The intricate machinery behind effective application techniques plays a vital role in various industries, from automotive refinishing to artistic endeavors. A thorough comprehension of these mechanisms enhances the efficiency and precision of the task at hand. By dissecting the essential elements, users can ensure optimal performance and longevity of their equipment.

Each component serves a unique function, contributing to the overall effectiveness of the mechanism. Familiarity with these segments not only aids in maintenance and repair but also empowers users to make informed decisions regarding upgrades or replacements. With a keen understanding of how these parts interact, one can master the art of application.

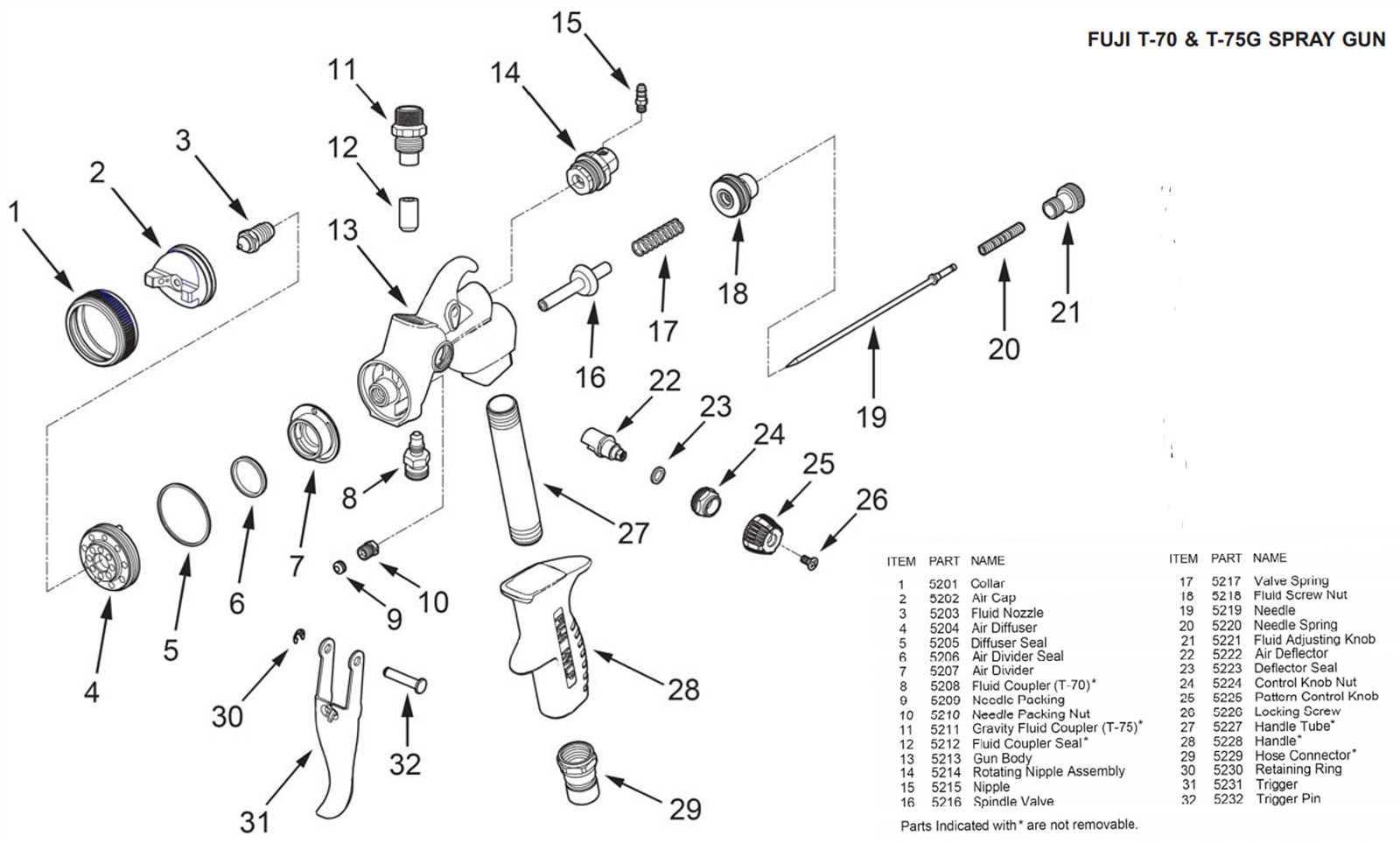

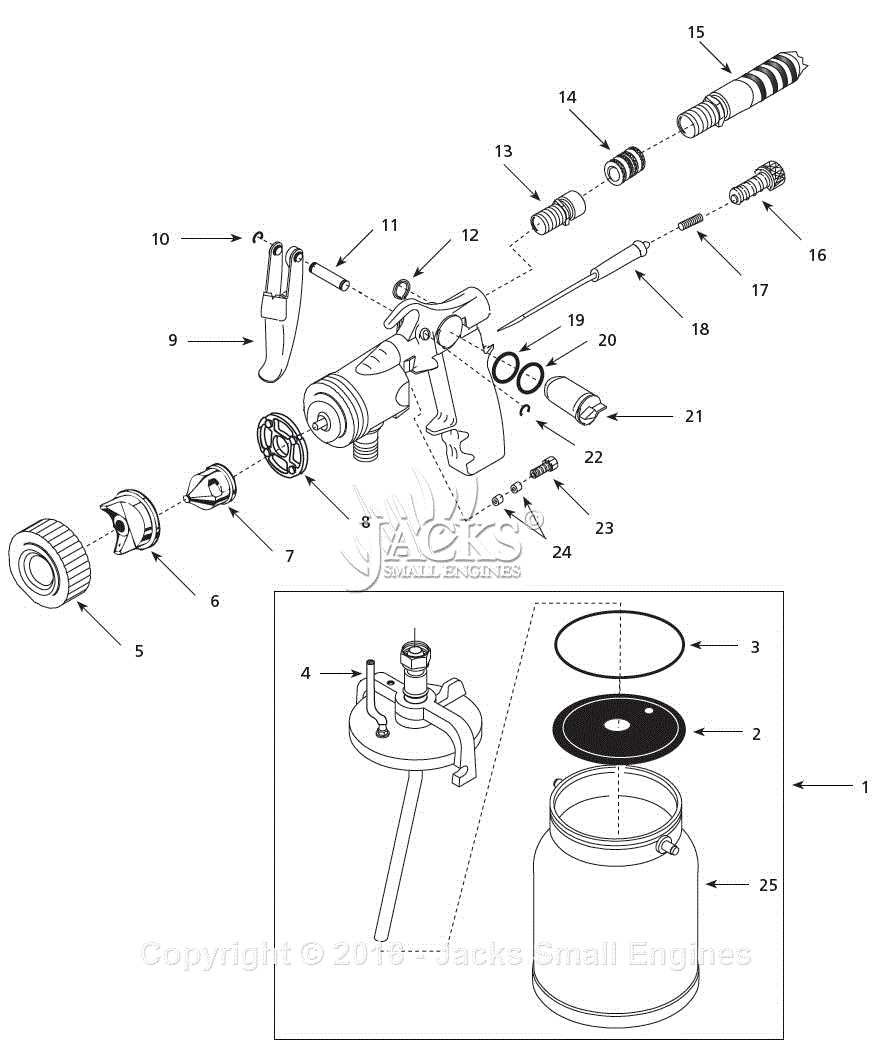

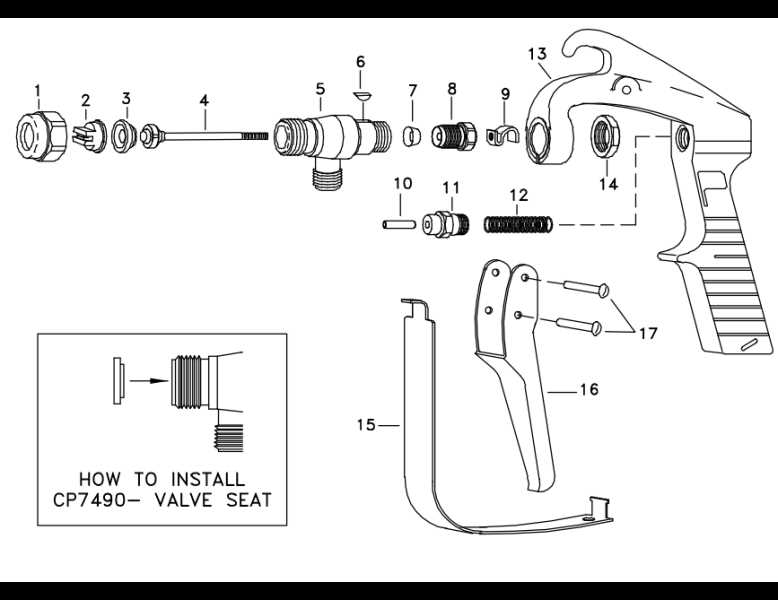

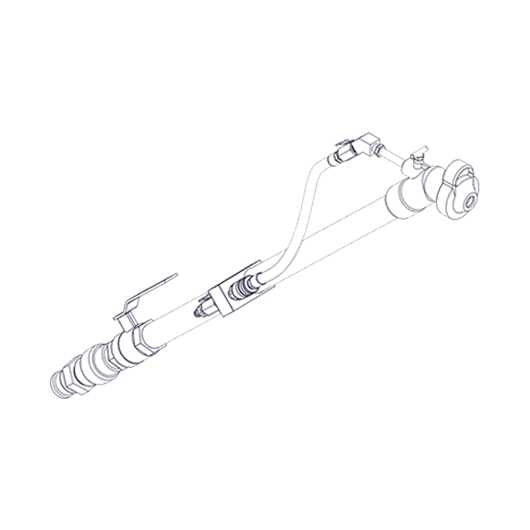

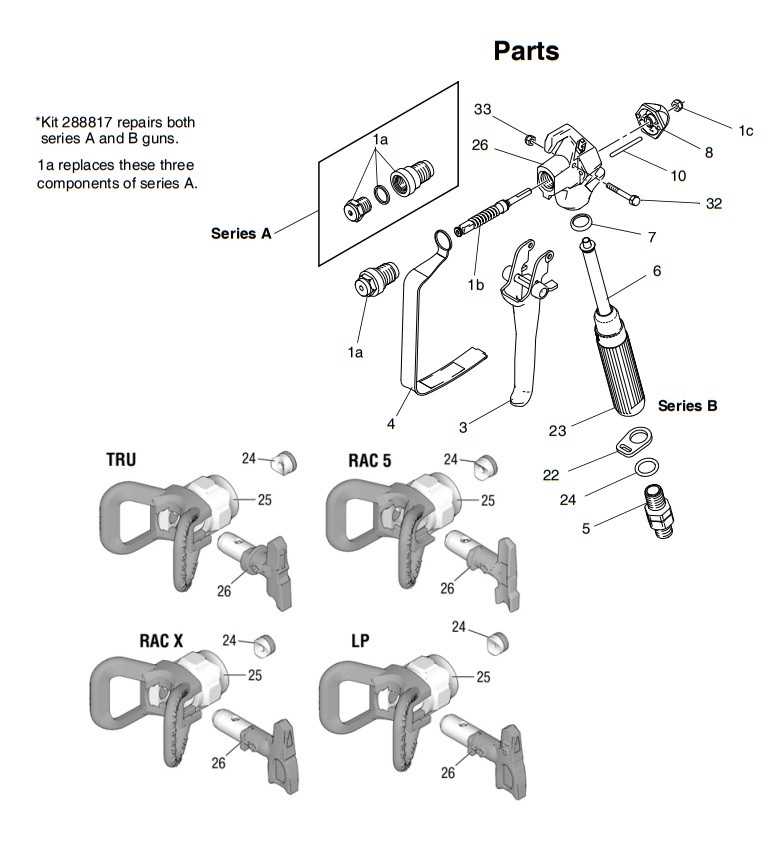

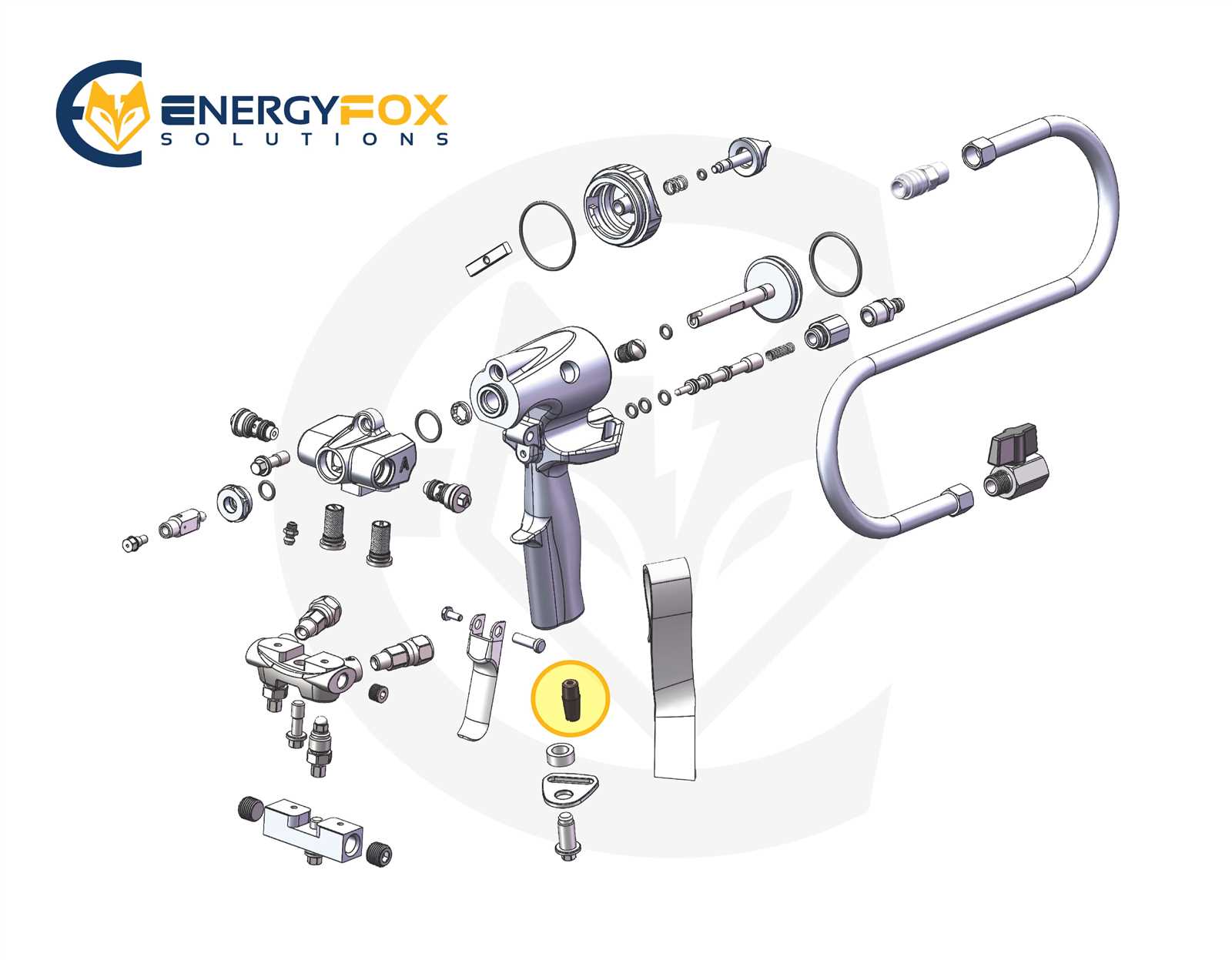

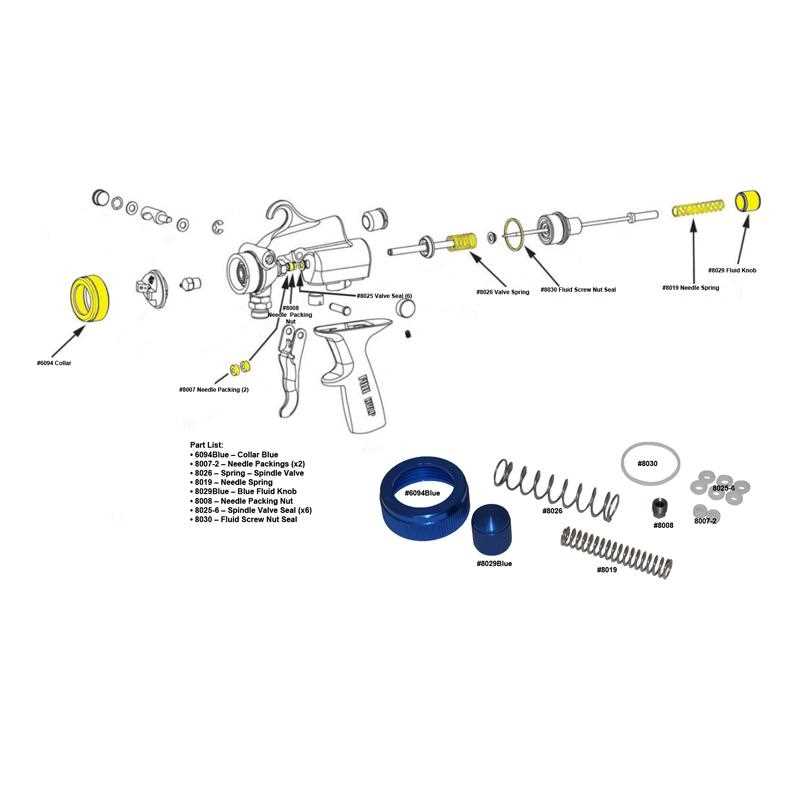

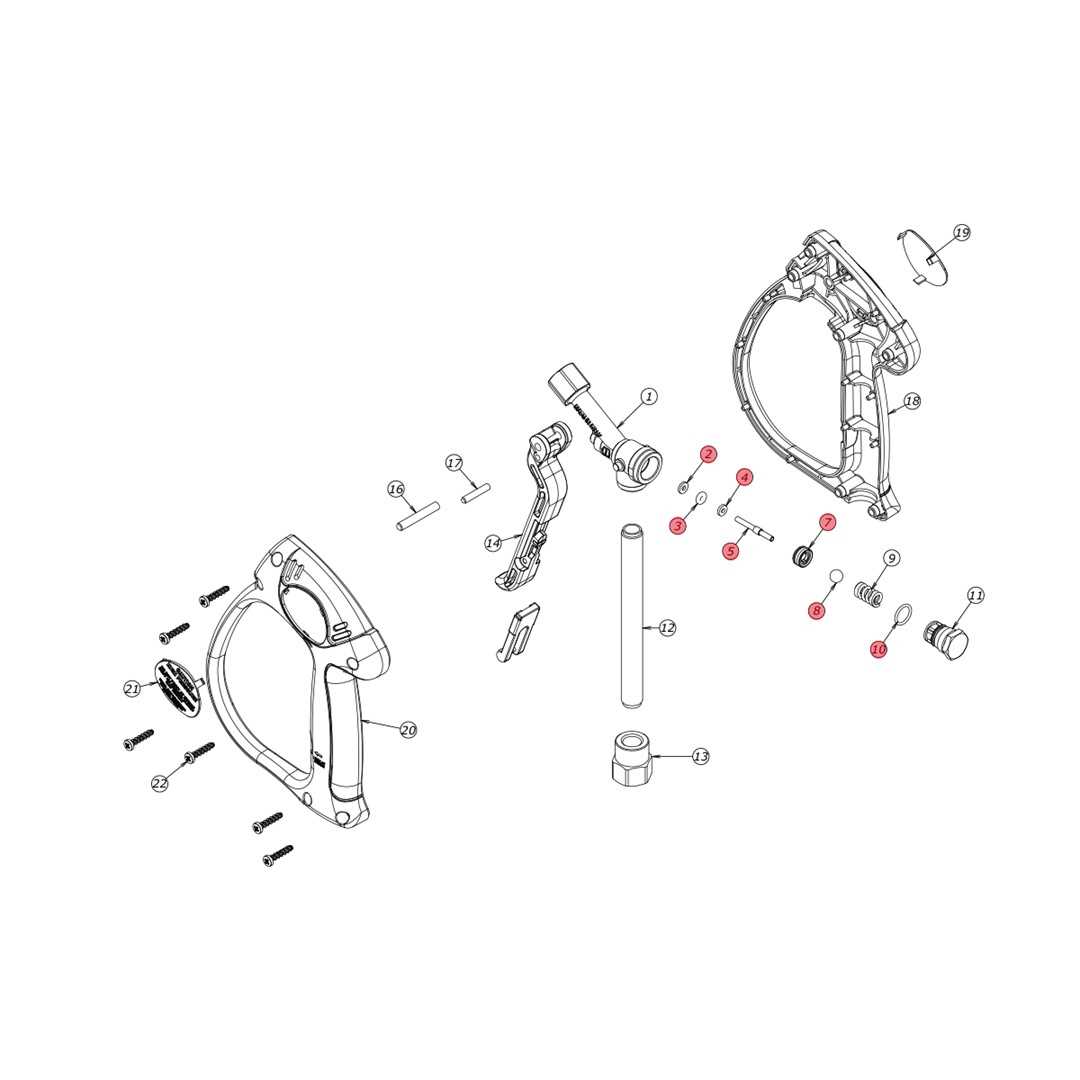

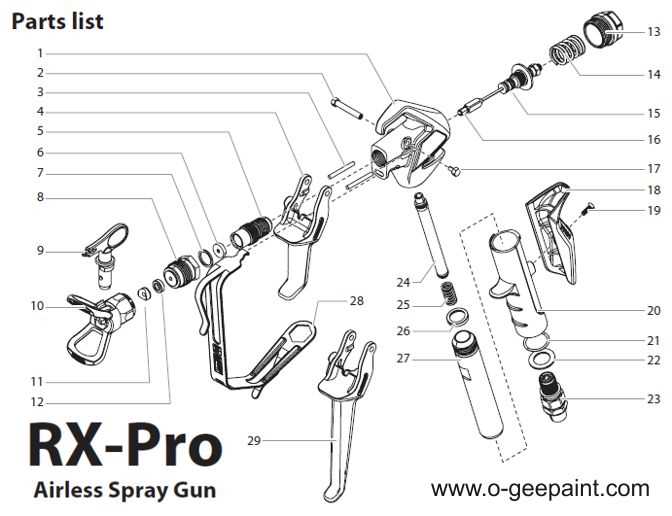

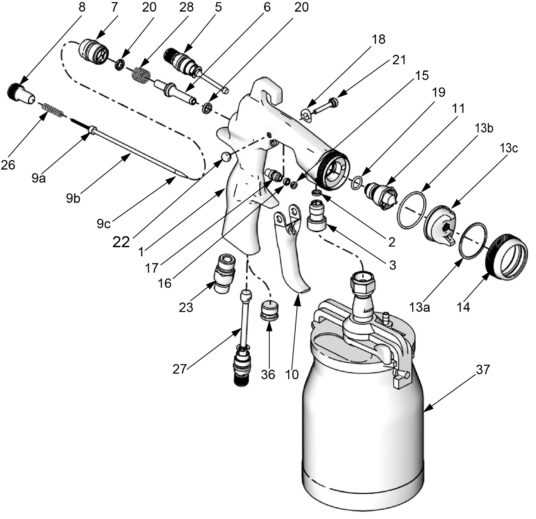

Moreover, visual representation of these elements can significantly aid in grasping their arrangement and functionality. By exploring a detailed overview, individuals can develop a clearer picture of the inner workings, allowing for a deeper appreciation of the technology involved. This knowledge is invaluable for anyone seeking to enhance their skills and results in practical applications.

Understanding Spray Gun Components

Grasping the elements of a painting tool is essential for optimal performance and maintenance. Each component plays a pivotal role in achieving precise application and efficiency.

- Nozzle: Responsible for the size and shape of the spray pattern.

- Trigger: Controls the flow of the material being used.

- Fluid cup: Holds the material to be dispensed.

- Air cap: Influences the atomization of the material.

Understanding these components allows users to make informed choices and ensure longevity in their tools.

Essential Parts of Spray Guns

Understanding the key components of these tools is crucial for achieving optimal results in various applications, from painting to finishing. Each element plays a significant role in ensuring effective performance and precision, allowing users to achieve their desired outcomes.

Key Components

At the core of these devices is the nozzle, which is responsible for atomizing the liquid into a fine mist, enabling even coverage. The fluid cup holds the material to be applied, and its capacity can vary depending on the task at hand. Additionally, the trigger mechanism controls the flow of the liquid, providing the user with the ability to adjust the spray pattern and intensity.

Additional Elements

Another vital element is the air cap, which influences the spray pattern and helps create a uniform distribution. The air compressor supplies the necessary pressure for operation, while hoses connect the components, allowing for a seamless flow of materials. Together, these elements form an intricate system that ensures efficiency and accuracy in application.

How to Identify Each Part

Understanding the various components of a tool can enhance its usage and maintenance. Recognizing each element’s function ensures optimal performance and longevity of the equipment.

Key Components Overview

Familiarize yourself with the main sections, including the nozzle, trigger, and fluid cup. Each section plays a crucial role in delivering the desired outcome during operation.

Detailed Identification Techniques

To accurately pinpoint each segment, consult a reference guide or visual representation. Pay attention to the shapes and connections; for instance, a nozzle typically has a tapered end for controlled output, while a trigger is often ergonomically designed for ease of use.

Functionality of Spray Gun Parts

This section explores the various components involved in the operation of an aerosol application tool, focusing on their roles and interconnections that contribute to efficient performance.

- Nozzle: The opening through which the liquid is atomized, affecting the spray pattern and droplet size.

- Trigger: Controls the flow of material, allowing for precise application and control over the output.

- Fluid Tip: Determines the viscosity of the material being applied and impacts the finish quality.

- Air Cap: Essential for mixing air with the liquid, influencing the spray pattern and atomization.

- Fluid Body: Houses the liquid reservoir, providing a path for material to reach the nozzle.

Understanding these components helps in maximizing efficiency and achieving the ultimate results in applications.

Maintenance Tips for Spray Guns

Regular upkeep is essential for ensuring optimal performance and longevity of your application tools. By implementing proper care techniques, you can avoid malfunctions and maintain consistent results in your projects.

Cleaning Procedures

After each use, thoroughly cleanse all components to prevent residue buildup. Utilize appropriate solvents and brushes to reach all nooks and crannies, ensuring no remnants affect future applications.

Storage Recommendations

Store your equipment in a dry, temperature-controlled environment. Use protective covers to shield from dust and debris, and ensure all moving elements are free from corrosion. Regular checks on seals and connections will help maintain functionality over time.

Common Issues with Spray Gun Components

Understanding the frequent challenges associated with these tools can enhance their performance and longevity. Identifying and addressing these issues promptly is crucial for maintaining efficiency and ensuring high-quality results.

Frequent Problems

| Issue | Description |

|---|---|

| Clogging | Build-up of materials can obstruct flow, leading to inconsistent application. |

| Leakage | Improper seals or worn components may cause unwanted fluid escape. |

| Poor Finish | Inconsistent spray patterns can result in uneven surfaces. |

Maintenance Tips

Regular cleaning and inspection of components are essential to avoid the above issues. Proper storage and use of quality materials can also prolong the lifespan of the equipment.

Choosing the Right Spray Gun Model

Selecting the appropriate equipment for applying coatings can significantly impact the quality of your work. Various models offer distinct features and capabilities, making it essential to understand your specific needs and preferences. This section will guide you through the process of finding the ideal solution for your projects.

Factors to Consider

When deciding on a model, several key factors should be taken into account. These include the type of material you intend to use, the size of the area to be covered, and your level of experience. Each of these aspects plays a vital role in ensuring you choose the most effective tool for your application.

Comparison Table

| Model Type | Material Compatibility | Best Use | Experience Level |

|---|---|---|---|

| High-Volume Low-Pressure | Water-based paints, stains | Large areas | Beginner |

| Airless | Thicker coatings | Heavy-duty applications | Intermediate to Advanced |

| Gravity Feed | Fine finishes | Detail work | Advanced |

| Siphon Feed | Various materials | General use | Beginner to Intermediate |

Taking the time to evaluate these factors will help you make an informed decision, ensuring optimal performance and satisfaction with your chosen model.

Comparing Different Spray Gun Designs

When exploring various designs for painting tools, it is essential to understand how each type functions and its suitability for different tasks. Each model offers unique features that cater to specific applications, resulting in diverse outcomes based on the user’s needs. This comparison highlights the critical aspects that differentiate these tools and aids in selecting the most effective one for particular projects.

Gravity-feed models are popular for their efficiency and ease of use. They utilize gravity to draw the fluid into the nozzle, allowing for a steady and consistent flow. This design is particularly advantageous for detailed work and fine finishes, as it provides excellent control over the material application.

On the other hand, pressure-feed alternatives operate under a different principle. They rely on external pressure to push the fluid into the nozzle, making them suitable for larger projects and heavy coatings. This type can handle thicker materials and is often preferred in industrial settings where speed and volume are crucial.

Another noteworthy option is the airless variant, which operates without the need for compressed air. This design uses a high-pressure pump to atomize the liquid, resulting in a powerful application that is effective for large surfaces. While they may be less precise than other models, their ability to cover vast areas quickly makes them a popular choice for exterior applications.

Finally, HVLP (High Volume Low Pressure) models stand out for their efficiency in minimizing overspray while maintaining a high transfer rate. This design is favored by professionals looking for a balance between speed and precision, making it ideal for intricate detailing as well as broader applications.

By understanding the strengths and limitations of each design, users can make informed choices that align with their specific requirements, ensuring optimal results in every project.

Upgrading Your Spray Gun Parts

Enhancing the components of your application tool can significantly improve its performance and efficiency. By selecting superior materials and innovative designs, you can optimize your equipment for better results and a smoother workflow. This section will explore the benefits and options available for upgrading your setup.

Improved Performance: One of the main advantages of upgrading is the potential for enhanced functionality. Newer components often come with advanced features that allow for finer adjustments, leading to more precise outcomes. Whether it’s better flow control or increased durability, each upgrade contributes to a more effective operation.

Increased Longevity: Replacing worn or outdated elements with high-quality alternatives can extend the lifespan of your equipment. Investing in durable materials can reduce the frequency of replacements and maintenance, saving both time and money in the long run.

Customization Options: Tailoring your tool to fit specific tasks can greatly enhance your overall experience. By selecting components that align with your unique needs, you can create a personalized setup that maximizes efficiency and comfort.

Overall, upgrading your equipment is a strategic move that can yield significant benefits, ensuring that your work remains top-notch while minimizing frustration and downtime.

Tools Needed for Spray Gun Repairs

To effectively maintain and restore your equipment, having the right set of tools is essential. A well-prepared toolkit can significantly simplify the process and ensure optimal performance.

- Wrenches and pliers for tightening and loosening components

- Small screwdrivers for precision adjustments

- Cleaning brushes to remove debris and buildup

- Replacement seals and O-rings for preventing leaks

- Air compressor for testing functionality after repairs

With these essentials in hand, you can delve into the maintenance process and achieve the ultimate results in performance and longevity.

Best Practices for Spray Gun Use

To achieve the ultimate results in any painting project, understanding the essential techniques and maintenance methods is crucial. Proper handling and care can significantly enhance performance and longevity, ensuring a flawless finish every time.

Preparation is Key

Before beginning, ensure that the surface is clean and free from debris. Choose the right material for your task, and adjust the settings according to the viscosity of the fluid being applied. This groundwork lays the foundation for success.

Technique Matters

Maintaining a consistent distance from the surface is vital. Employ smooth, even strokes to avoid uneven application. Additionally, practice controlling the pressure to achieve the desired effect, ensuring a professional outcome with minimal waste.