Exploring the intricate workings of heating mechanisms is essential for maintaining optimal performance and efficiency. Knowledge of the various elements that contribute to the overall functionality can empower users and technicians alike. By familiarizing oneself with the key components, individuals can enhance their understanding of how these systems operate and what is required for their upkeep.

In this section, we will delve into a comprehensive overview of the essential elements that make up these heating devices. A clear visual representation of these components can serve as a valuable reference, aiding in troubleshooting and repairs. Understanding the relationship between different parts enables users to identify potential issues and take proactive measures.

Moreover, grasping the layout of these systems not only facilitates efficient maintenance but also contributes to safety. With the right information at hand, both professionals and homeowners can navigate the complexities of their heating systems with confidence. This knowledge ultimately leads to improved longevity and reliability of the equipment.

Understanding Ruud Furnace Components

The intricate machinery behind residential heating systems plays a vital role in ensuring comfort during cold months. Familiarity with the various elements that contribute to the overall functionality can enhance maintenance and troubleshooting efforts. Each component is designed to perform specific tasks, and recognizing their roles can lead to more effective management and care.

Heating Unit: At the core of the system, this element generates warmth through a combustion process or electrical resistance. Its efficiency and performance directly affect the temperature regulation within the home.

Blower Assembly: This mechanism is responsible for distributing heated air throughout the living space. A well-functioning blower ensures even heat distribution, preventing cold spots and maximizing comfort.

Thermostat: Acting as the brain of the operation, this device monitors the indoor temperature and signals the heating unit to activate or deactivate, maintaining the desired comfort level. An accurate thermostat is crucial for energy efficiency.

Ventilation System: Proper airflow is essential for the effective operation of any heating solution. This network of ducts and vents allows for the exchange of air, ensuring that fresh air circulates while expelling exhaust gases safely.

Control Board: This component manages the various electrical functions, coordinating the operation of the heating unit, blower, and other elements. A malfunctioning control board can disrupt the entire system.

Understanding these key elements equips homeowners with the knowledge needed for routine maintenance and informed decision-making regarding repairs or upgrades, ultimately leading to a more efficient and reliable heating solution.

Common Parts of Ruud Furnaces

Understanding the essential components of heating systems is crucial for effective maintenance and efficient operation. Each element plays a vital role in ensuring optimal performance and reliability throughout the heating cycle.

Key Components

- Heat Exchanger

- Burner Assembly

- Blower Motor

- Control Board

- Thermostat

Functions of Each Element

- Heat Exchanger: Transfers heat to the air.

- Burner Assembly: Responsible for fuel ignition and combustion.

- Blower Motor: Circulates warm air throughout the space.

- Control Board: Manages the system’s operations and safety features.

- Thermostat: Regulates temperature settings for comfort.

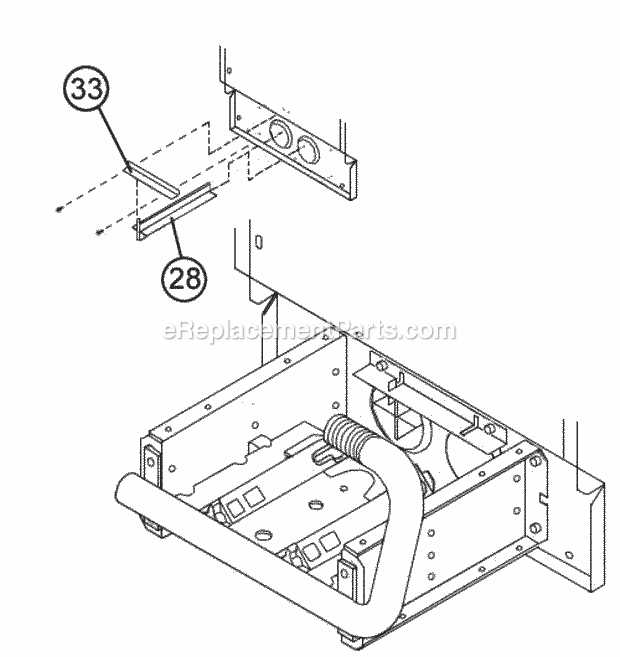

How to Read a Parts Diagram

Understanding a schematic can significantly enhance your ability to troubleshoot and maintain equipment effectively. These illustrations provide a visual representation of components and their interconnections, allowing for a clearer grasp of how everything works together.

Key Elements to Identify

When examining a schematic, focus on specific features such as labels, symbols, and numbers that correspond to components. Familiarizing yourself with these elements will make the process smoother.

Steps for Effective Interpretation

Follow these steps to improve your comprehension:

| Step | Description |

|---|---|

| 1 | Identify the main components and their symbols. |

| 2 | Trace connections to understand the flow of operation. |

| 3 | Cross-reference with a legend or key if available. |

| 4 | Take notes on any unfamiliar parts for further research. |

Maintenance Tips for Furnace Longevity

Ensuring the durability of your heating system requires regular care and attention. By following essential maintenance practices, you can enhance efficiency and extend the lifespan of your unit, providing consistent comfort in your home.

Regular Inspections

Schedule annual evaluations by a professional to detect potential issues early. These assessments can prevent major breakdowns and save on costly repairs. Don’t overlook visual checks, such as ensuring vents are unobstructed and the area around the system is clean.

Filter Replacement

Changing or cleaning filters regularly is crucial. A clogged filter restricts airflow, making your system work harder. Aim to replace or clean filters every one to three months, depending on usage, to maintain optimal performance.

Identifying Faulty Components Easily

Diagnosing issues in your heating system can be a straightforward process if you know what to look for. By understanding the common signs of malfunctioning elements, you can save time and resources, ensuring your unit operates efficiently. This section will guide you through identifying problematic components with ease.

Common Symptoms of Malfunction

Recognizing the symptoms of failing elements is the first step towards effective troubleshooting. Here are some common indicators:

- Unusual noises during operation

- Inconsistent temperature control

- Increased energy bills

- Frequent cycling on and off

- Visible damage or wear

Steps to Identify Issues

Follow these steps to pinpoint the source of trouble:

- Start with a visual inspection of accessible components.

- Listen for any irregular sounds when the system is running.

- Check for error codes or indicators on the control panel.

- Monitor performance over a period to detect inconsistencies.

- Consult user manuals for specific troubleshooting tips related to your model.

By methodically examining these aspects, you can effectively identify which components may need attention or replacement. This proactive approach not only enhances performance but also prolongs the lifespan of your heating system.

Where to Find Replacement Parts

Locating suitable components for your heating system can be a straightforward task with the right approach. Various sources offer a wide range of options, ensuring you can find exactly what you need to keep your unit running efficiently. Understanding where to look can save you time and effort in your search for the ideal solution.

Online Retailers

The internet is an invaluable resource when seeking components for your heating system. Numerous online retailers specialize in HVAC supplies, offering a comprehensive selection of items. You can easily browse through their catalogs, compare prices, and read customer reviews. Additionally, many websites provide detailed specifications, making it easier to find the right match for your unit.

Local Supply Stores

Visiting local supply stores can also be beneficial. These establishments often carry essential items and can provide personalized assistance. Staff members are typically knowledgeable and can help identify the correct components based on your needs. Furthermore, purchasing locally can reduce shipping times and costs.

Consider reaching out to professionals if you encounter difficulties in your search. HVAC technicians often have access to specialized suppliers and can guide you in sourcing the necessary items efficiently. By leveraging both online and local resources, you’ll be well-equipped to maintain your heating system effectively.

Importance of Regular Inspections

Conducting routine evaluations of heating systems is essential for maintaining their efficiency and longevity. These inspections serve as a preventive measure, identifying potential issues before they escalate into significant problems. Regular check-ups not only enhance performance but also ensure safety in the environment where the system operates.

Timely detection of wear and tear can prevent costly repairs down the line. By addressing minor faults promptly, homeowners can save on energy costs and avoid the inconvenience of system failures during critical times, such as the winter months.

Additionally, consistent evaluations contribute to optimal performance, helping systems operate at peak efficiency. This not only promotes a comfortable living space but also reduces environmental impact by minimizing energy waste.

Moreover, inspections often include cleaning and maintenance, which are crucial for the smooth operation of the unit. By ensuring that all components are in good condition, users can prolong the lifespan of their systems significantly.

Ultimately, prioritizing regular assessments fosters a proactive approach to system management, leading to a safer, more efficient, and cost-effective heating solution.

Common Issues and Solutions

In any heating system, various complications can arise, affecting efficiency and performance. Recognizing these challenges and understanding their solutions is crucial for maintaining optimal functionality. This section delves into frequent problems encountered and provides practical remedies to ensure smooth operation.

One prevalent issue is inadequate heating. This can stem from a variety of factors, such as dirty filters or blocked vents. Regular maintenance, including filter replacement and ensuring unobstructed airflow, can resolve this concern effectively.

Another common complication is unusual noises during operation, which may indicate loose components or wear and tear. Performing a thorough inspection and tightening or replacing faulty elements can eliminate these disruptive sounds.

Frequent cycling is also a problem, where the system turns on and off too often. This can result from a malfunctioning thermostat or improper sizing. Calibrating the thermostat and assessing the unit’s size relative to the space it heats can help stabilize its performance.

Lastly, unexpected shutdowns can occur, often linked to electrical issues or safety mechanisms activating. Checking electrical connections and understanding the safety features can prevent these interruptions and enhance reliability.

Upgrading Your Furnace Parts

Enhancing the efficiency and performance of your heating system can significantly improve your indoor comfort. By replacing outdated components with newer, more efficient versions, you can not only reduce energy consumption but also extend the lifespan of your unit. This section will explore the benefits and options available for updating essential elements of your heating system.

Modern advancements in technology have led to the development of high-performance alternatives that can elevate the operation of your system. Investing in quality components not only boosts efficiency but can also lead to lower utility bills over time.

| Component | Benefits of Upgrading | Considerations |

|---|---|---|

| Thermostat | Improved temperature control, programmable features | Compatibility with existing system |

| Blower Motor | Increased airflow, quieter operation | Energy efficiency ratings |

| Heat Exchanger | Enhanced heat transfer, reduced risk of leaks | Installation complexity |

| Filter | Better air quality, improved airflow | Regular maintenance required |

By carefully selecting components for enhancement, homeowners can achieve optimal performance and efficiency, making a significant impact on both comfort and energy savings.

Safety Precautions During Repairs

When undertaking maintenance tasks on heating appliances, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions ensure that the work environment remains secure and that individuals are protected from potential hazards associated with repair activities.

- Always disconnect the power supply before beginning any maintenance work.

- Utilize personal protective equipment, such as gloves and safety goggles, to safeguard against injury.

- Ensure proper ventilation in the workspace to avoid inhalation of harmful fumes.

- Keep a fire extinguisher accessible in case of emergencies.

Before starting, familiarize yourself with the manufacturer’s guidelines and recommendations. This knowledge helps in understanding the specific requirements and safety measures necessary for effective repairs.

- Inspect tools and equipment for any defects or damage before use.

- Work in pairs when possible to provide assistance in case of an accident.

- Stay alert and focused, avoiding distractions that could lead to mistakes.

By following these safety measures, individuals can significantly reduce the risk of accidents and ensure a smooth and efficient repair process.

Consulting Professionals for Assistance

When faced with complex issues regarding your heating system, seeking expert advice can be invaluable. Professionals possess the knowledge and experience to identify problems efficiently and provide tailored solutions, ensuring optimal performance and longevity of your equipment.

The Benefits of Professional Insight

Engaging with specialists not only streamlines the troubleshooting process but also guarantees that repairs and maintenance are conducted safely. Investing in professional support can ultimately save you time and resources, while enhancing the overall efficiency of your system.

When to Reach Out

Consider contacting a qualified technician if you notice unusual noises, inconsistent heating, or a sudden spike in energy bills. These signs may indicate underlying issues that require expert intervention to prevent further complications.