When maintaining or repairing complex equipment, having a clear understanding of how different elements come together can make the task more efficient. Every machine is made up of a variety of interconnected elements, each playing a crucial role in the overall performance. By familiarizing yourself with the structural arrangement of these elements, you can more easily troubleshoot potential issues and ensure that everything is functioning optimally.

The design of any mechanical system includes numerous interconnected parts, which need to be carefully examined to fully grasp their purpose. Knowing how these elements work together provides valuable insights that help in optimizing both the use and maintenance of the equipment. Such knowledge is essential for ensuring smooth operation and extending the lifespan of the machinery.

Whether you’re conducting routine upkeep or handling more in-depth repairs, understanding the configuration of the individual components allows you to add

Essential Components Overview

The key elements of any equipment are integral to its smooth operation. Each part works in harmony to ensure optimal performance, contributing to overall reliability. Understanding these main components helps in recognizing their roles and the ways they support efficient functioning.

Among the most important sections, the engine system drives the core operations, while additional mechanical features provide stability and control. Other sections focus on maintaining balance and reducing wear over time, ensuring longevity and consistent performance.

Each component is designed with precision to fit specific functions, making maintenance easier and enhancing durability. Proper understanding of these elements allows for better care and prolonged use of the equipment.

Engine Breakdown and Key Features

The internal structure of this power unit is designed to deliver efficiency and reliability. By breaking down the components that form the core of its operation, we can better understand how its key features come together to provide optimal performance in demanding conditions. Each element plays a critical role in ensuring smooth and consistent functioning, making this machine a dependable choice for various tasks.

At the heart of the system lies a robust mechanism, engineered for precision and durability. This engine is equipped with features that enhance fuel efficiency, reduce emissions, and provide high torque output. Its lightweight yet powerful build allows for greater maneuverability without compromising strength, ensuring long-lasting use and easy handling during extended operation periods.

Another notable aspect is its user-friendly design, with accessible components for maintenance and service. The integration of

Fuel System and Maintenance

Maintaining an efficient fuel system is essential for the longevity and performance of any equipment. Regular upkeep ensures smooth operation and helps prevent potential issues that could arise from neglected components. Understanding the key elements of this system allows for better control over its function and the ability to troubleshoot when needed.

One of the main priorities is to ensure that the fuel lines remain clean and free from blockages. Over time, debris and residues can accumulate, leading to restricted flow and reduced efficiency. Inspecting and cleaning these lines on a regular basis can significantly enhance the overall operation.

Another important aspect of care involves monitoring the filter. A clean filter plays a crucial role in preventing contaminants from reaching sensitive internal components. Replacing the filter when necessary helps keep the system running at optimal levels and prolongs its operational life.

Finally, proper storage and handling of fuel itself should not be overlooked. Using

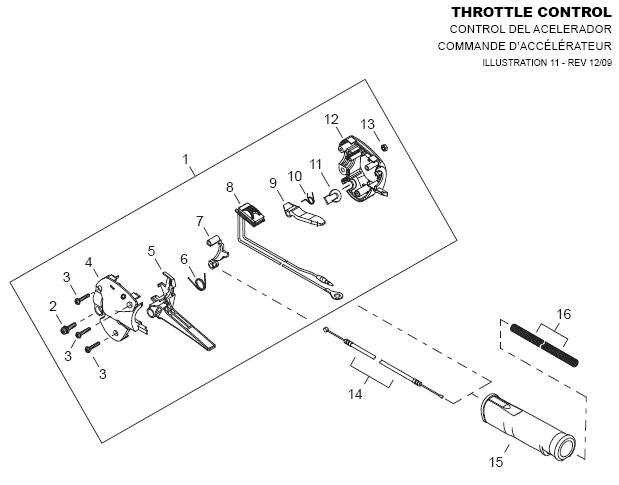

Throttle Assembly and Adjustments

The throttle system plays a crucial role in controlling the engine’s power, ensuring smooth and responsive operation. Properly setting up and fine-tuning this component is essential for maintaining optimal performance and preventing unnecessary strain on the engine. Understanding the different elements involved in the throttle mechanism allows for effective adjustments and maintenance.

- Ensure the throttle lever moves smoothly without any obstruction.

- Check the tension of the control cable, adjusting if there is too much slack or resistance.

- Inspect connections to avoid any loosened or worn-out components that could impact performance.

- After any adjustments, test the system under different operating conditions to verify responsiveness.

Making precise changes to the throttle assembly helps achieve better handling and enhances overall efficiency. Regular inspection and occasional adjustments contribute to the reliability and longevity of the machine.

Ignition System and Spark Plug Guide

The efficiency of the ignition system plays a crucial role in ensuring reliable performance. It involves a delicate balance of components that work together to initiate the engine’s combustion process. Proper maintenance and attention to this system can greatly enhance the overall functionality, allowing the equipment to run smoothly under various conditions.

Understanding the Core Mechanism

At the heart of the ignition system is a sequence of electrical interactions that generate the necessary spark to ignite the fuel-air mixture. This process depends on the quality of the ignition coil, the correct gap of the spark plug, and the condition of the electrical connections. Any failure in these areas can result in poor performance or complete failure to start.

Choosing and Maintaining Spark Plugs

Selecting the right spark plug is essential for the ignition system to function effe

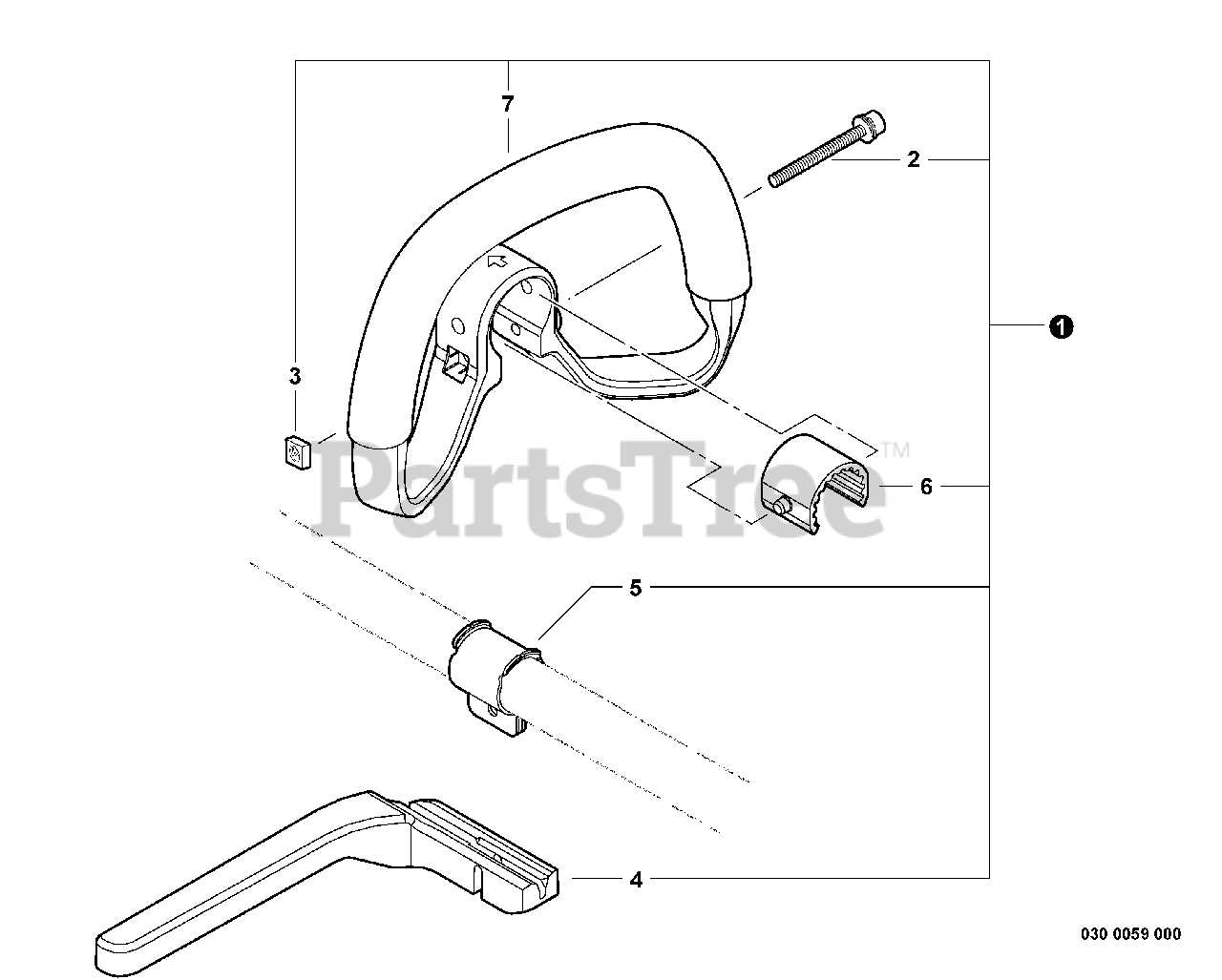

Handle and Grip Structure

The configuration of the handle and grip is crucial for effective operation and user comfort in handheld machinery. This section explores the components and design features that contribute to a secure and ergonomic grasp, facilitating better control during usage.

Typically, the handle is designed to offer optimal support and stability. It often incorporates materials that enhance grip, reducing the chances of slippage even in challenging conditions. Additionally, the contour of the handle plays a significant role in minimizing fatigue during extended use.

| Component | Description |

|---|---|

| Grip Material | High-friction substances that provide a non-slip surface for enhanced control. |

| Ergonomic Design | Shapes tailored to fit the natural contours of the hand, promoting comfort. |

| Handle Length | Optimized to allow a full range of motion without compromising stability. |

| Mounting Points | Secured attachments that ensure durability and resistance to wear. |

Understanding these elements assists users in selecting equipment that not only meets operational requirements but also enhances their overall experience by prioritizing comfort and efficiency.

Air Filter and Carburetor Details

The components responsible for the air intake and fuel delivery are essential for the optimal functioning of outdoor power equipment. Proper maintenance and understanding of these elements ensure efficient performance and longevity of the machine. This section highlights the critical aspects of the air filtration system and the fuel mixing unit.

| Component | Description | Function |

|---|---|---|

| Air Filter | A removable element that captures dirt and debris from the incoming air. | Prevents contaminants from entering the engine, ensuring cleaner combustion. |

| Carburetor | A mechanical device that blends air and fuel for combustion. | Regulates the fuel-air mixture, optimizing performance across various operating conditions. |

| Filter Cover | A protective cover securing the air filter in place. | Ensures the filter remains sealed to prevent unfiltered air from entering the engine. |

| Adjustment Screws | Screws used to fine-tune the air-fuel mixture. | Allow for precise adjustments to enhance engine performance and efficiency. |

Exhaust System and Muffler Components

The exhaust assembly plays a crucial role in managing engine emissions and noise levels. It ensures that harmful gases are expelled efficiently while minimizing sound output, contributing to the overall performance and compliance with environmental standards.

Key elements of the exhaust mechanism include:

- Muffler: This component is designed to reduce engine noise by altering sound wave patterns, allowing for a quieter operation.

- Exhaust Pipes: These channels direct exhaust gases from the engine to the atmosphere, optimizing airflow and enhancing efficiency.

- Gaskets: These seals ensure a tight connection between exhaust components, preventing leaks and maintaining optimal performance.

- Heat Shields: Protective barriers that safeguard surrounding components from excessive heat generated by exhaust gases.

- Mounting Brackets: These supports secure the exhaust assembly in place, ensuring stability during operation.

Understanding these components is essential for effective maintenance and repair. Regular inspections can help identify wear or damage, ensuring the assembly functions correctly and efficiently.

Drive Shaft and Gearbox Components

The transmission system of a machine plays a crucial role in converting power generated by the engine into usable energy for operation. Understanding the various elements involved in this system is essential for effective maintenance and performance optimization. This section delves into the key components responsible for power transfer and their functionalities.

Key Elements of the Drive Shaft

- Drive Shaft: A cylindrical component that transmits rotational motion from the engine to the gearbox.

- Universal Joints: Flexible connections that allow the drive shaft to maintain torque transmission despite angle changes.

- Bearings: Support structures that minimize friction and facilitate smooth rotation of the drive shaft.

Gearbox Features

- Gear Set: A series of gears that adjust rotational speed and torque to meet the operational requirements.

- Housing: A protective casing that contains and secures the internal components of the gearbox.

- Input and Output Shafts: Elements that connect the gearbox to the drive shaft and the working mechanism, ensuring efficient power transfer.

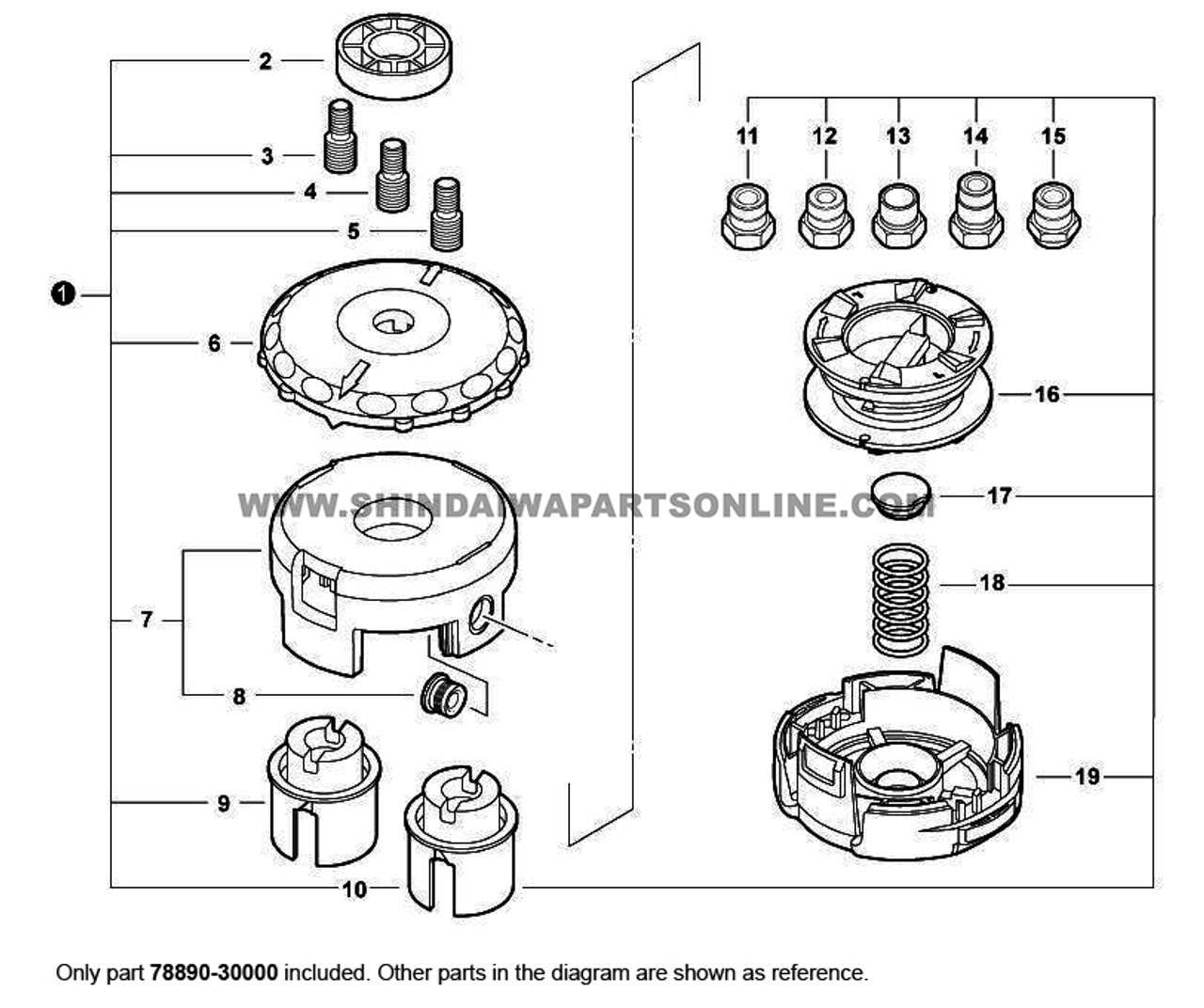

Clutch Mechanism and Functionality

The clutch system serves a vital role in the operation of handheld power equipment, providing a seamless transition between engine power and cutting performance. This mechanism allows for controlled engagement and disengagement, ensuring optimal efficiency during use.

At its core, the clutch consists of a series of components that work in harmony to transmit torque from the engine to the cutting tool. When the engine reaches a specific speed, the centrifugal force activates the clutch, engaging the cutting mechanism. This process allows the user to maintain consistent cutting speed without stalling the engine.

Additionally, the design of the clutch system aids in reducing wear on the engine by preventing unnecessary strain during operation. Proper maintenance of this mechanism is essential, as any malfunction can lead to decreased performance or potential damage to the equipment.

Blade Guard and Cutting Mechanism

The protection element and cutting apparatus are crucial components that ensure the efficient operation of trimming tools. Their design contributes significantly to safety and functionality during use. Understanding the interplay between these parts is essential for optimal performance and maintenance.

Functionality of the Guard

The protective cover serves multiple purposes:

- Enhances user safety by shielding against accidental contact with the cutting edge.

- Prevents debris from flying back toward the operator, minimizing the risk of injury.

- Assists in maintaining the alignment of the cutting instrument, ensuring accurate trimming.

Components of the Cutting Mechanism

The cutting mechanism consists of various elements that work together to achieve effective performance:

- Blade: The sharp element responsible for cutting through vegetation.

- Gear Assembly: Facilitates the transfer of power from the motor to the blade.

- Spindle: Supports the blade and allows for smooth rotation during operation.

Regular maintenance and inspection of these components ensure longevity and reliable performance during use.