Every sewing enthusiast knows the importance of maintaining their equipment in top condition. To ensure smooth operation, it is crucial to understand how various mechanisms come together, forming a well-coordinated system. This exploration dives into the core elements that keep a sewing device functioning seamlessly, breaking down the individual components and their roles in the overall structure.

The ability to troubleshoot and replace individual sections without guesswork can greatly extend the lifespan of your device. By having a detailed look at the main operational units, you can efficiently identify issues and make necessary adjustments or repairs. This guide will help you navigate through the mechanical layout, offering clarity on how the various elements interact to produce flawless stitching results.

Understanding the Key Components of Singer 4423

In any high-performance sewing machine, there are essential mechanisms that work together to ensure smooth and precise operation. Recognizing how these elements interact can significantly improve your experience and maintenance practices. By becoming familiar with each crucial part, users can diagnose issues more efficiently and keep the equipment in peak condition for years to come.

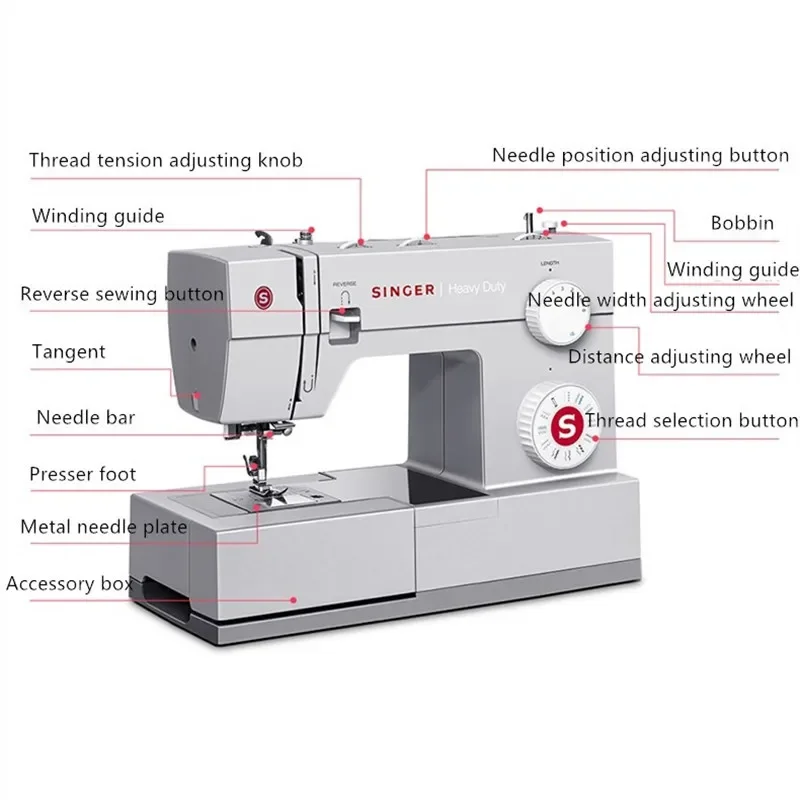

Drive Mechanism: The primary force behind fabric movement, the drive system controls the needle’s vertical and horizontal motions. This intricate setup allows for consistent stitching and adjustable speed, making it a vital component in any sewing task.

Threading System: A well-designed threading path ensures tension is properly regulated throughout the sewing process. The combination of guides, tensioners, and the take-up lever plays a pivotal role in creating uniform stitches across various fabric types.

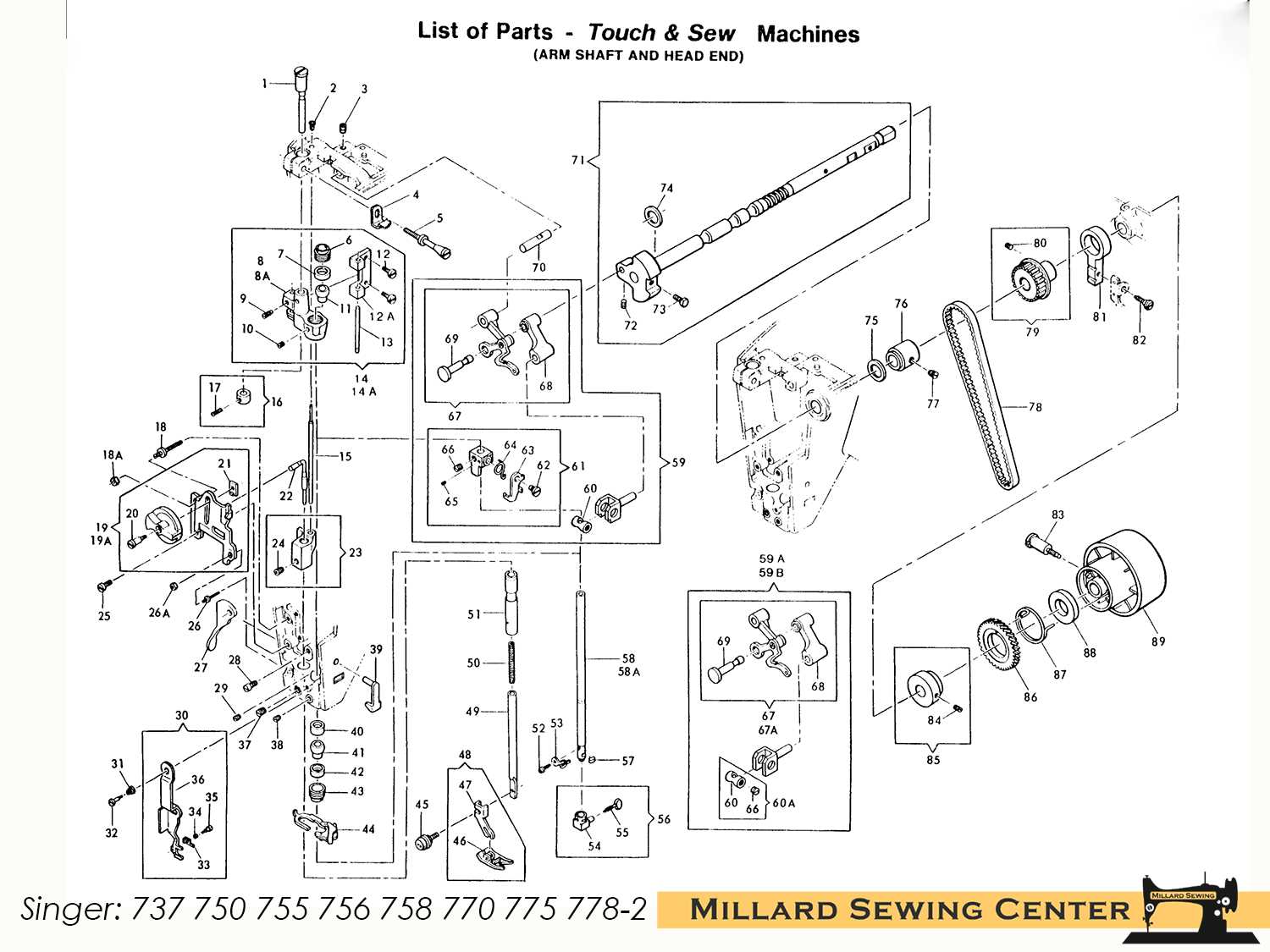

Exploring the Drive Mechanism Functionality

The drive mechanism plays a crucial role in ensuring smooth and efficient operation within a sewing machine. It translates the motor’s energy into precise movements that allow for consistent fabric stitching. Understanding how this mechanism functions can provide valuable insight into the overall performance and maintenance needs of the device.

How the Drive Mechanism Works

The drive system typically consists of interconnected gears and belts, which work together to synchronize the motion of various components. When the motor is activated, it engages these elements, causing the needle to move up and down in a controlled, repetitive pattern. This process is essential for creating even, reliable stitches during sewing.

Maintenance and Troubleshooting

Proper maintenance of the drive mechanism ensures long-lasting performance. Regular cleaning and lubrication are key to preventing wear on gears and belts, which can lead to malfunctions

How the Stitch Selector Works

The stitch selector is a crucial component of sewing machines, allowing users to choose from a variety of stitch types for different sewing tasks. This mechanism enables the adjustment of the sewing pattern, tailoring the output to specific needs such as straight stitching, zigzag, or decorative designs.

When the stitch selector is engaged, it interacts with the machine’s internal systems to modify the needle’s movement and thread tension. By turning the dial or lever, the user can easily switch between stitches, enhancing creativity and efficiency. Each setting corresponds to a specific configuration, ensuring that the chosen stitch is executed flawlessly.

In addition to functionality, the stitch selector contributes to the overall versatility of the machine. It empowers users to experiment with various techniques, from basic seams to intricate embellishments. Understanding how this feature operates can significantly enhance the sewing experience, allowing for more complex projects to be tackled with confidence.

Threading Path for Consistent Sewing

Establishing a precise threading route is crucial for achieving smooth and uniform stitching results. A correctly threaded machine ensures that the fabric is fed properly, minimizing issues such as skipped stitches and thread jams. Understanding the threading sequence can significantly enhance the sewing experience, allowing for consistent performance across various projects.

Understanding the Threading Sequence

The threading process typically starts with placing the spool of thread on the spindle, allowing it to unwind freely. From there, the thread follows a specific route through various tension mechanisms and guides. Each step in the sequence plays a vital role in maintaining the correct tension, which is essential for smooth operation.

Tension Adjustment and Maintenance

Adjusting the tension according to the type of fabric and thread used can further enhance the quality of sewing. Regularly checking the threading path for any obstructions or misalignments can prevent potential problems. Maintaining a clean and well-lubricated machine also contributes to the overall efficiency and longevity of the equipment.

Motor Assembly and Power Efficiency

The assembly of the motor plays a crucial role in determining the overall functionality and energy consumption of sewing machines. A well-designed motor not only enhances performance but also optimizes power usage, resulting in improved efficiency. Understanding the components involved in the motor system is essential for maintaining and upgrading these machines.

Key Components of Motor Assembly

- Electric Motor: The primary source of power, responsible for driving the needle and other moving parts.

- Power Supply: Converts electrical energy into a suitable form for the motor to operate efficiently.

- Gear Mechanism: Transfers motion from the motor to the needle, influencing speed and force.

- Control Circuit: Regulates the motor’s operation, allowing for precise speed adjustments and energy management.

Enhancing Power Efficiency

- Regular Maintenance: Keeping the motor clean and lubricated ensures smooth operation and prevents energy loss.

- Quality Components: Using high-quality materials in motor assembly can lead to better energy efficiency and longevity.

- Upgrading Technology: Implementing modern electronic control systems can significantly enhance power management.

By focusing on the motor assembly and understanding its components, users can maximize the performance and energy efficiency of their machines. This attention to detail not only improves functionality but also contributes to sustainable practices in sewing operations.

Needle Plate and Feed Dog Interaction

The interaction between the needle plate and the feed dog is crucial for the smooth operation of a sewing machine. This relationship ensures that fabric is accurately fed through the machine while the needle performs its stitching function. Understanding how these components work together can enhance sewing efficiency and improve the overall quality of the finished product.

Functionality of the Needle Plate

The needle plate serves as a sturdy base for the needle to penetrate the fabric. It is designed with precision openings that allow the needle to pass through while maintaining stability. This component also provides a reference point for aligning fabric pieces, helping to achieve consistent stitching. A well-maintained needle plate ensures that the fabric remains securely in place during the sewing process.

Role of the Feed Dog

Feed dogs are small, raised teeth located beneath the needle plate that grip the fabric and move it forward during sewing. Their synchronized movement with the needle is essential for creating even stitches. When the feed dog engages correctly with the needle plate, it allows for smooth fabric advancement, preventing issues such as puckering or uneven feeding. Regular maintenance of both components is vital for optimal performance.

Foot Pedal Adjustments and Control

The functionality of a sewing machine is significantly influenced by the foot pedal’s settings and responsiveness. Adjusting this component allows for a tailored experience, enhancing precision during operation. Proper management of the pedal can facilitate smoother transitions between various stitching techniques and speeds, enabling greater control over the fabric handling.

Adjustment Techniques

To achieve optimal performance, it is essential to understand the adjustment mechanisms available for the foot pedal. This can involve altering the tension or sensitivity settings, which can be accomplished by accessing the pedal’s internal mechanisms. Ensuring that the pedal responds accurately to foot pressure is crucial for achieving consistent results.

Maintaining Control

Effective control during sewing is vital for achieving desired outcomes. Users can practice varying their foot pressure to master the machine’s response. Regular maintenance, such as cleaning the pedal connections and ensuring proper alignment, also plays a critical role in sustaining the device’s functionality over time.

In conclusion, understanding foot pedal adjustments and their control mechanisms is essential for maximizing the efficiency of a sewing machine. By mastering these settings, users can enhance their overall sewing experience and achieve superior results in their projects.

The Bobbin Case and Threading System

The bobbin case and threading mechanism are essential components of any sewing machine, playing a crucial role in the overall stitching process. These parts work together to ensure smooth operation and consistent results, making it easier for users to create beautiful and durable seams. Understanding how these systems function can significantly enhance one’s sewing experience and improve the quality of the finished product.

Function of the Bobbin Case

The bobbin case serves as the housing for the bobbin, which holds the lower thread used during stitching. It is designed to secure the bobbin in place, allowing it to rotate freely as the machine operates. This rotation is vital for the formation of stitches, as it enables the upper and lower threads to interlock efficiently. Proper maintenance and correct placement of the bobbin case are essential to prevent issues such as thread jamming or uneven stitches.

Threading Mechanism Explained

The threading system guides the upper thread through various components of the machine, ensuring it is positioned correctly for optimal performance. This system typically includes a tension disk, thread guides, and a needle. Each part must be correctly threaded to achieve the desired stitch quality. Regularly checking and adjusting the threading can help avoid common problems like thread breakage or skipped stitches, enhancing the sewing experience.

Maintenance Tips for Internal Gears

Proper upkeep of internal mechanisms is essential for ensuring the longevity and efficiency of your machine. Regular maintenance not only enhances performance but also helps in identifying potential issues before they escalate. By following a few simple practices, you can maintain the internal gears in optimal condition, reducing the likelihood of wear and tear.

Regular Cleaning

Keeping the internal components clean is crucial. Dust, lint, and debris can accumulate over time, leading to increased friction and potential damage. Use a soft brush or compressed air to gently remove any particles. Additionally, consider using a suitable cleaning solution that will not harm the components, ensuring that all residues are wiped away thoroughly.

Lubrication Procedures

Lubrication plays a vital role in the performance of internal gears. Apply an appropriate lubricant to minimize friction and wear. Be sure to choose a lubricant that is specifically designed for mechanical parts, as this will ensure optimal performance. Regularly check the lubricant levels and reapply as necessary to maintain smooth operation.

Replacing Worn-Out Parts Efficiently

Maintaining the functionality of your sewing machine is crucial for optimal performance. When components begin to show signs of wear, addressing these issues promptly can enhance the overall efficiency of the device. This section outlines strategies for identifying and replacing these essential elements, ensuring your machine operates smoothly for years to come.

Identifying Worn Components

Before proceeding with replacements, it’s important to accurately assess which elements require attention. Look for signs such as unusual noises, difficulty in stitching, or visible damage. Regular inspections can help catch problems early and prevent further complications.

Replacement Process

Once you’ve identified the components that need to be replaced, follow these steps to ensure a seamless process:

| Step | Action |

|---|---|

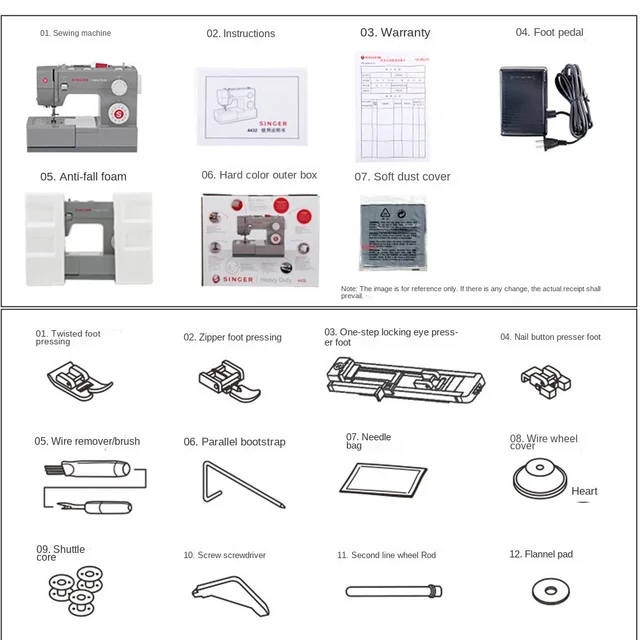

| 1 | Gather necessary tools, including screwdrivers and replacement items. |

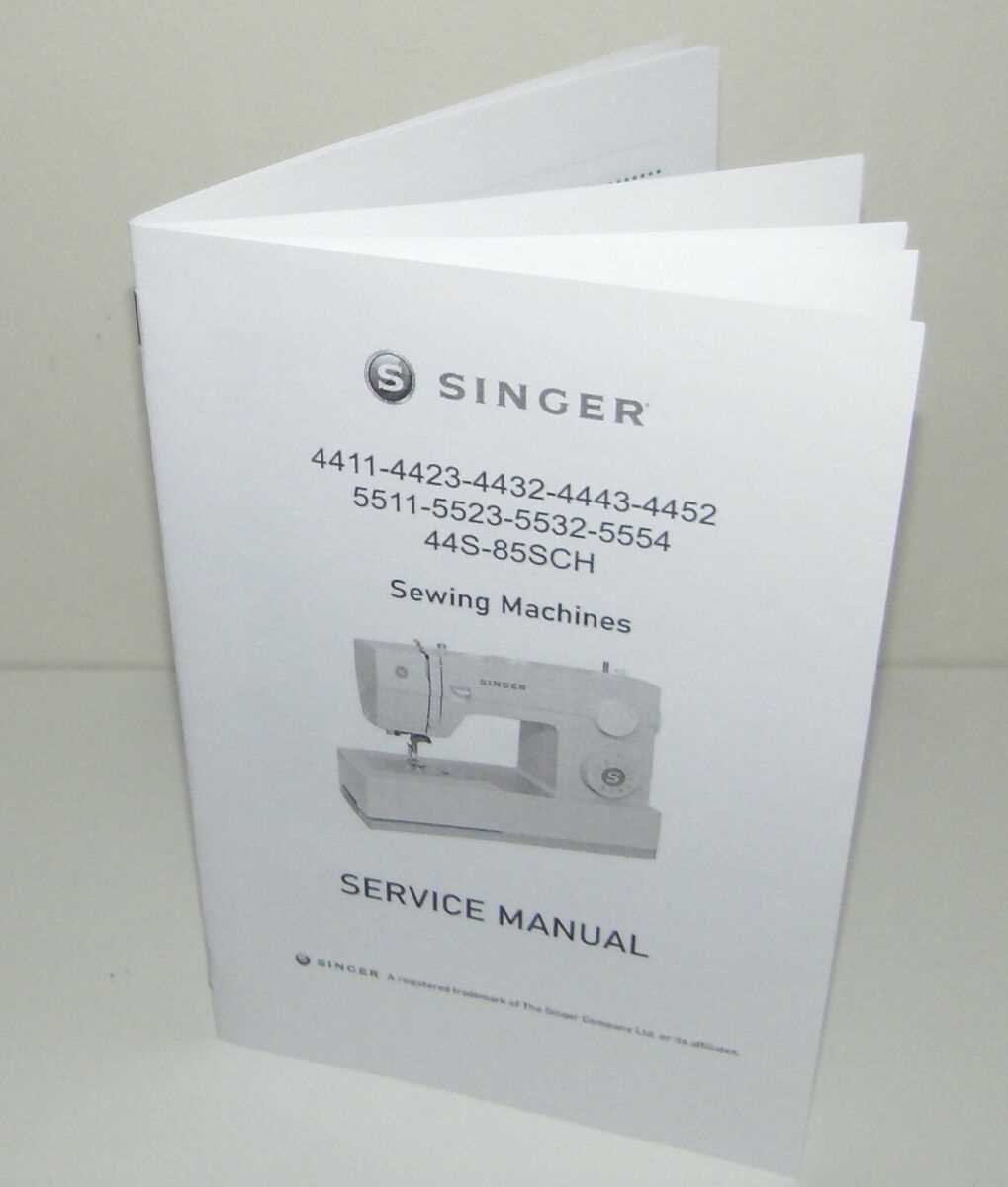

| 2 | Consult the user manual for specific instructions related to your model. |

| 3 | Carefully remove the worn-out components, taking note of their arrangement. |

| 4 | Install the new elements, ensuring they are fitted correctly. |

| 5 | Test the machine to confirm proper function after replacements. |

By following these steps, you can effectively restore your sewing machine’s performance and prolong its lifespan.

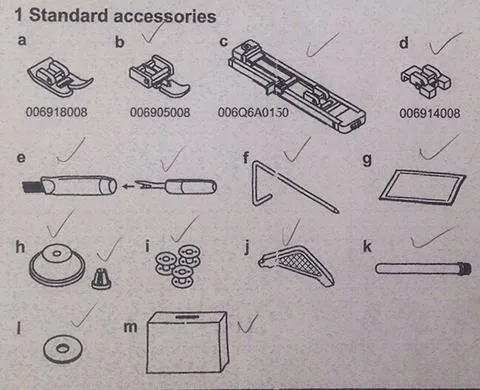

Tools Required for Proper Machine Upkeep

To ensure the longevity and efficiency of your sewing equipment, having the right tools at your disposal is essential. Regular maintenance not only enhances performance but also prevents potential issues that could disrupt your projects. Below is a list of necessary instruments that will aid in the upkeep of your device.

Essential Maintenance Instruments

Start with a basic toolkit that includes screwdrivers, pliers, and a seam ripper. These tools are vital for making adjustments and repairs. Additionally, a set of tweezers can be useful for handling small components, while a brush helps to clean dust and debris from sensitive areas.

Cleaning and Lubrication Supplies

Keeping your machine clean is crucial for its performance. Use soft cloths and specialized sewing machine oil to maintain moving parts. Regular oiling reduces friction and wear, prolonging the lifespan of your equipment. Remember to follow the manufacturer’s guidelines for cleaning frequency and techniques.