The intricate machinery of modern snow removal systems is essential for maintaining safety and accessibility during winter months. Each element plays a crucial role, and understanding how they interconnect can enhance efficiency and performance. Whether you are a seasoned operator or a newcomer, familiarizing yourself with these elements can significantly improve your operational knowledge.

In this section, we will explore the various components that make up these advanced systems. By delving into their functions and relationships, you can gain insights into the overall mechanics. This understanding will not only aid in effective operation but also in troubleshooting and maintenance, ensuring that your equipment remains in optimal condition throughout the season.

Additionally, knowing how different parts work together allows for better preparation when it comes to repairs and replacements. Recognizing potential issues before they escalate can save time and resources. Our detailed examination aims to equip you with the knowledge needed to navigate the complexities of these systems confidently.

This section provides a comprehensive insight into a high-performance equipment designed for effective snow and ice management. Its innovative features and robust construction make it a valuable tool for maintaining safe and accessible surfaces during winter conditions.

The device is engineered to enhance efficiency and user experience through several key components:

- Durability: Built to withstand harsh weather conditions, ensuring long-lasting performance.

- Versatility: Suitable for various applications, making it ideal for both residential and commercial use.

- User-Friendly Controls: Designed with intuitive controls for ease of operation, even in challenging environments.

- Efficient Material Distribution: Engineered to provide precise spreading capabilities, reducing waste and increasing effectiveness.

With its combination of strength and functionality, this equipment represents a significant advancement in snow removal technology, catering to the needs of professionals and homeowners alike.

Key Features of the V Maxx 8500

This section highlights the essential characteristics of this innovative equipment designed for optimal performance in various conditions. Its advanced engineering and thoughtful design ensure reliability and efficiency, making it a valuable tool for users.

- Durability: Crafted from high-quality materials, this model is built to withstand harsh environments and prolonged usage.

- Efficiency: Engineered to maximize productivity, it delivers exceptional performance, reducing operational time.

- Versatility: Suitable for a wide range of applications, this equipment adapts easily to different tasks, enhancing its usability.

- User-Friendly Design: With intuitive controls and straightforward setup procedures, it ensures a hassle-free experience for operators.

- Advanced Technology: Incorporates state-of-the-art features that enhance functionality and ease of use, setting it apart from traditional models.

- Maintenance-Friendly: Designed for easy upkeep, it minimizes downtime and prolongs the lifespan of the equipment.

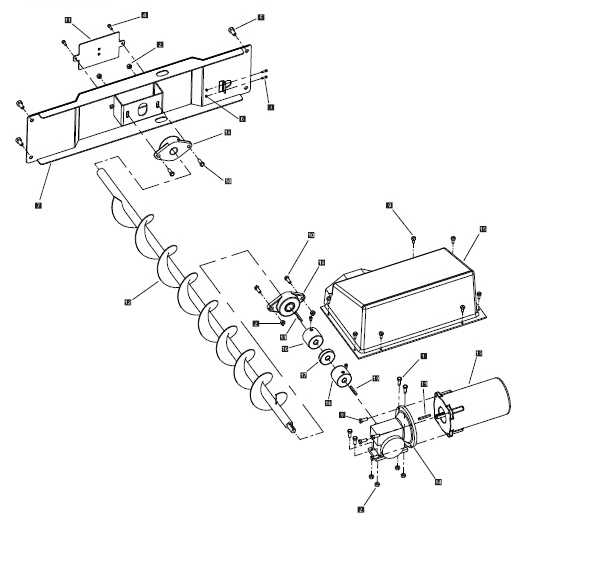

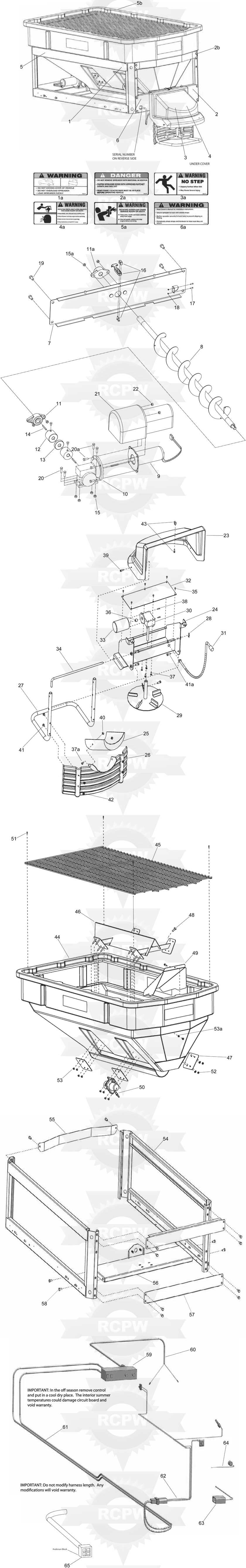

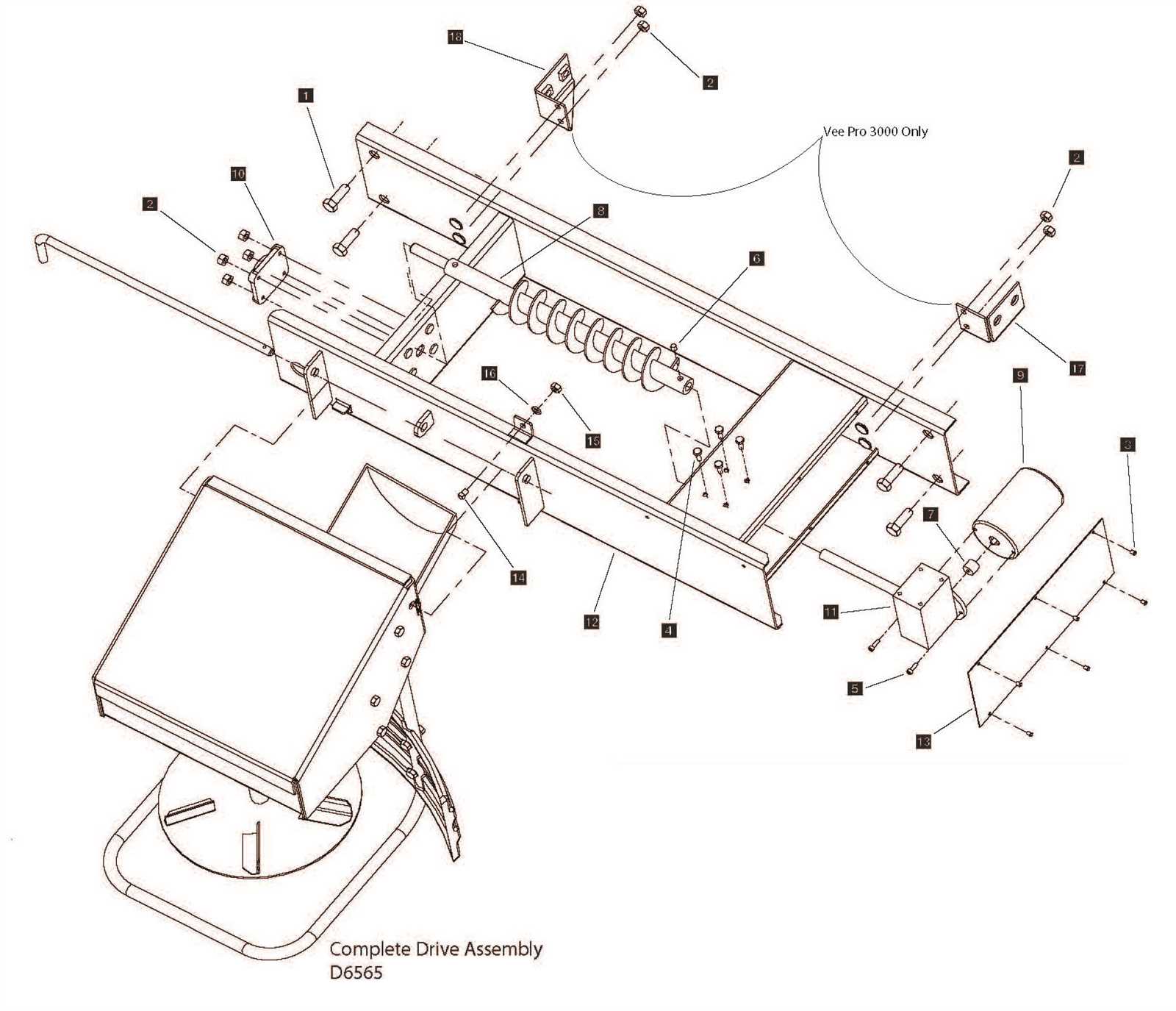

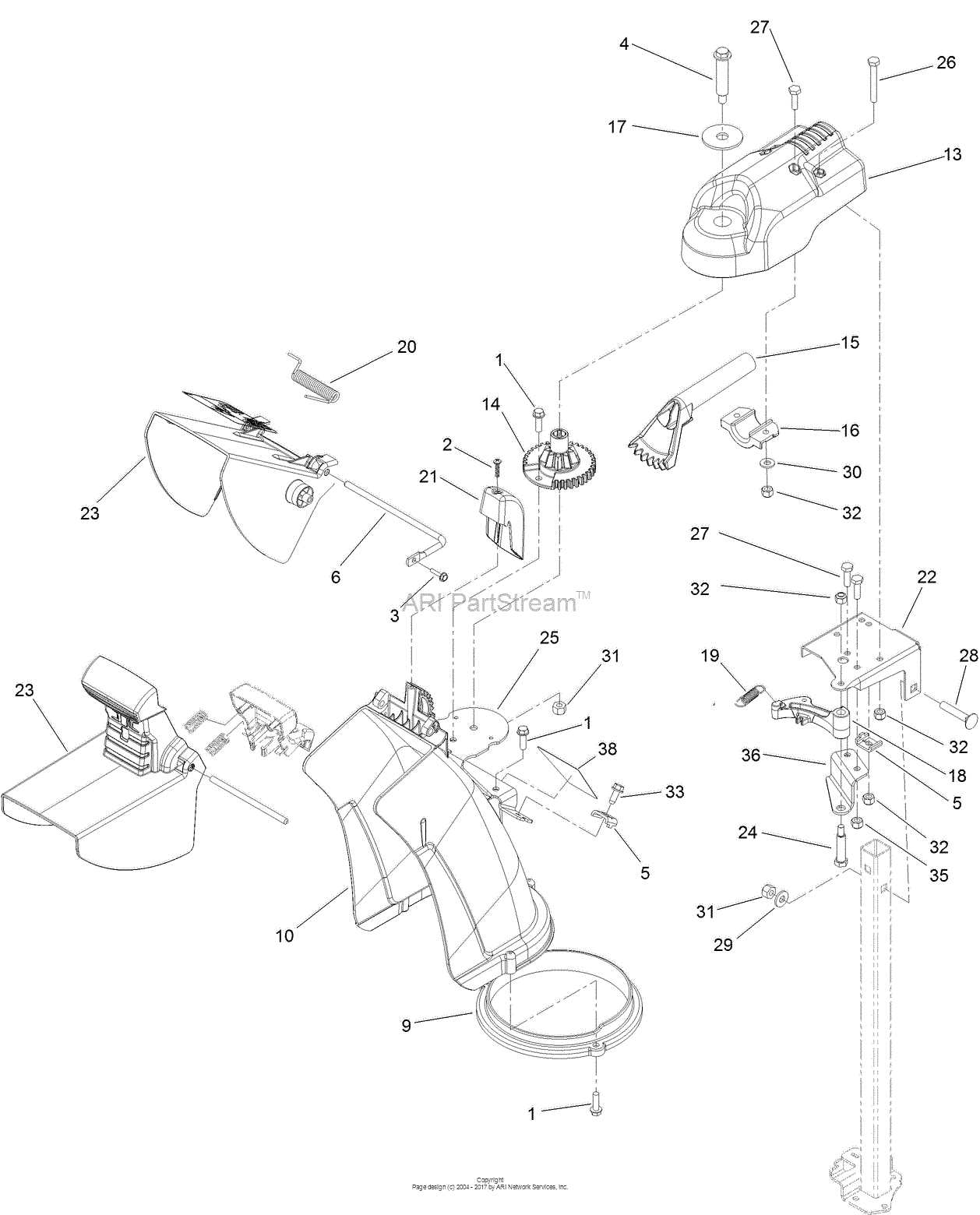

Parts Breakdown and Diagrams

This section provides a comprehensive overview of the various components and their arrangements within the system. Understanding the layout and individual elements is crucial for effective maintenance and troubleshooting.

By familiarizing yourself with the structure, you can easily identify the key elements and their functions. Here are some important aspects to consider:

- Component Identification: Recognizing each element is essential for efficient repairs.

- Layout Understanding: Grasping the configuration helps in diagnosing issues accurately.

- Maintenance Tips: Regular inspections can prevent larger problems down the line.

The following list outlines the main components typically involved:

- Motor Assembly

- Control Unit

- Hydraulic System

- Chassis Frame

- Connection Hoses

Visual representations play a pivotal role in clarifying the relationships and positioning of these elements. Referencing detailed illustrations can greatly enhance your understanding and effectiveness in handling repairs.

Common Components Explained

Understanding the key elements of a winter maintenance system is essential for effective operation and maintenance. These components work together to ensure reliable performance during challenging weather conditions. Below, we explore the most significant parts that contribute to the overall functionality of these systems.

- Controller: This unit manages the operation of the entire setup, allowing users to adjust settings and monitor performance efficiently.

- Hopper: This container holds the material to be dispensed, playing a crucial role in ensuring an even distribution.

- Spinner: Responsible for spreading the material over a wide area, the spinner’s design affects the coverage and effectiveness of the application.

- Auger: This component moves the material from the hopper to the spinner, ensuring a consistent flow and preventing clogs.

- Frame: The structural foundation that supports all components, it ensures stability and durability during use.

- Mounting Bracket: This part secures the equipment to the vehicle, providing a reliable attachment point for operation.

Each of these components plays a vital role in the successful deployment of materials, contributing to efficiency and effectiveness during winter operations.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of your equipment. Regular attention to maintenance not only enhances performance but also prevents costly repairs down the line.

- Check fluid levels frequently and top up as necessary.

- Inspect components for wear and tear, replacing parts as needed.

- Clean the machinery after each use to remove debris and prevent rust.

- Store equipment in a dry, sheltered area to protect it from the elements.

- Follow the manufacturer’s guidelines for routine servicing.

By implementing these strategies, you can ensure your equipment remains reliable and efficient for years to come.

Troubleshooting Common Issues

When dealing with equipment designed for winter maintenance, encountering difficulties can be frustrating. Understanding typical problems and their solutions is essential for ensuring smooth operation. This guide will help identify common challenges and provide effective troubleshooting steps to resolve them.

Identifying Common Problems

- Inconsistent performance during operation.

- Unusual noises or vibrations.

- Electrical malfunctions or failures to start.

- Fluid leaks or unusual odor.

Steps to Resolve Issues

- Check all connections for tightness and security.

- Inspect the power source and ensure it is functioning properly.

- Examine mechanical components for wear or damage.

- Clean any debris that may obstruct moving parts.

- Refer to the user manual for specific error codes or troubleshooting guidelines.

By following these steps, you can effectively address and rectify many common challenges, ensuring your equipment remains reliable throughout the winter season.

Replacement Parts Availability

Ensuring the longevity and optimal performance of your equipment often hinges on the accessibility of essential components. The availability of replacement elements plays a critical role in maintaining functionality and reducing downtime. This section delves into how easily one can procure the necessary items to keep their machinery running smoothly.

Sources for Procurement

Various suppliers and retailers specialize in providing a wide array of components for different machinery models. It’s advisable to explore both online and local distributors to find the most suitable options. Many companies offer comprehensive catalogs, allowing users to easily locate the required items. Additionally, some platforms feature customer reviews, which can guide you in selecting reputable sources.

Considerations When Purchasing

When looking for replacement items, it’s important to consider factors such as compatibility, quality, and pricing. Genuine components often ensure better performance and reliability compared to generic alternatives. However, cost-effective options may also be available. Conducting thorough research and consulting with experts can help in making informed decisions, ultimately leading to a successful repair or maintenance process.

Installation Guide for New Parts

This section provides a comprehensive overview for integrating new components into your equipment. Proper installation ensures optimal functionality and longevity, making it essential to follow guidelines closely. Whether you are replacing old elements or upgrading your system, this guide will help you navigate the process with ease.

Preparation Steps

Before beginning the installation, ensure you have all necessary tools and materials ready. Familiarize yourself with the specific components you will be working with, and review any accompanying documentation for detailed instructions.

| Item | Quantity | Tool Required |

|---|---|---|

| New Component | 1 | N/A |

| Screws/Bolts | Varies | Wrench/Screwdriver |

| Sealant (if applicable) | 1 tube | N/A |

Installation Procedure

Begin by disconnecting the power supply to ensure safety during the process. Carefully remove any existing components as instructed in your manual. Once cleared, position the new element in place, securing it with the appropriate fasteners. If sealant is required, apply it as specified before completing the assembly.

After the installation, double-check all connections and re-establish power. Conduct a thorough test to confirm that everything operates correctly. Following these steps will help ensure a successful upgrade and maintain the efficiency of your equipment.

Accessories for Enhanced Performance

Upgrading your equipment with the right accessories can significantly boost efficiency and effectiveness during operation. These enhancements not only improve functionality but also ensure that the system operates at its peak potential. Below are some essential add-ons that can take performance to the next level.

- Custom Nozzles: Tailored nozzles can provide better coverage and precision, allowing for more controlled distribution of materials.

- Heated Hoppers: Keeping the materials at optimal temperatures prevents clumping and ensures a smooth flow during usage.

- Advanced Control Systems: Upgrading to a sophisticated control panel can enhance user experience and allow for real-time adjustments.

- Durable Shields: Protective shields help maintain equipment integrity by minimizing wear and tear from harsh conditions.

- Lighting Kits: Enhanced visibility during low-light conditions increases safety and operational accuracy.

Incorporating these accessories not only streamlines the workflow but also extends the lifespan of the machinery. Investing in quality enhancements can lead to long-term benefits and improved results.

Comparative Analysis with Similar Models

This section aims to explore the nuances and features of various equipment within the same category. By examining comparable models, we can uncover strengths and weaknesses that might influence user decisions.

Feature Comparison

When assessing similar machinery, key attributes such as capacity, efficiency, and usability come into play. Certain models may offer enhanced functionalities that cater to specific operational needs, while others excel in simplicity and reliability. Evaluating these aspects is essential for identifying the most suitable option for diverse applications.

Performance Metrics

Performance is a critical factor in this comparison. Different units may showcase varying levels of effectiveness under similar conditions, impacting overall productivity. Analyzing user feedback and performance data can reveal insights into which machines consistently deliver the best results, thus guiding potential buyers towards making informed choices.

Expert Recommendations and Insights

In the realm of equipment maintenance and optimization, informed guidance plays a crucial role in enhancing performance and longevity. Professionals often emphasize the importance of understanding the intricacies of machinery, ensuring that users can effectively troubleshoot issues and streamline operations.

Key insights from industry experts suggest that regular inspections and a solid grasp of each component’s functionality can lead to improved efficiency. By familiarizing oneself with the inner workings, operators can anticipate potential problems and address them proactively.

| Recommendation | Description |

|---|---|

| Routine Maintenance | Schedule regular check-ups to prevent minor issues from escalating. |

| Documentation Review | Keep a thorough record of all maintenance and repairs for reference. |

| Component Familiarity | Learn the function of each part to enhance troubleshooting skills. |

| Seek Professional Help | Consult with experts for complex repairs or upgrades. |

Ultimately, integrating these practices into regular operations can significantly enhance the overall effectiveness and reliability of your equipment. By staying informed and proactive, users can ensure optimal performance in challenging conditions.