In the realm of plumbing equipment upkeep, understanding the inner workings of plumbing systems is essential. When it comes to ensuring the smooth operation of your plumbing setup, familiarity with the intricate components that facilitate its functionality proves invaluable.

When it’s time for maintenance or repair tasks, having a grasp of the integral parts that comprise your plumbing mechanism becomes crucial. This knowledge empowers you to navigate the labyrinth of plumbing systems with confidence and efficiency.

Exploring the anatomy of plumbing setups involves delving into the various elements that harmoniously work together to maintain optimal performance. From connectors to mechanisms that manage fluid flow, each component plays a pivotal role in the operational integrity of your plumbing configuration.

Understanding Saniflo Systems

In the realm of domestic wastewater management, Saniflo systems play a pivotal role in ensuring efficient disposal and processing. These innovative solutions integrate seamlessly into various plumbing setups, offering robust functionality beyond traditional sewage systems.

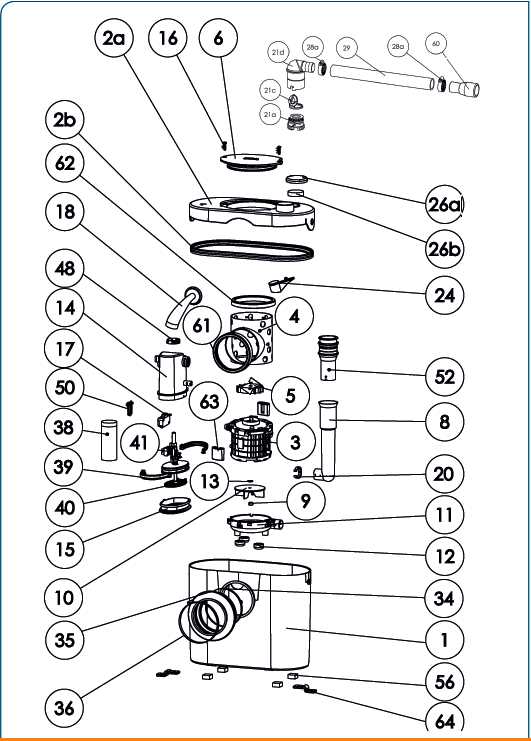

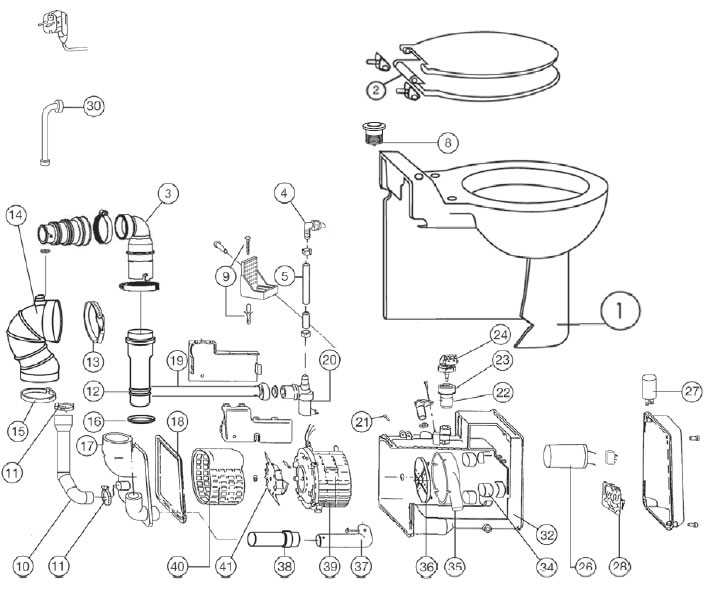

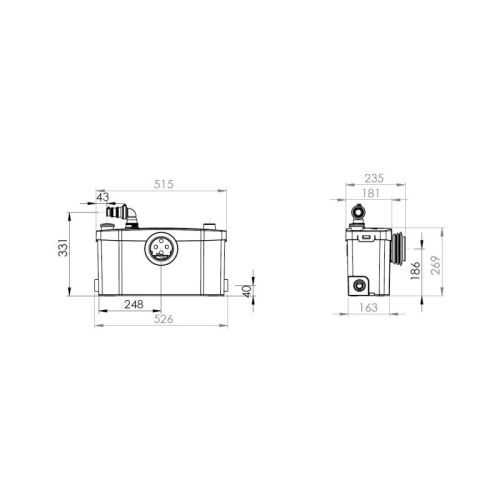

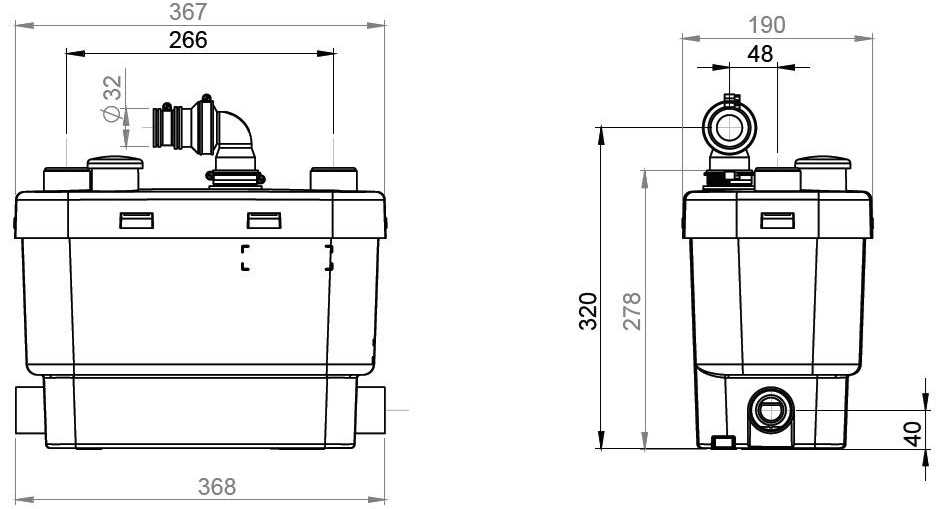

The Anatomy of Saniflo Systems

At the core of Saniflo systems lies a sophisticated assembly of components designed to handle wastewater from toilets, sinks, and other sanitary fixtures. These setups typically include pumps, macerators, and intricate piping configurations that facilitate the safe and hygienic transfer of waste.

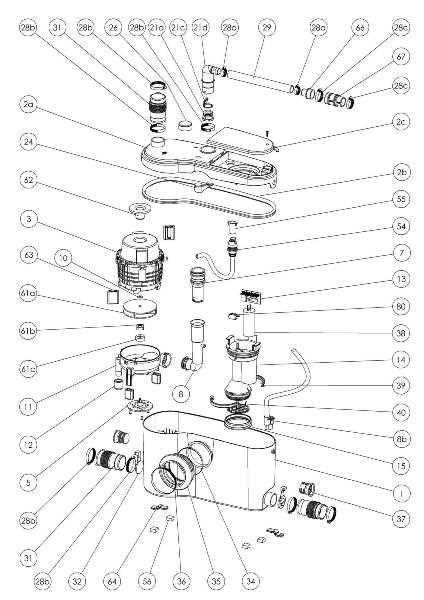

Key Components and Their Functions

Essential elements such as the macerator blades effectively break down solid waste into manageable particles, ensuring smooth passage through the plumbing network. Meanwhile, pumps provide the necessary pressure to propel wastewater vertically or horizontally to the main sewer line or septic tank.

Understanding these fundamental aspects is crucial for maintaining and troubleshooting Saniflo systems, ensuring optimal performance and longevity.

Stay tuned for more detailed insights into each component’s role in the comprehensive functionality of Saniflo systems.

Components of Saniflo Units

In examining the inner workings of Saniflo systems, one encounters a complex assembly of interconnected elements, each playing a crucial role in its function. These units integrate various components that facilitate efficient wastewater management and disposal.

Primary Mechanisms

At the core of these units are the primary mechanisms responsible for initiating and maintaining the wastewater disposal process. These components are designed to handle diverse types of waste materials effectively.

Within these units, there exist specialized parts that work together to ensure seamless operation, from initial waste reception to final discharge. Each component contributes uniquely to the overall reliability and performance of the system, ensuring consistent functionality over time.

Importance of Spare Parts

The availability of replacement components plays a crucial role in maintaining the longevity and efficiency of various mechanical systems. Ensuring that every element functions properly helps prevent unnecessary breakdowns and extends the overall lifespan of the equipment.

High-quality replacements can restore original performance, making sure that maintenance is efficient and cost-effective. Choosing compatible components also helps avoid long-term issues and improves the reliability of the system.

Whether it’s regular upkeep or addressing unexpected malfunctions, having the right resources ensures that downtime is minimized and performance remains optimal.

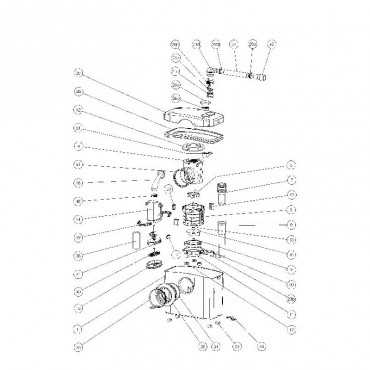

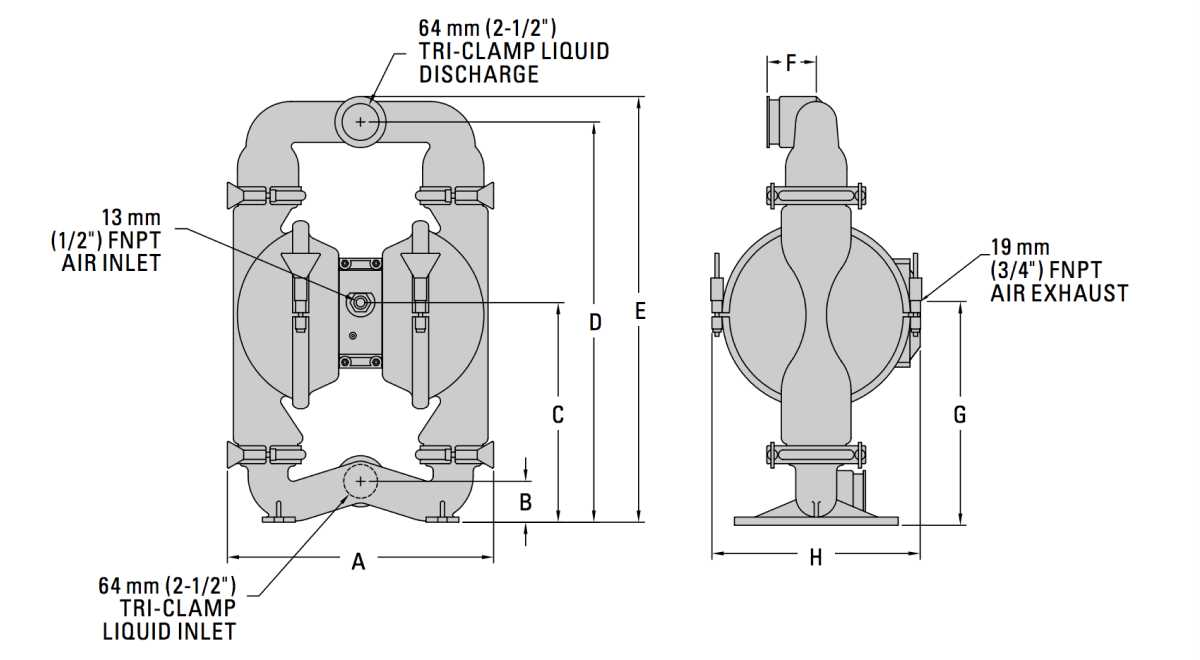

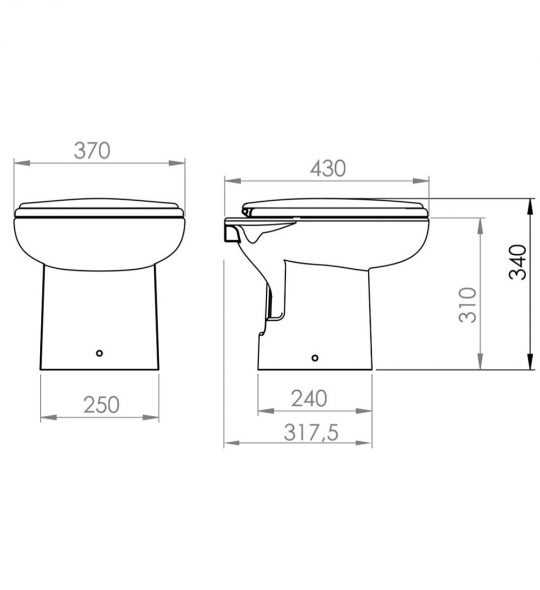

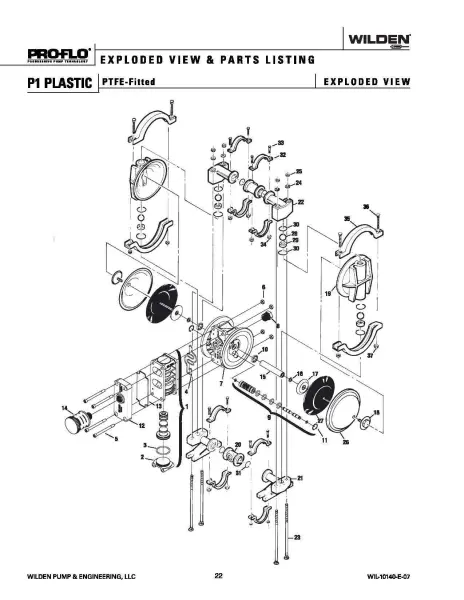

How to Read Diagrams

Understanding technical illustrations can greatly simplify the process of assembling or repairing various devices. Diagrams offer a visual representation that clarifies the relationships between different components and how they interact within a system.

Identifying Key Components

Each element in a technical drawing is represented by symbols, labels, or numbers that make it easier to locate and understand their function. Paying attention to these indicators helps you follow the structure step by step, ensuring accurate interpretation.

Following the Flow

In many diagrams, components are organized in a logical sequence, which can guide you through the process of understanding how the system operates. Follow the flow of connections between elements to get a clearer picture of their role in the overall design.

Commonly Replaced Parts

Over time, certain elements of plumbing systems can wear out and require attention. These components are often subject to stress, frequent usage, and external conditions, which makes them prone to needing regular replacement. Addressing these issues promptly can prevent larger problems and ensure that the system operates smoothly.

Some of the most frequent replacements include seals, valves, and connectors. These small yet crucial elements help maintain the integrity of the system and prevent leaks or malfunction. Keeping them in good condition is essential for the long-term functionality of the equipment.

Regular checks and timely interventions can extend the lifespan of these key elements, reducing the likelihood of more costly repairs. Paying attention to these components will keep the system in optimal working order.

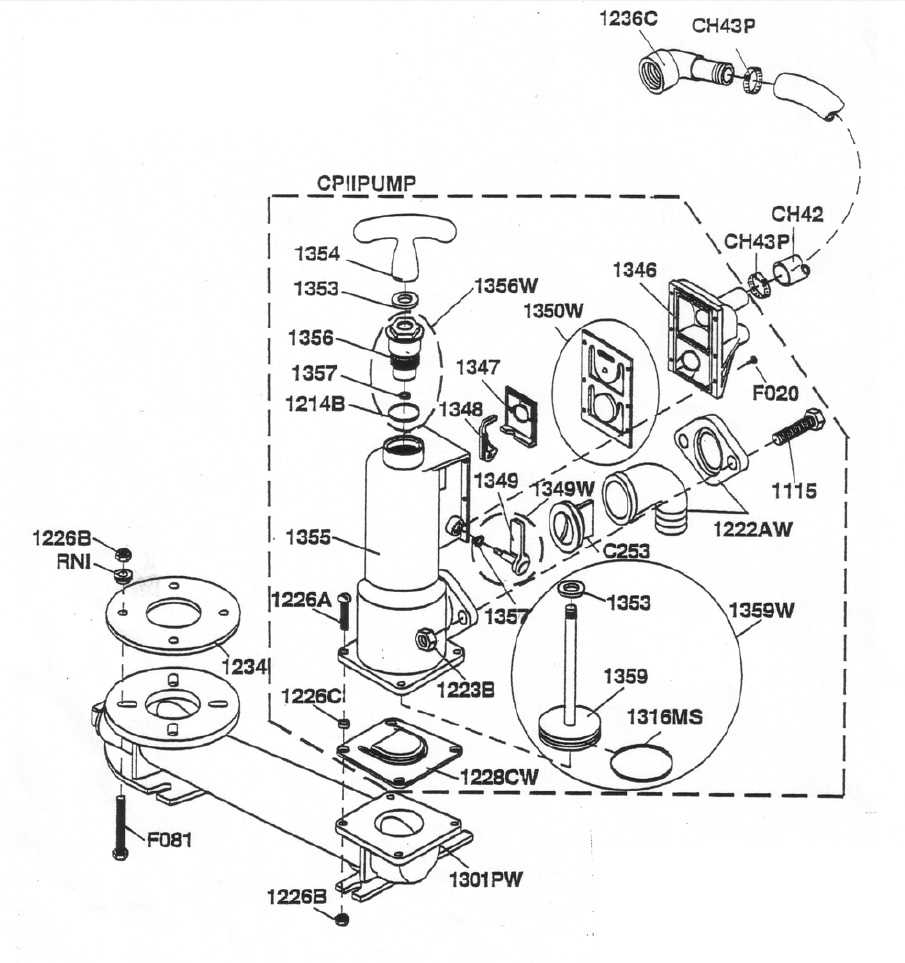

Identifying Part Numbers

Understanding how to recognize specific numbers assigned to individual components is essential for efficient maintenance and ordering replacements. Each element within a system is typically assigned a unique identifier, which simplifies the process of locating the exact match during repairs.

Where to Find Numbers

These identifiers are often located on the component itself, or within the product manual. They might also be listed on packaging or official documentation. It’s important to check multiple locations to ensure accuracy when searching for specific components.

Using Reference Lists

Many manufacturers provide detailed reference lists that group similar components together. These lists are organized to allow quick cross-referencing, ensuring that users can match numbers with the correct component efficiently.

- Locate the number on the component or packaging.

- Cross-check with a reference list for accuracy.

- Consult official documentation for detailed information.

Tools Needed for Repairs

When it comes to maintaining or fixing your system, having the right equipment is essential for a successful job. The appropriate selection of tools will not only make the repair process smoother but also help avoid further complications. Below is a detailed list of instruments commonly required for mechanical adjustments and maintenance.

| Tool | Purpose |

|---|---|

| Adjustable Wrench | Used for loosening and tightening bolts and fittings of various sizes. |

| Screwdriver Set | Essential for removing and fastening screws of different types and sizes. |

| Pipe Cutter | Helps in cutting through pipes cleanly and efficiently. |

| Plumber’s Tape | Seals connections to prevent leaks at threaded joints. |

| Plunger | Useful for clearing blockages in drains. |