| Connector |

Blade Types and Their Uses

Blades come in various designs, each crafted for specific tasks in food preparation. They serve different functions based on their shape, sharpness, and material, offering versatility for different culinary needs. Understanding the purpose of each type can greatly enhance efficiency and consistency in results.

Slicing blades are designed for cutting through soft or firm ingredients, making them ideal for achieving even slices of vegetables or fruits. Their sharp edge ensures smooth cuts without crushing the food.

Shredding blades are perfect for reducing ingredients into fine strips. Whether it’s cheese, cabbage, or other firm produce, these blades quickly break down foods into thin shreds.

Chopping blades are suited for coarse or fine chopping of various ingredients, from herbs to nuts. Their structure enables quick, efficient dicing or mincing with minimal effort.

Each blade type serves a unique role in food preparation, helping achieve precision and saving time during the cooking process.

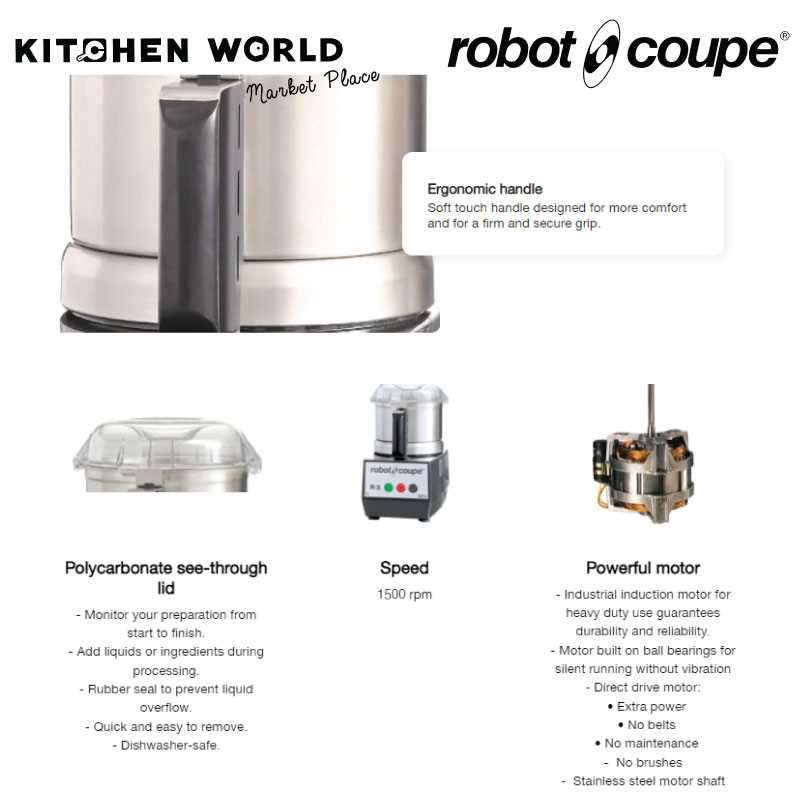

Exploring the Control Panel Layout

The control panel layout is designed for easy navigation and efficient operation. It offers a clear structure, allowing users to quickly access essential functions and adjust settings as needed. The layout is intuitive, minimizing the learning curve and ensuring smooth operation in various tasks.

Central Controls are placed in the middle, ensuring quick access to the most frequently used functions. The toggle switches and buttons are grouped logically, reducing the time spent searching for specific controls.

On the sides, additional options such as speed adjustments and other fine-tuning elements allow for more precise control, making the overall experience seamless and user-friendly.

Maintenance of the Drive Shaft

Proper care of the transmission component is essential for optimal performance and longevity. Regular maintenance not only ensures smooth operation but also helps prevent potential issues that may arise from wear and tear. This section provides insights into effective practices for maintaining this crucial element.

Regular Inspection

Conducting frequent checks on the transmission unit is vital. Look for signs of damage or wear, such as cracks, corrosion, or unusual noises during operation. Early detection of these issues can save time and resources in the long run.

Lubrication and Cleaning

Keeping the transmission well-lubricated is crucial for reducing friction and preventing overheating. Use appropriate lubricants to maintain optimal functionality. Additionally, cleaning the component regularly helps remove debris and contaminants that could hinder performance.

Functions of the Cutter Bowl

The cutter bowl serves a vital role in food preparation processes, enhancing efficiency and precision. This essential component is designed to streamline various tasks, making it indispensable in professional kitchens and culinary environments.

Key Functions

One of the primary functions of the cutter bowl is to facilitate the chopping and blending of ingredients. Its sharp blades ensure uniformity in texture, which is crucial for achieving consistent results in recipes. Moreover, the bowl’s design allows for efficient mixing of ingredients, enabling the creation of various culinary creations.

Additional Benefits

In addition to chopping and blending, the cutter bowl also aids in emulsifying sauces and dressings. This capability allows chefs to combine oil and vinegar or other liquids seamlessly, resulting in smooth and well-integrated mixtures. Furthermore, the bowl’s structure promotes easy cleaning and maintenance, making it user-friendly for everyday kitchen use.

Importance of the Sealing Ring

The sealing ring plays a crucial role in ensuring the efficiency and longevity of various mechanical devices. Its primary function is to create a tight barrier that prevents the escape of fluids or gases, thereby maintaining optimal performance during operation. This component is essential for the overall functionality and reliability of equipment.

Preventing Leaks

One of the key benefits of the sealing ring is its ability to prevent leaks. By forming a secure connection between different parts, it safeguards against the unintended release of liquids or gases. This not only enhances the performance of the machinery but also contributes to safety by minimizing the risk of hazardous spills.

Enhancing Durability

Moreover, the sealing ring contributes to the durability of the equipment. By reducing friction and wear between moving parts, it helps maintain the integrity of the device over time. This results in lower maintenance costs and prolonged service life, making it an invaluable component in various applications.

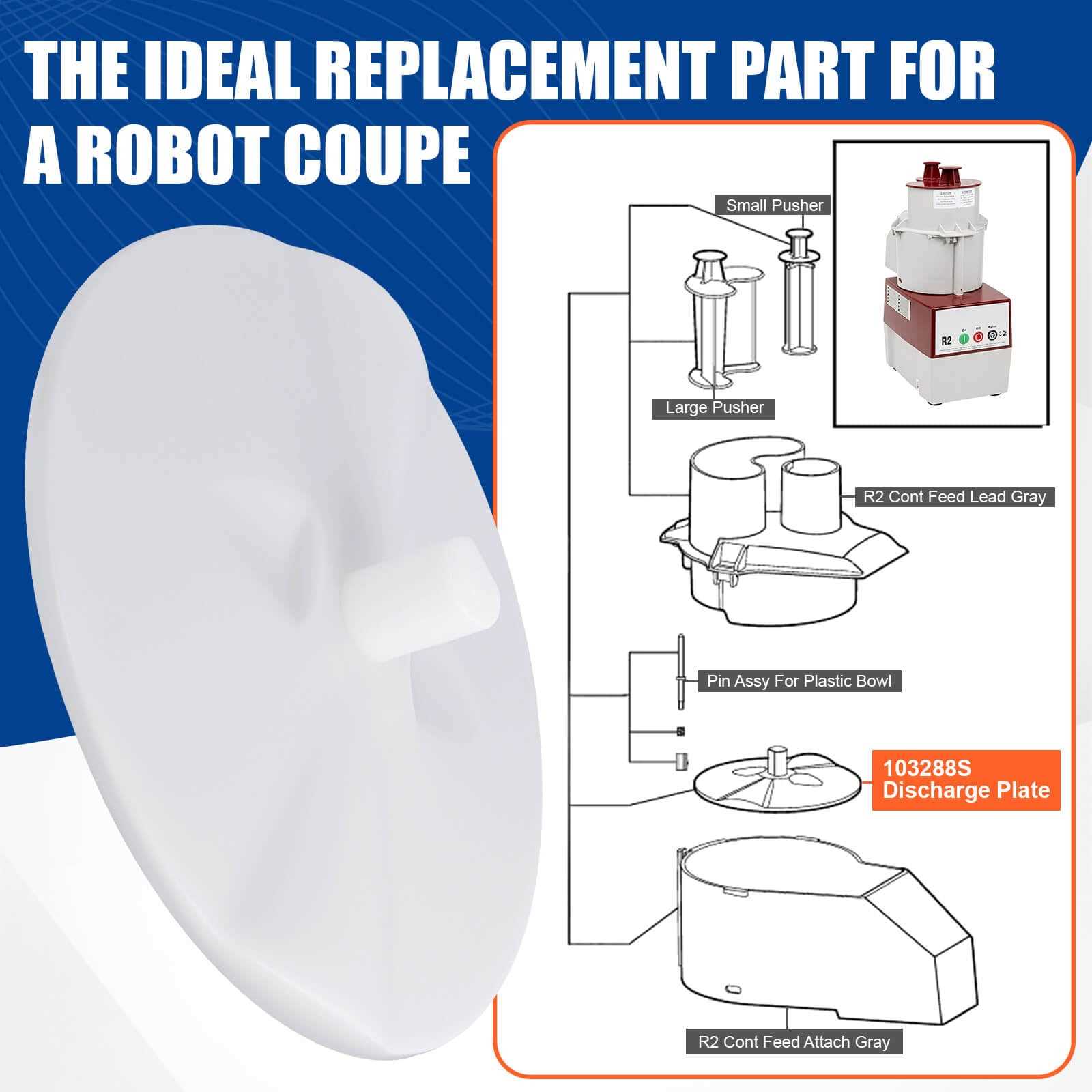

Choosing the Right Discs

Selecting appropriate slicing tools is essential for achieving desired culinary results. These tools come in various designs, each suited for specific tasks, allowing users to process ingredients efficiently. Understanding the options available will enable better decisions when preparing meals.

Understanding Different Types

Different varieties of cutting tools serve distinct purposes. For instance, some are designed for fine chopping, while others excel in thicker cuts. Familiarizing oneself with these options can significantly enhance the cooking experience and improve food presentation.

Material Considerations

The materials used in constructing these tools also play a crucial role in performance. Durable options ensure longevity and consistent results. It’s important to consider the intended use and frequency of use when selecting the right material to meet specific needs.

Cleaning the Food Pusher Safely

Maintaining the hygiene of kitchen equipment is essential for optimal performance and food safety. One crucial component in food preparation is the mechanism that helps guide ingredients into the processing chamber. Ensuring that this tool is cleaned properly prevents contamination and promotes longevity.

Before starting the cleaning process, it’s vital to unplug the appliance to avoid any accidental activation. Use a soft cloth or sponge with warm, soapy water to gently wipe down the surface of the food pusher. Avoid using abrasive cleaners or scrubbers, as these may damage the finish. Rinse thoroughly with clean water to remove any soap residue, ensuring no harmful substances remain.

For areas with stubborn residues, a mild vinegar solution can be effective. Soak a cloth in the solution and let it sit on the affected area for a few minutes before wiping it clean. Once the cleaning is complete, allow the food pusher to air dry completely before reassembling or using it again.

By following these simple steps, you can ensure that your food processing tool remains clean and safe for your culinary tasks.

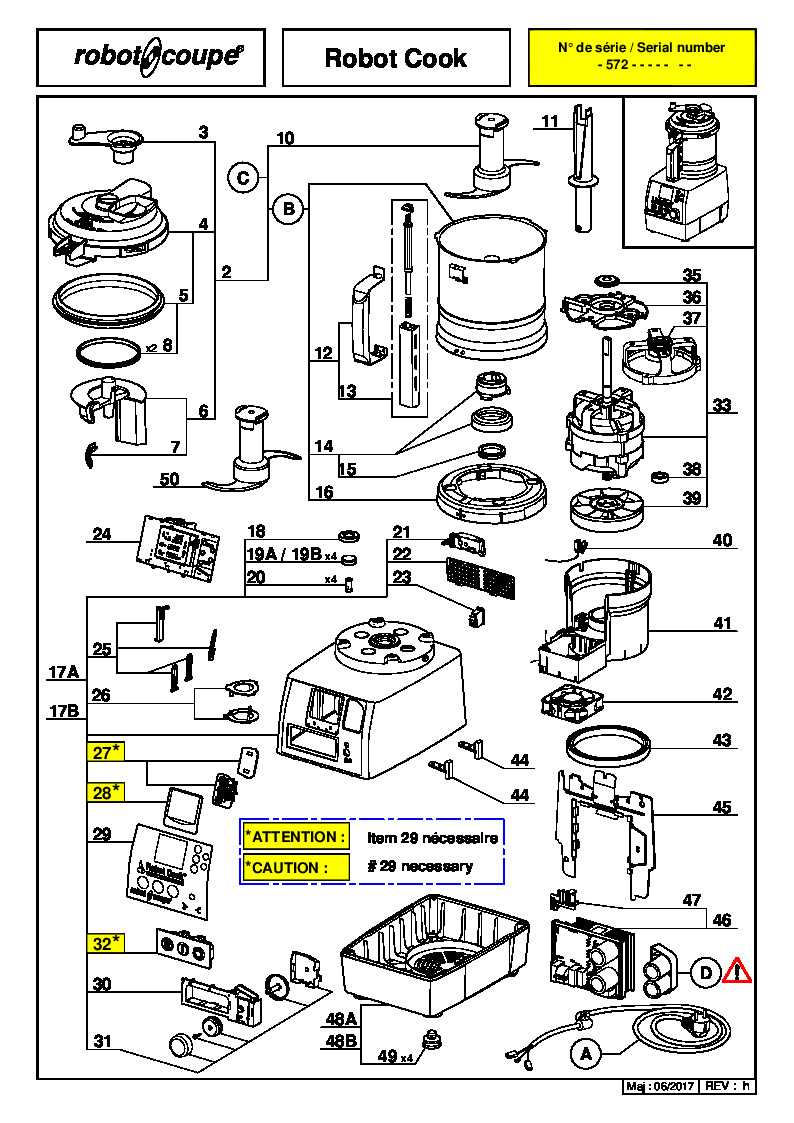

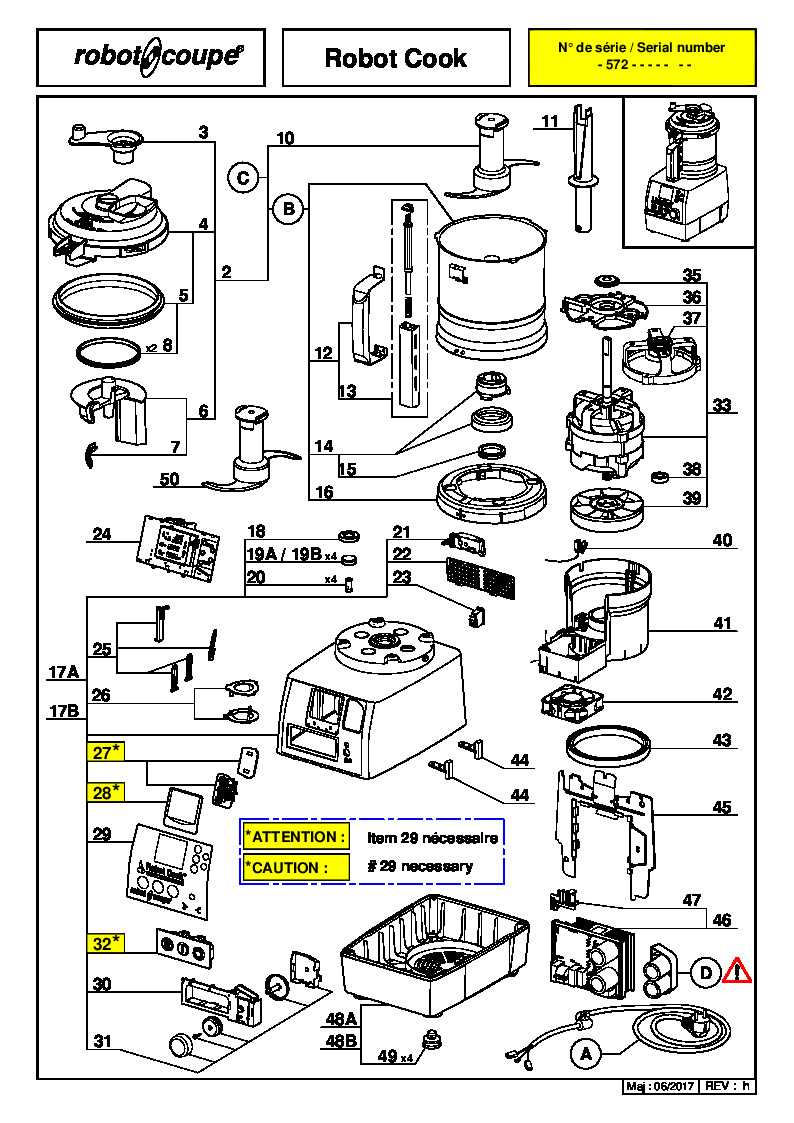

How to Replace Worn Parts

Over time, certain components of your appliance may experience wear and tear, affecting its overall performance. Recognizing when to replace these elements is crucial for maintaining efficiency and prolonging the lifespan of your device. This section provides a step-by-step guide to help you through the replacement process.

Identifying Worn Components

Begin by thoroughly inspecting the unit for any signs of damage or wear. Look for cracks, excessive fraying, or any unusual noises during operation. Pay special attention to areas that experience frequent movement or friction, as these are often the first to show signs of deterioration.

Replacement Process

Once you have identified the worn components, gather the necessary tools and replacement items. Follow the manufacturer’s instructions to disassemble the unit carefully. Ensure all power sources are disconnected to prevent accidents. Replace the worn components with new ones, making sure they fit securely. Finally, reassemble the unit and test it to confirm that everything operates smoothly.

Upgrading the Electrical Components

Enhancing the electrical systems of kitchen appliances can significantly improve their efficiency and performance. This process often involves replacing outdated or malfunctioning elements with more advanced alternatives, ensuring the device operates at its best.

Here are some considerations when upgrading:

- Assess Compatibility: Ensure that new components are compatible with existing systems to avoid operational issues.

- Select Quality Parts: Opt for high-quality replacements to guarantee durability and reliability.

- Consider Energy Efficiency: Upgrading to energy-efficient components can lead to lower energy consumption and reduced operational costs.

- Consult Professionals: When in doubt, seek advice from technicians or experts to ensure proper installation and functionality.

By focusing on these aspects, one can effectively enhance the overall performance and longevity of the kitchen equipment, leading to improved outcomes in food preparation tasks.

Troubleshooting Common Issues

When operating a culinary appliance, it’s common to encounter various challenges that may hinder performance. Understanding these potential problems can help in diagnosing and resolving issues effectively. This section aims to outline typical complications and offer practical solutions.

| Issue |

Possible Cause |

Solution |

| Device not starting |

Power supply issue |

Check the power cord and outlet for connectivity. |

| Inconsistent blending |

Blade misalignment |

Ensure blades are correctly positioned and tightened. |

| Overheating |

Continuous operation |

Allow the appliance to cool down before resuming use. |

| Unusual noises |

Foreign objects inside |

Inspect the container and remove any debris. |