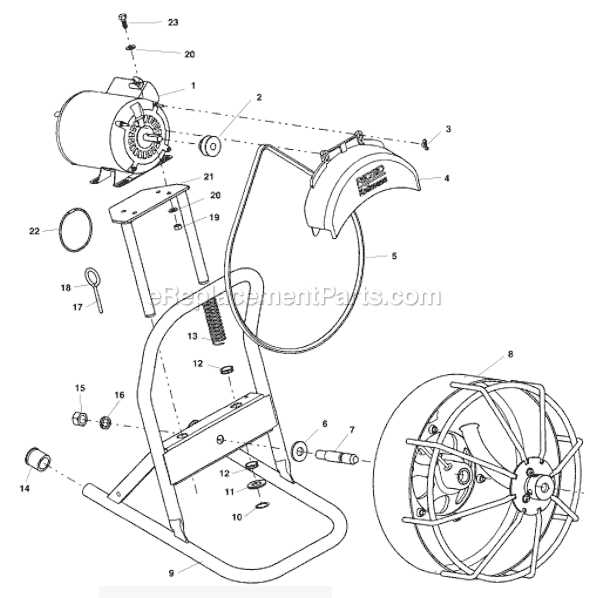

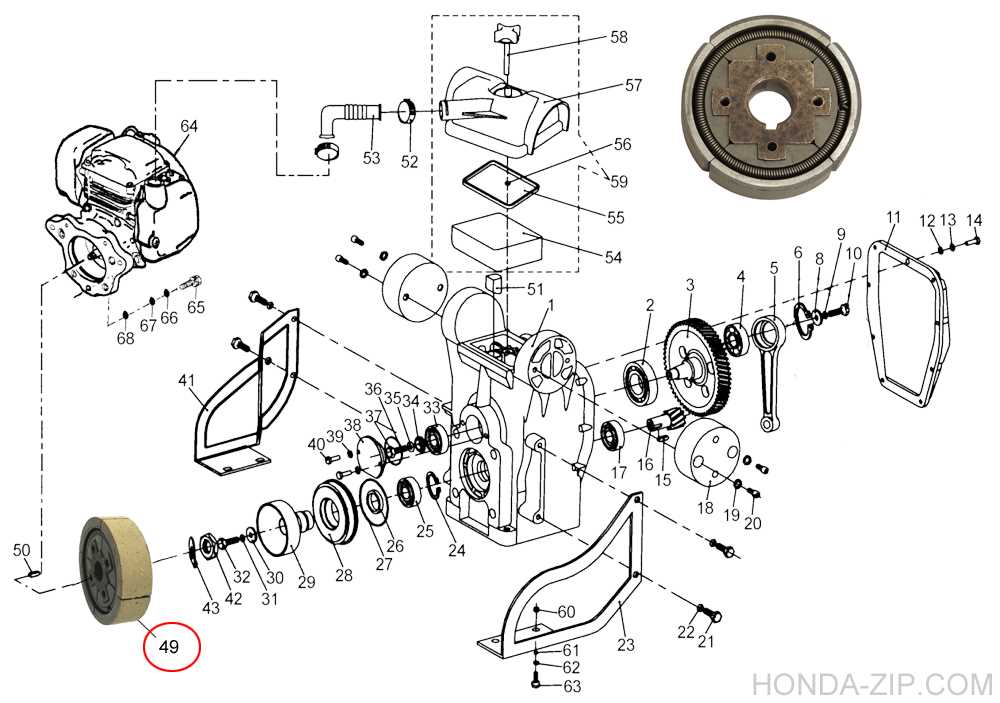

Ridgid K-400 Parts Overview

The essential components of this plumbing tool play a crucial role in its overall functionality and efficiency. Understanding each element’s function can greatly enhance the user experience and ensure optimal performance during operation.

Key Elements: Familiarizing yourself with the various sections of the device will aid in effective troubleshooting and maintenance. Each section contributes to the tool’s capacity to tackle challenging tasks, making it important to recognize their individual roles.

Maintenance Tips: Regular inspection of these crucial segments is advisable. This practice helps in identifying wear and tear, allowing for timely replacements to maintain peak performance. Ensuring all components are in good condition guarantees reliability and efficiency during use.

Key Components of Ridgid K-400

The effectiveness of any plumbing tool relies heavily on its essential elements. Understanding these vital components can enhance the functionality and longevity of the equipment. In this section, we will explore the primary features that contribute to the overall performance of this device.

Motor and Power Source

The motor is the heart of the system, providing the necessary energy to operate. It is crucial for delivering the required torque and speed for various tasks. Additionally, the power source must be reliable and efficient, ensuring consistent performance during operation.

Drum and Cable Assembly

The drum holds the cable, allowing for easy retrieval and storage. Its design plays a significant role in the ease of use and maneuverability of the unit. The cable itself is engineered to navigate through pipes, breaking up clogs and facilitating effective drainage solutions.

Understanding the Parts Diagram

The illustration representing various components of a device is crucial for effective maintenance and repair. It allows users to identify and comprehend each section’s role, enhancing the overall understanding of the equipment’s functionality.

Familiarity with the visual representation can lead to better troubleshooting and efficient repairs. Here are some key aspects to consider:

- Component Identification: Recognizing individual elements helps in assessing their condition and performance.

- Assembly Insights: Understanding how parts fit together provides clarity on the assembly process.

- Maintenance Guidance: The visual guide serves as a reference for routine upkeep, ensuring optimal operation.

By analyzing the illustration carefully, users can improve their skills in managing the equipment effectively.

How to Identify Parts Easily

Recognizing components within machinery can enhance maintenance efficiency and troubleshooting. Knowing how to differentiate these elements simplifies repairs and replacements, ensuring smooth operation.

Here are some effective strategies to assist in the identification process:

- Consult Manuals: Reference user guides or maintenance manuals that provide detailed descriptions and illustrations.

- Visual Inspection: Examine each piece closely for unique identifiers such as model numbers or serial codes.

- Online Resources: Utilize online platforms that offer comprehensive visuals and specifications related to the machinery.

- Manufacturer Support: Contact the manufacturer’s customer service for guidance on specific elements.

By applying these methods, individuals can more easily recognize and understand the various components required for effective functionality.

Common Issues and Replacement Parts

Many users encounter typical challenges with their plumbing devices over time, often requiring specific components to restore functionality. Understanding these common problems can help streamline the troubleshooting process and identify necessary replacements efficiently.

One prevalent issue involves clogs that hinder proper drainage. This often necessitates the replacement of specific tools designed to address blockages. Additionally, wear and tear on seals can lead to leaks, prompting users to seek out new sealing materials. Regular maintenance and timely replacement of worn components can significantly extend the lifespan of these machines.

Furthermore, power loss or malfunctioning motors may require users to obtain new drive belts or motors altogether. Staying informed about these typical concerns and the relevant replacement options is essential for ensuring the device operates effectively and reliably.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any equipment. Regular maintenance not only ensures optimal performance but also helps in preventing costly repairs and replacements. Adopting simple practices can significantly enhance the reliability and efficiency of your machinery.

Regular Cleaning

Consistent cleaning is crucial to eliminate dust, debris, and other contaminants that may affect functionality. Ensure that all components are free from buildup to maintain optimal operation. Using appropriate cleaning agents and tools will prevent damage while ensuring thoroughness.

Scheduled Inspections

Conducting routine inspections allows for early detection of wear and tear. Regularly check for any signs of malfunction or deterioration, addressing issues promptly to avoid further complications. Keeping a maintenance log can also help in tracking the health of your equipment over time.

Where to Purchase Replacement Parts

Finding quality components for your equipment can enhance its performance and longevity. Various options are available for sourcing these necessary elements, ensuring you can maintain your device effectively.

One of the best places to look is at authorized dealers, which often provide original items and reliable customer support. Additionally, online retailers offer a wide selection and competitive pricing, making it convenient to compare options from the comfort of your home.

Local hardware stores may also stock compatible items, allowing you to inspect them in person before making a purchase. Consider checking specialty shops that focus on tools and machinery, as they can offer expert advice and tailored solutions.

Online Marketplaces: Websites like eBay or Amazon can be excellent resources for both new and used components. Be sure to read reviews and verify seller ratings to ensure a positive experience.

Manufacturer Websites: Often, visiting the official site can direct you to a reliable source for genuine items, including additional information about compatibility and installation.

By exploring these various avenues, you can ensure that you acquire the right replacements to keep your equipment running smoothly.

Step-by-Step Assembly Instructions

Assembling the device requires careful attention to detail and following the instructions methodically. Each component plays a vital role in the overall functionality, and proper assembly ensures optimal performance.

1. Prepare the Workspace: Begin by clearing a flat, spacious area. Gather all necessary tools and parts to streamline the process.

2. Identify Components: Familiarize yourself with each piece and its purpose. Lay them out systematically to facilitate easy access during assembly.

3. Begin Assembly: Start by connecting the main body with the base. Ensure that all fittings are secure and aligned correctly to avoid any instability.

4. Attach Additional Parts: Gradually add the secondary components, following the provided guide. Pay special attention to the orientation of each piece for proper function.

5. Tighten Connections: Once all parts are in place, review each connection. Use the appropriate tools to tighten any loose fittings, ensuring everything is firmly secured.

6. Final Inspection: Conduct a thorough check to confirm that all components are correctly assembled. Look for any misalignments or loose parts before using the equipment.

Following these instructions will help achieve a successful assembly, leading to efficient operation and longevity of the device.

Frequently Asked Questions about Parts

This section aims to address common inquiries related to components of the equipment. Understanding these elements can enhance the user experience and improve maintenance efforts.

Here are some frequently asked questions:

- What should I consider when selecting components?

When choosing elements, evaluate compatibility with your model and consider quality to ensure optimal performance.

- How can I identify specific elements?

Refer to the user manual or seek assistance from customer support for accurate identification based on your device’s specifications.

- Where can I purchase replacement items?

Replacement items are typically available through authorized dealers, online marketplaces, and dedicated parts suppliers.

- What is the warranty on components?

Warranties vary by manufacturer, so check the purchase details or consult with the seller for specific terms and conditions.

- How can I maintain the longevity of my components?

Regular maintenance, such as cleaning and timely replacements, can significantly extend the life of your elements.

If you have additional inquiries not covered here, feel free to reach out to customer support for more tailored assistance.

Using the Diagram for Troubleshooting

Understanding a visual representation of components can greatly assist in identifying issues and resolving them effectively. By analyzing the layout and relationships between different elements, users can pinpoint malfunctions and ensure a thorough assessment of the equipment. This approach not only simplifies the diagnostic process but also enhances the overall maintenance strategy.

Identifying Common Issues

Familiarity with the visual schematic allows users to recognize frequent problems quickly. For instance, one might notice discrepancies in the flow of materials or unusual sounds originating from specific parts. Such insights lead to faster resolutions, reducing downtime and improving efficiency.

Ensuring Proper Assembly

Using the representation also helps confirm that all components are assembled correctly. Misalignments or misplaced elements can lead to operational failures. Regular reference to the visual guide ensures that everything is in its designated position, promoting optimal functionality.

Expert Recommendations on Upgrades

Improving your equipment’s functionality can significantly enhance its performance and longevity. By considering various enhancements, users can optimize their experience and achieve better results. Here are some expert suggestions to help you make informed choices for upgrades.

Key Upgrades to Consider

- Enhanced Accessories: Investing in high-quality attachments can expand your device’s capabilities and improve efficiency.

- Power Supply Options: Upgrading to a more robust power source can ensure consistent performance, especially during demanding tasks.

- Maintenance Tools: Incorporating specialized tools for regular upkeep can prolong the life of your equipment and prevent unnecessary breakdowns.

Performance Boosters

- Quality Materials: Opt for durable components that withstand wear and tear, enhancing overall reliability.

- Improved Controls: Consider ergonomic upgrades that provide better handling and ease of use.

- Regular Updates: Stay informed about the latest advancements and software updates that can optimize functionality.

By following these recommendations, users can effectively elevate their equipment’s performance, ensuring it meets their evolving needs.

Comparing with Other Models

When evaluating this drain cleaning solution against other models, several key distinctions become clear. The primary differences often lie in the equipment’s overall power, maneuverability, and ease of use. Some competitors may offer more lightweight designs, which can be beneficial for smaller, quick jobs, while others focus on providing more advanced features that target tougher blockages.

Durability plays a crucial role in choosing the right machine, with some models boasting longer lifespans due to enhanced materials. On the other hand, portability can also vary, with certain machines offering more compact designs that favor frequent transportation or confined workspaces. It’s essential to consider the type of projects each machine is designed for, as not all options deliver the same performance across different tasks.