In the realm of marine navigation, a comprehensive grasp of steering mechanisms is crucial for both safety and performance. These systems, designed for precision and reliability, consist of various essential elements that work in unison to ensure smooth operation. By examining the individual components, one can appreciate the intricate design that underpins effective maneuverability on the water.

Each element plays a vital role in the overall functionality, contributing to the seamless interaction between the vessel and its operator. Familiarity with these components not only enhances one’s understanding but also aids in maintenance and troubleshooting. A well-structured overview of the system allows for a deeper insight into how these parts integrate and function together.

Exploring the layout of these critical pieces offers a roadmap for enthusiasts and professionals alike. This knowledge empowers users to make informed decisions regarding repairs and upgrades, ultimately leading to improved performance. By delving into the specifics, one can uncover the nuances that define the effectiveness of steering apparatuses in maritime environments.

Understanding Seastar Parts Diagram

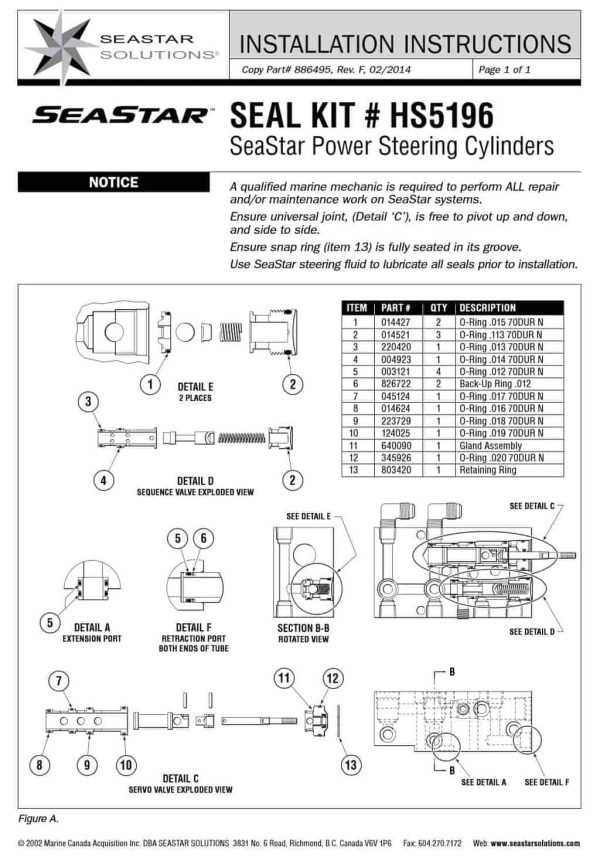

This section aims to provide clarity on the components involved in hydraulic steering systems commonly used in marine applications. By breaking down these elements, one can gain insight into their functions and interactions, facilitating better maintenance and troubleshooting practices.

Key Components

The system consists of various integral elements that work together to ensure smooth operation. Each component plays a distinct role, contributing to the overall functionality.

| Component | Function |

|---|---|

| Helm | Controls the direction of the vessel. |

| Cylinder | Converts hydraulic pressure into mechanical motion. |

| Hoses | Transport hydraulic fluid between components. |

| Fluid Reservoir | Stores hydraulic fluid for the system. |

Understanding Interactions

Recognizing how these components interact enhances one’s ability to diagnose issues effectively. A thorough comprehension of this system is essential for optimal performance and longevity.

Overview of Seastar Steering Systems

This section provides a comprehensive look into marine steering solutions, highlighting their significance in ensuring safe and precise navigation. Understanding these systems is essential for both performance enhancement and maintenance of watercraft.

Key Components

- Helm: The control interface for the operator.

- Hydraulic Cylinder: Transmits force to the steering mechanism.

- Connections: Hoses and fittings that facilitate fluid movement.

Advantages of Hydraulic Steering

- Smooth operation with minimal effort.

- Enhanced responsiveness for better handling.

- Durability under various marine conditions.

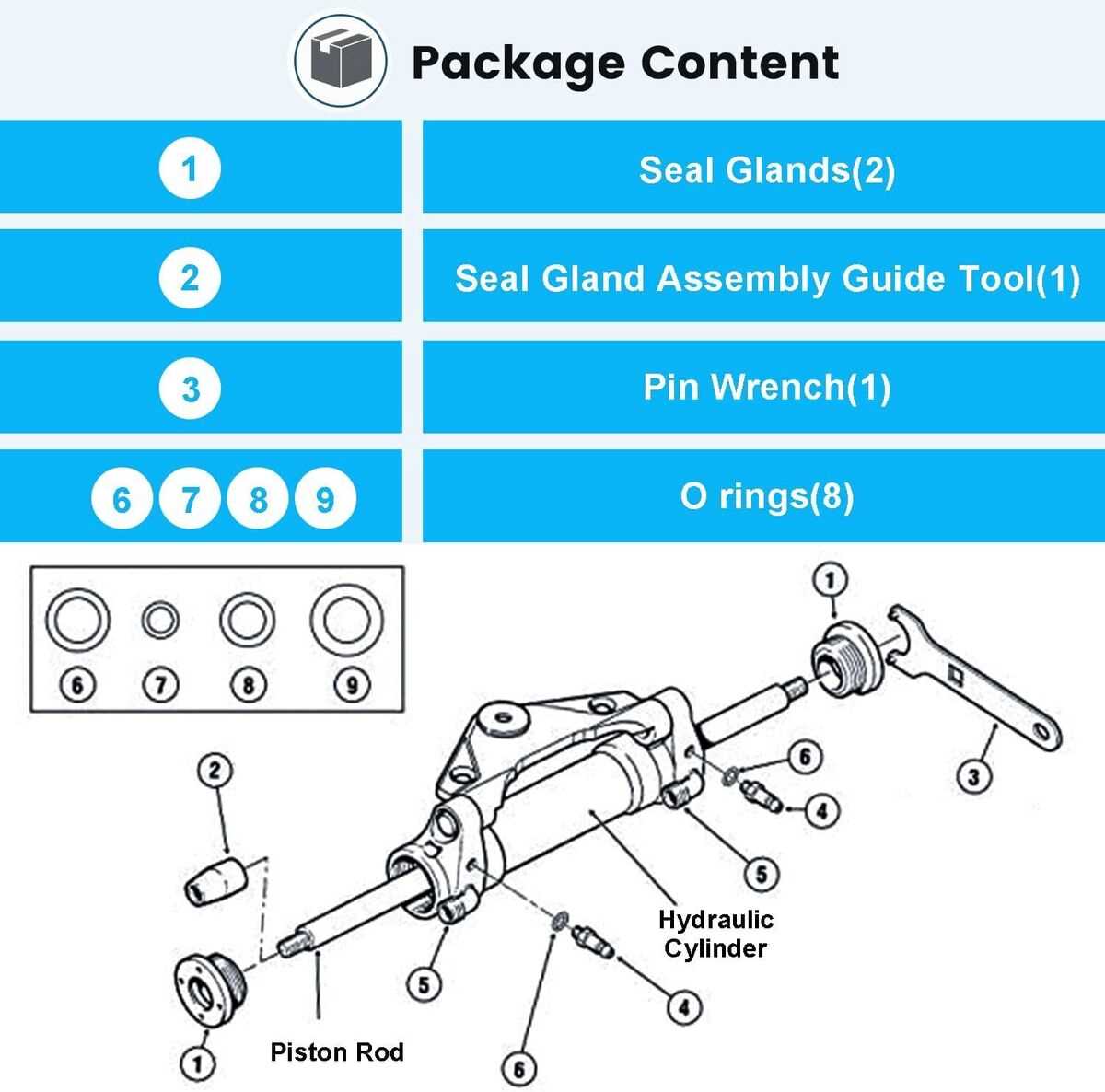

Key Components Explained

This section will explore the essential elements that contribute to the overall functionality of a hydraulic steering system. Understanding these components is crucial for effective maintenance and operation.

- Helm Unit: The control center for steering input, translating the driver’s movements into hydraulic pressure.

- Ram: A cylinder that converts hydraulic pressure into linear motion, allowing for precise steering adjustments.

- Hoses: Durable conduits that transport hydraulic fluid between the helm and the ram, ensuring smooth operation.

- Fluid Reservoir: The storage for hydraulic fluid, maintaining the system’s pressure and function.

Each of these components plays a vital role in ensuring a responsive and reliable steering experience.

Importance of Accurate Diagrams

Precise visual representations play a crucial role in understanding complex systems. They serve as vital tools that simplify intricate structures, making it easier to identify components and their functions. The clarity offered by these visuals can significantly enhance comprehension and efficiency in various fields.

Facilitating Communication

Well-crafted visuals improve communication among team members. They provide a common reference point, reducing the chances of misunderstandings and errors. When everyone has access to the same clear imagery, collaboration becomes more effective.

Enhancing Problem-Solving

Accurate illustrations enable quick identification of issues within a system. By allowing individuals to pinpoint specific areas needing attention, they streamline troubleshooting processes. Ultimately, this leads to faster resolutions and improved overall performance.

Common Issues with Steering Parts

Understanding the frequent challenges encountered with steering mechanisms is crucial for maintaining optimal performance. Various factors can lead to complications, impacting maneuverability and safety.

Worn Components

Components can wear down over time, resulting in decreased responsiveness. Regular inspections are essential to identify signs of wear early.

Hydraulic Leaks

Fluid leaks are a common issue that can lead to steering failure. Monitoring fluid levels and checking for leaks is vital for effective operation.

| Issue | Symptoms | Solutions |

|---|---|---|

| Worn Components | Loose steering, excessive play | Replace worn parts, regular maintenance |

| Hydraulic Leaks | Low fluid levels, poor steering response | Inspect and repair leaks, refill fluid |

Maintenance Tips for Longevity

Ensuring the durability of your marine equipment requires consistent care and attention. By implementing effective maintenance strategies, you can significantly extend the lifespan of your essential components. Regular upkeep not only prevents unexpected breakdowns but also enhances overall performance.

Regular Inspections

Conducting frequent evaluations of your gear is crucial. Look for signs of wear, corrosion, or damage. Identifying issues early allows for timely repairs, which can save you time and money in the long run. Make a habit of checking connections, seals, and other critical elements to maintain optimal function.

Proper Lubrication

Utilizing appropriate lubricants can greatly enhance performance. Ensure that moving parts are well-greased to minimize friction and reduce the risk of failure. Refer to manufacturer recommendations for suitable products and application techniques, as this will ensure compatibility and effectiveness.

By following these tips and staying proactive in your maintenance routine, you can enjoy smoother operations and a longer service life for your equipment.

Identifying Seastar Parts by Model

Understanding the components of various models can significantly enhance maintenance and repair processes. Each variant comes with its own unique features, which may require specific elements for optimal performance. Recognizing these distinct characteristics is essential for ensuring that replacements are both accurate and effective.

Model Identification serves as the foundation for recognizing individual components. By examining the serial number or model specifications, users can access information regarding compatible elements. This practice not only streamlines the selection process but also helps avoid potential errors that could arise from using incorrect substitutes.

Furthermore, familiarity with model variations allows users to appreciate the subtle design changes that may impact functionality. By studying the official documentation or reference materials, individuals can gain insights into how these differences influence the assembly and performance of each unit.

Ultimately, precise identification of components based on the model ensures a smoother experience in both routine maintenance and unexpected repairs. This knowledge empowers users to make informed decisions, prolonging the lifespan and efficiency of their equipment.

How to Read a Parts Diagram

Understanding the layout of components is essential for effective maintenance and repair tasks. A visual representation of elements can greatly assist in identifying specific pieces and their functions. By familiarizing yourself with this graphical guide, you can streamline the process of locating and addressing any issues.

When approaching the visual schematic, consider the following key elements:

| Element | Description |

|---|---|

| Labels | Each item is typically accompanied by a label that denotes its name or part number, facilitating easy identification. |

| Connections | Arrows or lines often indicate how components interconnect, which is crucial for understanding the overall assembly. |

| Legends | A legend may be provided to explain symbols or color codes used in the illustration, enhancing clarity. |

| Groupings | Components are usually organized into groups based on their functions or locations, helping you focus on specific areas. |

By taking the time to analyze these aspects, you can gain valuable insights into the organization of the components, making repairs and maintenance tasks more efficient.

Differences in Hydraulic vs. Mechanical Systems

Understanding the distinctions between fluid-driven and mechanically operated systems is crucial for optimizing performance and functionality in various applications. Each type has unique characteristics that affect their efficiency, responsiveness, and maintenance requirements.

Performance and Efficiency

Fluid-driven systems typically offer smoother operation and can handle larger loads with less effort. In contrast, mechanical systems may provide more direct control but can be limited by friction and wear, affecting their overall efficiency.

Maintenance and Reliability

While hydraulic systems can require more frequent fluid checks and potential leak repairs, they generally deliver reliable performance in demanding conditions. Mechanical systems, however, often need regular inspections to manage wear and tear, impacting their longevity and reliability.

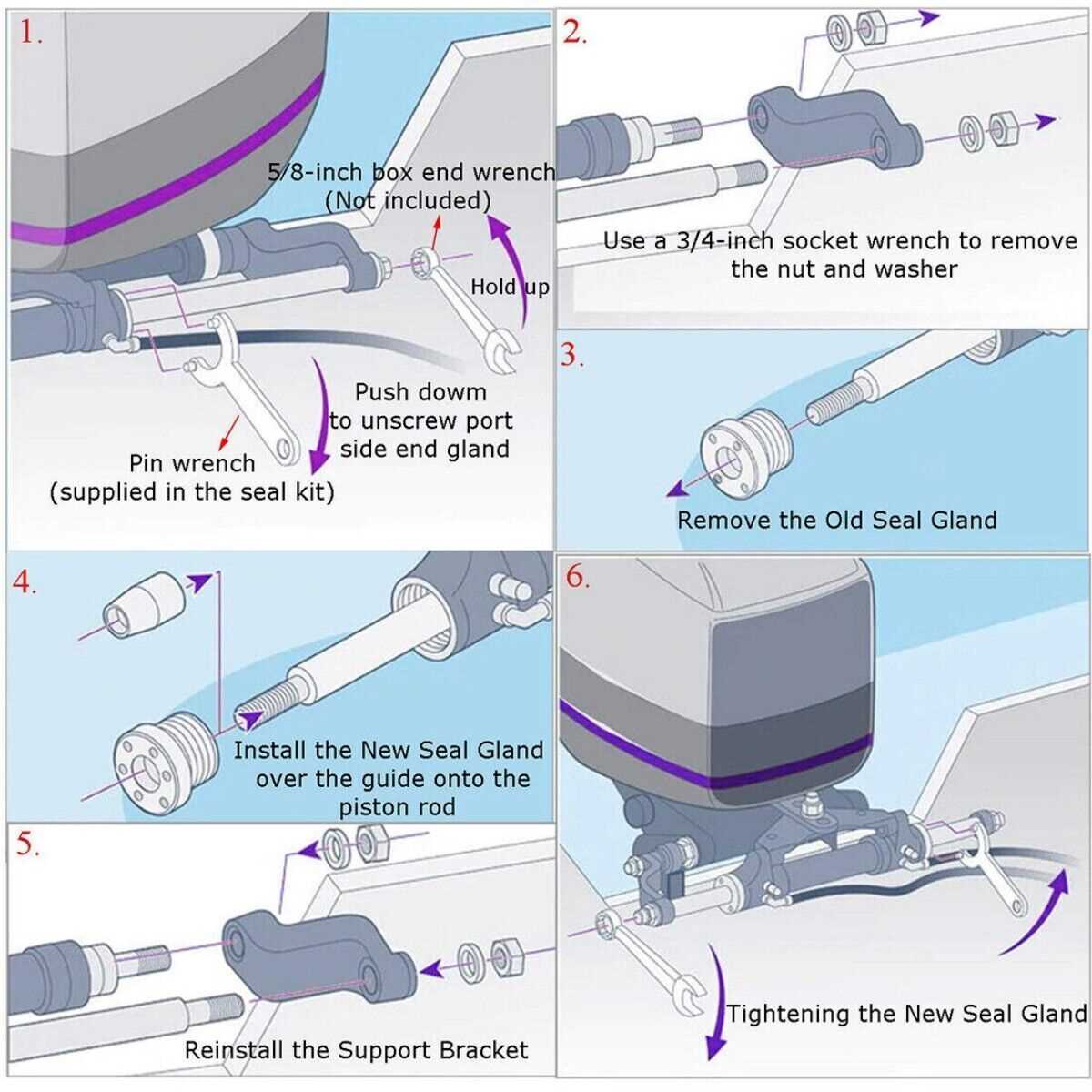

Tools Needed for Installation

To ensure a smooth and efficient setup process, having the right instruments is essential. These tools will facilitate the installation, making it easier to achieve a successful outcome.

Essential Instruments

Begin with a screwdriver set to handle various fasteners. A wrench or socket set will be necessary for tightening bolts securely. Additionally, a measuring tape will assist in achieving precise placements.

Safety Gear

Don’t forget to wear appropriate safety goggles and gloves to protect yourself during the installation process. Safety should always be a priority when working with tools.

Upgrading Your Steering System

Enhancing your vessel’s steering mechanism can significantly improve handling, responsiveness, and overall safety on the water. Whether you’re looking to replace outdated components or simply enhance your current setup, understanding the available options is crucial for achieving a smoother and more efficient experience while navigating.

Assessing Your Current Setup

Before diving into upgrades, it’s essential to evaluate your existing steering arrangement. Consider factors such as the age of the system, the materials used, and any performance issues you’ve encountered. Identifying these aspects will guide your selection of new components, ensuring compatibility and optimal performance.

Choosing the Right Upgrades

When selecting new elements for your steering system, focus on quality and durability. Look for components that offer enhanced responsiveness and reduced friction. Hydraulic systems often provide better control compared to traditional setups, while electronic systems can offer advanced features like autopilot integration. Researching reputable brands and consulting with professionals can also ensure you make informed decisions that meet your boating needs.

Frequently Asked Questions

This section addresses common inquiries related to the components and functionality of marine steering systems. Here, you’ll find answers to some of the most prevalent questions that users encounter.

What are the main components of a marine steering system?

The primary elements include the helm, hydraulic cylinder, hoses, and the linkage system. Each part plays a vital role in ensuring smooth operation and maneuverability.

How do I know if my steering system needs maintenance?

Signs of wear include difficulty in steering, unusual noises, or leaks. Regular inspections can help identify issues before they become severe.

Can I replace components myself?

While some users may opt for DIY repairs, it’s essential to have a good understanding of the system. Consulting a professional is advisable for complex replacements to ensure safety and proper function.

What type of fluid is required for hydraulic systems?

Most hydraulic systems use a specific type of fluid designed for marine environments. Always refer to the manufacturer’s recommendations for the best results.

Is it necessary to use original components?

Using original parts is generally recommended to maintain compatibility and performance. However, high-quality aftermarket options may also be suitable if they meet the required specifications.

Resources for Further Learning

Exploring advanced concepts can greatly enhance your understanding of intricate systems. Below are various resources that offer valuable insights and knowledge to deepen your expertise.

- Online Courses: Platforms like Coursera and Udemy provide comprehensive classes focused on technical skills and applications.

- Books: Consider reading specialized literature that covers the mechanics and functionalities of similar systems.

- Forums and Communities: Engage with online groups where enthusiasts and professionals share experiences and advice.

- Webinars: Attend virtual seminars hosted by experts in the field to stay updated on the latest trends and technologies.

Utilizing these resources will not only enhance your learning but also connect you with a community of like-minded individuals.