Understanding the structure of complex tools can significantly enhance their performance and maintenance. When each element is properly identified and its function clearly recognized, it becomes easier to ensure that everything works in harmony, especially for tools designed to offer precise cuts and smooth operations.

In this guide, we will delve into the detailed arrangement of various internal and external components, highlighting the purpose of each part. From the main framework to smaller elements involved in fine adjustments, every piece plays a vital role in achieving reliable results over time.

Additionally, knowing how these elements connect with one another ensures that replacements and repairs can be handled efficiently. This knowledge minimizes downtime and helps maintain peak performance, making the entire system more durable and effective.

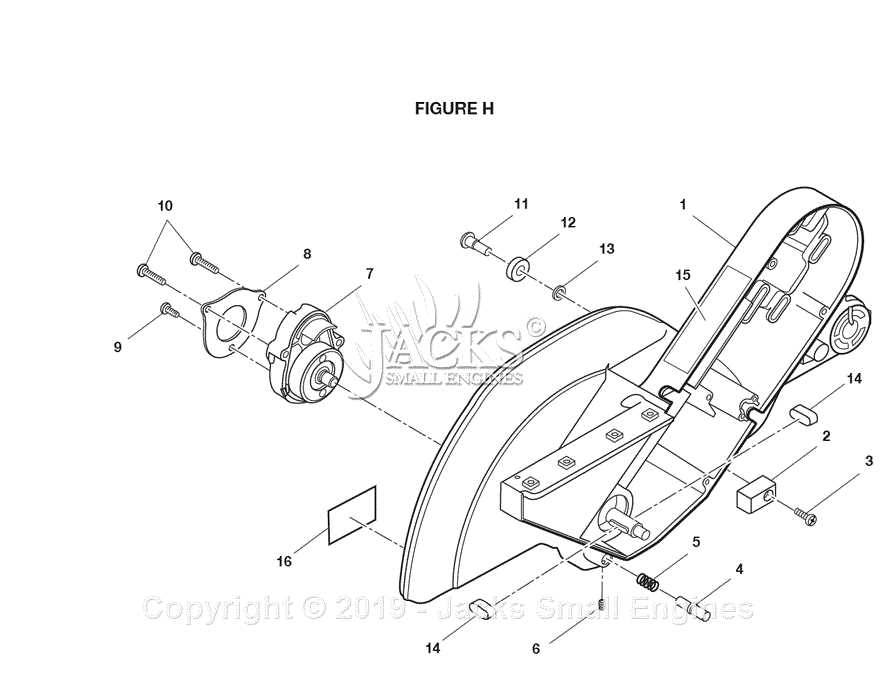

Overview of the R4222 Tool Structure

This section introduces the design layout of a versatile cutting tool, focusing on the arrangement of its essential elements. The goal is to understand how different components are organized to enhance operational precision and efficiency.

The tool’s foundation integrates a stable base that supports both the cutting surface and the guiding mechanisms. Key assemblies include adjustable arms, control levers, and a rotating platform that enables smooth angle adjustments for a variety of applications.

Additionally, protective elements and safety switches are strategically placed to ensure secure operation. The tool’s ergonomic handles and locking features provide users with better control, contributing to both accuracy and comfort during extended tasks.

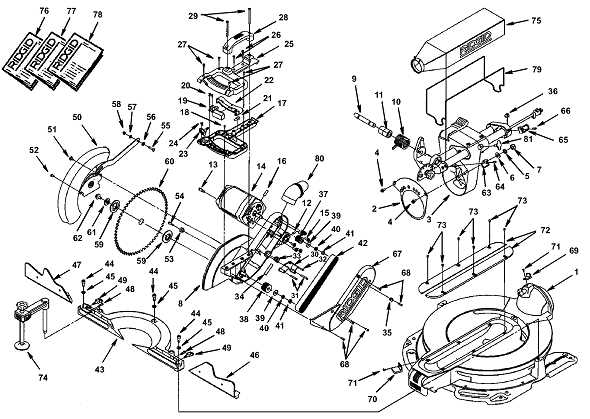

Key Components for Precision Cutting

Achieving smooth and accurate cuts requires the right combination of specialized elements. These components work together to ensure stability, control, and precise material handling during the cutting process.

- Blade Assembly: The primary cutting edge, designed for different materials and offering varying tooth configurations for fine or aggressive cuts.

- Guide Rails: Provide alignment support, ensuring the cutting angle remains consistent throughout the operation.

- Adjustable Fence: A movable barrier that holds the material steady and allows for repeatable cuts at specific angles.

- Bevel Adjustment Mechanism: Enables angled cuts by tilting the cutting head to the desired degree.

- Clamping System: Secures the material firmly, minimizing movement and improving safety during operation.

These components, when properly maintained and aligned, play a vital role in delivering consistent and precise results, regardless of the material being processed.

Blade Alignment and Adjustment Mechanism

Achieving precise cuts requires careful calibration of the rotating edge and its guiding components. Ensuring the proper alignment minimizes uneven edges and enhances accuracy, helping to maintain the quality of every cut. Adjusting the mechanism correctly also extends the lifespan of both the blade and the supporting framework by reducing unnecessary wear.

Key Components in the Alignment Process

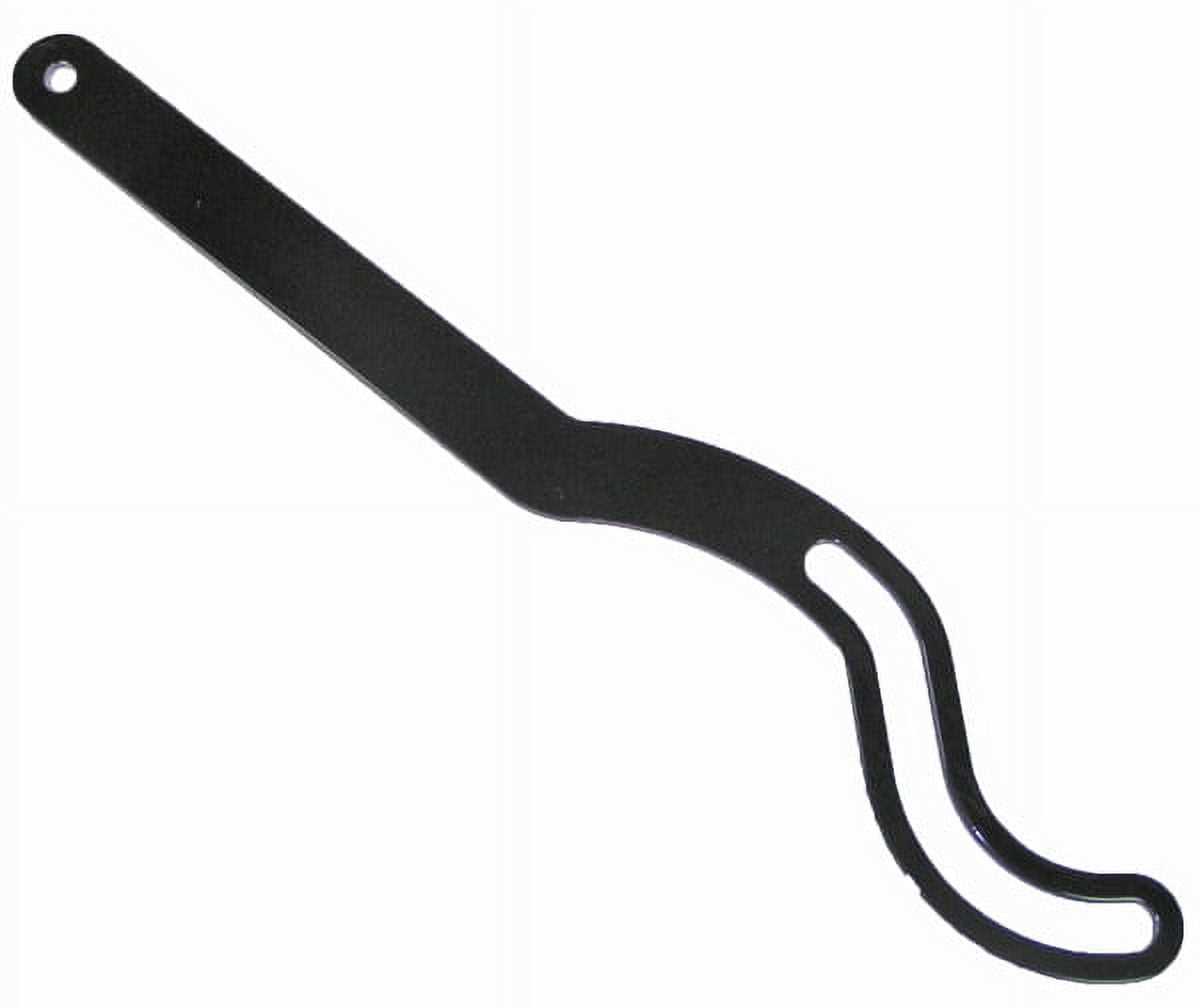

Several crucial elements contribute to keeping the cutting tool in optimal position. Mounting brackets secure the blade housing, preventing shifts during operation. Tension knobs or locking levers play a vital role in maintaining consistent pressure, while adjustable arms provide fine-tuning for angular accuracy.

Steps for Smooth Adjustment

The alignment process typically begins with releasing any locking mechanism to free the blade’s position. After loosening, small calibration screws are turned incrementally to adjust both tilt and lateral movement. Once aligned, locking

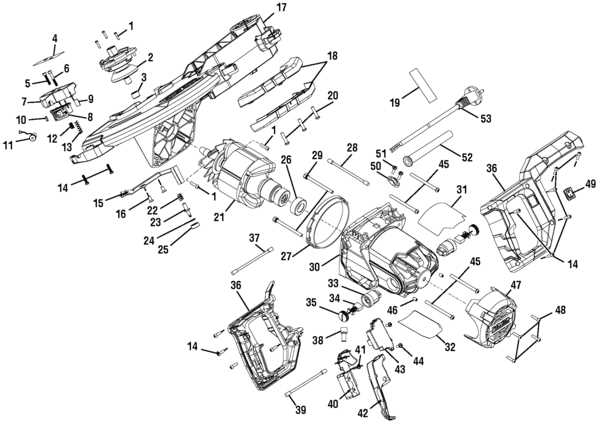

Motor and Drive Assembly Explained

The power unit and its transmission mechanism play a crucial role in converting electrical energy into controlled motion. This section explores how the primary source of motion interacts with other mechanical components to ensure smooth operation, maintaining precision and stability.

The motor unit functions as the core source of energy, generating rotational force that powers the connected elements. It operates through an electromagnetic process, ensuring consistent performance even under variable loads.

The drive system transmits the generated motion efficiently through a combination of shafts, gears, and couplings. These components synchronize to control speed and torque, providing balanced output across different operational modes. Proper alignment and maintenance of the assembly are essential to minimize wear and ensure long-term reliability.

Understanding this interaction between power generation and transmission is key to optimizing efficiency, preventing mechanical failure, and extending the lifespan of the equipment.

Handle and Trigger Design Overview

The structure of the operating grip plays a crucial role in user interaction, ensuring both comfort and control during prolonged use. The mechanism that initiates movement must be intuitive and responsive, contributing to both efficiency and safety. This section provides insights into the arrangement and function of key elements involved in this system.

Ergonomics and Comfort

The grip is contoured to fit naturally in the hand, minimizing fatigue and enhancing precision. The material used offers an anti-slip surface, ensuring secure handling even in challenging conditions. Proper weight distribution further optimizes the ease of maneuverability, especially during extended tasks.

Trigger Functionality and Safety

The trigger mechanism is designed with responsiveness in mind, providing smooth operation with minimal effort. It features an integrated safety switch to prevent unintentional activation, requiring deliberate engagement for operation. This dual-action design emphasizes both user control and operational safety.

| Component | Function | |

|---|---|---|

| Grip Cover | Provides comfort and secure handling |

| Component | Description | Benefits |

|---|---|---|

| High-Quality Blade | Premium cutting edge designed for durability and precision. | Enhances cutting accuracy and reduces wear on the tool. |

| Blade Guard | Protective cover that shields the blade when not in use. | Increases safety and prevents accidents during operation. |

| Laser Guide | Attachment that projects a line for precise cutting alignment. | Improves accuracy and helps in achieving clean cuts. |

Upgrades for Enhanced Performance

In addition to replacements, certain upgrades can enhance the overall functionality of your cutting tool. Consider the following enhancements:

| Upgrade | Description | Advantages |

|---|---|---|

| Dust Collection System | System that captures debris during operation. | Maintains a cleaner workspace and improves visibility. |

| Extended Base | Wider support for increased stability and precision. | Facilitates handling larger materials with ease. |

| Power Upgrade Kit | Components that increase motor efficiency and power. | Enhances cutting capability for tougher materials. |

Tips for Long-Term Tool Maintenance

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. Regular attention to maintenance tasks can prevent wear and tear, improve functionality, and save you money on replacements. This section outlines effective strategies to keep your tools in excellent condition over time.

Regular Cleaning and Inspection

Frequent cleaning is crucial for removing dust, debris, and residue that can hinder performance. After each use, wipe down surfaces and check for any signs of damage or wear. Addressing minor issues promptly can prevent more significant problems down the line.

Lubrication and Storage

Applying the right lubricants to moving parts can enhance efficiency and reduce friction. Store tools in a dry, cool environment to protect them from moisture and temperature fluctuations, which can cause rust and other forms of deterioration.