The intricate workings of vintage sewing machines reveal a world of mechanical artistry and engineering prowess. Each element plays a vital role in ensuring smooth operation and precision, making these devices cherished tools for many enthusiasts. A comprehensive overview of these essential components allows users to appreciate the craftsmanship involved and aids in maintenance and repair efforts.

By exploring the various sections and elements, one gains insight into how each contributes to the machine’s overall functionality. From the primary mechanism that controls the needle’s movement to the intricate feed systems that guide fabric, every component has its purpose. Familiarity with these elements not only enhances the sewing experience but also empowers users to troubleshoot and resolve common issues.

This knowledge becomes particularly valuable when considering upgrades or restorations. Understanding the different parts enables users to make informed decisions about replacements or enhancements, ensuring their machines continue to perform optimally. A detailed examination of these components serves as a guide for anyone looking to delve deeper into the world of sewing machine mechanics.

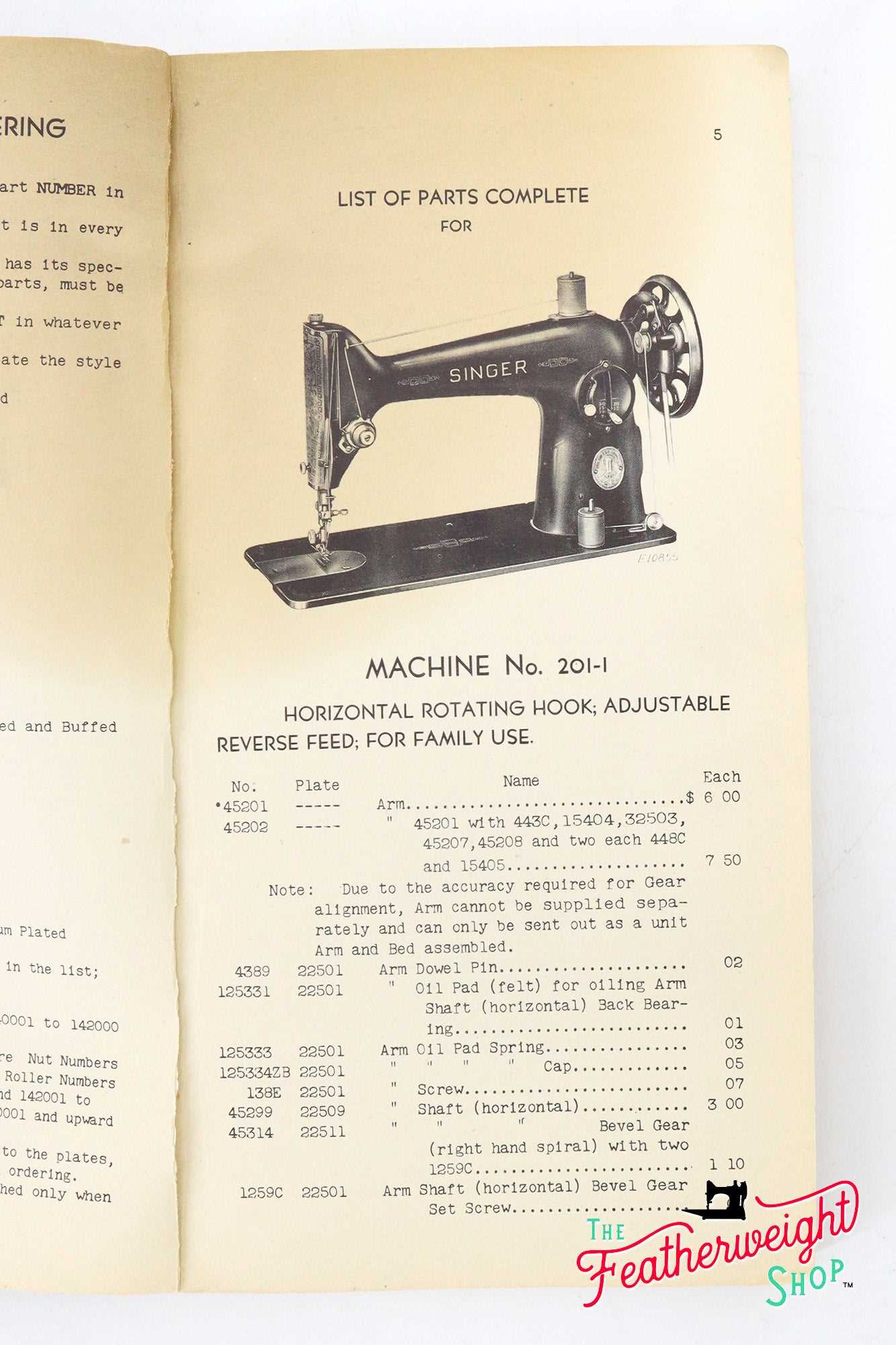

This section aims to provide a comprehensive overview of a renowned sewing machine model, highlighting its key features and components. Understanding the fundamental elements and their functions is essential for effective usage and maintenance. This analysis will delve into the machine’s operational mechanics, illustrating how each element contributes to its overall performance.

The following table outlines the crucial components of this sewing device, detailing their roles and importance:

| Component | Description |

|---|---|

| Needle Holder | Secures the needle in place, allowing for precise stitching. |

| Bobbin Case | Holds the bobbin, ensuring smooth thread flow during sewing. |

| Thread Tension Regulator | Controls the tension of the upper thread for consistent stitch quality. |

| Feed Dogs | Moves the fabric forward as the needle stitches, facilitating smooth operation. |

| Presser Foot | Keeps the fabric in place while sewing, allowing for even feeding. |

| Hand Wheel | Manually raises and lowers the needle, providing control over stitching. |

Key Features of Singer 201

This sewing machine model is celebrated for its exceptional performance and user-friendly design, making it a favorite among both novice and experienced crafters. Its reliability and durability ensure that it can handle a variety of fabrics and projects with ease.

One of the standout characteristics is its powerful motor, which provides consistent stitching speed and allows for effortless sewing through thick materials. Additionally, the machine is equipped with a robust metal frame, contributing to its stability during operation and enhancing longevity.

The straightforward control layout simplifies the sewing process, enabling users to quickly adjust settings and switch between different functions. The availability of various stitch patterns and adjustable stitch lengths offers creative flexibility, allowing individuals to customize their projects to their preferences.

Another notable feature is the high-quality needle system, which ensures precise needle placement and minimizes fabric snags. The easy-to-access bobbin and threading mechanisms reduce downtime and streamline the overall sewing experience.

With its combination of advanced technology and practical design, this model stands out as a reliable tool for anyone looking to create beautiful garments or home decor items.

Common Issues with Singer 201

Many users encounter various challenges when operating their vintage sewing machines. Understanding these frequent problems can help enthusiasts maintain their equipment in optimal working condition. From mechanical glitches to electrical issues, addressing these concerns can enhance the overall sewing experience.

Mechanical Glitches

One of the most prevalent issues involves the machine jamming during operation. This can often result from incorrect threading or the presence of lint in the mechanisms. Regular cleaning and proper threading techniques can significantly reduce the likelihood of such disruptions. Additionally, worn-out needles may cause fabric snags, leading to further complications. It is advisable to replace needles frequently and ensure they are suitable for the type of fabric being sewn.

Electrical Problems

Electrical malfunctions are another common concern, particularly in older models. Users might experience inconsistent power supply or the machine failing to start. This could be due to frayed wires or a faulty foot pedal. Inspecting the electrical components and ensuring secure connections can help mitigate these issues. Regular maintenance checks are recommended to prevent unexpected electrical failures and prolong the lifespan of the machine.

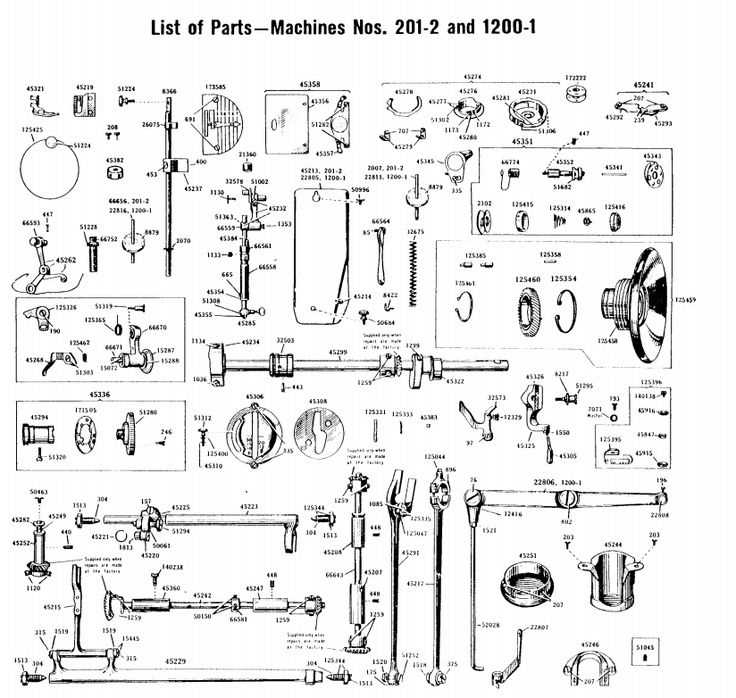

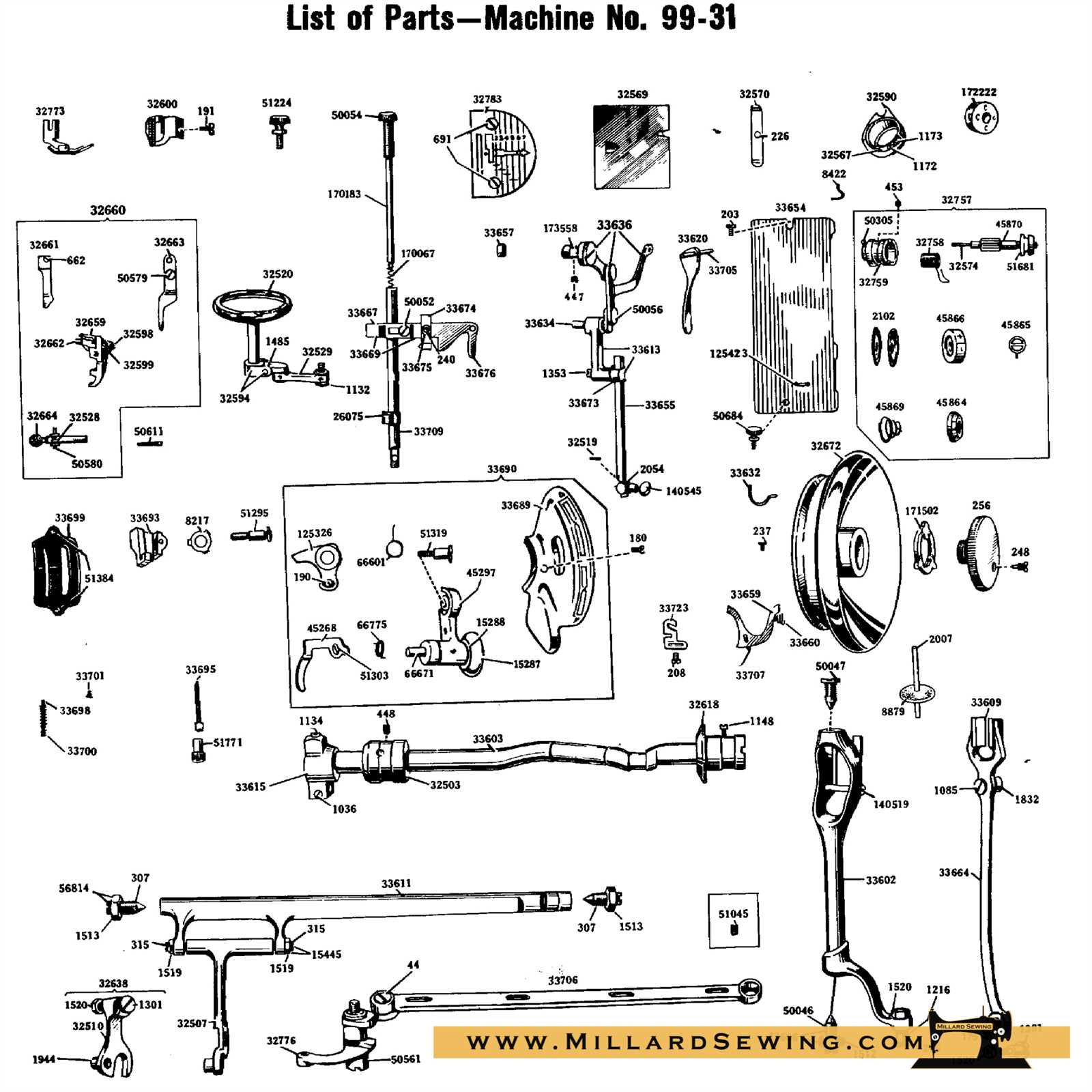

Understanding the Parts Diagram

Comprehending the layout of mechanical components is essential for effective maintenance and repair. Each element plays a crucial role in the overall functionality, and recognizing their arrangement can greatly enhance the efficiency of your machine. This section aims to provide insights into the structure and significance of various components, facilitating a deeper understanding of how they interact.

The visual representation serves as a roadmap, guiding users through the intricate network of elements. It is vital to familiarize oneself with this illustration to ensure proper assembly and troubleshooting. By analyzing the configuration, one can identify potential issues and perform necessary adjustments with confidence.

| Component | Description | Function |

|---|---|---|

| Drive Mechanism | Transmits power from the motor to the needle | Facilitates stitching action |

| Needle Holder | Holds the needle in place | Ensures precision in stitching |

| Feed Dog | Controls the movement of fabric | Allows for even feeding during sewing |

| Bobbin Case | Holds the bobbin | Enables lower thread supply |

Essential Components and Their Functions

Understanding the fundamental elements of a sewing machine is crucial for both novice and experienced users. Each component plays a specific role in the machine’s operation, contributing to the overall functionality and efficiency of the sewing process. A well-functioning mechanism relies on the synergy between these elements, ensuring smooth performance and high-quality stitching.

Needle: The needle is the primary tool for creating stitches. It penetrates the fabric and carries the thread through to form a secure seam. Different types of needles are available, each designed for specific materials and stitching techniques.

Presser Foot: This component holds the fabric in place while sewing, allowing for consistent feeding through the machine. Various presser feet are available for different applications, such as zipper insertion or quilting, enhancing versatility.

Feed Dogs: Located beneath the needle plate, these small metal teeth move the fabric forward as the needle penetrates. The height and position of the feed dogs can be adjusted to accommodate various thicknesses of fabric.

Bobbin: The bobbin holds the lower thread and is essential for forming stitches. It works in conjunction with the needle, with the upper thread looping around the bobbin thread to create a secure stitch on both sides of the fabric.

Thread Tension Mechanism: This system controls the tightness of the thread during sewing. Proper tension is crucial for achieving balanced stitches; too tight can cause puckering, while too loose can result in skipped stitches.

Motor: The motor powers the machine, enabling the needle to move up and down at varying speeds. A reliable motor is key for consistent operation and can significantly affect sewing performance.

Familiarizing oneself with these essential elements enhances not only the understanding of machine mechanics but also improves sewing proficiency and creativity.

Tools Needed for Repairs

When undertaking repairs on a sewing machine, having the right tools is essential for achieving successful results. A well-equipped toolkit can make the process more efficient and enjoyable, allowing you to address various issues with confidence. Ensuring you have the necessary instruments at hand will save time and prevent potential frustration during maintenance tasks.

Some fundamental tools include a set of screwdrivers, specifically a flathead and a Phillips, which are crucial for loosening and tightening screws in various machine components. Additionally, a pair of tweezers is invaluable for handling small parts, while a seam ripper can assist in removing any stitching errors quickly. A cleaning brush and lint remover will help maintain the machine’s interior, ensuring smooth operation.

For more advanced repairs, consider incorporating a multimeter to diagnose electrical issues and a set of pliers for gripping or bending components as needed. A tape measure is also helpful for checking the alignment of parts, ensuring everything is positioned correctly. By assembling a comprehensive toolkit, you will be well-prepared to tackle a range of repairs effectively.

How to Identify Parts Easily

Recognizing individual components of your sewing machine can significantly enhance your maintenance and repair experience. Understanding the various elements that make up the machine allows for smoother troubleshooting and more effective usage. This knowledge empowers users to efficiently locate, replace, or upgrade any necessary components, ensuring optimal performance and longevity.

To begin, familiarize yourself with the main sections of the machine, such as the needle assembly, tension control, and feed mechanism. Each section plays a crucial role in the overall functionality, and knowing their locations will help you pinpoint issues quickly. Additionally, consulting the user manual can provide valuable insights into the specific names and functions of each element.

Visual aids, like reference images or charts, can be beneficial in reinforcing your understanding. Compare the components on your machine with those depicted in these resources to establish a clear connection. Over time, as you gain hands-on experience, you will develop a more intuitive grasp of the equipment’s layout and individual features.

Lastly, consider joining online forums or local sewing clubs. Engaging with fellow enthusiasts allows for the sharing of knowledge, tips, and tricks. Collective experience can provide deeper insights into component identification, further enhancing your skills and confidence in managing your sewing tasks.

Maintenance Tips for Longevity

To ensure the extended life of your sewing machine, regular care and attention are essential. Implementing simple maintenance practices can enhance performance, reduce wear and tear, and prevent potential issues that could arise from neglect. This section will outline effective strategies to keep your machine in optimal condition, allowing you to enjoy your crafting experience without interruptions.

Regular Cleaning

Consistent cleaning is crucial for removing dust, lint, and debris that accumulate over time. Use a soft brush to gently remove particles from the feed dogs and surrounding areas. Regularly check and clean the bobbin case and throat plate to maintain smooth operation and prevent thread jams. Establish a cleaning routine that fits your usage frequency, ensuring your machine remains in peak condition.

Lubrication and Adjustments

Proper lubrication is vital for smooth functioning. Refer to the manufacturer’s guidelines on where to apply oil, ensuring you use the appropriate type. Additionally, check for any necessary adjustments, such as tension settings or alignment, to maintain the quality of your stitches. Regularly inspecting and making minor adjustments can significantly enhance the longevity of your equipment.

Comparing Singer 201 to Other Models

When evaluating a classic sewing machine, it’s essential to understand how it stands against its contemporaries. Each model brings unique features, strengths, and weaknesses that cater to different sewing needs. This section delves into the characteristics and functionalities that differentiate this particular machine from others in its category.

Several key aspects highlight the distinctions among various sewing machines:

- Stitch Options: Different models offer varying stitch types and capabilities. Some prioritize decorative stitches, while others focus on utility and ease of use.

- Speed and Performance: The rate at which a machine can sew, along with its ability to handle multiple layers of fabric, is crucial. Some machines excel in speed, while others are designed for precision.

- Build Quality: The materials used in construction can significantly impact durability and longevity. Comparing metal frames versus plastic components reveals differences in resilience.

- User Experience: The interface and ease of operation can vary widely. Some models feature advanced computerized systems, while others may have more straightforward mechanical designs.

In addition to these factors, it’s beneficial to consider the availability of accessories and support. Different brands may offer a wider range of attachments, making them more versatile for various sewing projects.

Ultimately, understanding these differences allows enthusiasts to make informed decisions based on their specific requirements and preferences.

Resources for Parts Replacement

When it comes to maintaining and restoring your sewing machine, having access to reliable resources for component exchange is essential. Whether you are a seasoned technician or a novice hobbyist, understanding where to find quality replacements can greatly enhance your sewing experience.

Here are some valuable resources to consider for acquiring the necessary components:

- Online Retailers: Many e-commerce platforms specialize in sewing equipment, providing a wide selection of replacement components. Look for vendors with good customer reviews and return policies.

- Manufacturer Websites: The official websites of machine manufacturers often offer a catalog of replacement items. This ensures compatibility and quality assurance.

- Local Sewing Shops: Visiting local craft stores or sewing machine dealers can provide personalized assistance. They often have spare parts in stock or can order them for you.

- Forums and Community Groups: Engaging with online communities dedicated to sewing can lead to recommendations for trustworthy suppliers and shared experiences on sourcing specific items.

Utilizing these resources will facilitate a smoother replacement process, ensuring your equipment remains in optimal condition for all your sewing endeavors.

Step-by-Step Repair Guide

This guide aims to provide clear and concise instructions for effectively restoring a vintage sewing machine. Following these steps will help you navigate common issues and ensure optimal performance of your device.

Preparation and Assessment

Begin by gathering all necessary tools and supplies, including screwdrivers, lubricants, and cleaning materials. Carefully assess the machine for any visible damage or wear, taking note of specific components that may require attention. This initial evaluation is crucial for identifying areas that need repair or replacement.

Disassembly and Cleaning

Once you have assessed the machine, proceed with disassembly. Remove the outer casing and carefully detach any internal components, keeping track of their arrangement. After disassembling, thoroughly clean all parts to remove dust, lint, and old lubricants. Use a soft brush and a suitable cleaning solution to ensure each element is free from debris, which can impede functionality.

After cleaning, inspect the components for signs of wear or damage. Replace any defective parts as needed, and reassemble the machine by reversing the disassembly process. Finally, apply a small amount of lubricant to moving parts to ensure smooth operation.

Expert Advice on Usage

Understanding the intricacies of a sewing machine is essential for achieving the best results in your projects. Proper usage not only enhances the performance of the device but also extends its lifespan. Familiarity with the components and their functions allows users to troubleshoot issues effectively and maintain smooth operation.

Begin by reading the manual thoroughly, as it contains valuable information regarding the setup and operation of your machine. Make sure to keep it clean and well-lubricated to ensure optimal functionality. Regularly inspect the needle and thread types, as using the correct combination significantly impacts the quality of your stitching.

Additionally, be mindful of the fabric you are working with. Different materials require specific settings and techniques. Testing on scrap fabric can help you determine the best approach before starting on your main project. Don’t hesitate to seek assistance from experienced users or online communities for tips and tricks to enhance your sewing experience.