Working with classic equipment requires a deep understanding of its structure and function. To maintain and repair these tools, it’s important to grasp how individual pieces work together, ensuring long-term efficiency and accuracy. Without proper knowledge, addressing wear and tear or upgrading functionality can become challenging.

In this guide, we’ll explore the essential elements of a vintage woodworking machine, highlighting the key components necessary for optimal performance. By breaking down the technical makeup of the device, you’ll gain insight into how each part contributes to the overall operation.

Whether you’re restoring an older model or simply aiming to enhance its functionality, knowing the critical elements is a vital first step. Let’s delve into the intricacies of these mechanical components and understand their roles in ensuring a smooth, productive experience.

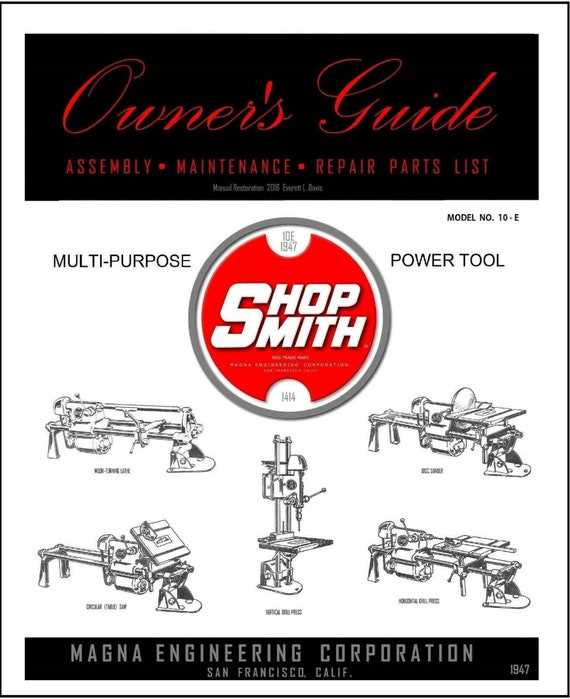

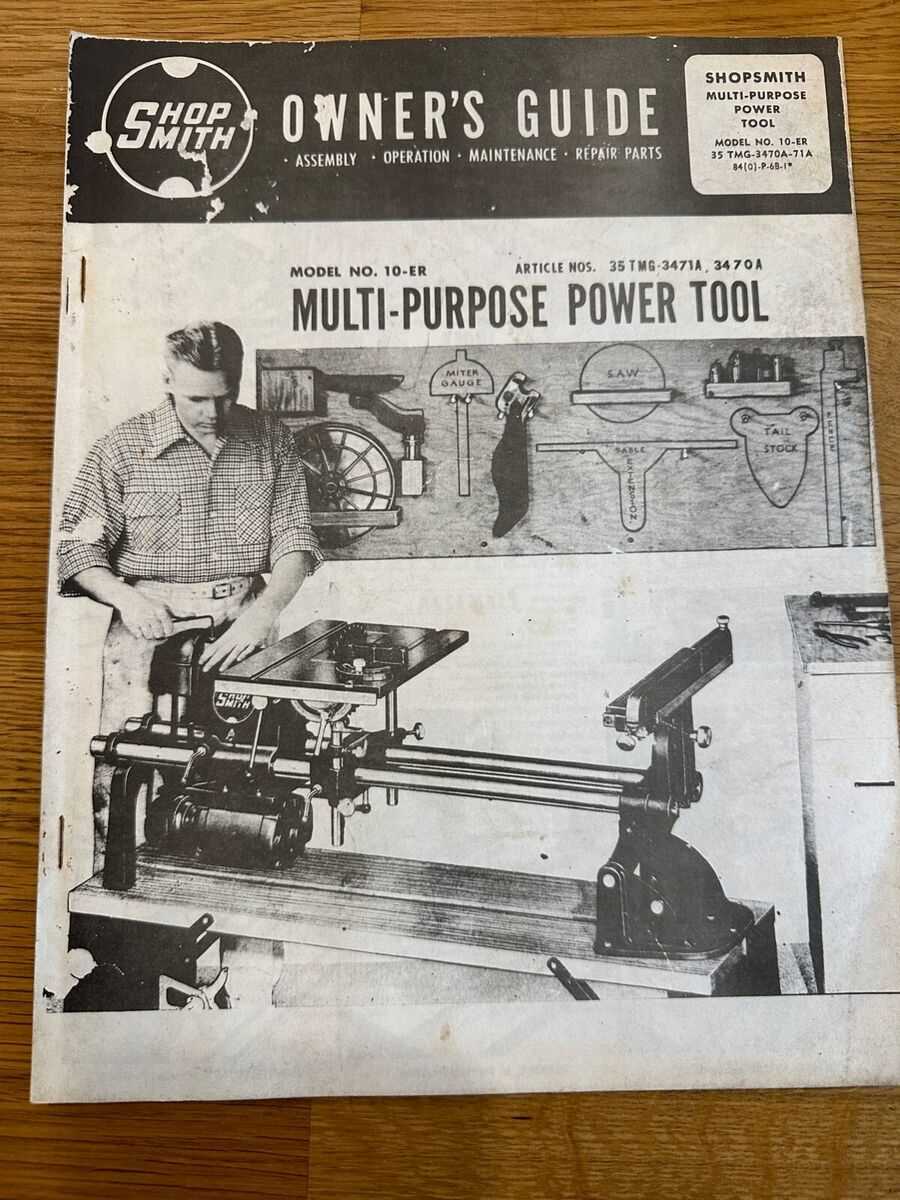

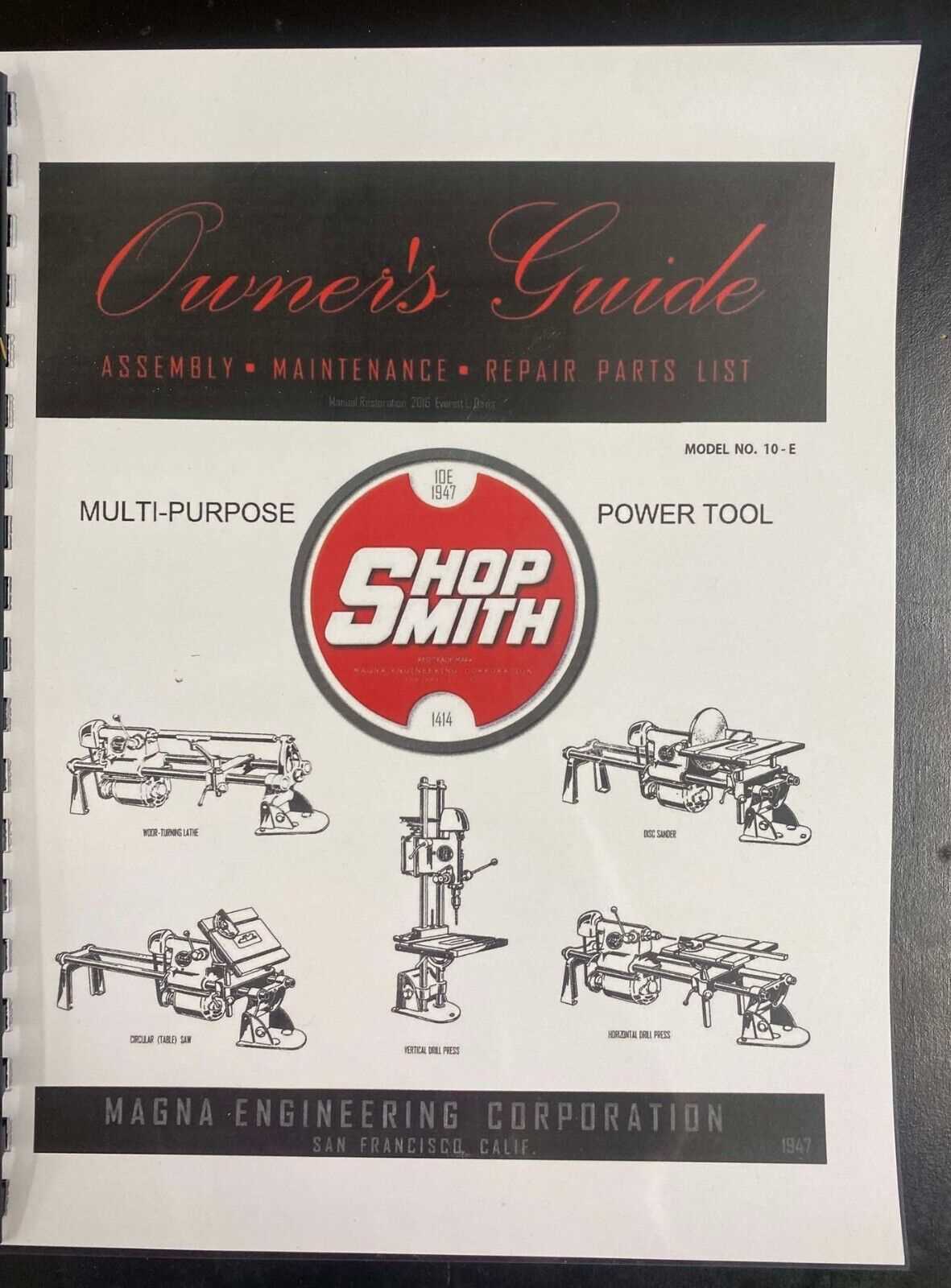

Understanding the Shopsmith 10ER Tool System

The multi-functional woodworking system offers a versatile approach to home projects, designed to optimize the user’s workspace while providing various capabilities. This system integrates multiple tools into a single platform, making it a popular choice for those who need flexibility without sacrificing performance.

Efficiency and Versatility

One of the key advantages of this tool is its ability to perform numerous tasks without requiring constant reconfiguration. Whether you are working on precision cuts, shaping, or drilling, the system adapts quickly to your needs, minimizing downtime and enhancing productivity.

Durability and Longevity

Built with robust materials, the system ensures long-lasting performance, even under heavy use. Its durable construction not only extends the lifespan of the tool but also contributes to consistent results over time. Maintaining this setup can be simple, thanks to easily accessible components and straight

Key Components of the Shopsmith 10ER

The multifunctional system in question is comprised of various essential parts that work together to ensure optimal performance. Understanding these core elements allows users to maintain the equipment efficiently and extend its operational life.

Main Frame Structure

The central framework provides the stability and support needed for the other components to function smoothly. This foundational element ensures balance during operation and serves as the base for multiple attachments and accessories.

Drive Mechanism

The driving system is crucial for powering the tool’s various operations. It includes a powerful motor connected to a transmission system that converts electrical energy into mechanical motion. Ensuring proper alignment

Exploring the Motor Assembly

The motor unit is a key component responsible for driving the overall mechanism. Understanding its structure and function is crucial for anyone looking to maintain or repair the device effectively. By examining the internal setup and connections, you can better grasp how each element interacts to deliver power and control to the system.

Below is a simple breakdown of the motor assembly:

| Component | Function | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotor | Generates rotational movement by interacting with the magnetic field. | |||||||||||||||||||||||||

| Stator | Produces a stationary magnetic field that interacts with the rotor. | |||||||||||||||||||||||||

Brush

Functions of the Drive Mechanism

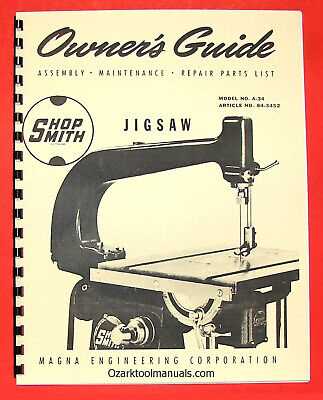

The drive mechanism plays a crucial role in ensuring the smooth operation of any machine, enabling the transfer of power from the motor to various components. Its purpose is to convert the motor’s rotational energy into controlled, precise movement, allowing for efficient performance of tasks. Power Transmission: One of the primary roles of the drive mechanism is to transmit energy. By adjusting the speed and torque, it ensures that the machine functions optimally under varying loads and conditions. This capability allows for versatility in handling different tasks with precision. Speed Regulation: The mechanism also controls the rotational speed. This regulation is essential for performing diverse functions that require varying levels of speed, ensuring that each task is completed efficiently and with accuracy. A well-tuned drive system prevents overloading and extends the lifespan of the machine. Direction Control: Another important function is changing the direction of movement. Whether it’s switching between forward and reverse motion or Accessories for the Shopsmith 10EREnhancing the versatility of this multipurpose tool involves integrating a wide range of additional attachments. These components allow users to perform more specialized tasks and expand the functionality of their equipment. Whether focusing on precision work or broadening capabilities, having the right add-ons can significantly improve productivity. Common AttachmentsMany users opt for basic attachments that offer improved control and accuracy. Examples include various blade types for woodworking or sanding discs that deliver smooth finishes. These essentials help to handle different tasks effectively, making the unit adaptable to diverse projects. Specialty Add-ons

For more specific needs, there are attachments designed for advanced operations. These might include drilling guides, adjustable clamps, or expansion kits that allow for more complex projects. By incorporating these specialized acc Table and Fence Setup GuideEstablishing an accurate and effective workspace is crucial for any woodworking project. Proper alignment of the table and fence enhances precision and safety, ensuring that your materials are cut to the desired dimensions. This guide will walk you through the steps to achieve optimal setup, allowing you to focus on your craftsmanship. Initial PositioningBegin by selecting a stable and level surface for your machine. Ensure that the main table is securely attached and free from debris. Position the fence parallel to the blade, adjusting as needed to eliminate any gaps. Use a reliable measuring tool to verify that both components are aligned, facilitating consistent cuts. Fine-Tuning AdjustmentsOnce the initial setup is complete, perform fine-tuning to enhance accuracy. Make slight adjustments to the fence, locking it firmly in place after confirming alignment with the blade. It is beneficial to conduct a test cut with a scrap piece of material to evaluate the setup. If discrepancies arise, revisit the alignment process to ensure everything is perfectly configured for your woodworking tasks. Spindle and Quill Mechanism ExplainedThe spindle and quill assembly is a vital component in many woodworking machines, serving as the interface between the motor and cutting tools. This mechanism enables precise control over the depth and angle of cuts, enhancing the versatility and functionality of the equipment. Understanding how these parts work together is essential for optimal performance and maintenance. Functionality of the SpindleThe spindle is responsible for rotating the cutting tool at varying speeds, allowing for adjustments based on the material being worked on. It typically features a tapered or threaded design to securely hold the tool in place while minimizing vibrations during operation. This stability is crucial for achieving clean, accurate cuts. Role of the Quill

The quill, on the other hand, allows for vertical movement of the cutting tool, facilitating depth adjustments with ease. This component can often be controlled through a lever or crank mechanism, enabling the user to make quick modifications while working. The combination of spindle rotation and quill adjustment creates a seamless workflow, empowering woodworkers to tackle a wide range of projects efficiently. Electrical System OverviewThe electrical framework of the tool serves as a crucial element, providing the necessary power for its various functions. Understanding this system is essential for effective operation and maintenance, ensuring that the equipment runs smoothly and efficiently. This section will explore the key components and their roles within the electrical setup, highlighting their importance in the overall functionality. Main ComponentsThe electrical configuration comprises several integral parts, each contributing to the optimal performance of the machine. These components work in harmony to deliver consistent energy flow, enabling the tool to perform its tasks effectively.

Safety ConsiderationsWhen working with the electrical aspects of the machinery, it is vital to adhere to safety protocols. Proper handling and regular inspections can prevent accidents and ensure that the system remains in good condition. Familiarity with the components and their functions enhances both safety and efficiency in operation. Maintaining the Shopsmith 10ER Bearings

Proper upkeep of rotating components is essential for ensuring smooth operation and longevity in machinery. Bearings play a crucial role in this process, providing support and reducing friction during use. Regular maintenance helps identify issues before they escalate, ultimately preserving the functionality of the equipment. To maintain these critical elements, begin by cleaning them periodically. Use a suitable solvent to remove dirt and debris, which can hinder performance. After cleaning, apply a light layer of high-quality lubricant to ensure optimal movement and prevent wear. Additionally, it is vital to inspect the bearings for signs of damage or excessive wear. Look for cracks, pitting, or abnormal sounds during operation. If any issues are detected, replace the affected components promptly to avoid further complications. Regular checks and proper care will enhance the reliability and efficiency of the entire system. How to Replace Worn Parts

Maintaining your equipment is essential for optimal performance. Over time, certain components may wear out due to regular use, impacting functionality and safety. This guide will provide steps to help you effectively replace these worn-out elements, ensuring your tools remain in top shape. Before starting the replacement process, gather the necessary tools and materials. Ensure you have the appropriate replacements ready, as well as basic tools such as screwdrivers, wrenches, and pliers. Following the correct procedure will not only enhance performance but also extend the lifespan of your equipment.

Regularly inspecting and replacing worn components is key to maintaining the efficiency and longevity of your equipment. Following these steps will help ensure your tools continue to perform reliably. Troubleshooting Common Issues with the 10ERWhen working with a versatile woodworking tool, encountering problems is not uncommon. Understanding potential malfunctions and their solutions is essential for maintaining efficiency and ensuring optimal performance. This section outlines typical challenges users may face and provides practical advice to address them. One frequent issue is the machine’s inability to start. This can often be traced back to power supply problems or faulty connections. Ensure that all electrical components are functioning correctly and check the power source to confirm it is providing adequate voltage. Another common concern is excessive vibration during operation. This may indicate misalignment or improper setup. Examine the assembly to ensure that all parts are securely fastened and aligned according to manufacturer specifications. Adjustments may be necessary to restore stability. Users may also notice a decrease in cutting efficiency. This could be a result of dull blades or incorrect settings. Regularly inspect and sharpen the cutting tools as needed, and verify that all settings are properly configured for the material being processed. Lastly, unusual noises during use can signal underlying problems. Listen for any irregular sounds that could indicate wear or damage to internal components. If these noises persist, it may be wise to disassemble the unit for a thorough inspection to identify and rectify any issues. |